Automation device for storage of oil drilling string

An automatic device and oil drilling technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as high safety risks and high labor intensity, and achieve the effects of reliable work, reduced labor intensity, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the drawings:

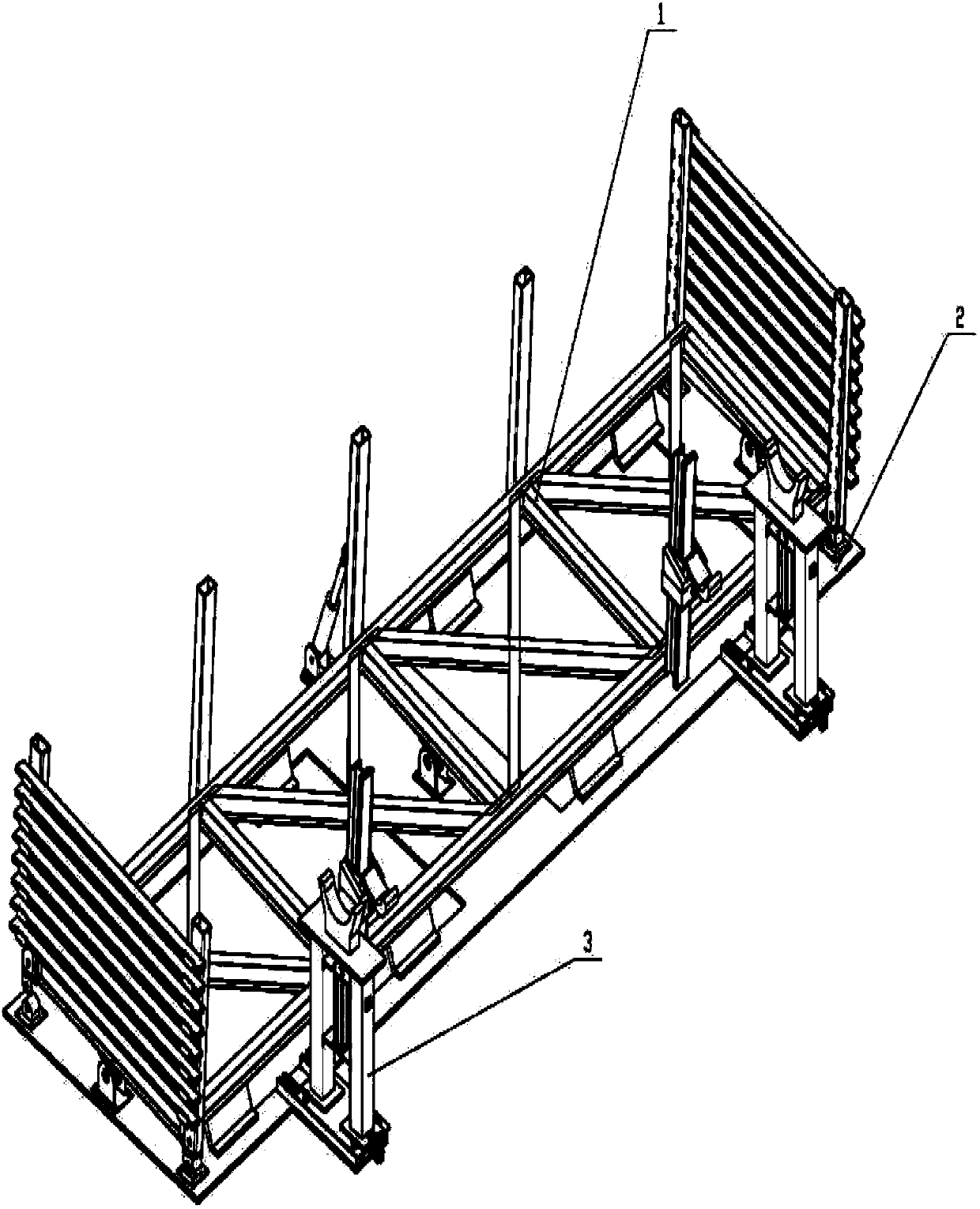

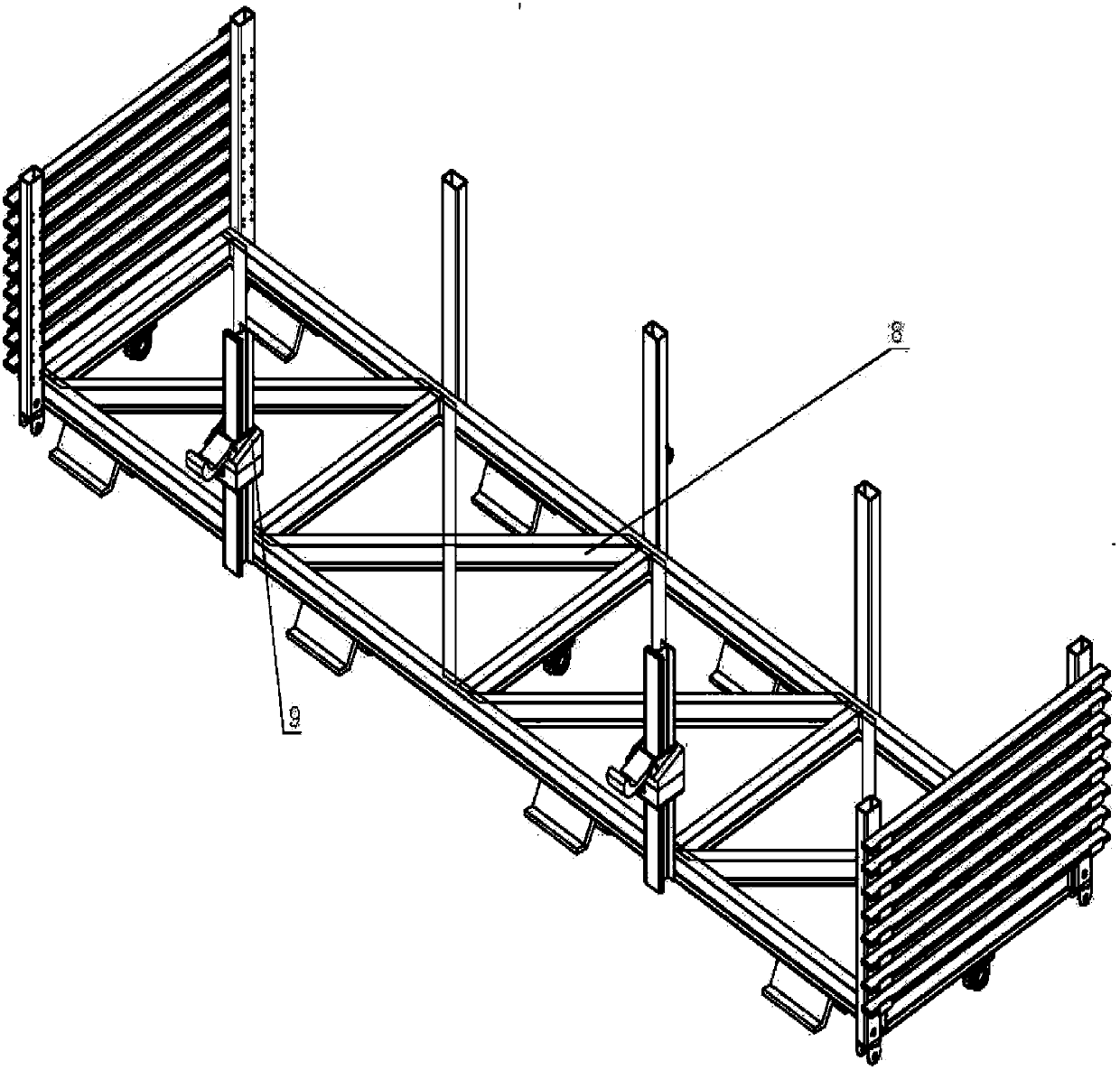

[0036] by Figure 1 to 20 As shown, this kind of petroleum drill string storage automation device is divided into three parts, namely the drill string storage unit 1, the installation base unit 2 and the support unit 3.

[0037] The drill string storage unit 1 is formed by connecting two parts of a storage frame 8 and a pipe shifting mechanism 9.

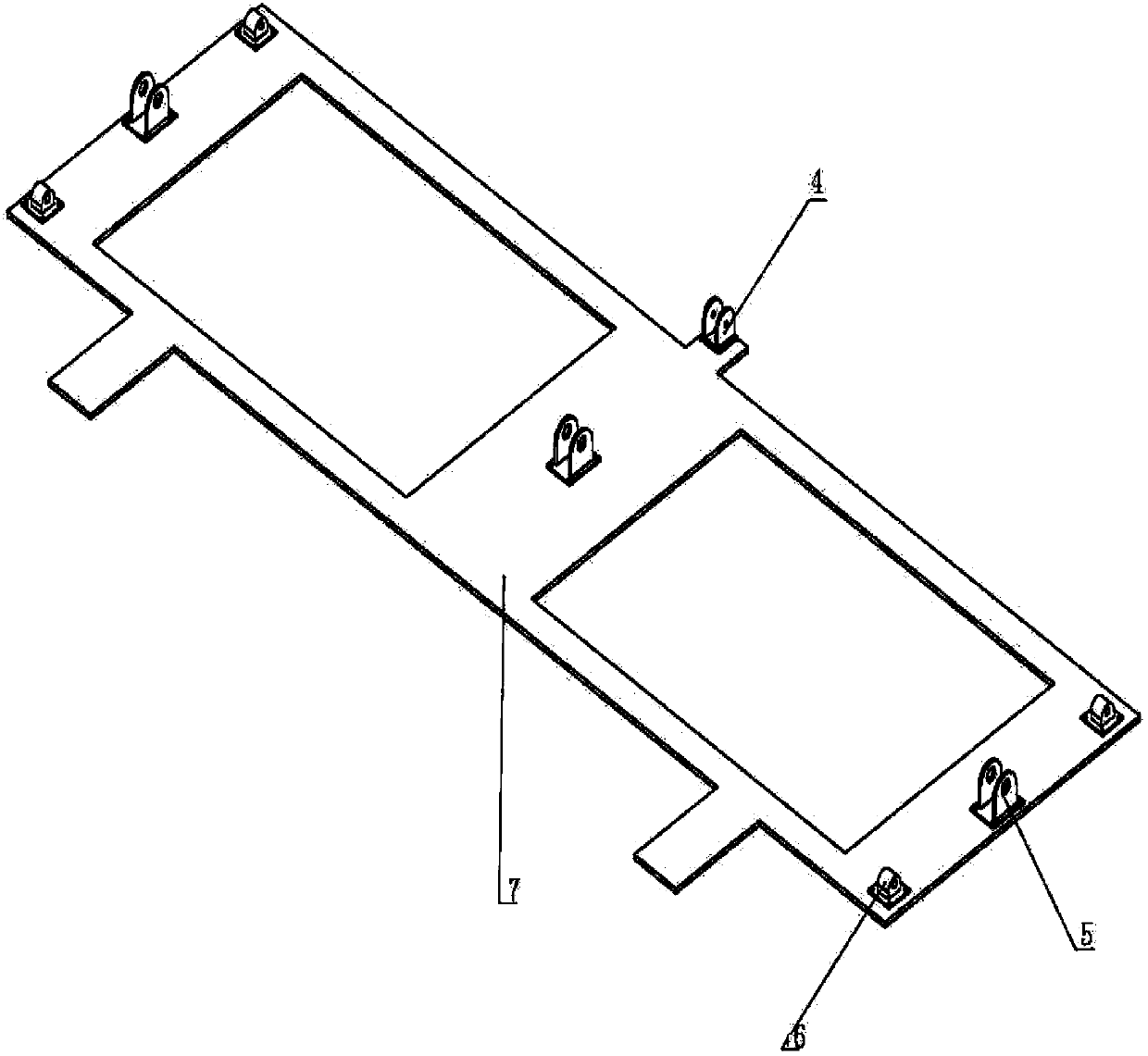

[0038] Wherein, the storage frame body 8 includes outer beam I-beam 10, beam I-beam 11, supporting beam I-beam 12, feet 13, block beam rectangular steel 14, rod support 15, drill string layered beam 16, Frame hinge support 17, bearing seat 18, guide rail H-shaped steel 19, rack 20 and rectangular steel support 21; outer beam I-beam 10, beam I-beam 11, support beam I-beam 12, support foot 13 and stop The beam rectangular steel 14 is connected by welding, the rod support 15 and the retaining beam rectangular steel 14 are connected by bolts, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com