Ice drill bit for warm ice layer drilling

A drill bit and ice layer technology, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the technical problems that cannot be solved in warm ice layer drilling, complex and difficult accident handling, and increase the cost of polar drilling. Cooling effect, avoiding a lot of sticking, facilitating cooling and carrying ice chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

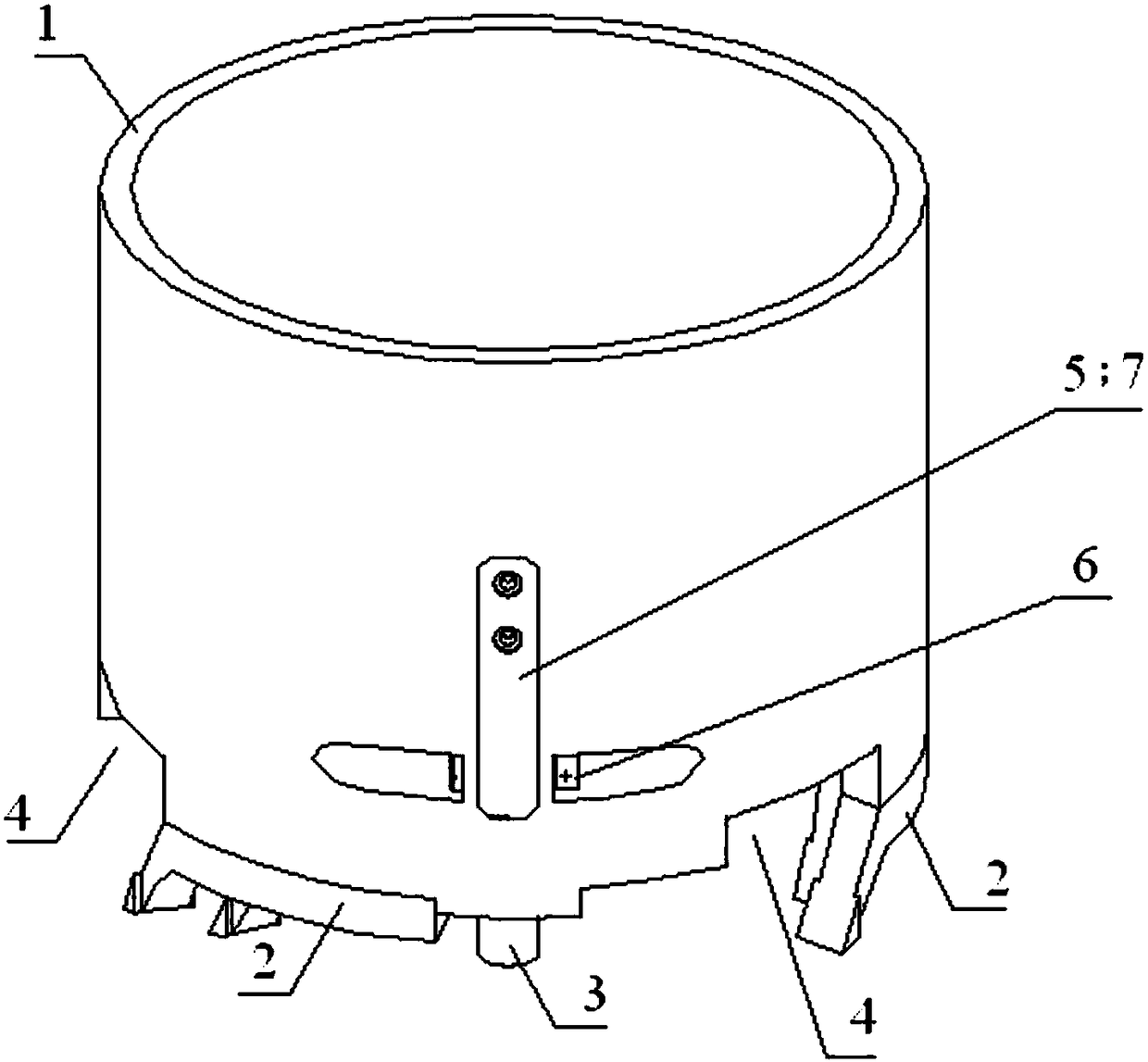

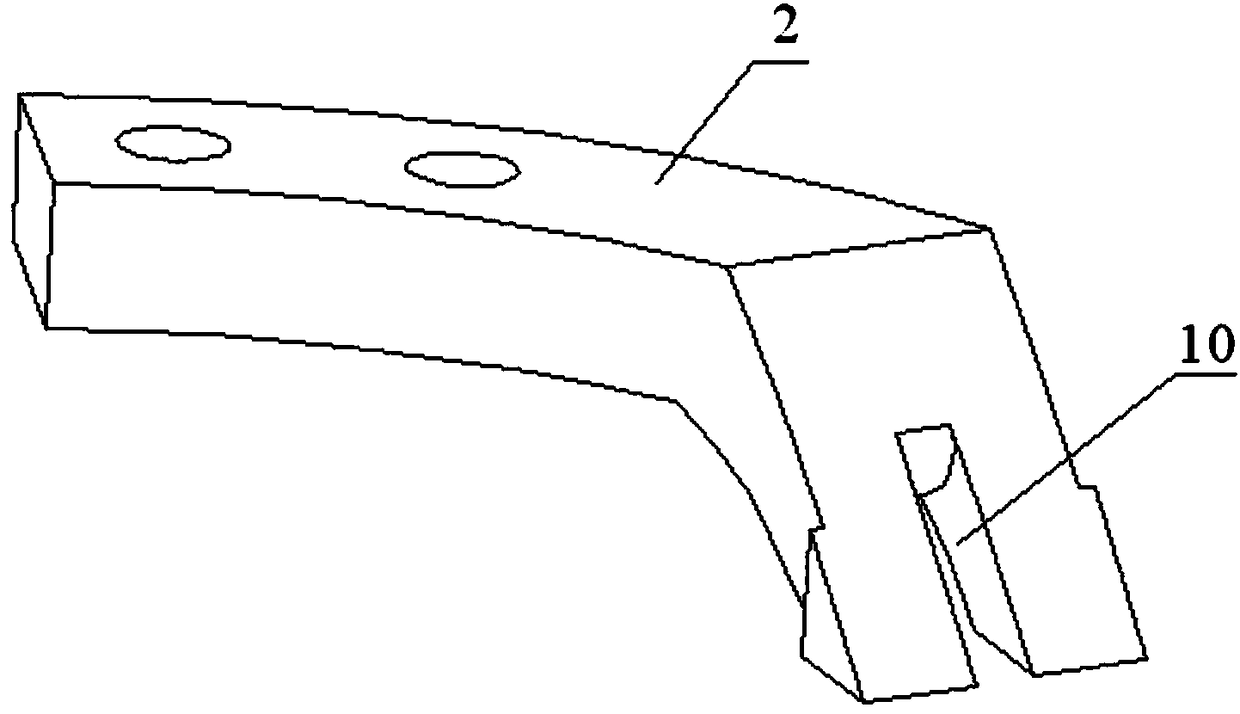

[0024] When the two cutting edges of the special-shaped cutting tool 2 are arranged side by side, a through groove 10 is arranged between the two cutting edges, and the through groove 10 is cylindrical or rectangular.

Embodiment 2

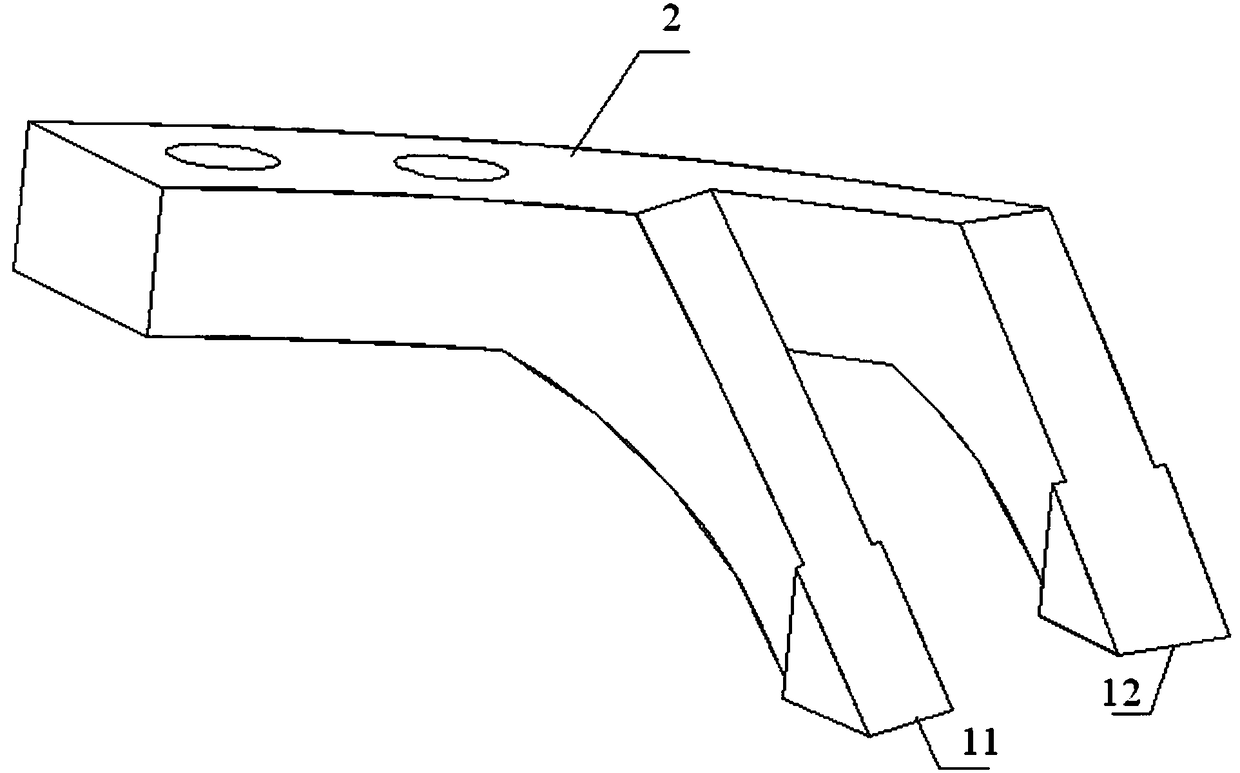

[0026] When the two cutting edges of the special-shaped cutting tool 2 are arranged front and back, the outer diameter of the rear cutting edge 11 is greater than the inner diameter of the front cutting edge 12 .

Embodiment 3

[0028] When the two cutting edges of the special-shaped cutting tool 2 are arranged up and down, the outer diameter of the upper cutting edge 13 is greater than the inner diameter of the lower cutting edge 14 .

[0029] Working principle of the present invention:

[0030] When the drill body 1 rotates and cuts, the two cutting edges of the special-shaped cutter 2 cut the ice layer respectively to generate ice chips, and the ice chips rise along the two cutting surfaces of the special-shaped cutter 2 respectively. Due to the design of the double cutting edges, it not only reduces The width of a single cutting edge is reduced to effectively reduce the heat generated by rotary cutting, and the amount of ice chips generated by one revolution is greatly reduced. Drilling fluid descends from the annular gap between the drill body 1 and the ice hole wall, and when it flows through the water tank 4 at the bottom of the drill body 1, it cools the special-shaped cutting tool 2 and carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com