Well bore structure for out-of-round oversized hole

A wellbore structure and big belly technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of pump holding, failure to drill to the target layer, accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

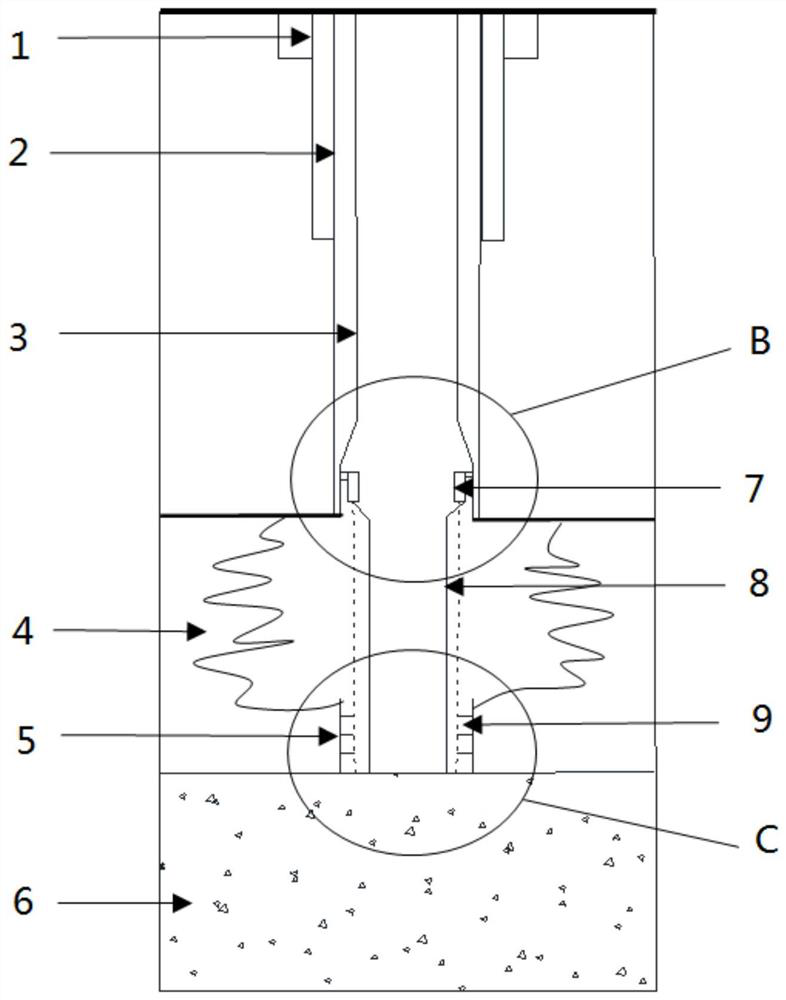

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

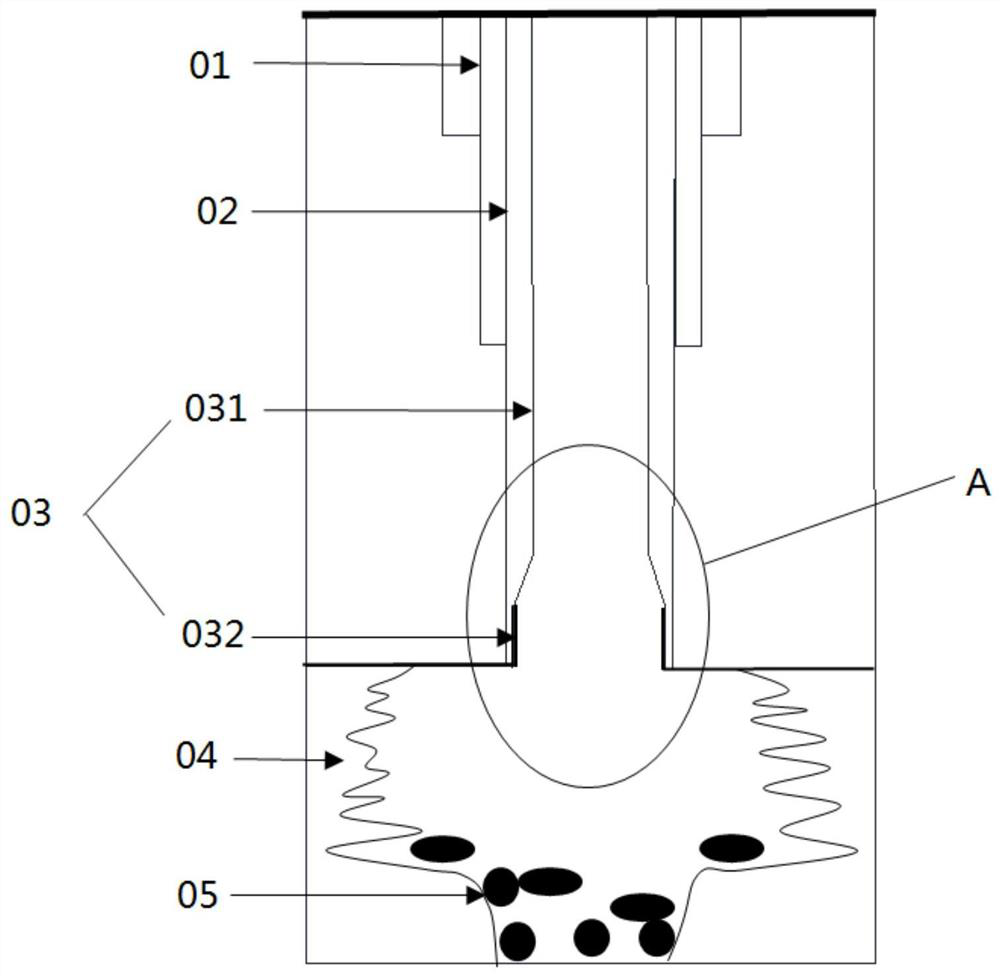

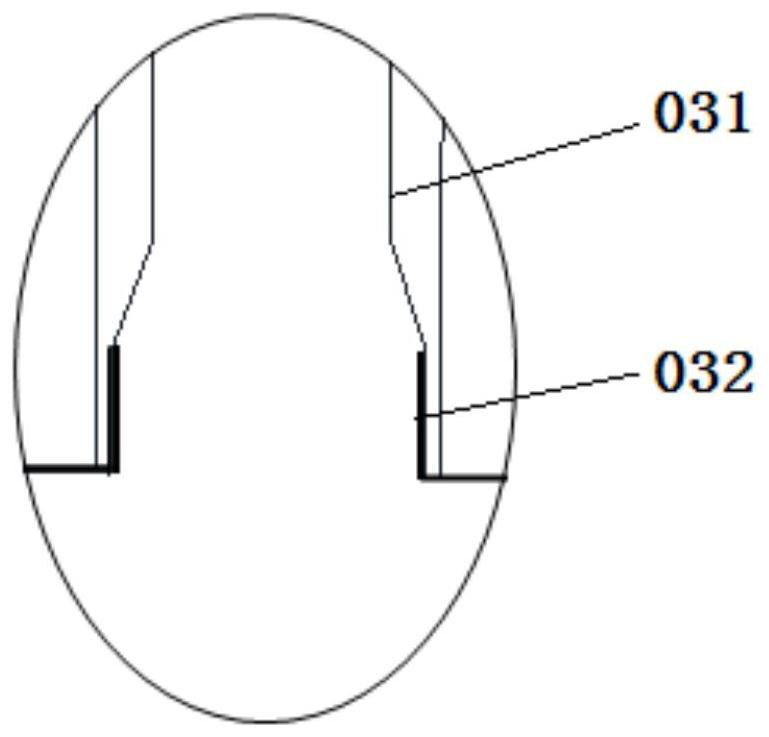

[0037] Such as Figure 3 to Figure 5 As shown, this embodiment provides a wellbore structure for a pot-bellied wellbore, including N well-opening intervals, and first casings are run in the first well-opening interval to the Nth well-opening interval respectively. From the 1st to the Nth casing opening, there is a complex interval 4 with a big belly in the Mth opening interval, wherein, N is a positive integer greater than or equal to two, and M is a positive integer greater than or equal to two and less than N. A section of the first reaming well wall 5 is provided below the complex section 4 of the big belly, and an expansion pipe 8 (also called an expandable solid steel pipe or an expandable pipe steel pipe) is sleeved at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com