Moving hydraulic anchoring drill rig for coalface

A coal mining face, mobile technology, applied in the direction of drilling equipment, directional drilling, mining equipment, etc., can solve the problems of low efficiency and slow moving speed of pneumatic rock bolter, achieve light weight, improve moving efficiency, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

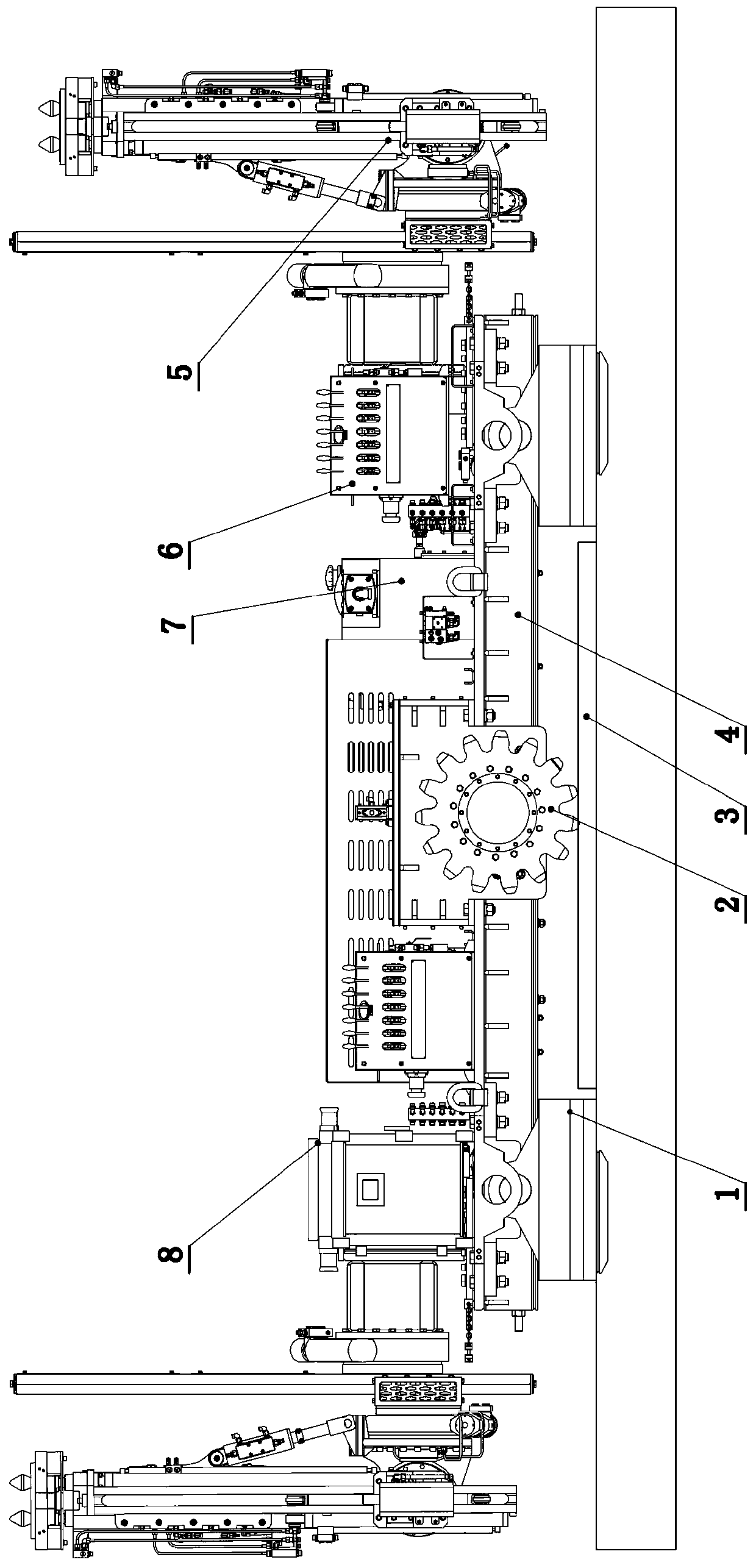

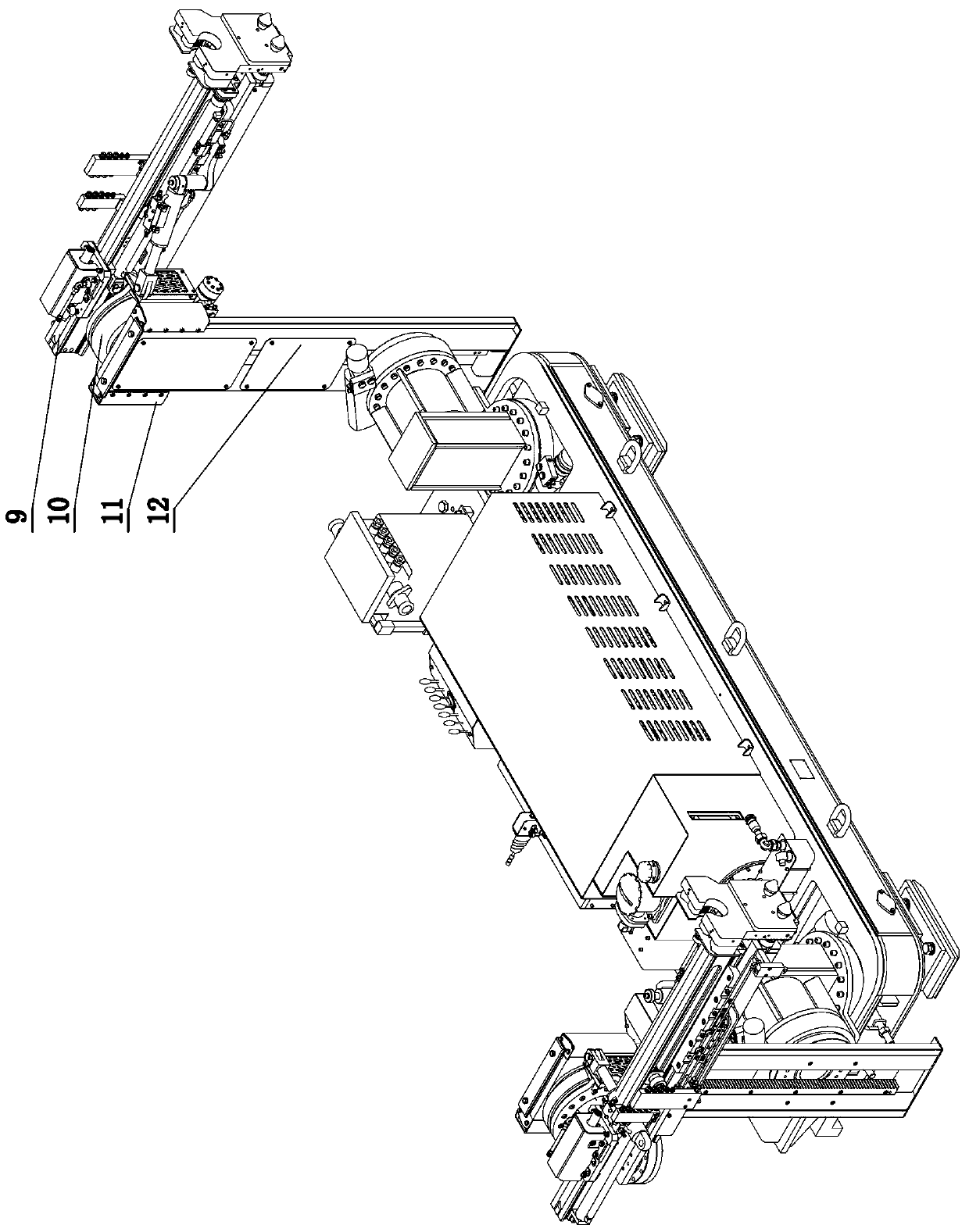

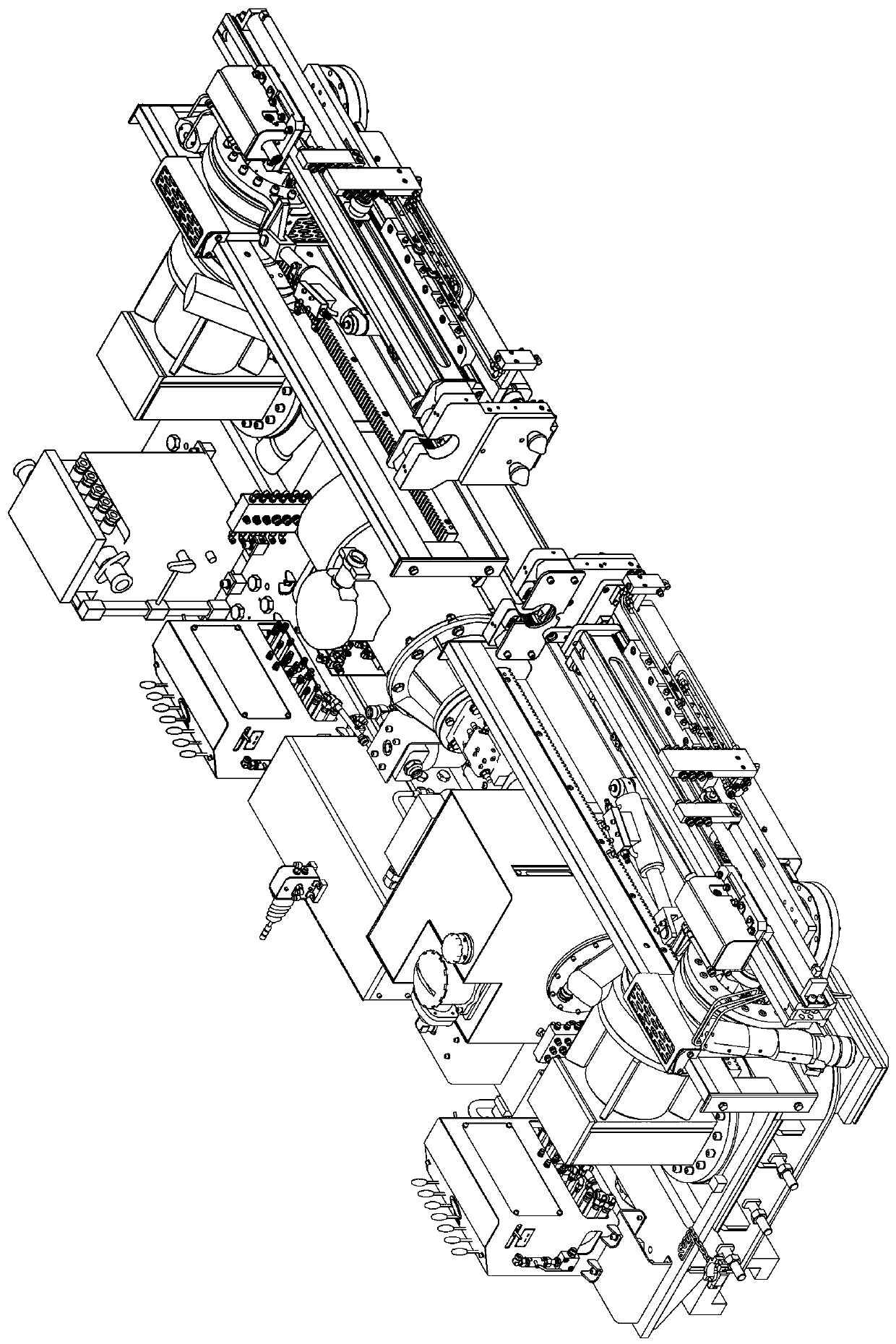

[0020] The mobile hydraulic anchoring drilling rig for coal mining face is mainly composed of chassis assembly 4, walking assembly 2, operating table 6, pumping station system 7, and drilling rig assembly 5. Among them, the walking assembly, operating table, and drilling rig assembly are all installed on the chassis.

[0021] The invention adopts a self-moving structure to solve the problem of self-walking of the drill rig.

[0022] The structure and principle of the traveling assembly of the hydraulic anchoring rig. The walking assembly is composed of rack drive wheels, transmission mechanism and hydraulic motor. The hydraulic motor is installed in the middle position of the chassis assembly, the output shaft of the hydraulic motor is connected with the rack drive wheel, and the rack drive wheel is meshed and connected with the scraper rack 3 on the scraper. The hydraulic motor adopts a direct drive form, and the motor and chassis assembly are fixed with high-strength bolts. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com