Method for testing erosion resistance of throttle valve of three-high oil-gas well

A test method and throttle valve technology, applied in the direction of strength characteristics, test wear resistance, measuring devices, etc., can solve the problems such as the working conditions that do not take into account the continuous ejection, and achieve the effect of rapid drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

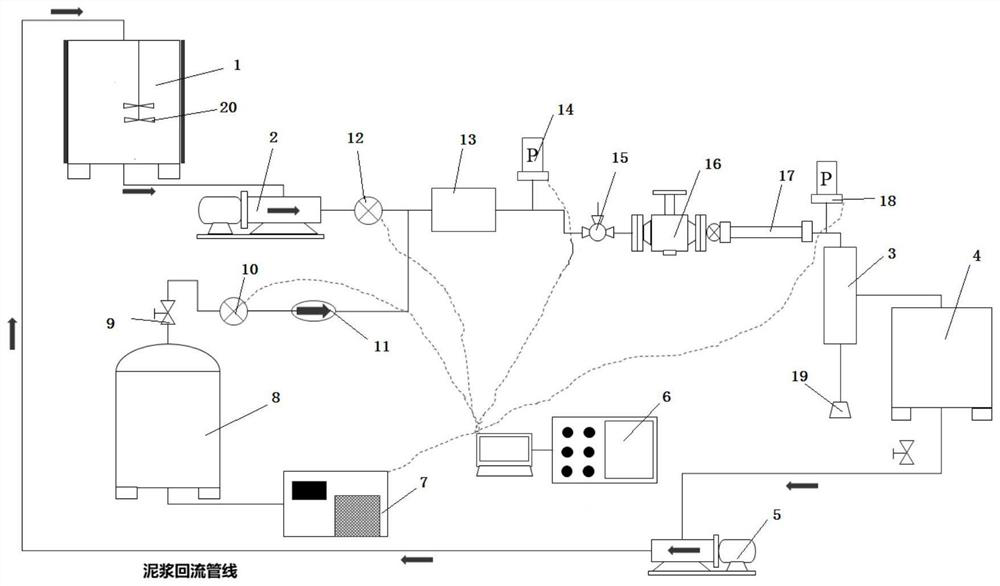

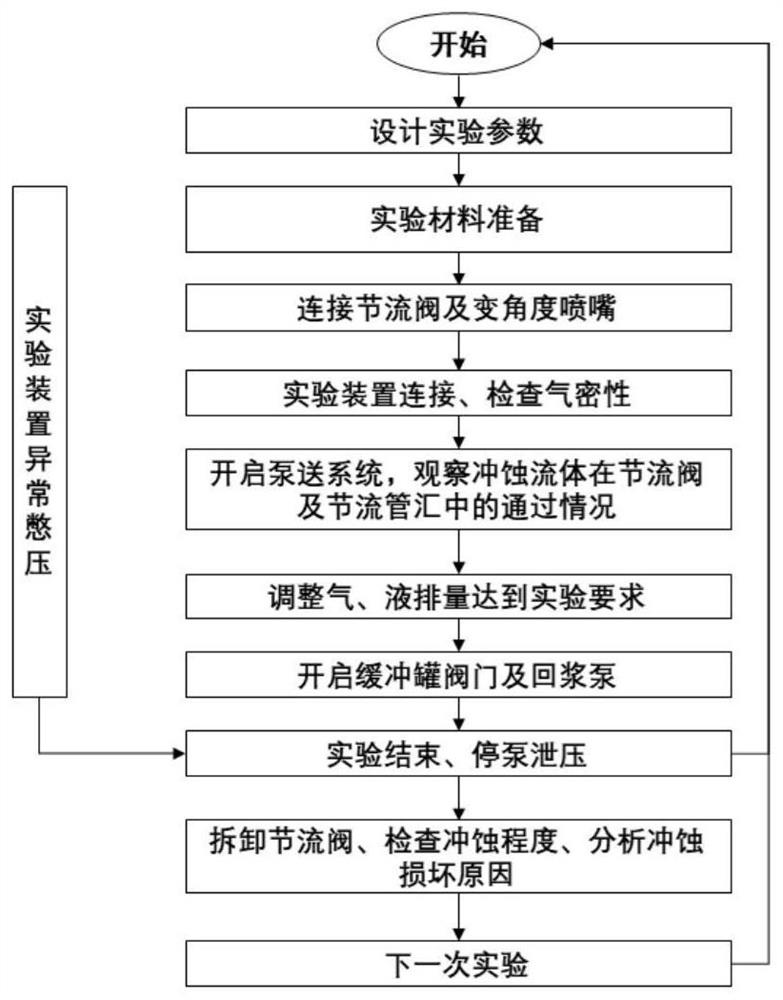

Method used

Image

Examples

Embodiment 1

[0095] PCV throttle valve erosion test

[0096] Test process: the test medium is 1.8g / cm 3 For mud, the whole process is accompanied by nitrogen injection, the test pump strokes 60-80 times / min, the test pump pressure is 20-35MPa, the valve opening is about 1 / 8 (7mm~9mm), and the test time is 490min.

[0097] Test results: The highest pump pressure reaches 44MPa instantaneously, accompanied by multiple instantaneous pressure rises. Because the impact pressure is too large, the pressure difference between the upper and lower sides is 10MPa, so the control pressure is 30MPa. The experiment shows that the valve can be stabilized at a pressure of 30±5MPa. run.

Embodiment 2

[0099] Wedge throttle valve erosion test

[0100] Test process: test medium 1.8g / cm 3 For mud, the whole process is accompanied by nitrogen injection, the test pump strokes 110 times / min, the test pump pressure is 12-17MPa, the valve opening is about 1 / 10 (2mm~4mm), and the test time is 486min.

[0101] Test results: When the pump speed is raised to the highest and the opening is the smallest, the pump pressure cannot exceed 20MPa when using the wedge-shaped throttle valve. The experiment shows that the valve can operate stably at a pressure of 12.5±2.5MPa.

Embodiment 3

[0103] Erosion test of orifice throttle valve

[0104] Test process: the test medium is 1.8g / cm 3 For mud, the whole process is accompanied by nitrogen injection, the test pump strokes 110 times / min, the test pump pressure is 14-23MPa, the valve opening is about 1 / 8 (7mm-9mm), and the test time is 315min.

[0105] Test results: During the test, the pump pressure dropped from high pressure to 4MPa many times instantaneously, and the pressure rose to the original pressure after switching the movable valve. The last time the pressure dropped from 14MPa to 4MPa, the time was 1min. The valve was considered damaged and stopped. test.

[0106] test results

[0107] According to the analysis of the dynamic test results, the evaluation results of PVC throttle valve, wedge throttle valve and orifice throttle valve are shown in the following table:

[0108] Type of throttle valve Erosion resistance Choke and kill reliability Compliance with well control process require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com