Drill press with a quick drilling apparatus

A drilling machine, fast technology, applied in the direction of drilling/drilling equipment, parts of boring machine/drilling machine, metal processing equipment, etc., can solve the problem of increasing the risk of the operator's work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

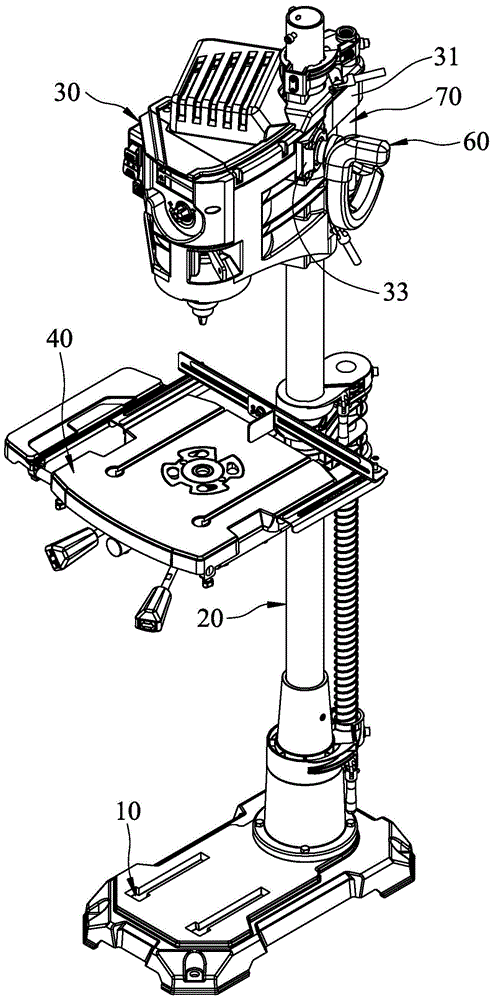

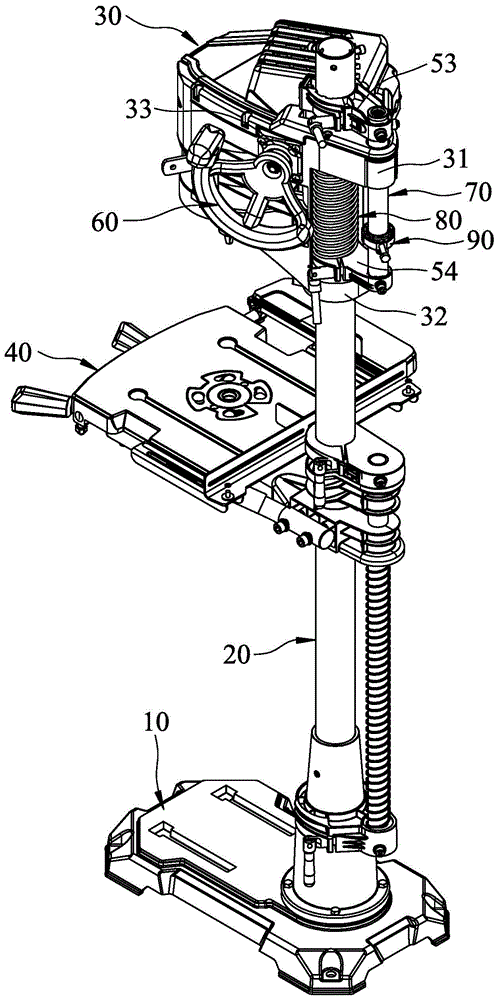

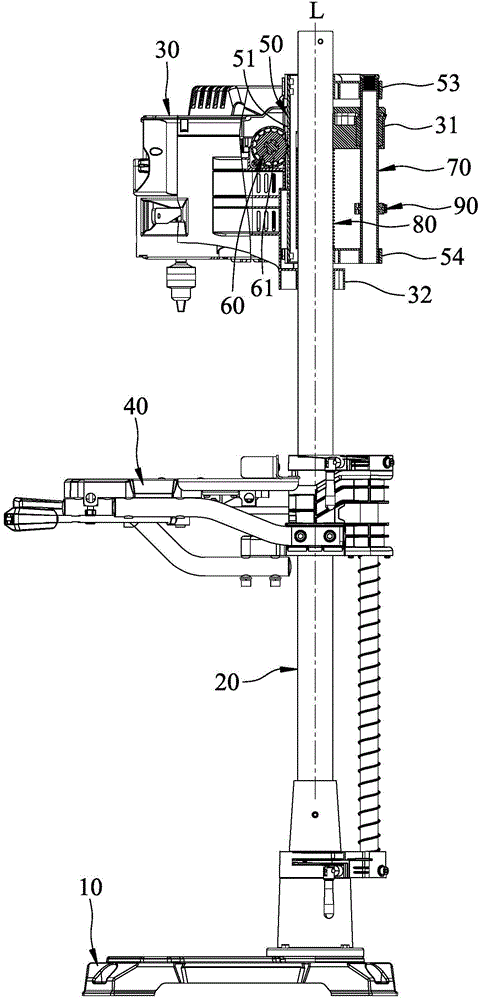

[0020] refer to figure 1 , figure 2 and image 3 , an embodiment of the drill press that can be drilled quickly in the present invention includes a base 10, a guide column 20, a head unit 30, a workbench 40, a locking unit 50, a driving unit 60, a guide Lead rod 70 , a return spring 80 and a depth positioning adjustment member 90 .

[0021] The base 10 can be stably fixed on the ground.

[0022] The guide post 20 is fixed on the base 10 and extends along an axis L. As shown in FIG.

[0023] The head unit 30 can be lifted and connected to the top of the guide post 20, and has an upper fitting part 31 that can slide and is sleeved on the guide post 20, and an upper fitting part 31 that is spaced apart from the upper fitting part 31 and can slide and The lower fitting portion 32 of the guide post 20 is sheathed on and a shaft seat 33 corresponding to the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com