Oily sludge pyrolysis treatment and residue biohumic acid green repair process

A biological humic acid and humic acid technology, which is applied in pyrolysis treatment of sludge, water/sludge/sewage treatment, petroleum industry, etc., can solve the problems of long reaction time, low heating rate, low liquid yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

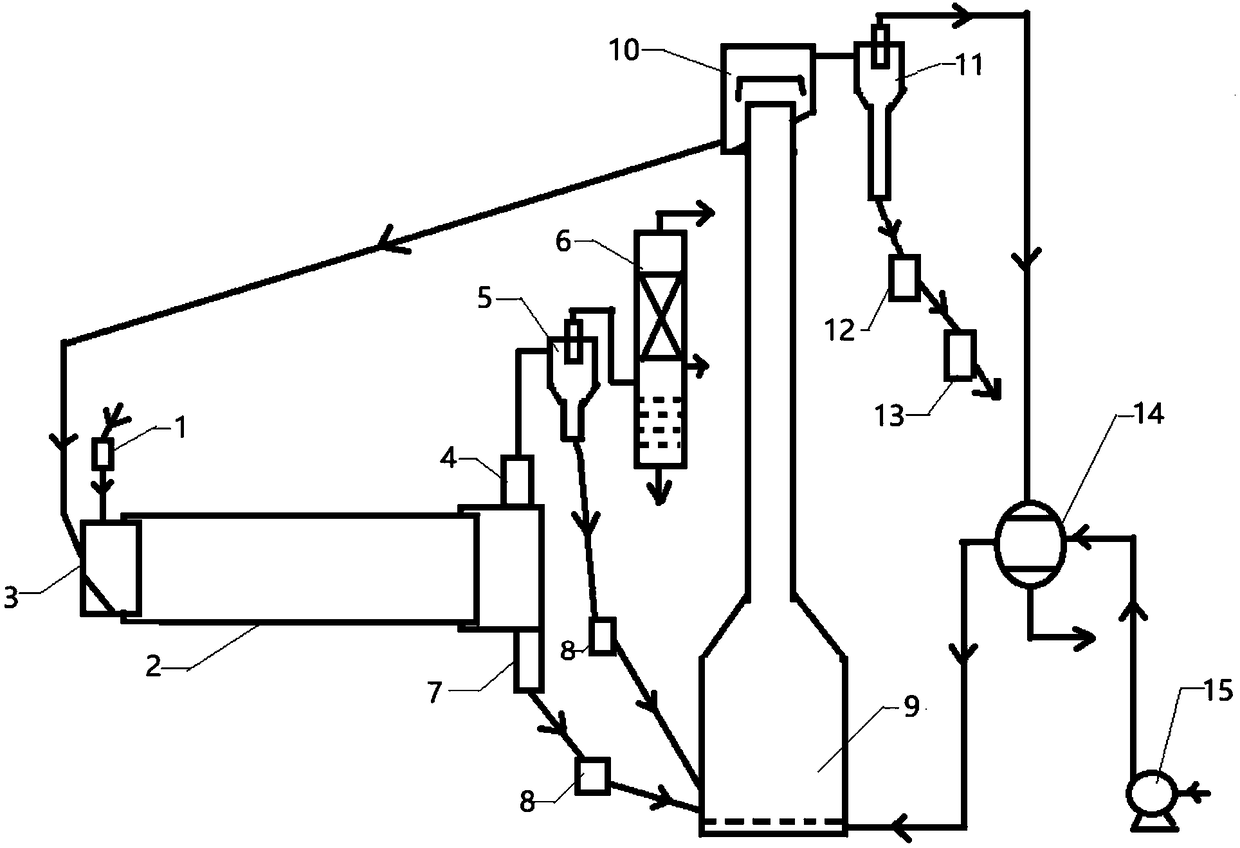

[0022] The sludge with 15% oil content is crushed by the cone crusher (1), and then added from the top of the front end of the internal mixing rotary reactor (2), and the circulating solid hot ash added to the upper side of the front top plate (3) is rotating Stirring and mixing in the reactor (2), rapid heating, vaporization and pyrolysis; the dusty pyrolysis oil gas flows out from the top oil gas outlet (4) at the end of the rotary reactor (2) and enters the gas-solid separator (5), pyrolysis The slag flows out from the bottom pyrolysis slag outlet (7) at the end of the rotary reactor (2) and enters the bottom of the calcining fluidized bed (9) through the return controller (8); Oil and gas enter the fractionation tower (6) to obtain distillate oil or synthetic crude oil and tower bottom oil, solid ash flows into the bottom of the calcining fluidized bed (9) through the return controller (8), and the tower bottom oil returns to mix with oily sludge; pyrolysis The slag and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com