Supporting structure

A technology of support structure and support rod, which is applied in the directions of ships, ship salvage, underwater operation equipment, etc., and can solve the problems of the backing of mud arching robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

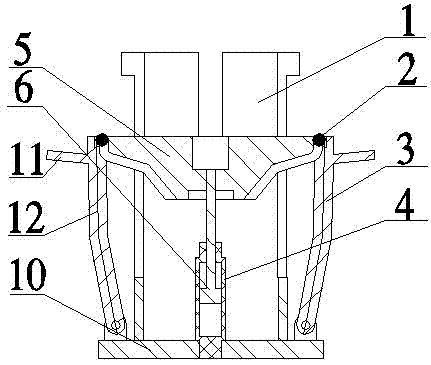

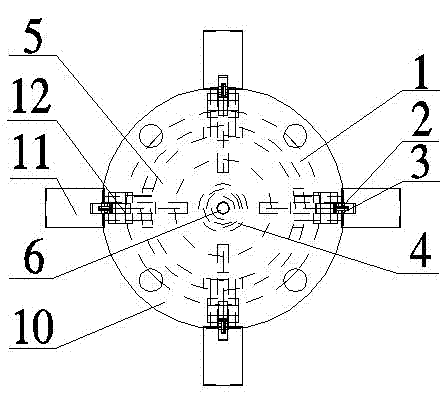

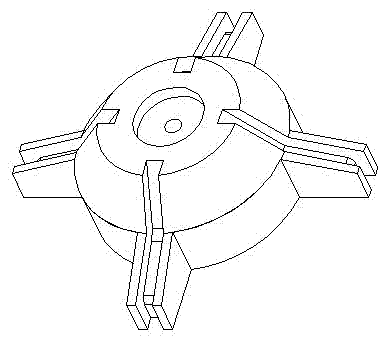

[0022] The device will be further described in detail below in conjunction with the accompanying drawings and examples. The device provides a support structure for a mud-arching robot, which is composed of a barrel wall (1), a roller (2), a support rod (3), a sleeve (4), a slider (5), a piston rod (6), a barrel Wall base (10) constitutes. The piston rod (6) is nested in the sleeve (4). There is a gap between the bottom of the piston rod (6) and the sleeve (4) for filling hydraulic oil. The piston rod (6) and the sleeve (4) are combined to form a hydraulic cylinder. One end of the sleeve (4) is fixed on the bottom of the barrel wall (1), and the central axis of the sleeve (4) coincides with the central axis of the barrel wall (1); the slider (5) is nested on the piston rod (6), and the slider (5) There are grooved bosses protruding from all around, and the included angle between two adjacent bosses is 90°. The roller (2) is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com