Well killing polyacrylamide strong gel and preparation method thereof

A technology of polyacrylamide and strong gel, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of limited compressive strength, high cost, poor temperature resistance, etc., and achieve good compressive strength, Effect of High Viscosity Modulus and High Elastic Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

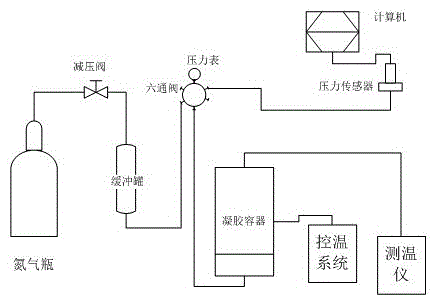

Method used

Image

Examples

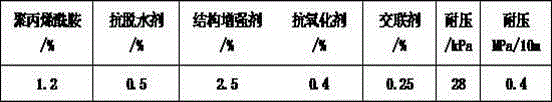

Embodiment 1

[0026] A polyacrylamide strong gel for well killing consists of the following components and contents:

[0027] Base fluid: 1% polyacrylamide, 8% structural enhancer, 8% anti-dehydration agent, 0.2% anti-oxidant, and the balance is water, based on the total mass of the prepared polyacrylamide strong gel for well killing;

[0028] Cross-linking agent: based on the mass fraction of the cross-linking agent relative to the base liquid, the cross-linking agent accounts for 10%.

[0029] The viscosity of the polyacrylamide strong gel is greater than 100000 mPa?s (1.5s -1 , 100℃), the compressive strength reaches 0.4-1.7MPa / 10m.

[0030] In the present invention, the polyacrylamide is a mixture of one or more of nonionic, cationic, anionic and amphoteric polyacrylamide in any proportion.

[0031] In the present invention, the molecular weight of the polyacrylamide is between 1 million and 12 million.

[0032] In the present invention, the structural reinforcing agent is a mixture ...

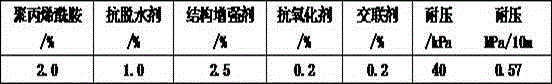

Embodiment 2

[0039] This embodiment is basically the same as the above-mentioned embodiment, and the main differences are as follows:

[0040] A polyacrylamide strong gel for well killing consists of the following components and contents:

[0041] Base fluid: 6% polyacrylamide, 2% structural enhancer, 0.4% anti-dehydration agent, 4% antioxidant, and the balance is water, based on the total mass of the prepared polyacrylamide strong gel for well killing;

[0042] Cross-linking agent: based on the mass fraction of the cross-linking agent relative to the base liquid, the cross-linking agent accounts for 0.2%.

[0043] A preparation method of polyacrylamide strong gel for well killing, comprising: adding polyacrylamide, antioxidant, anti-dehydration agent and structure enhancer in sequence in water at a stirring speed of 450 rpm / min, and fully dissolving After that, add the cross-linking agent, and gelatinize at 120℃.

[0044] In the present invention, after adding the cross-linking agent, t...

Embodiment 3

[0046] This embodiment is basically the same as the above-mentioned embodiment, and the main differences are as follows:

[0047] A polyacrylamide strong gel for well killing consists of the following components and contents:

[0048] Base fluid: based on the mass of the total polyacrylamide strong gel solution for well killing, 3% polyacrylamide, 4% structural enhancer, 4% anti-dehydrating agent, 2% antioxidant, and the balance is water;

[0049] Cross-linking agent: based on the mass fraction of the cross-linking agent relative to the base liquid, the cross-linking agent accounts for 6%.

[0050] A preparation method of polyacrylamide strong gel for well killing, comprising: adding polyacrylamide, antioxidant, anti-dehydrating agent and structural enhancer in water at a stirring speed of 400 rpm, fully dissolving Finally, add a cross-linking agent and form a gel at 100°C.

[0051] In the present invention, after adding the crosslinking agent, the crosslinking reaction time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com