A deep-sea double-tube bottomhole three-channel pressure control system and control method

A technology of pressure control and double-layer pipes, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve problems such as complex structure, high economic cost, and poor reliability, and achieve simple system structure and improved control High precision and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

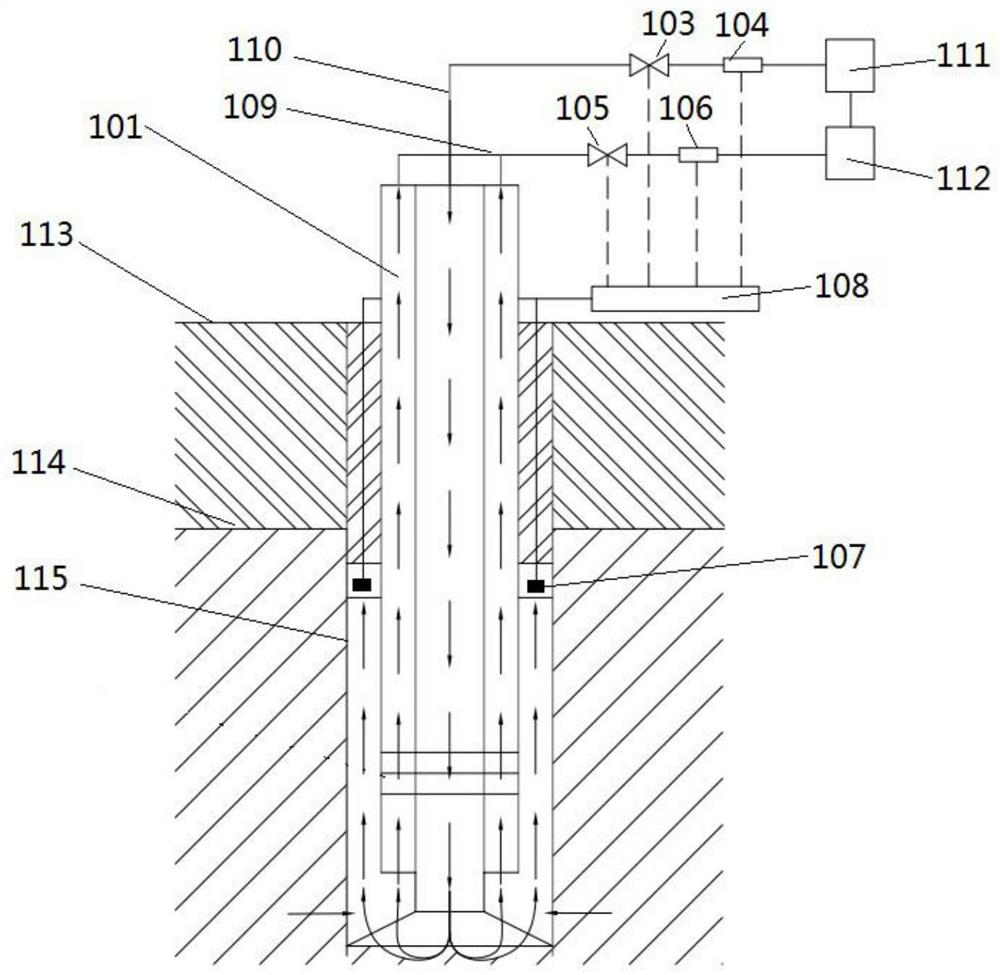

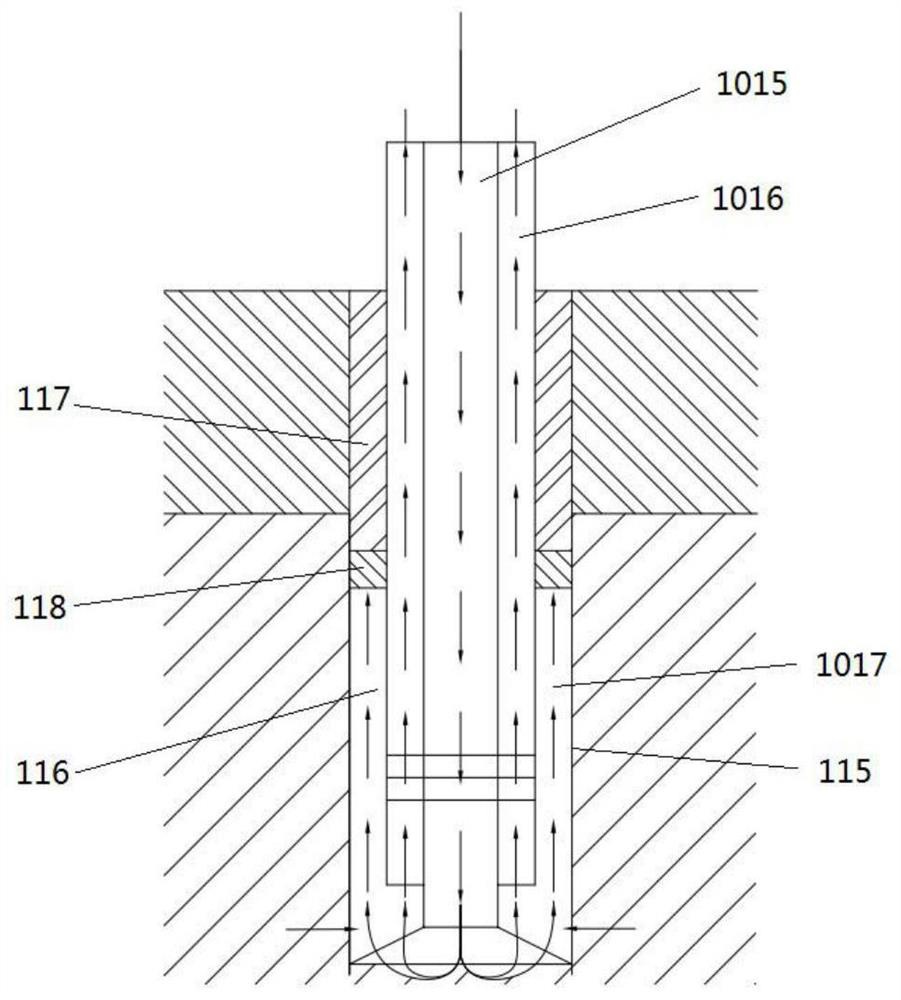

[0039] Such as figure 1 As shown, the present invention is a deep-sea double-tube bottom hole three-channel pressure control system, including double-layer tube 101, conversion joint 1021, casing 115, drill bit 119, outer sleeve 1022, axial flow pump 1024, turbine motor 1023, liquid Position monitoring sensor 107, valve group control unit 108, double-layer pipe return manifold 109, drilling fluid pumping manifold 110, drilling pump 111, drilling fluid circulation tank 112;

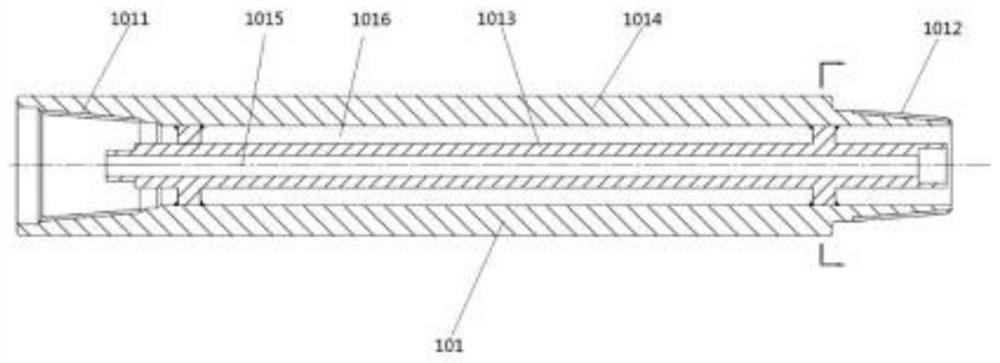

[0040] Such as figure 2 with 9 As shown, the double-layer pipe 101 includes an outer pipe 1014 and an inner pipe 1013 installed in the outer pipe 1014. The upper end of the inner cavity of the outer pipe 1014 is provided with an outer pipe female thread 1011, and the lower end of the outer surface is provided with an outer pipe male thread. 1012, the inner pipe 1013 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com