Industrial wastewater discharging monitoring system

A monitoring system and industrial wastewater technology, which is applied in the direction of water treatment parameter control, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of whether the monitoring content meets the discharge standard, etc., to improve equipment treatment efficiency and improve Stability, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

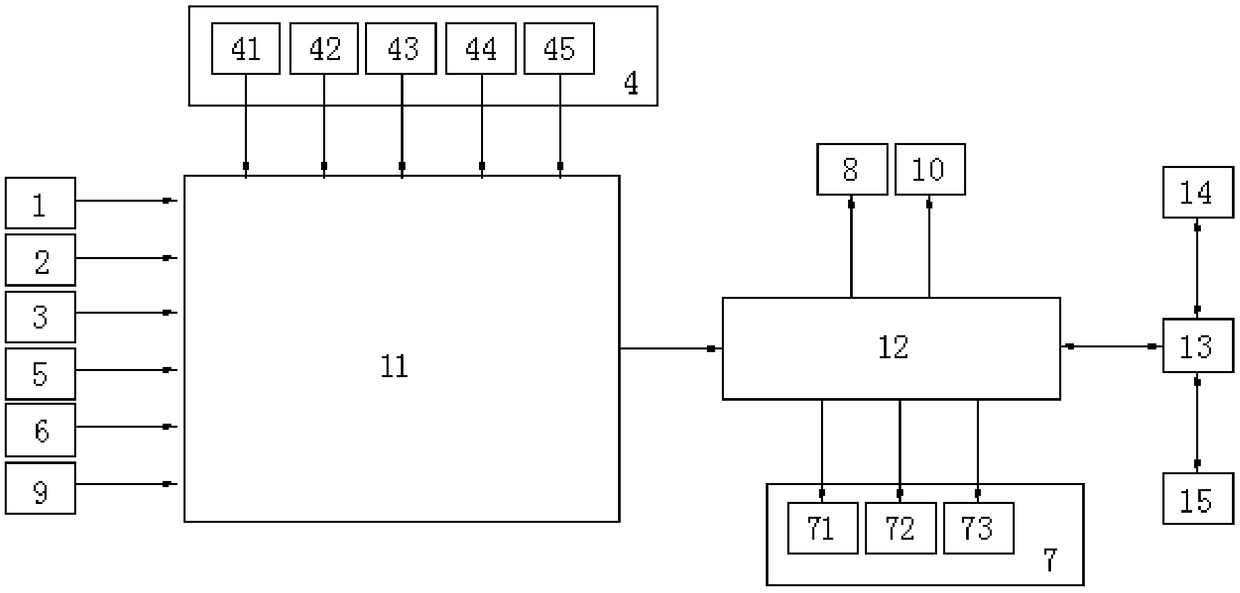

[0026] Embodiment: a kind of industrial wastewater discharge monitoring system, such as figure 1 As shown, it includes controller, liquid level detection module 1, pH detection module 2, water temperature detection module 3, water quality detection module 4, pressure detection module 5, flow rate detection module 6, drug dosing control module 7, valve control module 8, Video acquisition module 9 and alarm module 10;

[0027] The liquid level detection module 1 includes a liquid level sensor located in each processing unit; the pH detection module 2 includes a pH meter for detecting the pH of waste water; the water temperature detection module 3 includes a temperature sensor for detecting the temperature of waste water; The water quality detection module 4 includes a suspended matter sensor 41, an ammonia nitrogen sensor 42, a COD sensor 43, a BOD sensor 44, and a sulfide sensor 45 for detecting wastewater quality; the pressure detection module 5 includes connecting pipes posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com