Gas lift reverse circulation drilling process

A gas lift reverse circulation and process technology, which is applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., to reduce labor intensity, reduce production costs, and improve drilling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

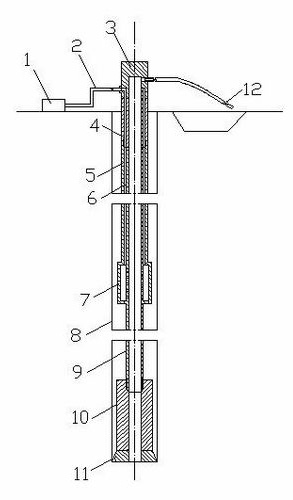

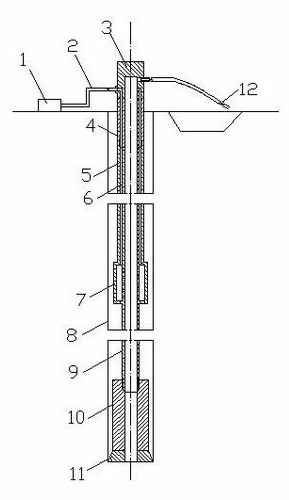

[0016] As shown in the figure, the process steps of gas lift reverse circulation drilling process are as follows: ①Remove the double-arm kelly and fill the core pipe with liquid, then reinstall the double-arm kelly; ②Close the outlet of the slag discharge pipe Start the air compressor to supply air to the high-pressure valve at the place, ③When the intake pressure rises to 5.5-6Mpa, quickly open the high-pressure valve at the outlet of the slag discharge pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com