Coal engineering hole directional drilling method

A directional drilling and engineering technology, applied in directional drilling and other directions, can solve the problems of low drilling accuracy and complex procedures, and achieve the effects of improving drilling utilization, simple procedures and high drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

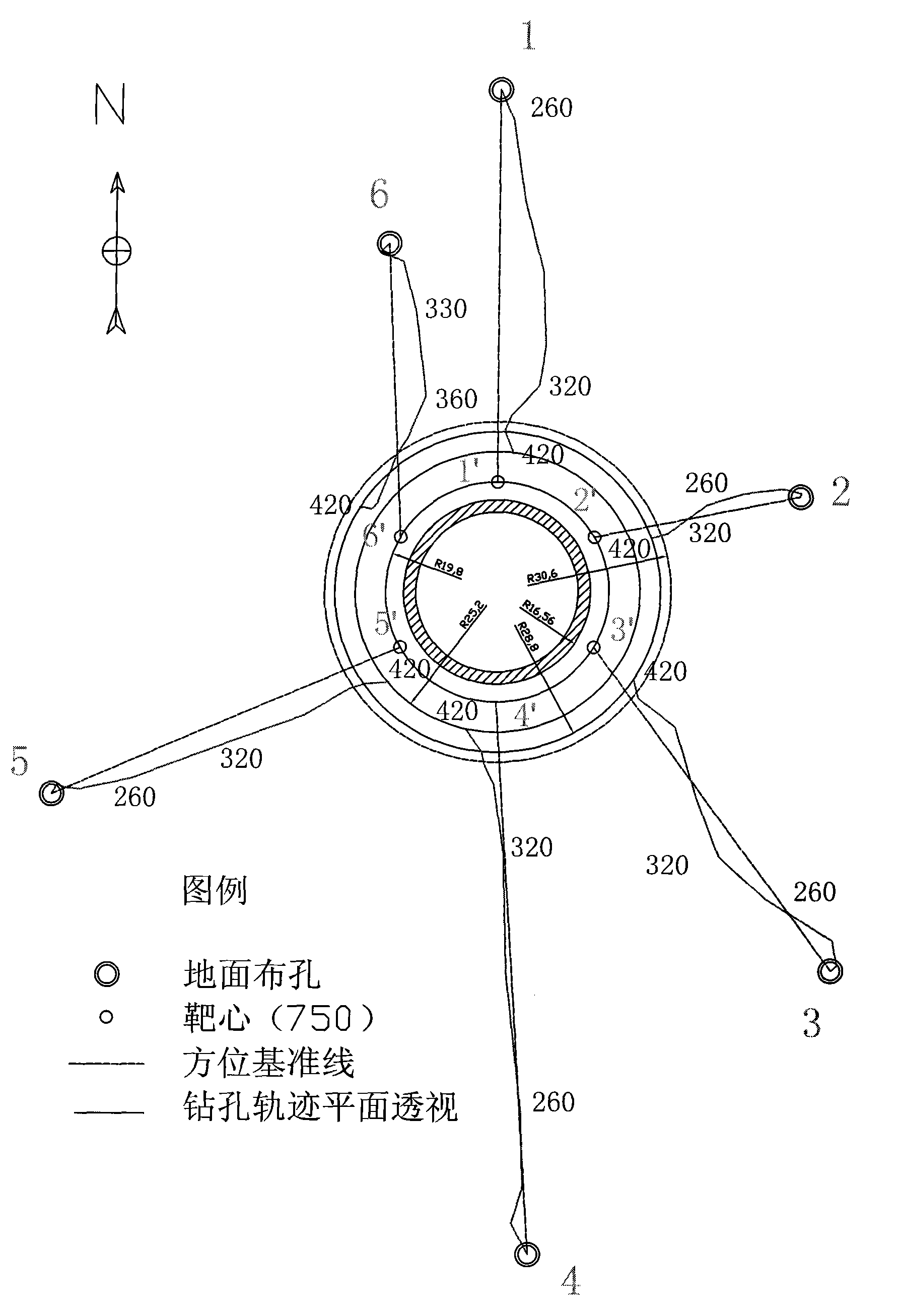

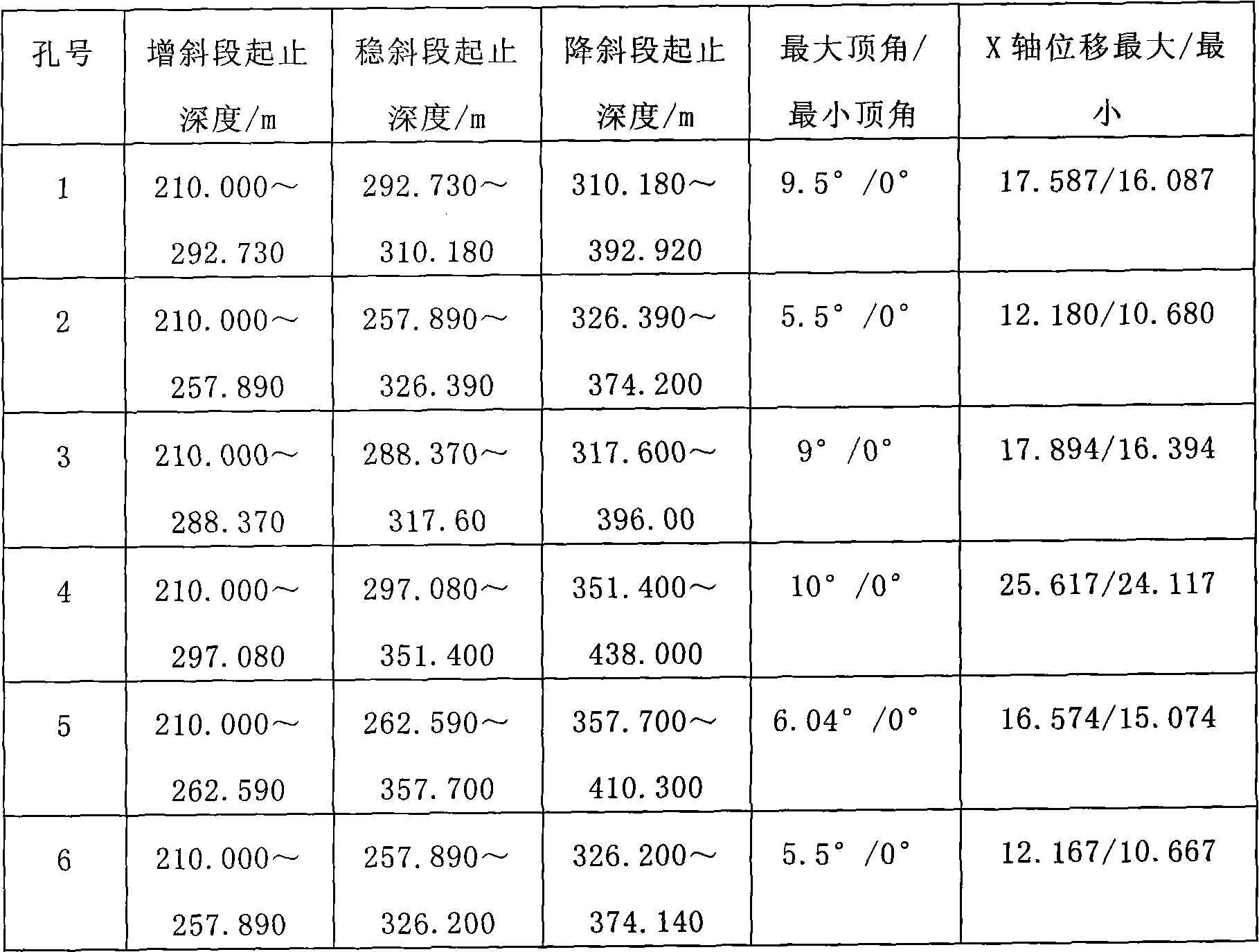

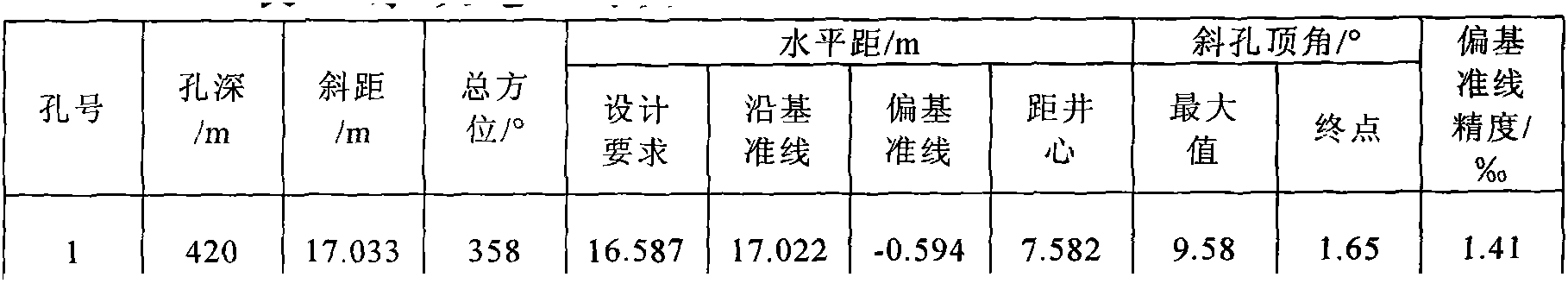

[0019] Example 1: Directional Drilling of No. 2 Well Group Holes in Donghuantuo Mine

[0020] The design well depth of Donghuantuo No. 2 well of the former Kailuan Mining Bureau is 737m, the depth of the pre-grouting hole on the ground is 750m, and the shallow section below 420m adopts the freezing method, which has already met the excavation conditions. In order to shorten the construction period of the well, the lower grouting and the excavation of the upper frozen section need to be operated in parallel. Since the surrounding of the wellhead is occupied by drilling facilities, it is impossible to arrange vertical grouting holes. The opening positions of the grouting holes are all a certain distance from the wellhead, bypass the frozen section through the S hole, and enter the grouting hole design drop point range in the grouting section , Complete the grouting construction of the section deeper than 420m.

[0021] The specific steps are as follows:

[0022] 1. Design the ...

example 2

[0053] Example 2: Directional correction of grouting holes in the main shaft of Dashucun Coal Mine

[0054]The Dashucun mine of the former Fengfeng Mining Bureau has a designed annual output of 900,000 tons. The main and auxiliary shafts adopt ground pre-grouting technology for water plugging, and the three grouting holes of the auxiliary shaft use directional drilling technology for deviation correction. The depth of the grouting hole in the auxiliary shaft is 703.5m, and the deviation rate is required to be no more than 10‰. When the deviation rate of the grouting hole is close to 10‰, the deviation will be corrected to meet the requirements of verticality and basically uniform distribution of landing points.

[0055] 1. Design the trajectory of the grouting hole

[0056] Because the grouting hole is required to be a straight hole, the purpose of directional drilling is to correct the deviation, so no trajectory design is required.

[0057] 2. The main equipment, instrument...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com