Patents

Literature

52results about How to "The construction method is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drilling with casing method for gas extraction hole of soft broken coal seam

InactiveCN103726869APrevent collapseIncrease drilling speedGas removalDrilling machines and methodsSlagCoal

The invention relates to a drilling with casing method for a gas extraction hole of a soft broken coal seam. The problems that a deep gas extraction hole in a soft broken coal seam is difficult to drill and the hole forming effect is poor can be effectively solved. According to the technical scheme for solving the problems, the method comprises the following steps: 1, stabilizing a drilling machine; 2, installing a drilling tool; 3, drilling; 4, carrying out drilling with casing operation; 5, connecting a long sleeve and a drill stem; 6, rinsing boring mud; 7, drilling the deep hole in circulation; and 8, retreating the drilling tool. The construction method disclosed by the invention is scientific and reasonable, the collapse of a hole wall is avoided, and meanwhile, a smooth slag discharge channel is provided for the boring mud at the bottom of the hole, so that not only are the drilling speed and the drilling depth of the gas hole improved, but also the target of protecting the hole is achieved, and the gas extraction efficiency is significantly improved. The method is simple and practical in operation, the operation environment is improved, and the drilling with casing method is an innovation of gas extraction methods of a soft broken coal seam.

Owner:HENAN POLYTECHNIC UNIV

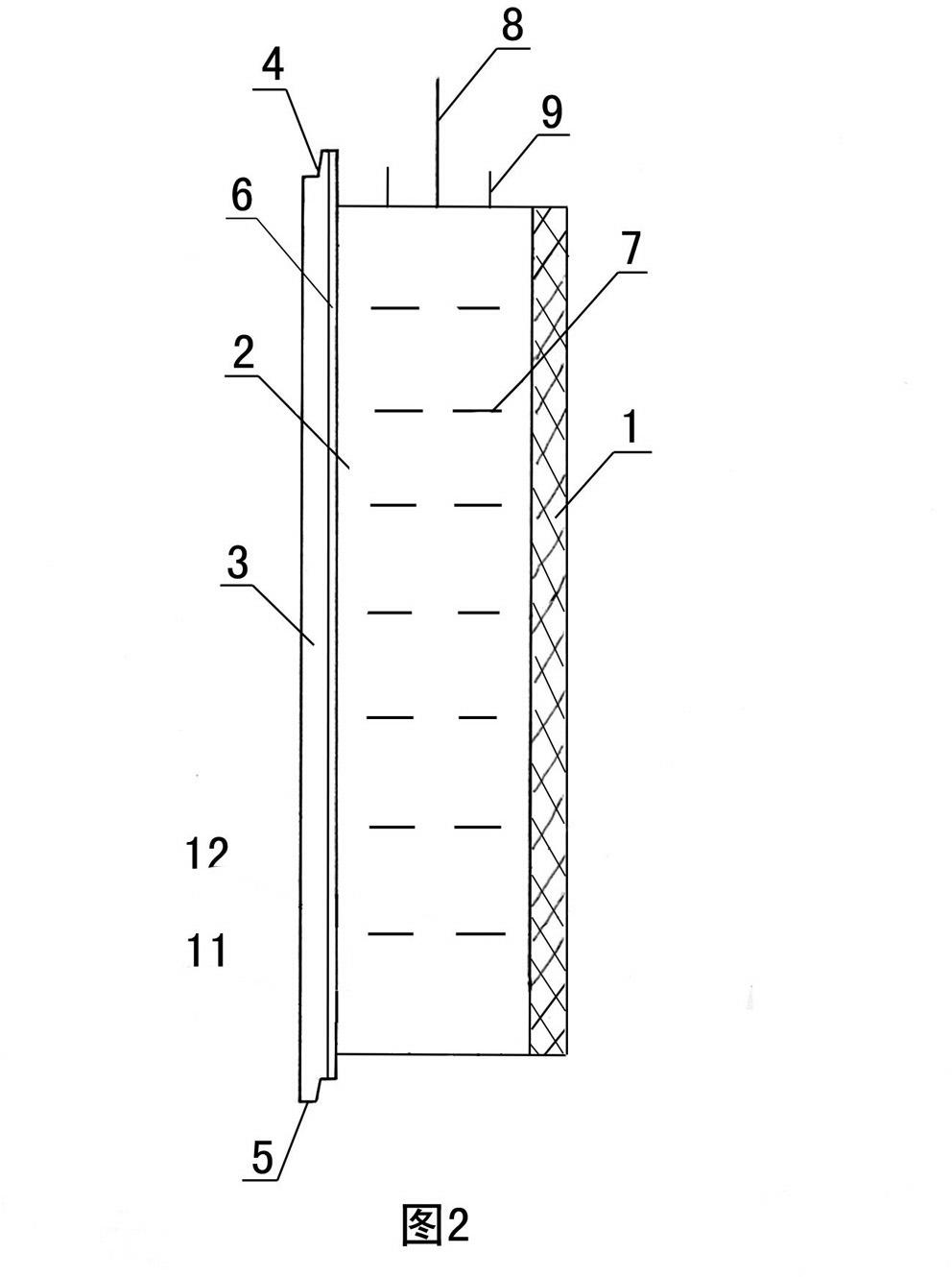

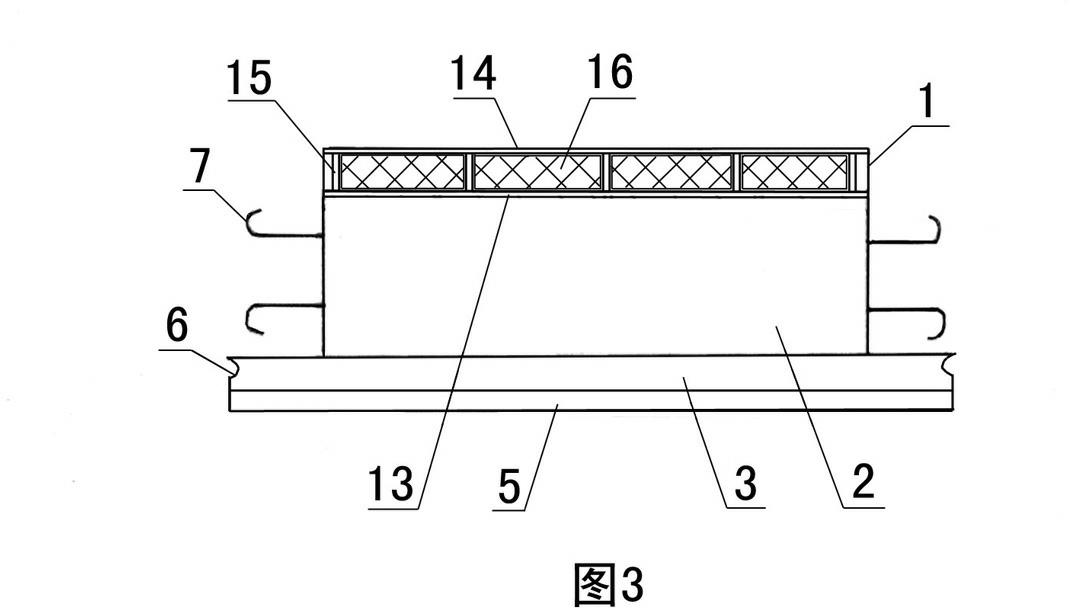

Block type wall system assembled by hoisting and construction method thereof

ActiveCN102505779ASimple construction methodReduce generationWallsClimate change adaptationSurface layerInsulation layer

Disclosed are a block type wall system assembled by hoisting and a construction method thereof. Multiple prefabricated wall board blocks are assembled into a whole, each prefabricated wall board block is provided with a reinforcing mesh concrete layer and a heat insulation layer outside in sequentially, the reinforcing mesh concrete layer consists of a structural layer and an outer surface layer disposed on the outer surface of the structural layer, four edges of the outer surface layer are protruded from four edges of the structural layer, the lower surface of the structural layer is provided with inner reinforcing bar holes corresponding to vertical long reinforcing bars on the lower adjacent prefabricated wall board block, and the heat insulation layer comprises external nonorganic boards, internal nonorganic boards, vertical nonorganic rib plates and fireproof heat insulation rock wool. The wall system is light in weight, simple in structure, convenient in installation and capable of realizing industrialized production. The wall system utilizes the external wall and internal heat insulation structure, the specially-made heat insulation layer and the concrete structural layer are connected quite closely and tightly, and the heat insulation layer is located on the innermost side, so that the probability of wetting due to seepage is reduced greatly.

Owner:沈汉杰

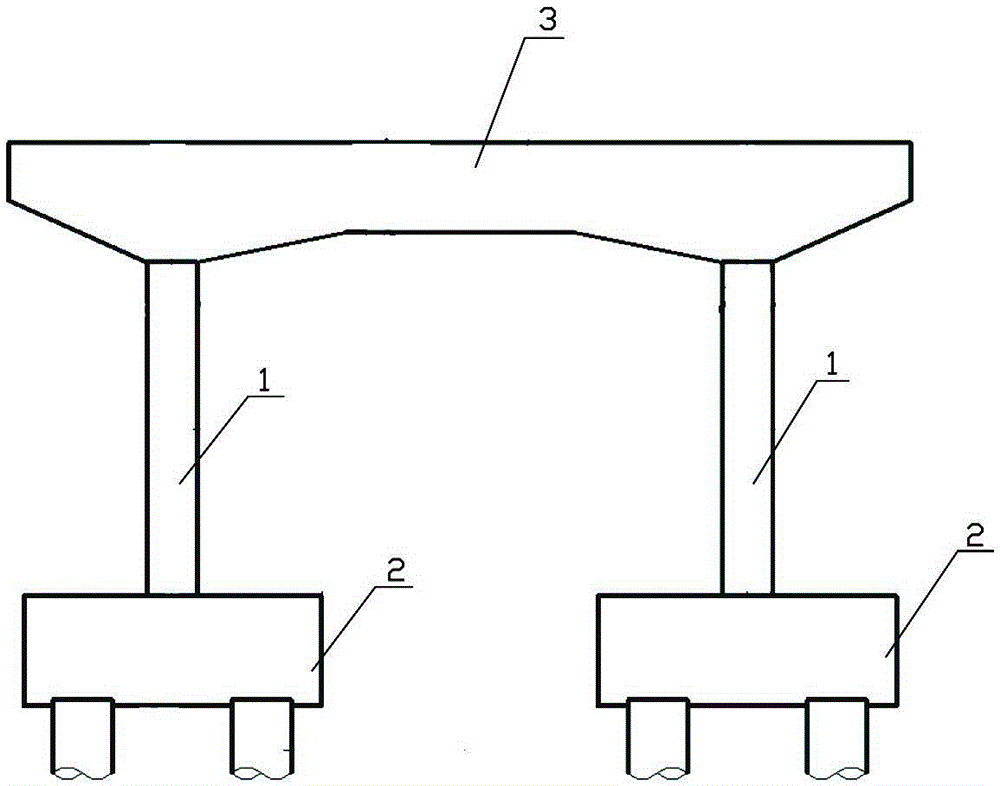

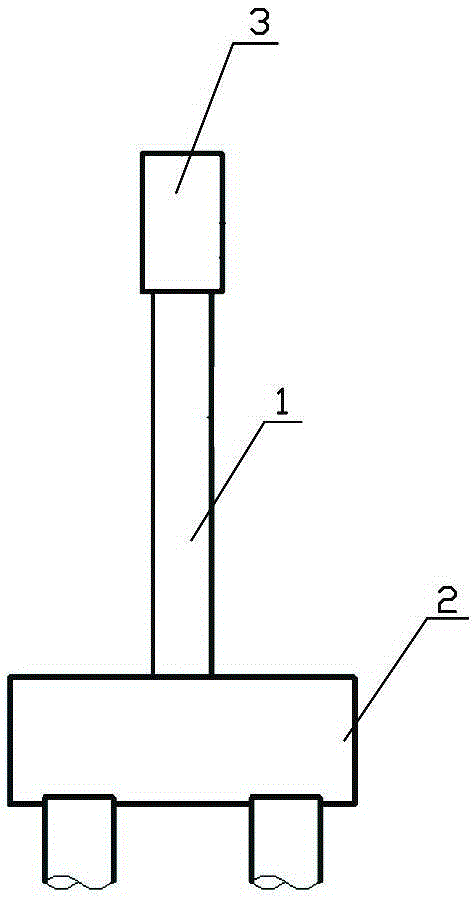

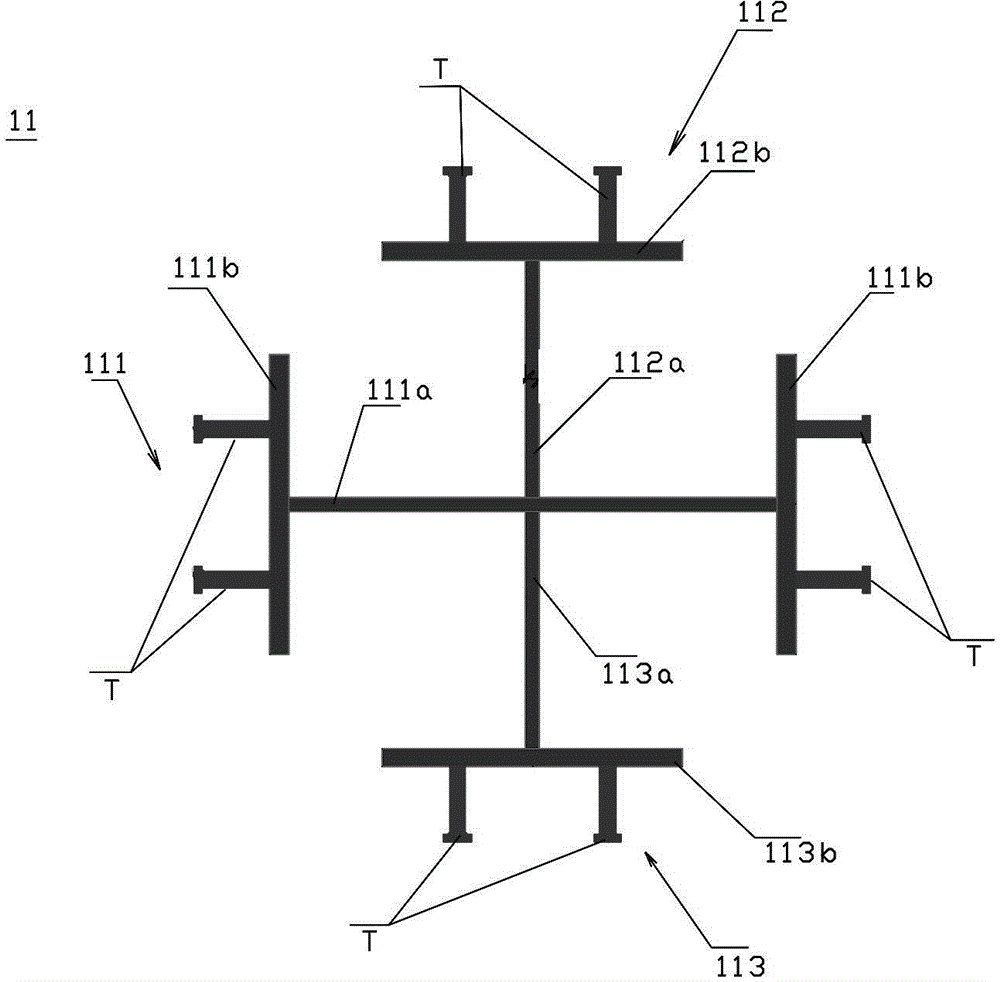

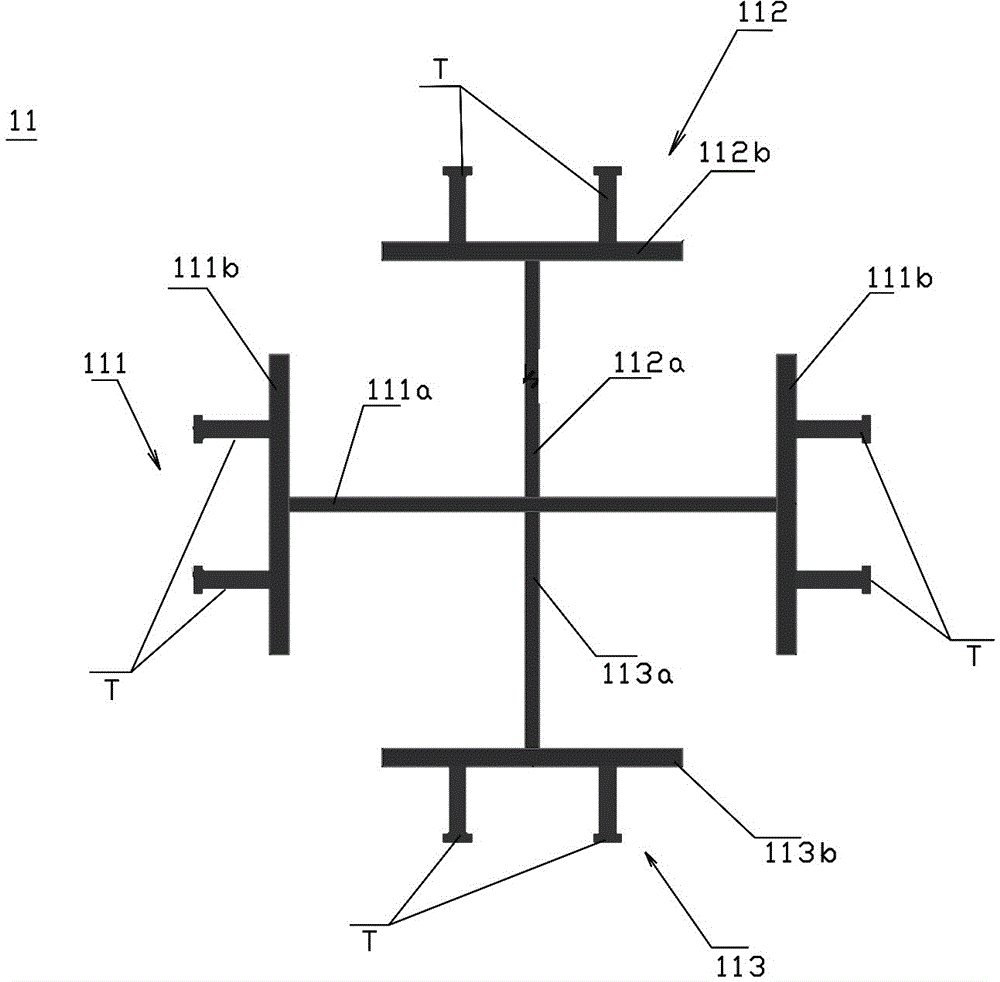

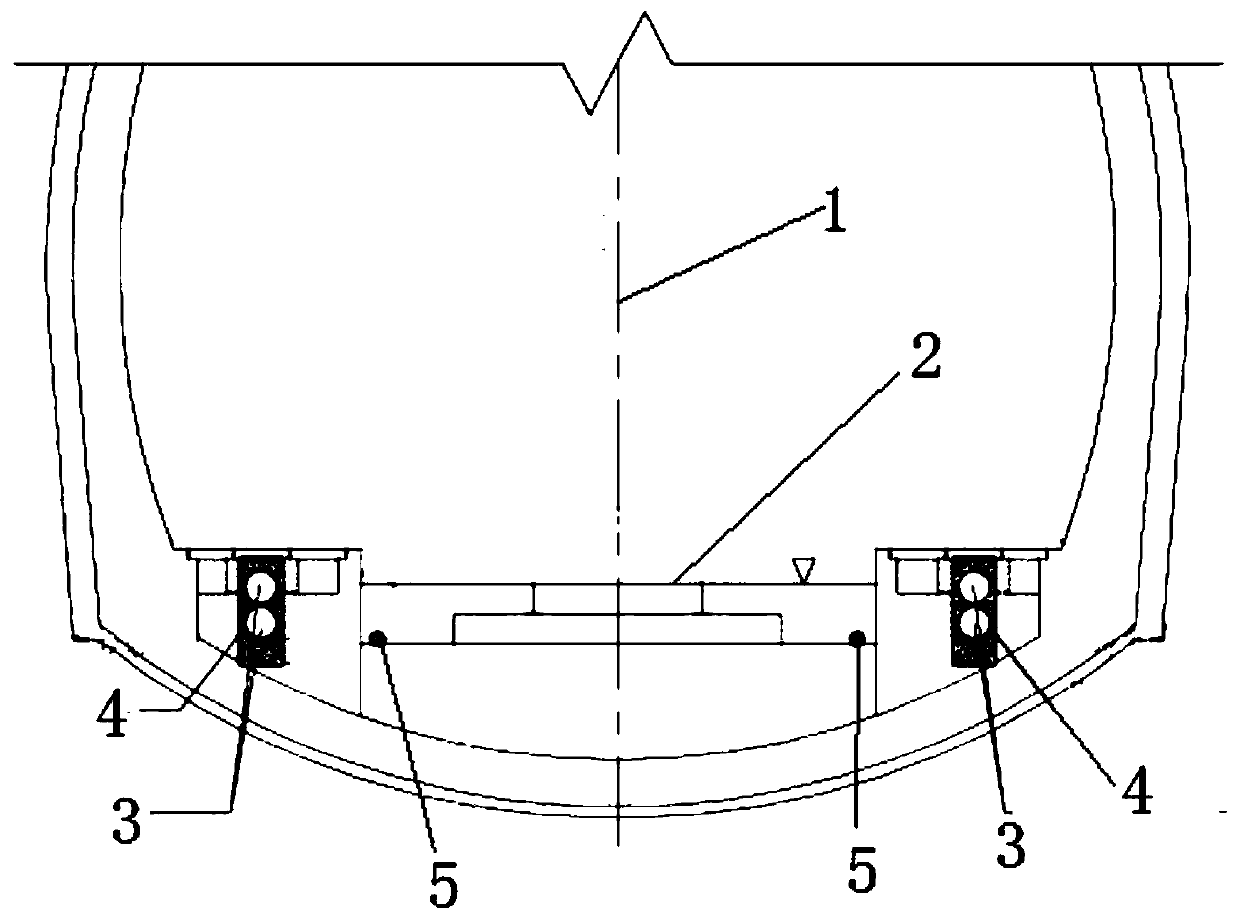

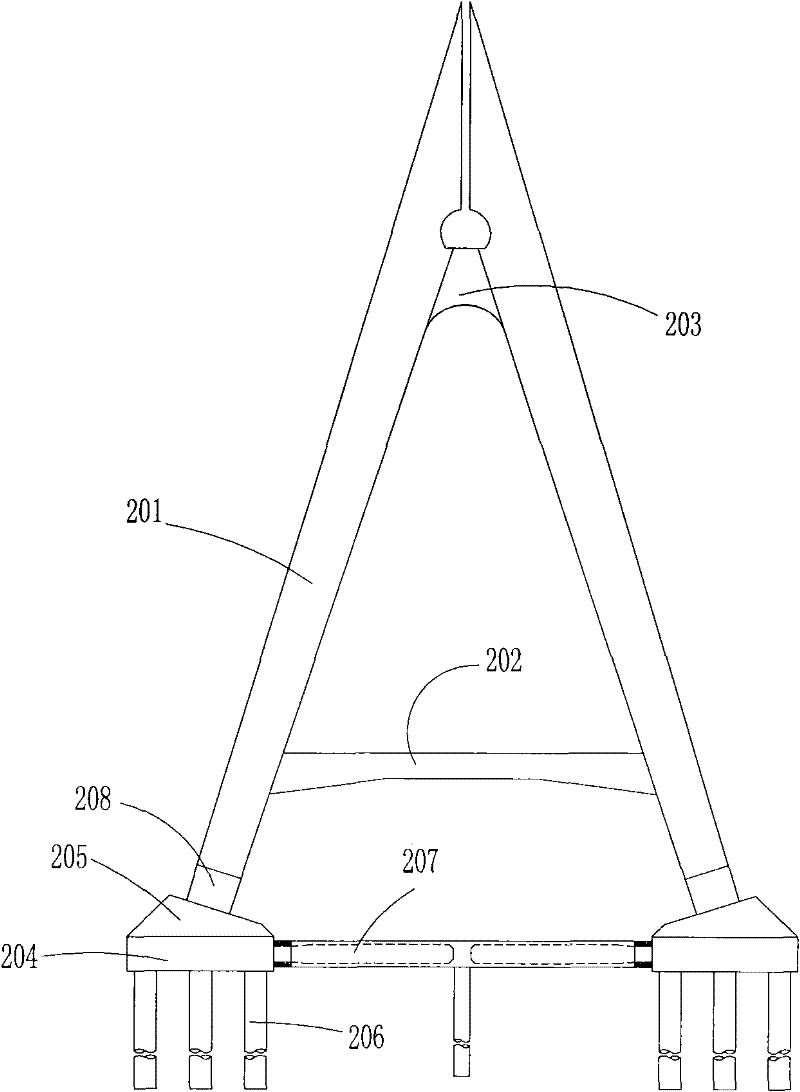

Profile steel concrete column for urban mass transit elevated railway station and preparing method thereof

ActiveCN105421586AImprove pressure resistanceImprove impact resistanceStrutsBridge structural detailsSteel columnsStructural safety

The invention discloses a preparing method for a profile steel concrete column for an urban mass transit elevated railway station. The method comprises the following steps that steel or a steel plate is prepared and used for preparing a first profile steel part, and a plurality of hole positions for penetrating are formed in a first web; locating welding is carried out on the first web and a first wing edge plate so that a first profile part can be formed; a second profile steel part and a third profile steel part are prepared; the second profile steel part and the third profile steel part are assembled at the two opposite sides of the first wing edge plate of the first profile steel part respectively to form a cross-shaped steel column; bolt screws are welded to the first profile steel part, the second profile steel part and the third profile steel part respectively. The invention further discloses the profile steel concrete column for the urban mass transit elevated railway station. By applying the profile steel concrete column for the urban mass transit elevated railway station and the preparing method thereof, the profile steel concrete column has good pressure bearing performance, is high in deformation ability, resists fatigue, and is good in impact resistance; the requirements for structural safety and project economy are met, and feasibility and working procedure arrangement of site construction are involved.

Owner:中铁五局集团路桥工程有限责任公司 +1

Essential plant fragrance smell area capable of improving depression symptoms and construction method thereof

InactiveCN101530040ANo side effectsGood spiritsNervous disorderMammal material medical ingredientsHibiscusPlant growth

The invention relates to an essential plant fragrance smell area capable of improving depression symptoms and a construction method thereof. The construction method comprises the steps of: selecting at least 10 from 21 essential plants including eucalypt, frankincense, lemon, bitter orange, hibiscus and the like; planting the selected plants according to a certain proportion and number; at the same time, uniformly arranging a certain number of sound systems in the fragrance smell area to create a natural fragrance smell environment capable of making people relax and happy, and raising spirit and improving depression symptoms in aspects of olfaction, vision, audition and the like at last. When the plants in the fragrance smell area grow to a certain stage, people for smelting fragrance can carry out fragrance smell activities in a certain mode for a certain period in fragrance smell area on the premise that the number of the people for smelling fragrance is no larger than the maximum holding capacity of the fragrance smell area. After a certain period of fragrance smell, the depression symptoms of the people for smelling fragrance can be improved obviously.

Owner:苏州市吴江胜地生态园有限公司

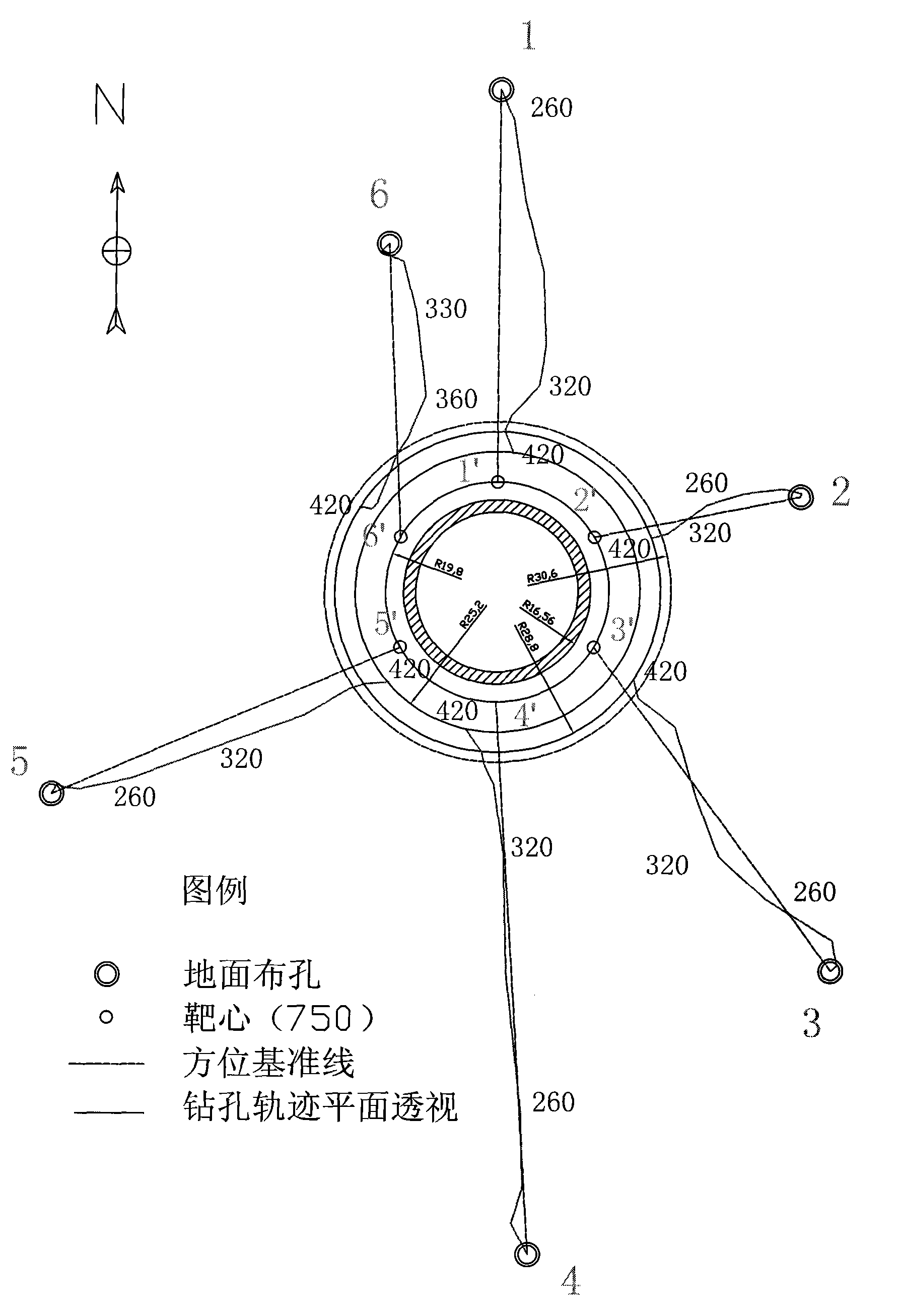

Coal engineering hole directional drilling method

InactiveCN102094580AWon't breakImprove drilling accuracyDirectional drillingCoalDirectional drilling

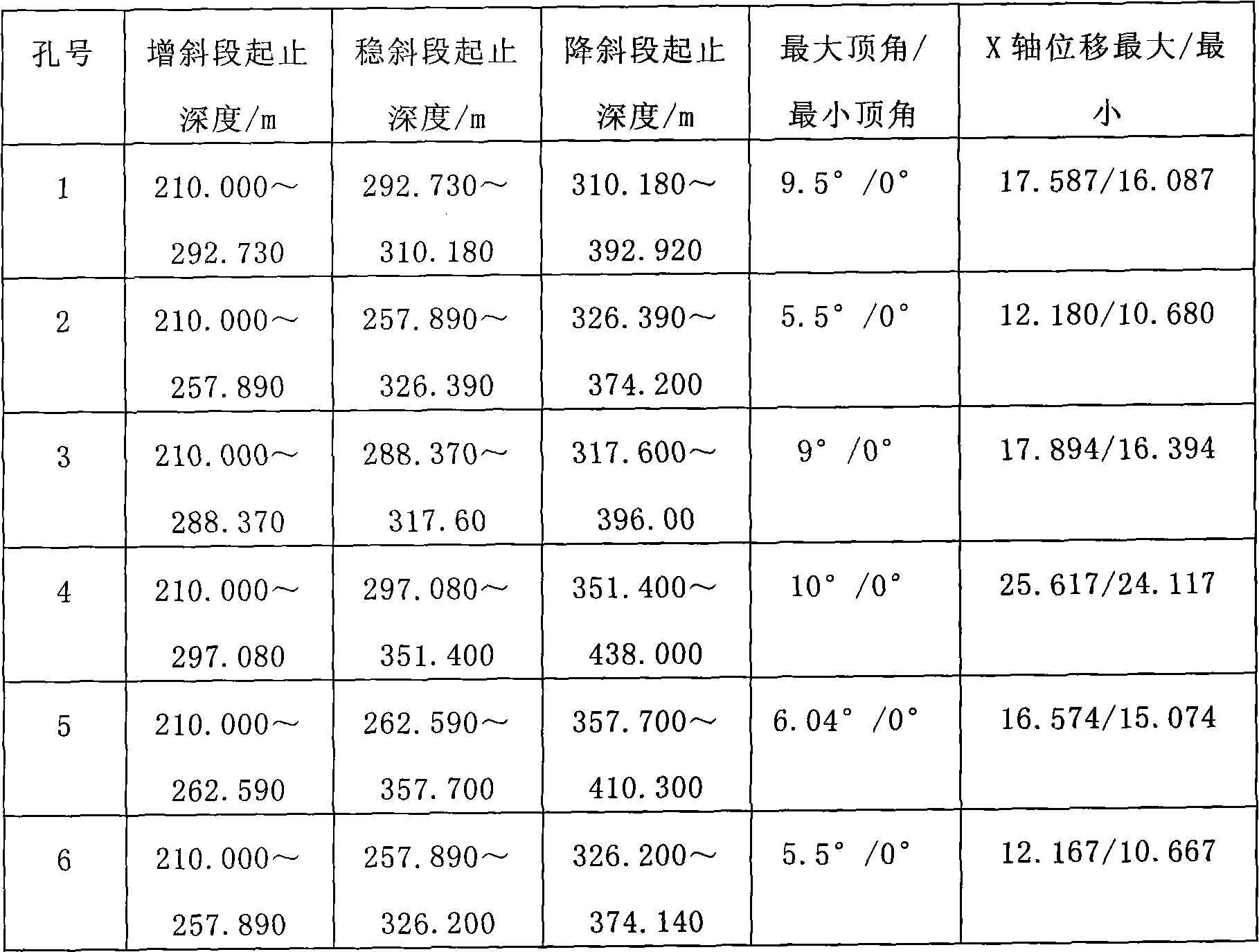

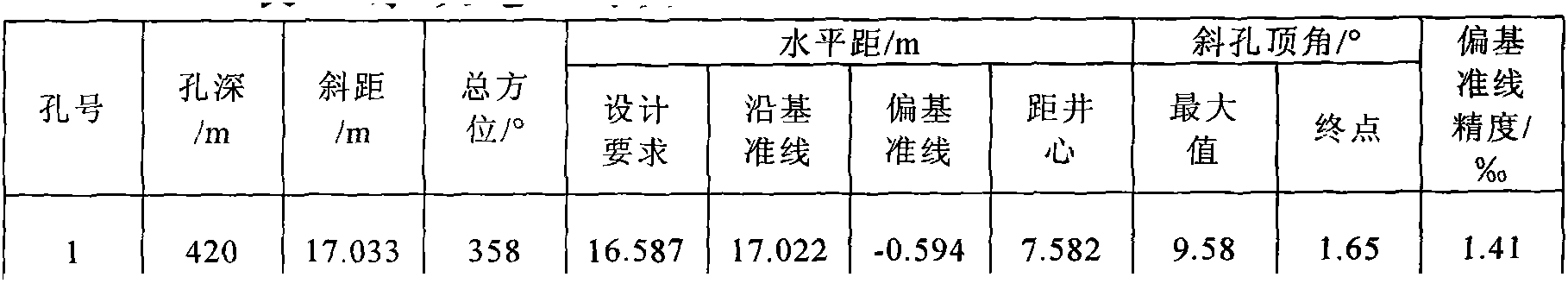

The invention provides a coal engineering hole directional drilling method, which mainly solves the problems of low drilling precision and complex procedure of the conventional directional drilling method. The directional drilling method is characterized by comprising the following steps of: 1, designing a drilling trace: designing the drilling trace and drilling parameters according to the requirement of engineering drilling; 2, determining special equipment, machines and devices which are required by the engineering, and combining the drilling equipment according to the requirements of all drilling stages; 3, constructing according to the trace and the parameters which are designed in the step 1, measuring the finished drilling trace by using an inclinometer after one stage is finished, analyzing whether data is the same as the designed trace, and expecting the next trace tendency; and 4, performing error correction design if error correction is needed to be performed in the step 3, repeating the content in the step 2, and cycling until the drilling is finished; and if error correction is not needed in the step 3, continuing to drill the next hole section until the drilling is finished. The coal engineering hole directional drilling method has the characteristics of high drilling precision, simple procedure, smooth drilled holes and contribution to the next work of drilling.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

method for optimizing tunnel construction based on improved Topsis method

InactiveCN109345029AImprove objectivityThe construction method is reasonableForecastingResourcesRock engineeringCalculation error

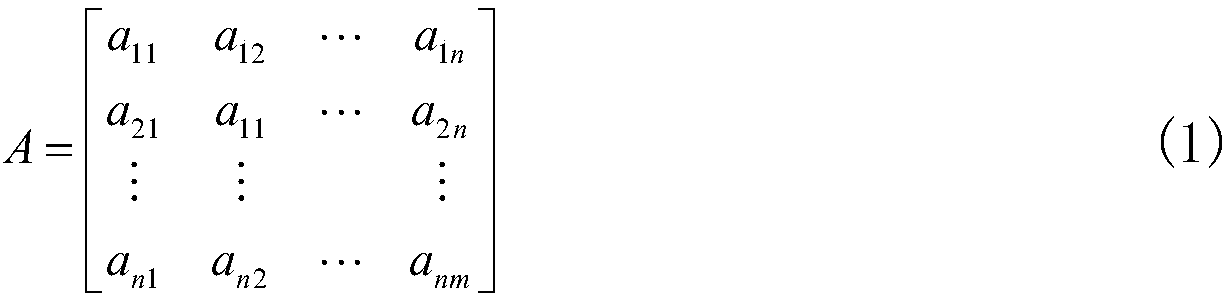

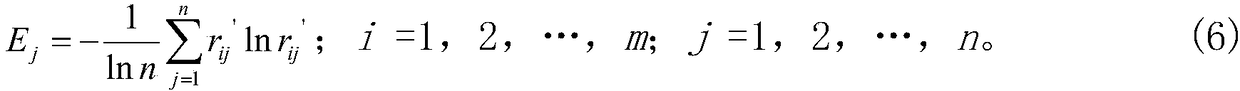

The invention discloses a method for optimizing tunnel construction based on improved Topsis method which includes the following steps: step selection method, three-pilot method, middle pilot method,CRD method of main tunnel and annular excavation reserved core soil method of main tunnel are used in this paper. According to the five selected tunnel construction schemes, the following eight indexes are selected to establish the evaluation index system: surrounding rock engineering geological conditions, vault settlement, surface settlement, inverted arch uplift, Great Wall settlement, engineering progress, engineering cost and local inclination ratio of Great Wall. AHP method is used to determine the subjective weight Omega _ 1, information entropy method is used to determine the objective weight Omega _ 2, and game theory aggregation model is introduced to determine the comprehensive weight. The improved Topsis method is used to eliminate the calculation errors caused by different units. Grey relational grade is adopted to improve the sticking progress. On the basis of ensuring the safety of the Great Wall in the construction process, the invention selects a more reasonable construction method to maximize the engineering income.

Owner:SHIJIAZHUANG TIEDAO UNIV

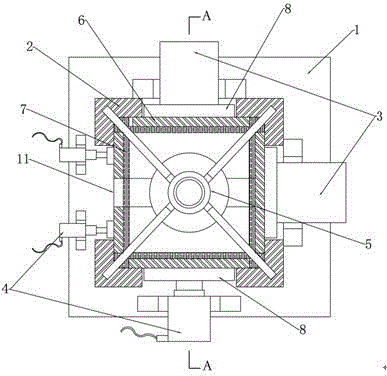

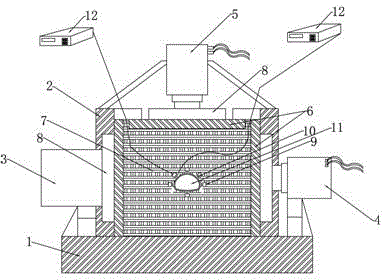

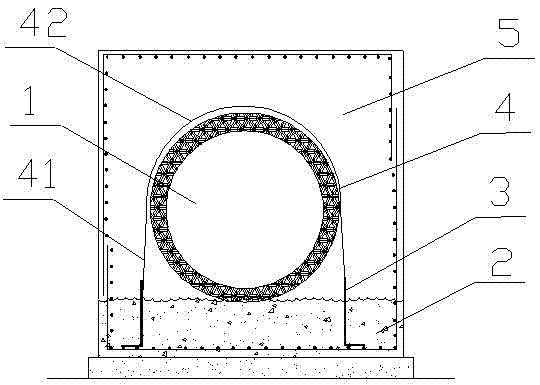

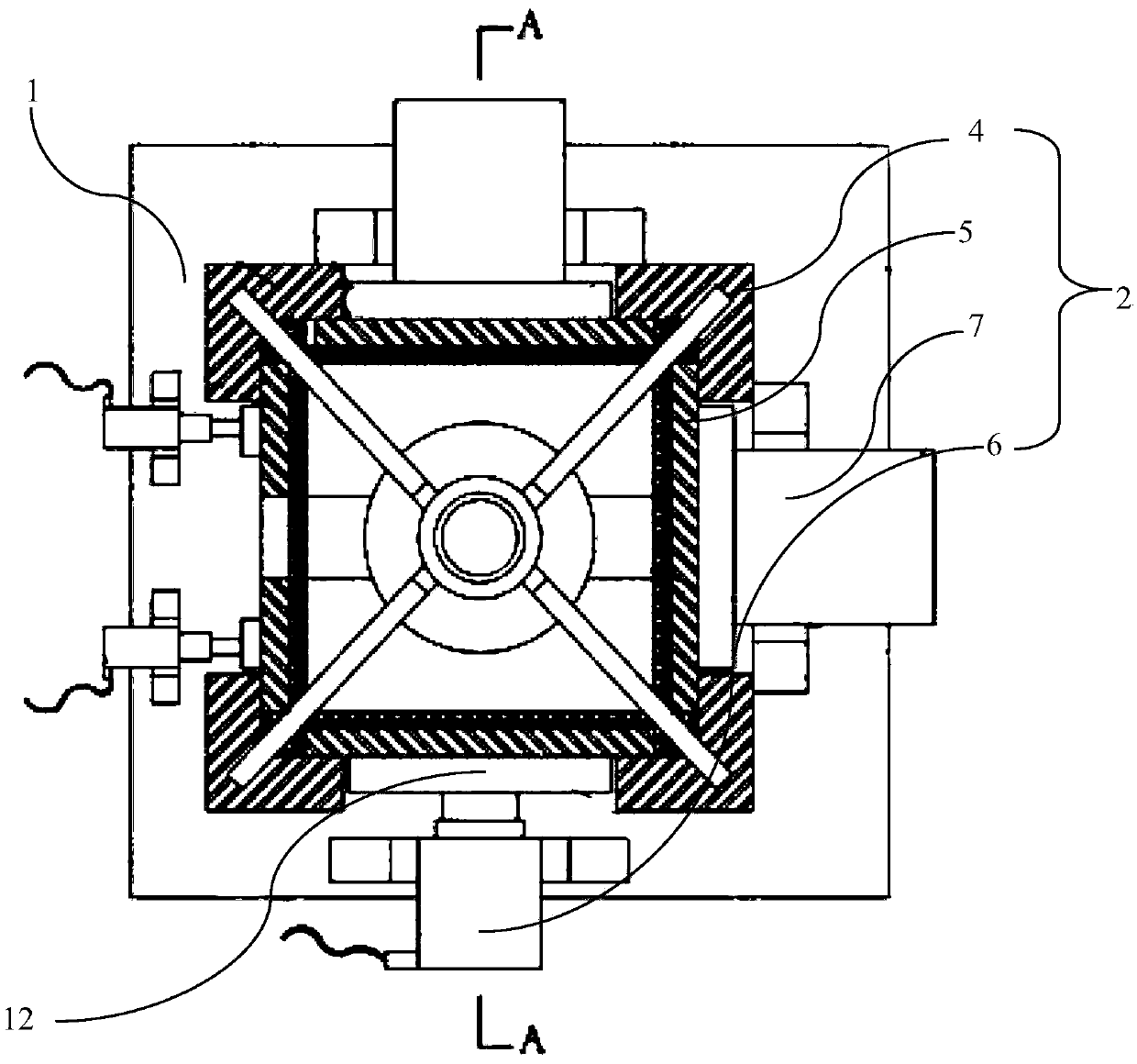

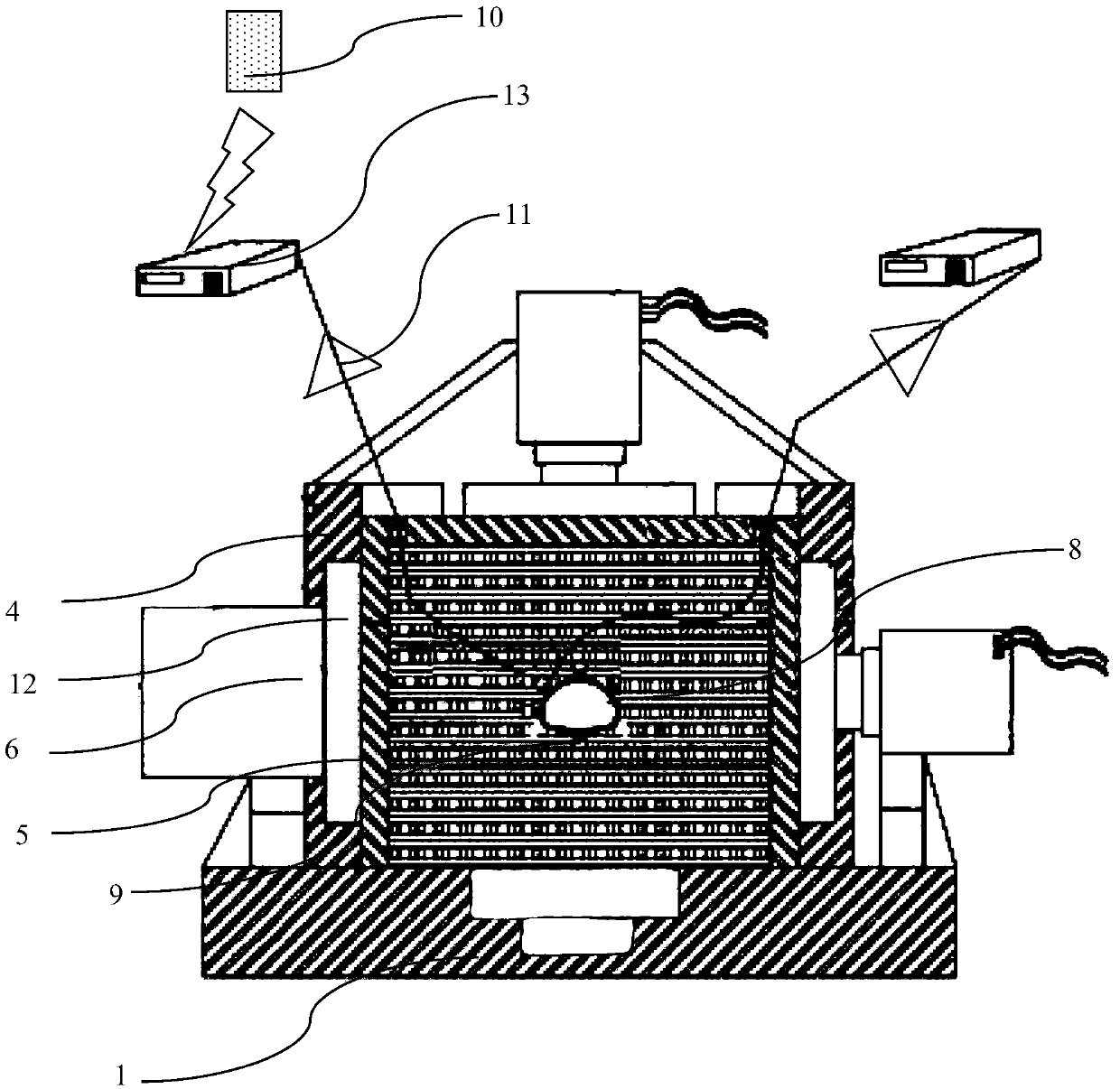

Excavation and surrounding rock stress and strain monitoring model testing device for rock-soil chamber under complicated conditions, and method thereof

InactiveCN104614242AFlexible disassemblyScientific decision-making basisMaterial strength using tensile/compressive forcesModel testingEngineering

The invention relates to an excavation and surrounding rock stress and strain monitoring model testing device for a rock-soil chamber under complicated conditions, and a method thereof. Four stand columns with L-shaped cross sections are arranged at four corners of the upper surface of a substrate, pressure plates capable of moving horizontally are arranged between adjacent L-shaped stand columns to form a cuboid cavity which is filled with rock-soil test samples. The testing device has the technical effects that the stress, strain and volume change rules of the chamber surrounding rock when a rock-soil chamber is excavated under the complicated conditions of high pressure, high temperature and the like, so that the model testing device can provide scientific base for the design and construction decision of the chamber, and also provides a theoretical basis for the prevention and control of geological disaster during the chamber construction.

Owner:EAST CHINA UNIV OF TECH

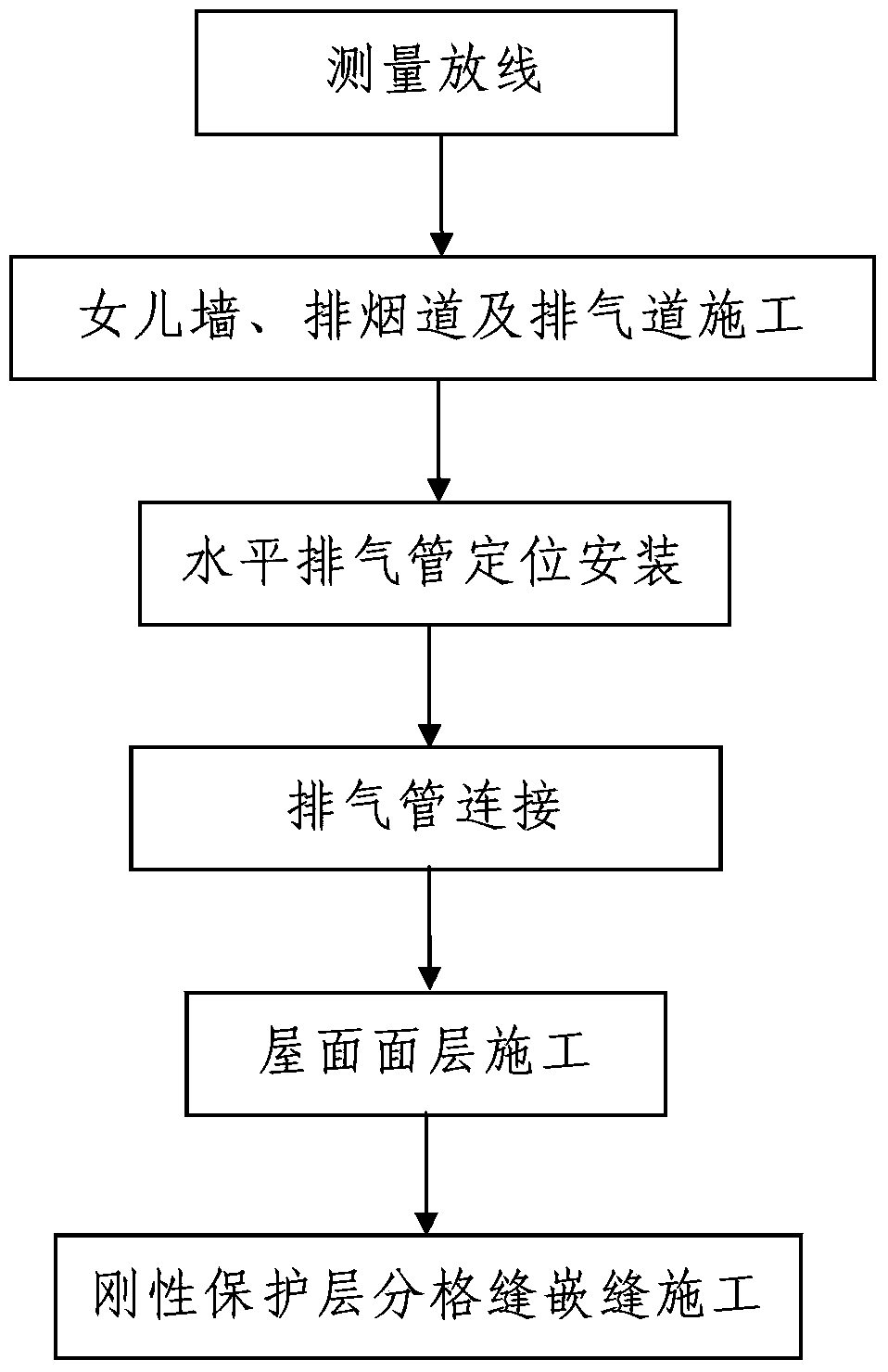

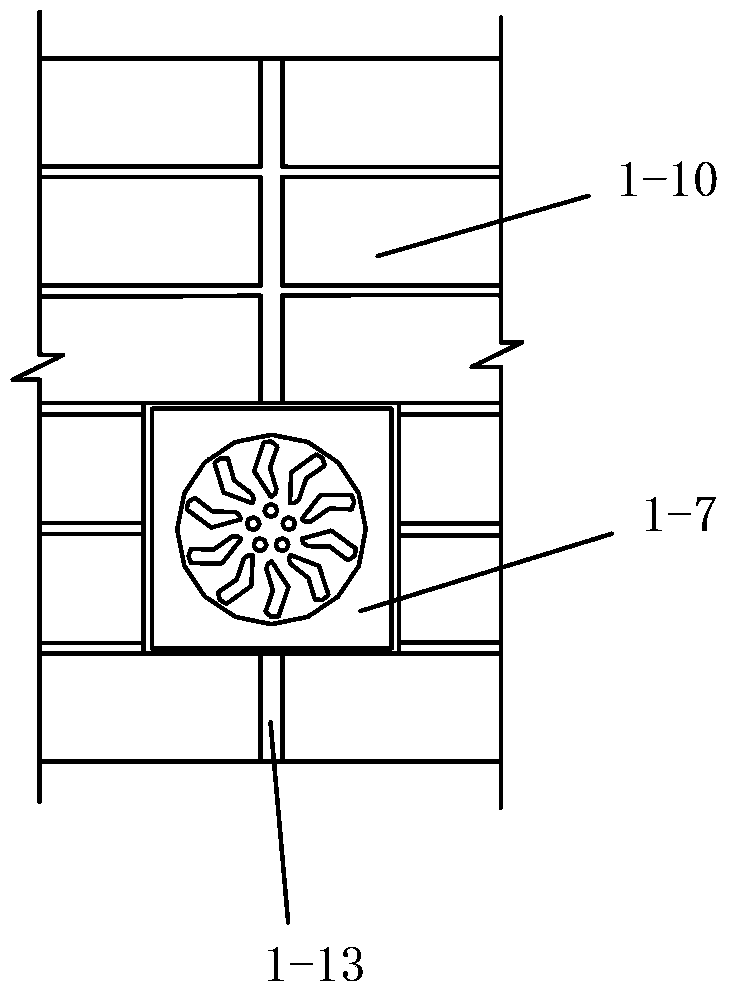

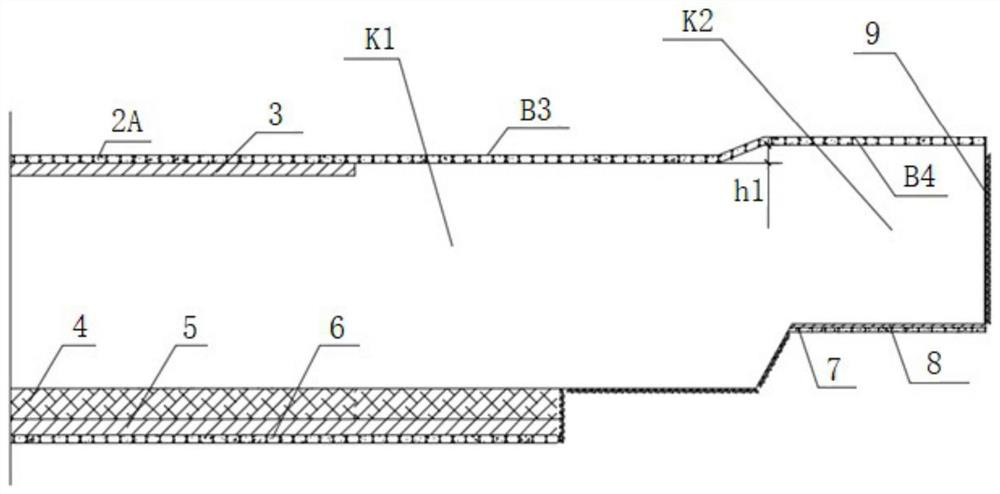

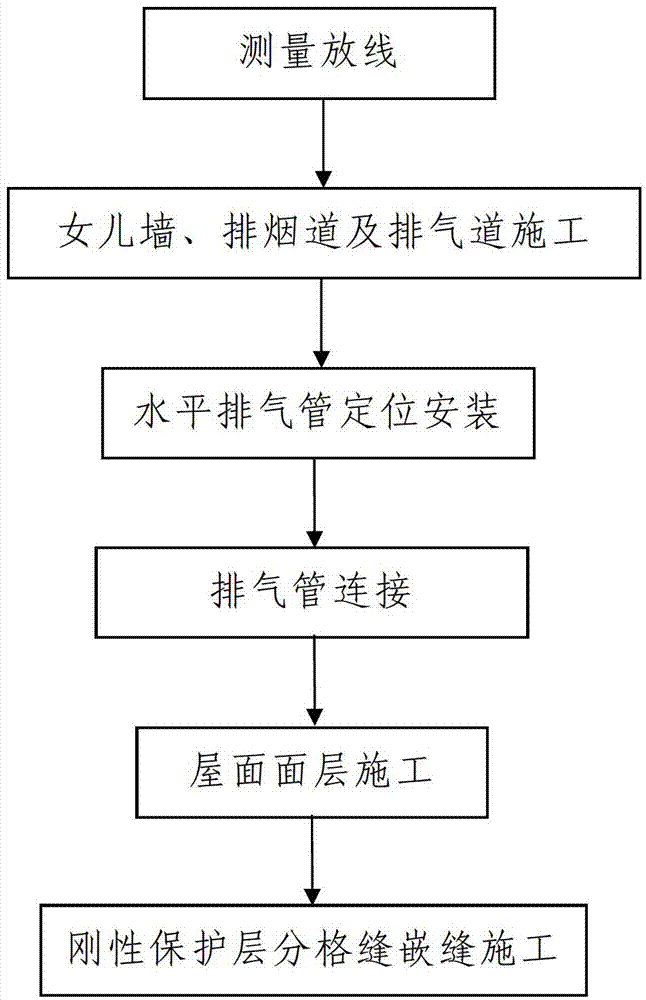

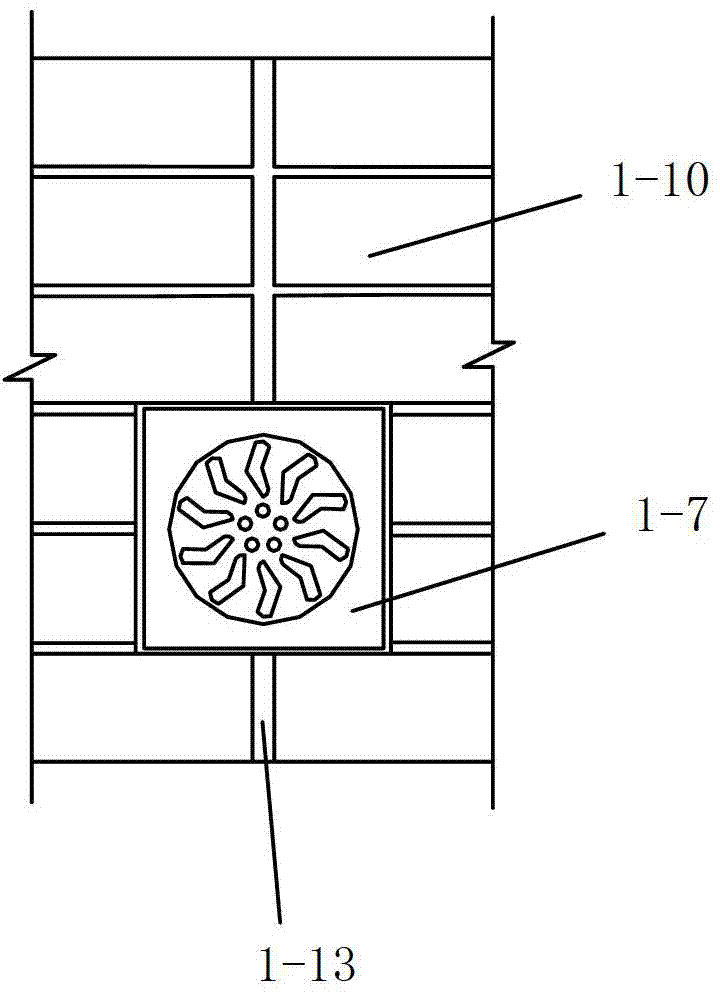

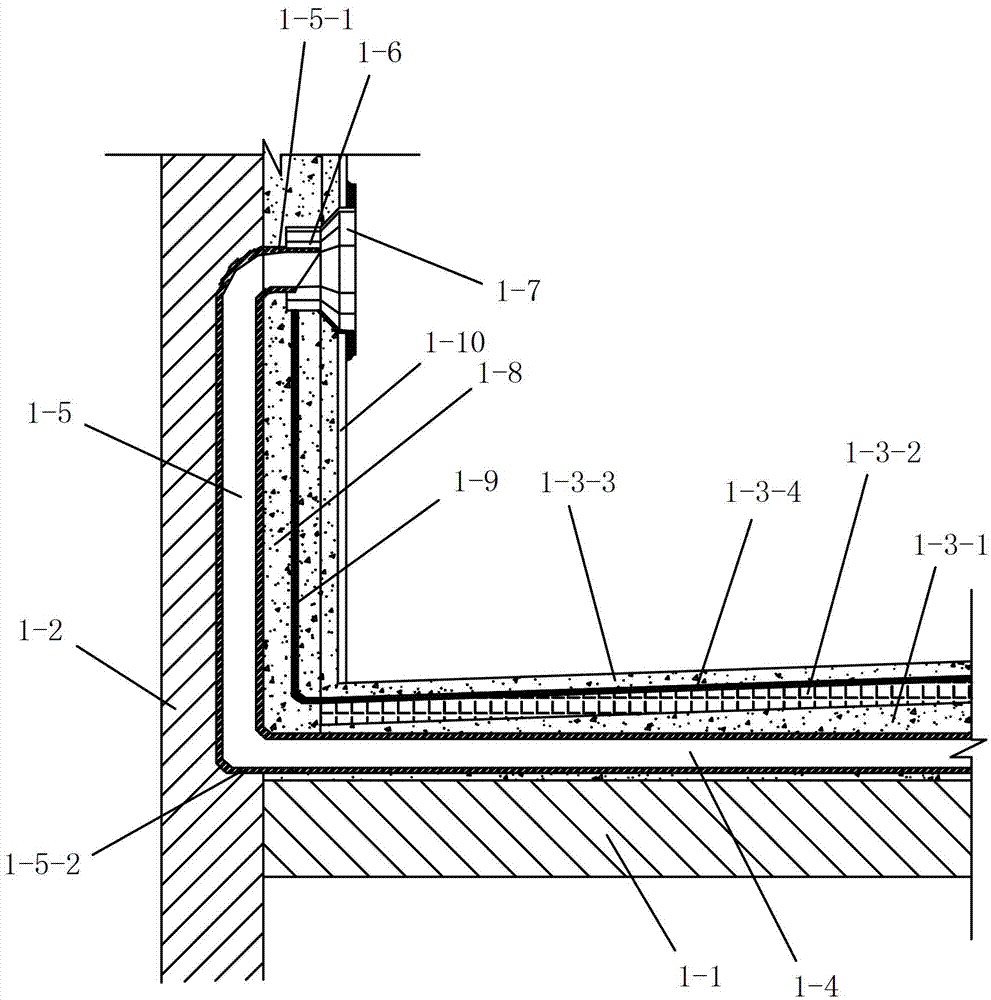

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

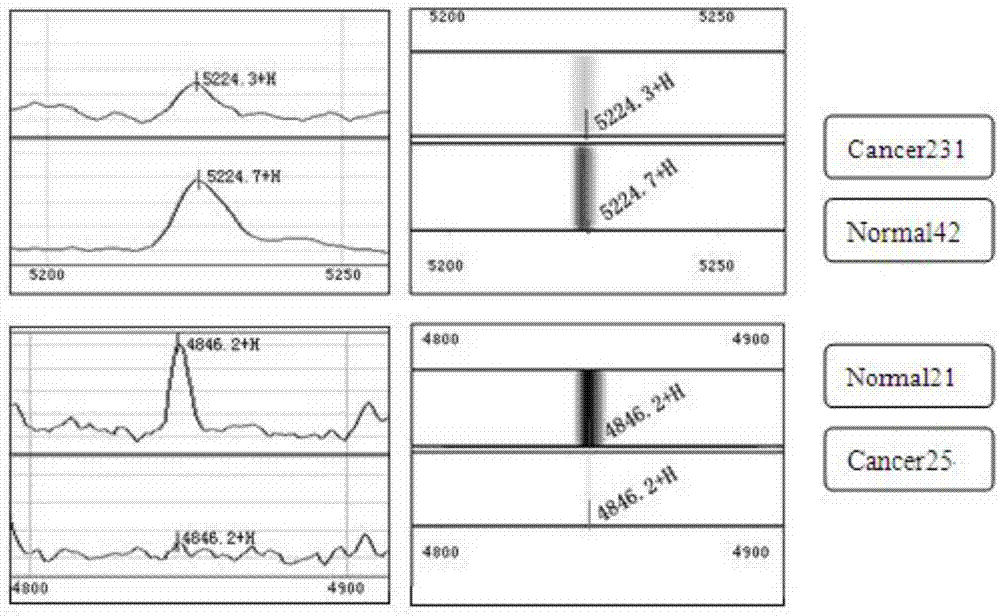

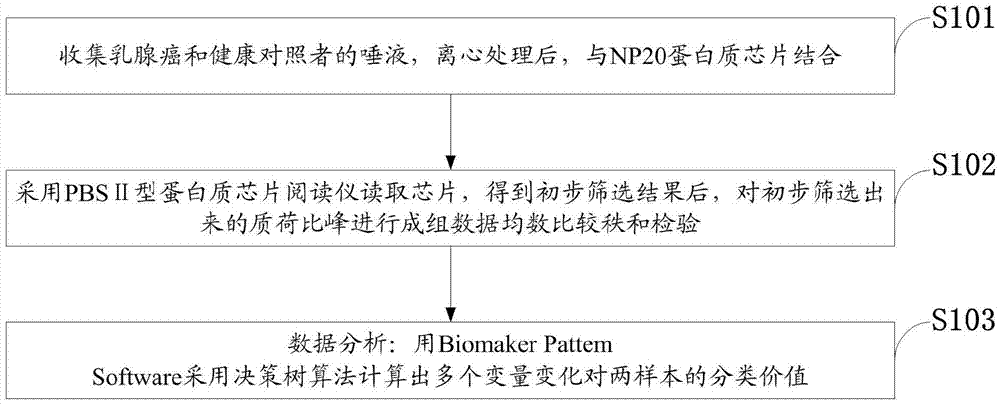

Breast cancer early stage diagnosis sialoprotein fingerprint model and construction method thereof

InactiveCN104515797AThe construction method is reasonableSimple and fast operationMaterial analysis by electric/magnetic meansOncologyDecision tree

The invention discloses a construction method of a breast cancer early stage diagnosis sialoprotein fingerprint model. The construction method of the breast cancer early stage diagnosis sialoprotein fingerprint model comprises the following steps: collecting saliva of a breast cancer patient and a health control, centrifuging,a nd combining with an NP20 protein chip; reading the chip by adopting a PBSII protein chip reader to obtain a preliminarily screened result, and carrying out burst data means comparing rank-sum test on the preliminarily screened mass-to-charge ratio peak; and carrying out data analysis through calculating the classification values of many variable changes on two samples via a decision tree algorithm by Biomaker Pattern Software. The breast cancer early stage diagnosis sialoprotein fingerprint model comprises human salivay proteins with the mass-to-charge ratio (m / z) of 4849.31, 5224.96, 3439.02 and 3559.89 respectively. The breast cancer diagnosis can be preliminarily realized by analyzing the m / z and model of corresponding proteins in human saliva, the predication accuracy is 78.02%, and the construction method has the advantages of reasonability, feasibility, simple operation and batch treatment.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

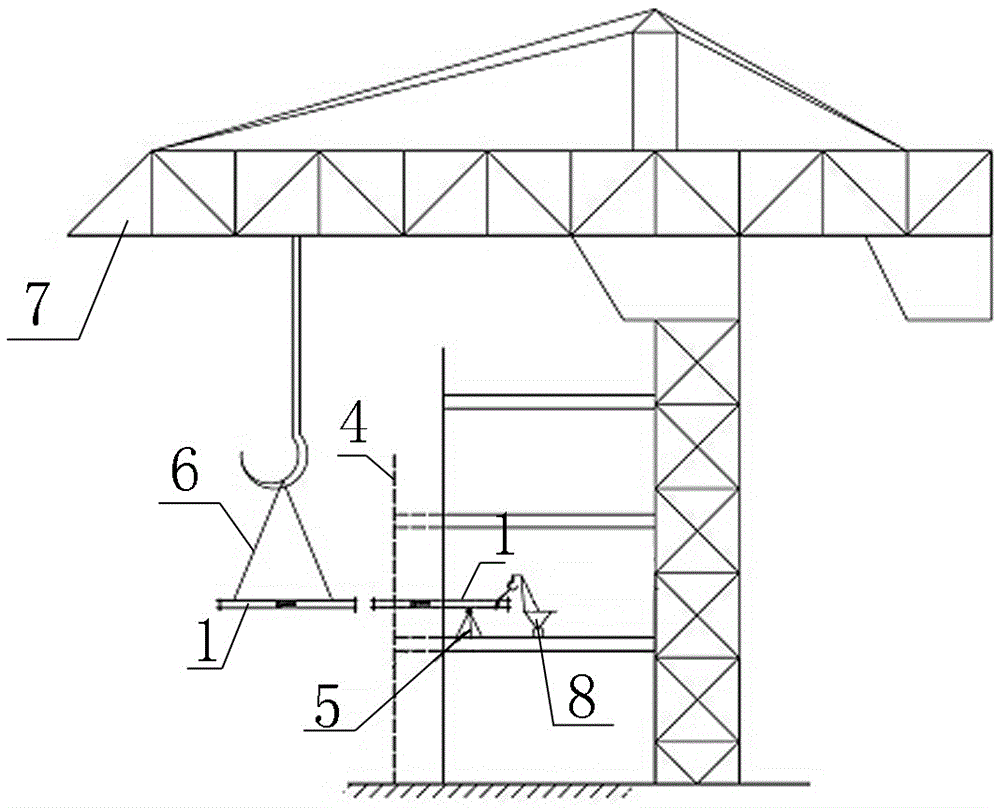

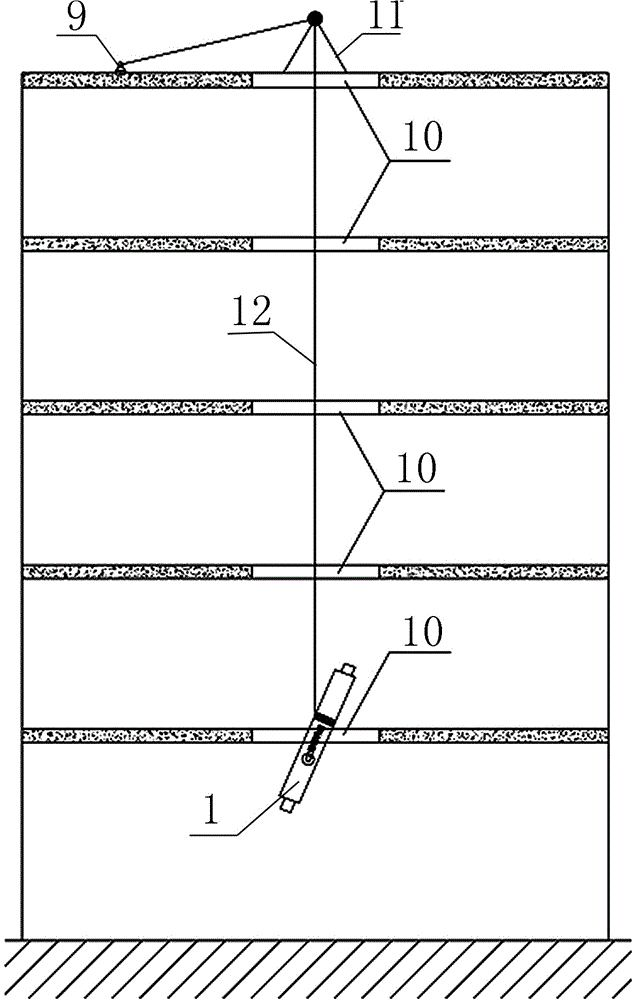

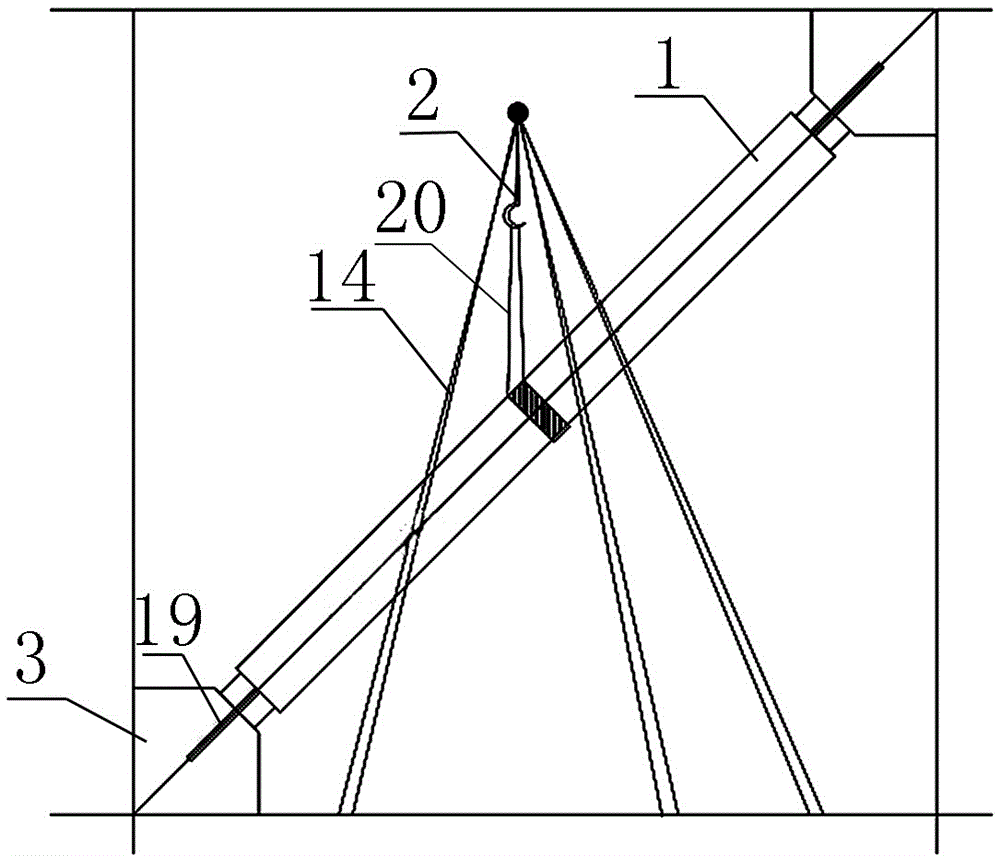

Construction method for buckling-restrained brace structure

InactiveCN106760841AEasy to transportSolve the technical problems of construction inconvenienceProtective buildings/sheltersShock proofingBuckling-restrained braceFire prevention

The invention relates to a construction method for a buckling-restrained brace structure. Buckling-restrained braces are located in a frame structure composed of beams and columns. The construction method comprises the following steps that firstly, construction preparation is conducted; secondly, embedded parts are installed; thirdly, joint plates are installed, including determining of the size of the joint plates and blanking of the joint plates; fourthly, the buckling-restrained braces are transported, including transporting of the buckling-restrained braces in the vertical direction and the horizontal direction; fifthly, the buckling-restrained braces are hoisted and connected; sixthly, connecting joints are checked; and seventhly, corrosion prevention and fire prevention coating is conducted. The technical problems that in a traditional construction method, the requirement for a construction plant is high, the construction period is long and the safety quality is low are solved.

Owner:北京城建建设工程有限公司

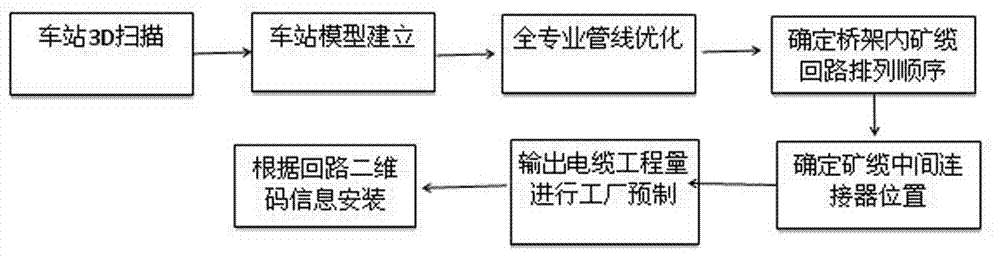

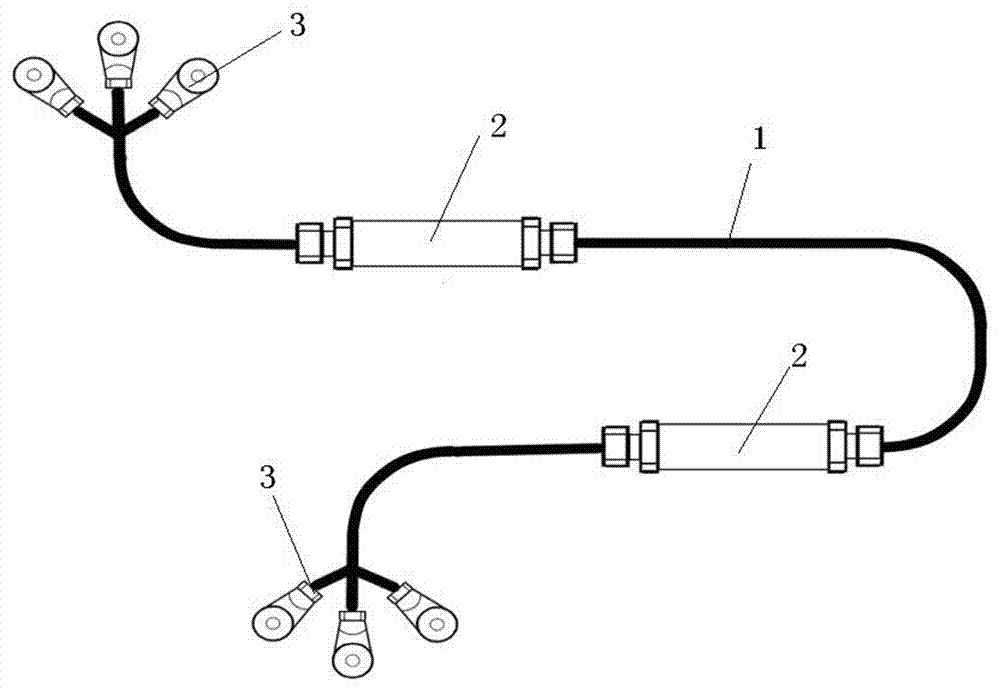

Mineral substance insulated cable factory-like pre-configuration processing method based on BIM technology

ActiveCN107317272ALow costImprove construction progressApparatus for joining/termination cablesThree-dimensional spaceSubway station

The invention belongs to the field of mineral substance cable installation and laying of mechanical and electrical installation inside subway stations, and specifically relates to a mineral substance insulated cable factory-like pre-configuration processing method based on a BIM technology. The method overcomes the defects of mineral substance insulated cables in the processing and site installation process. The method comprises the following steps: actual measurement of site three-dimensional space of a subway station, station modeling, full-profession pipeline optimization, mineral substance cable circuit arrangement sequence determination, mineral substance cable intermediate connector position determination, subsection cable work amount and total circuit work amount of mineral substances according to BIM model output, and two-dimensional information code information installation according to a mineral substance cable circuit. The labor cost and construction cost are effectively reduced, the material utilization amount of mineral substances is reduced, the construction period is reduced, a more reasonable construction method is provided, and simultaneously compared with original construction blueprint, the maintenance space is more sufficient, the overhaul and later operation maintenance are facilitated, and the method is high in practicability and beneficial for popularization.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

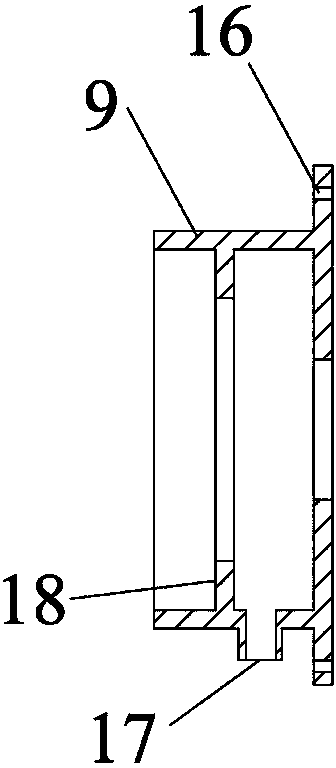

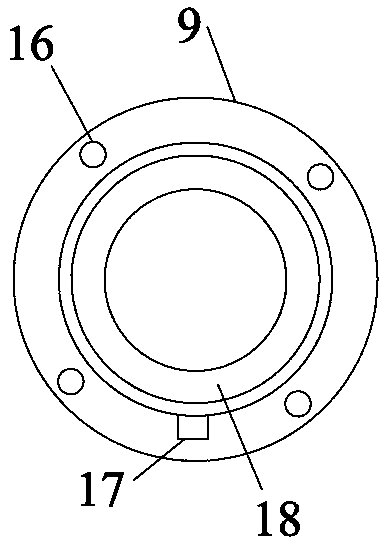

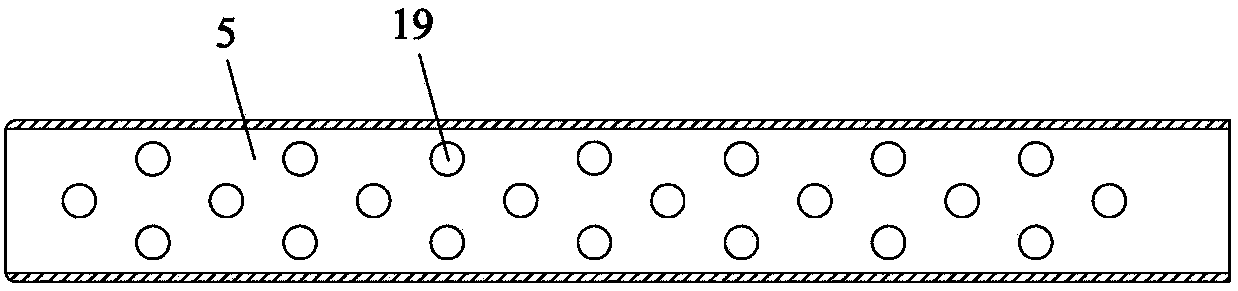

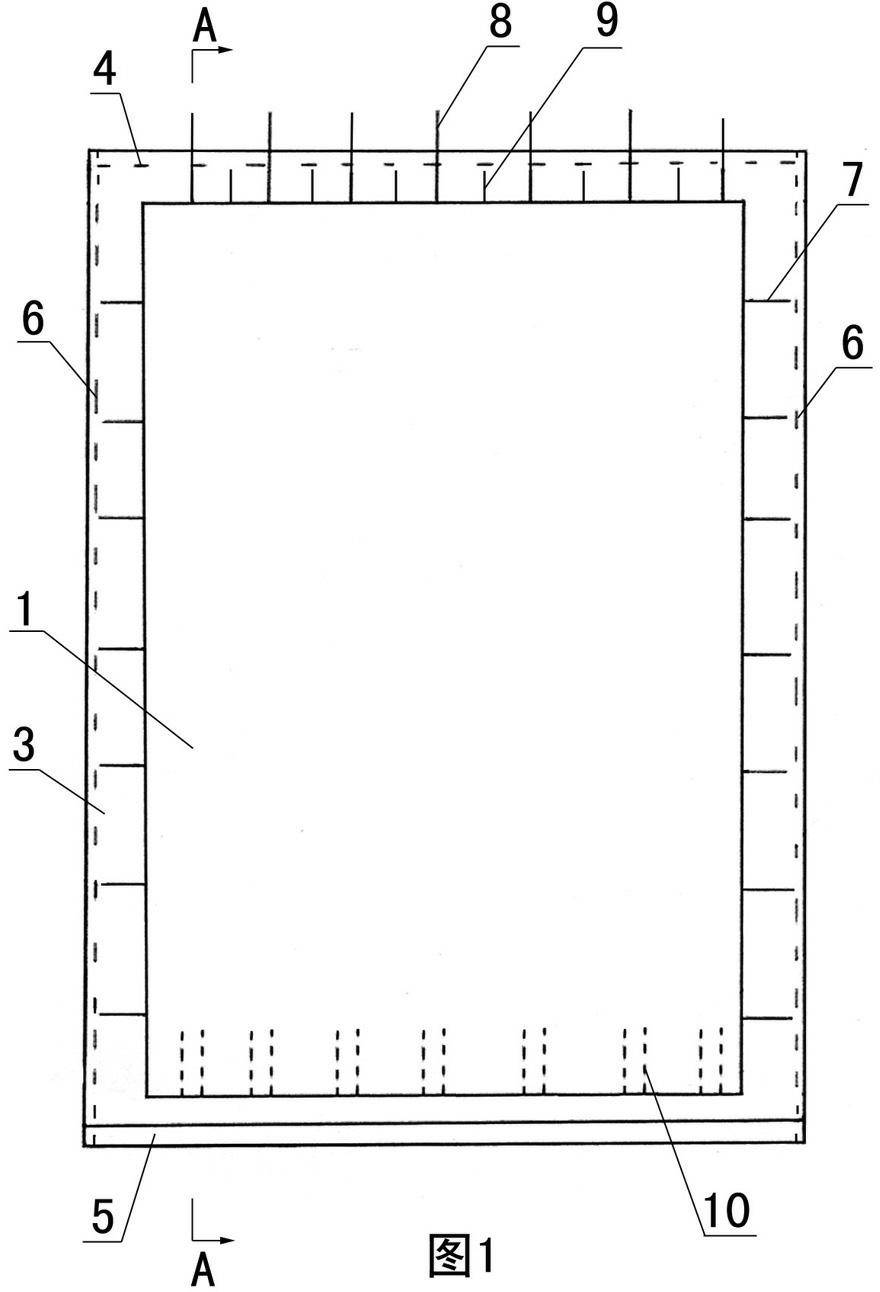

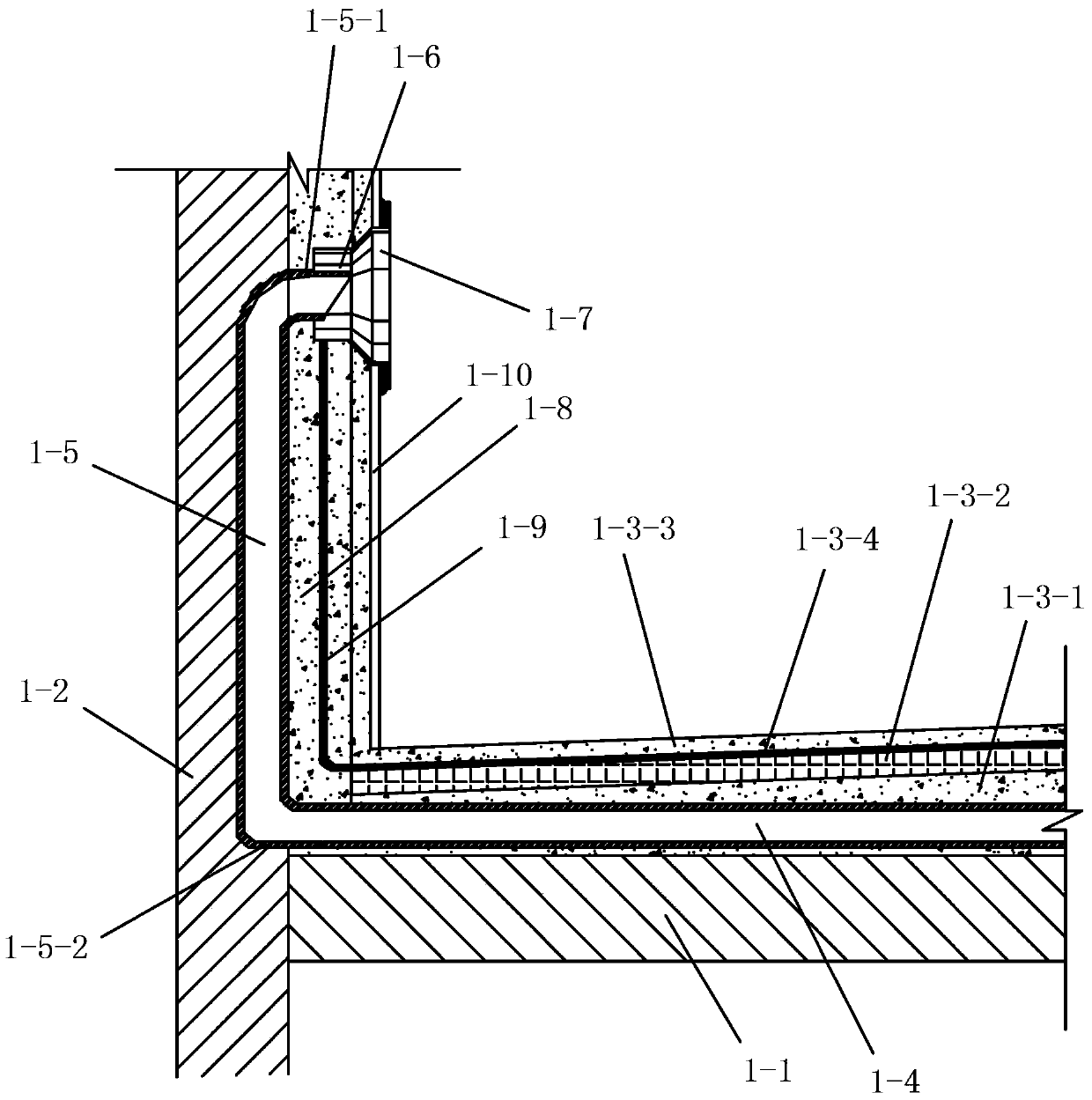

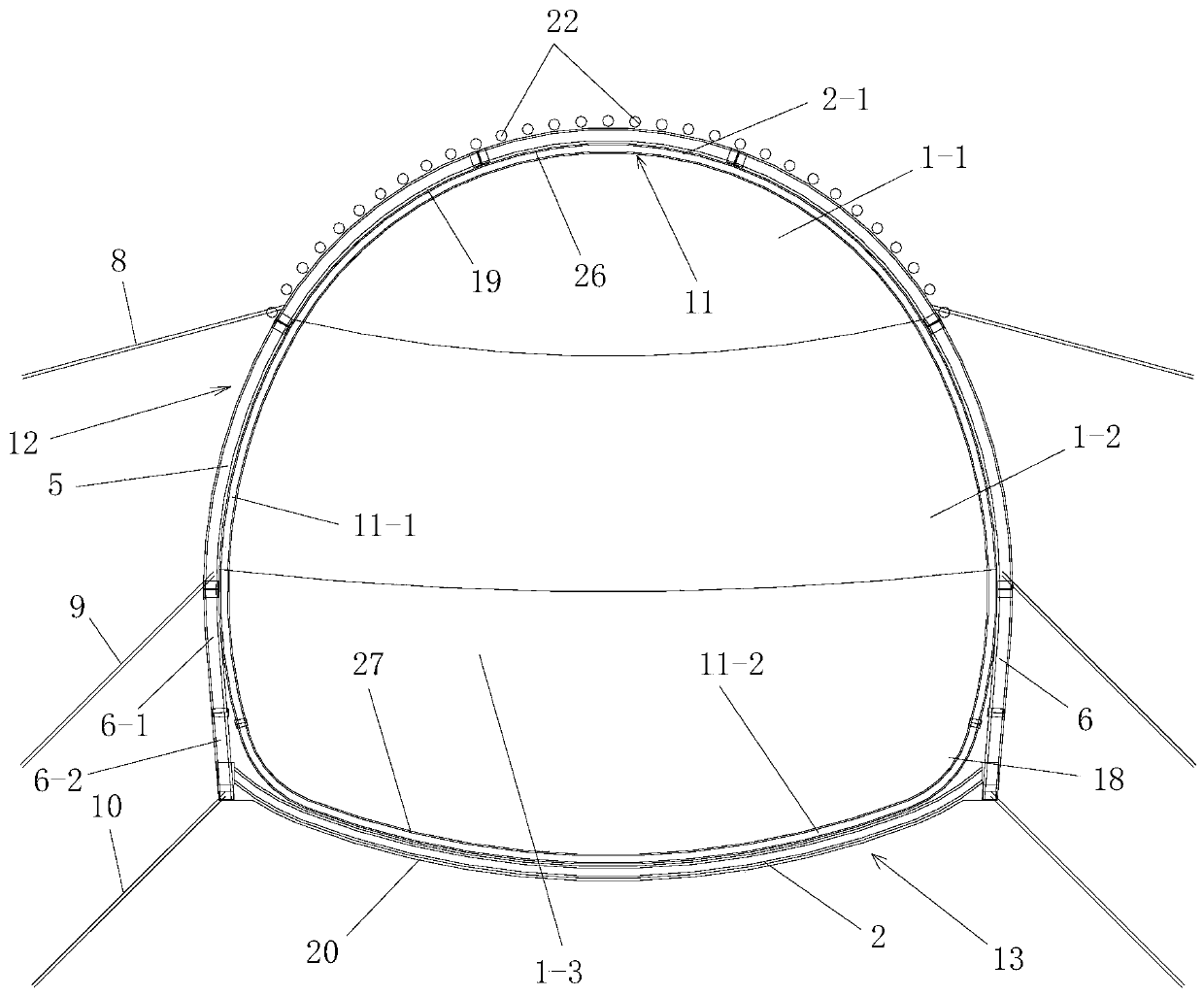

Connecting structure of assembly type underground structure vertical member and construction method thereof

InactiveCN109024870AAvoid double pouringShorten the construction periodProtective foundationBuilding constructionsRebarBuilding construction

The invention discloses a connecting structure of an assembly type underground structure vertical member. The connecting structure comprises an upper component and a lower component which are connected in a mortise joint manner, and a plurality of sleeves are arranged in the lower component and close to the joint. An upper side steel bar is arranged in the upper component, at the position corresponding to each sleeve, and one end of the upper side steel bar extends into the sleeve. The connecting structure of an upper side steel bar inserting into a sleeve and the mortise connecting structureare combined, so that the bearing limitation of a simple mortise joint structure is overcome. Secondary pouring of concrete is avoided, the construction period is shortened, and the pollution to the environment is reduced.

Owner:SOUTHEAST UNIV

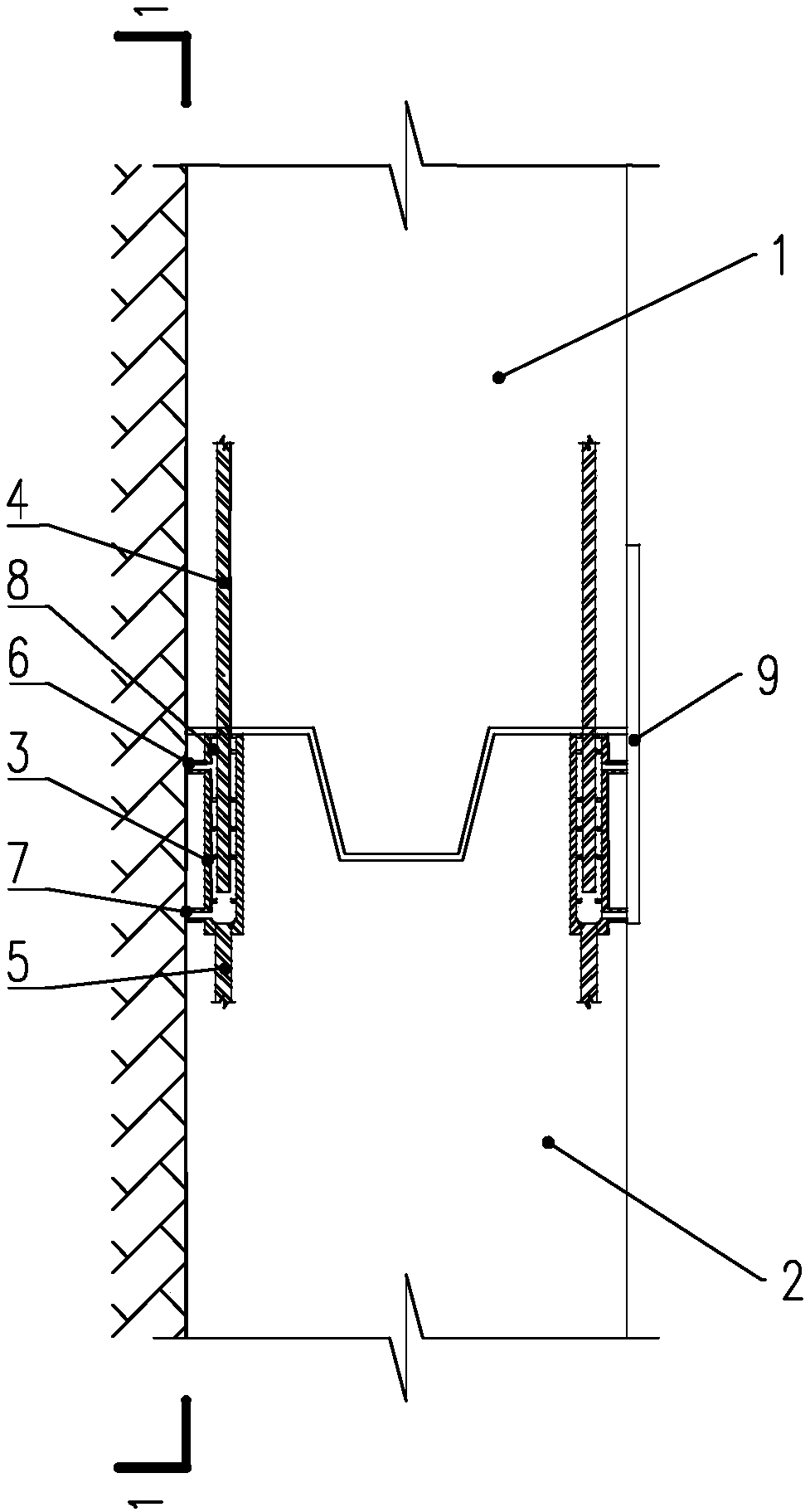

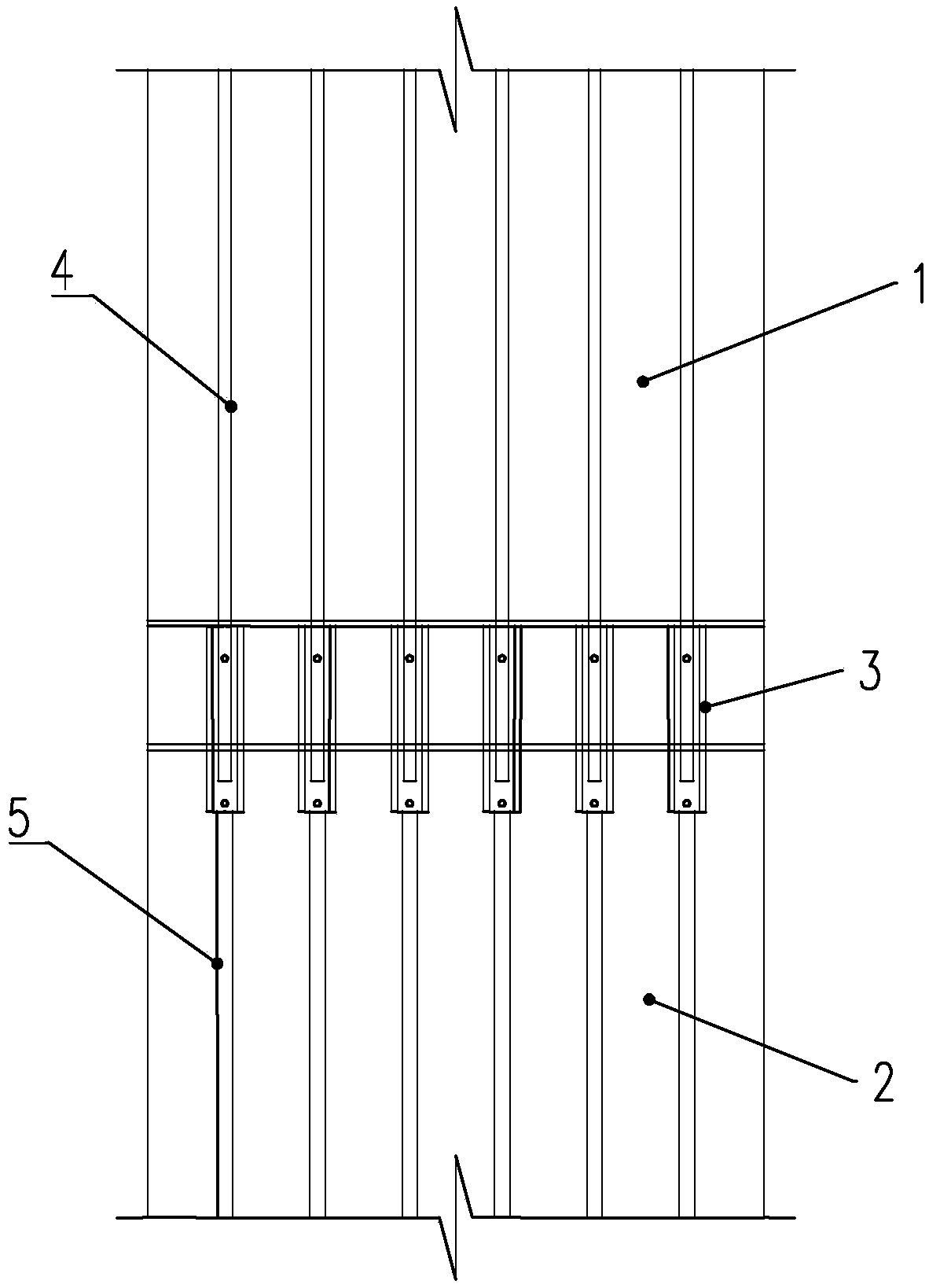

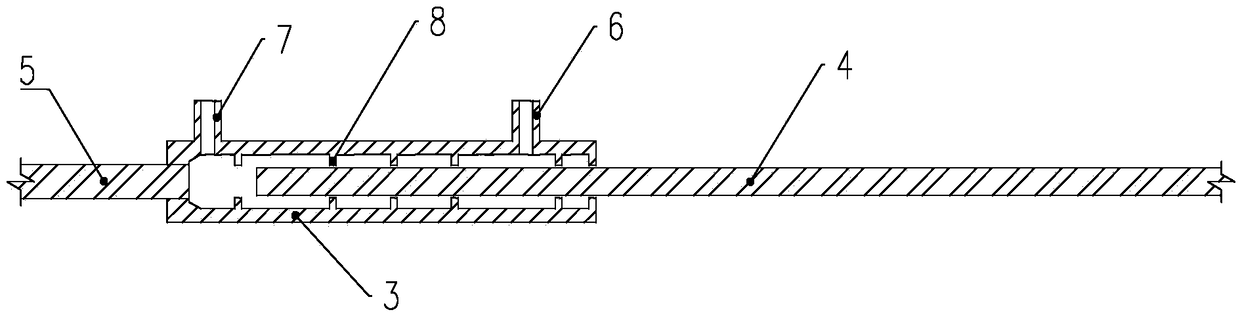

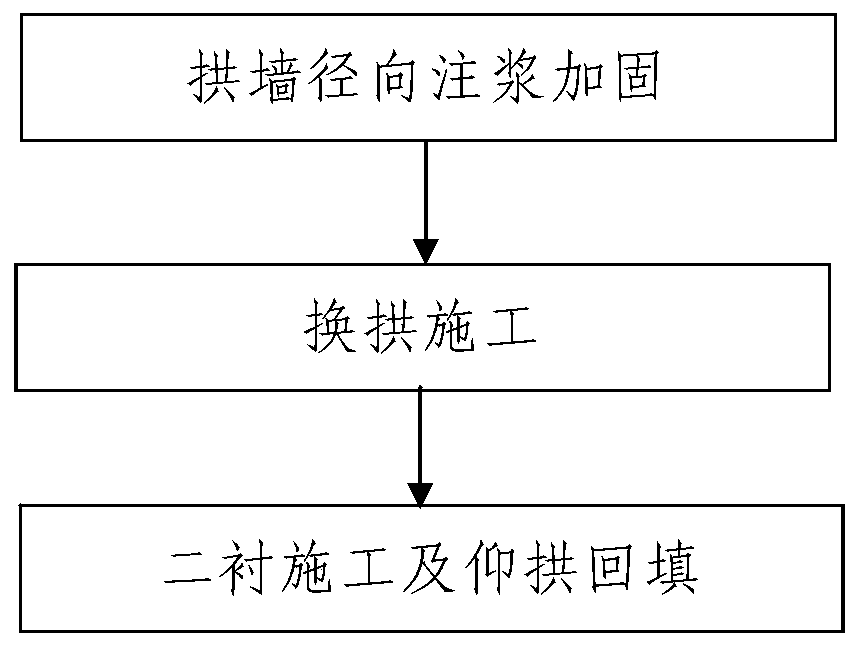

Method for beyond-limit arch replacing construction during preliminary bracing of large-section loess tunnel

ActiveCN110656959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a method for beyond-limit arch replacing construction during preliminary bracing of a large-section loess tunnel. The method includes the steps of firstly, conducting radial grouting reinforcement on an arch wall, wherein radial grouting reinforcement is conducted on an arch replacing required section where arch replacing is required in the constructed loess tunnel from back to front; and secondly, conducting arch replacing construction, wherein a reinforced preliminary bracing structure in the arch replacing required section is detached, and preliminary bracing construction is conducted on the arch replacing required section synchronously in the detaching process. The method is simple in step, reasonable in design, simple in construction and good in use effect; theradial grouting reinforcement is conducted on the arch wall to reinforce the arch wall of a tunnel hole first, so the structural stability of the tunnel in the arch replacing process is ensured; segmented reinforcing is conducted on the preliminary bracing structure of the tunnel through a plurality of sleeve arch units for a reinforced sleeve arch in the arch replacing required section, so detaching is convenient; and moreover, the sleeve arch units are complementary and together improve the supporting force, so the adverse effects on the structural stability of the tunnel in the detaching process of each sleeve arch unit can be effectively reduced, and the safety and reliability of the arch replacing construction process are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

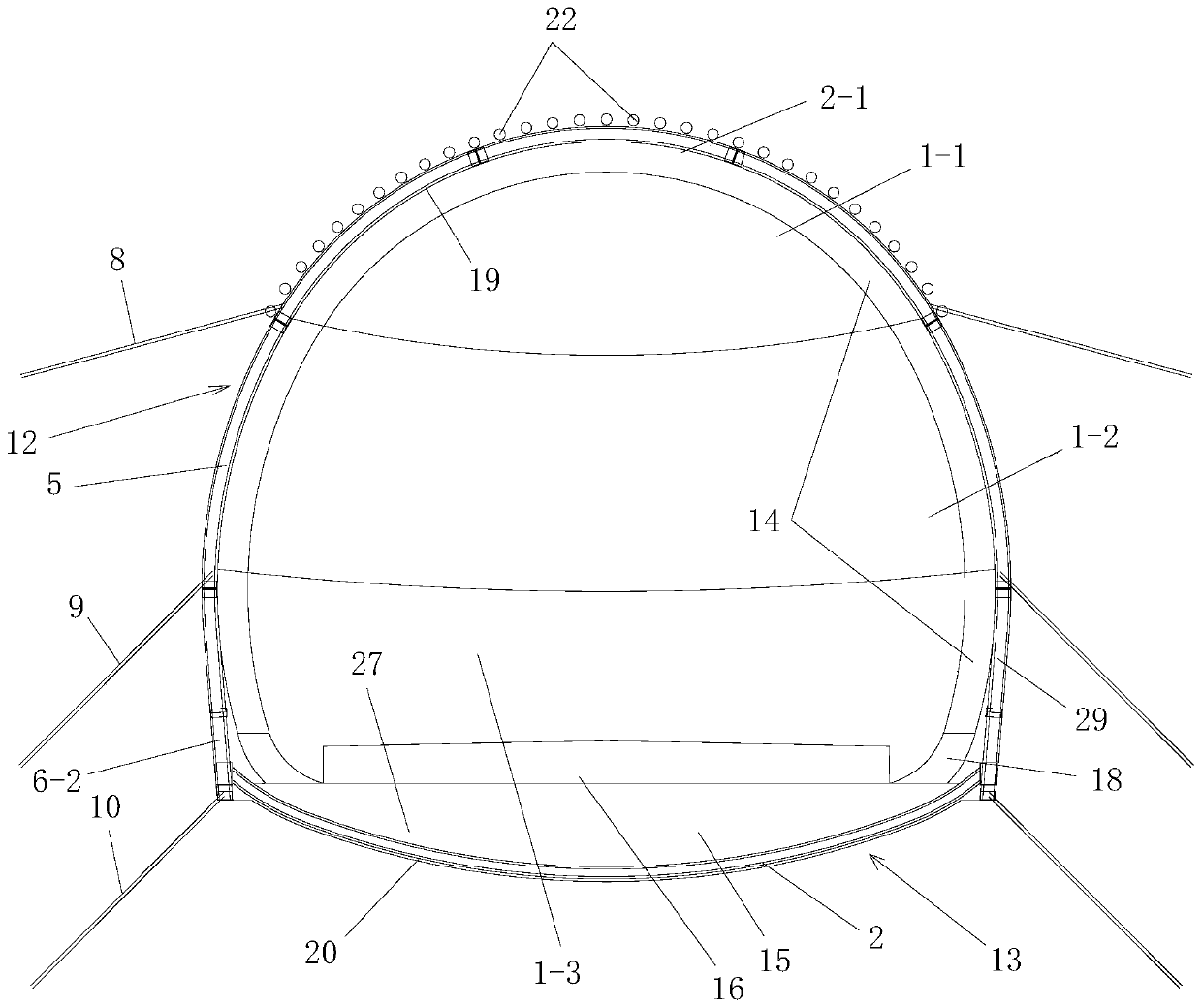

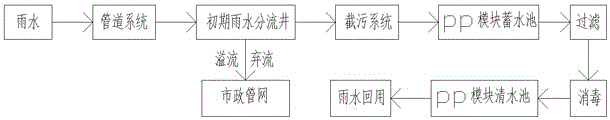

Urban building sewage treatment system, construction method and filter element material preparation process

ActiveCN106145478AAchieve reuseAchieve adsorptionFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationMaterials preparationWater treatment system

The invention relates to an urban building sewage treatment system, a construction method and a filter element material preparation process. The urban building sewage treatment system comprises a settling basin, a split well, a distributing well, a sewage intercepting well, a reservoir, a fine filtration device, a sterilization device and a clean water basin, the side face of the settling basin is provided with a water inlet pipe allowing building rain sewage to flow into conveniently, and the clean water basin is internally provided with a clean water recycling device. The urban building sewage treatment system is reasonable in design, reutilization of sewage is achieved, and the water quality of reuse water is effectively guaranteed.

Owner:ZHONGHUAN BUILDING FUJIAN CO LTD

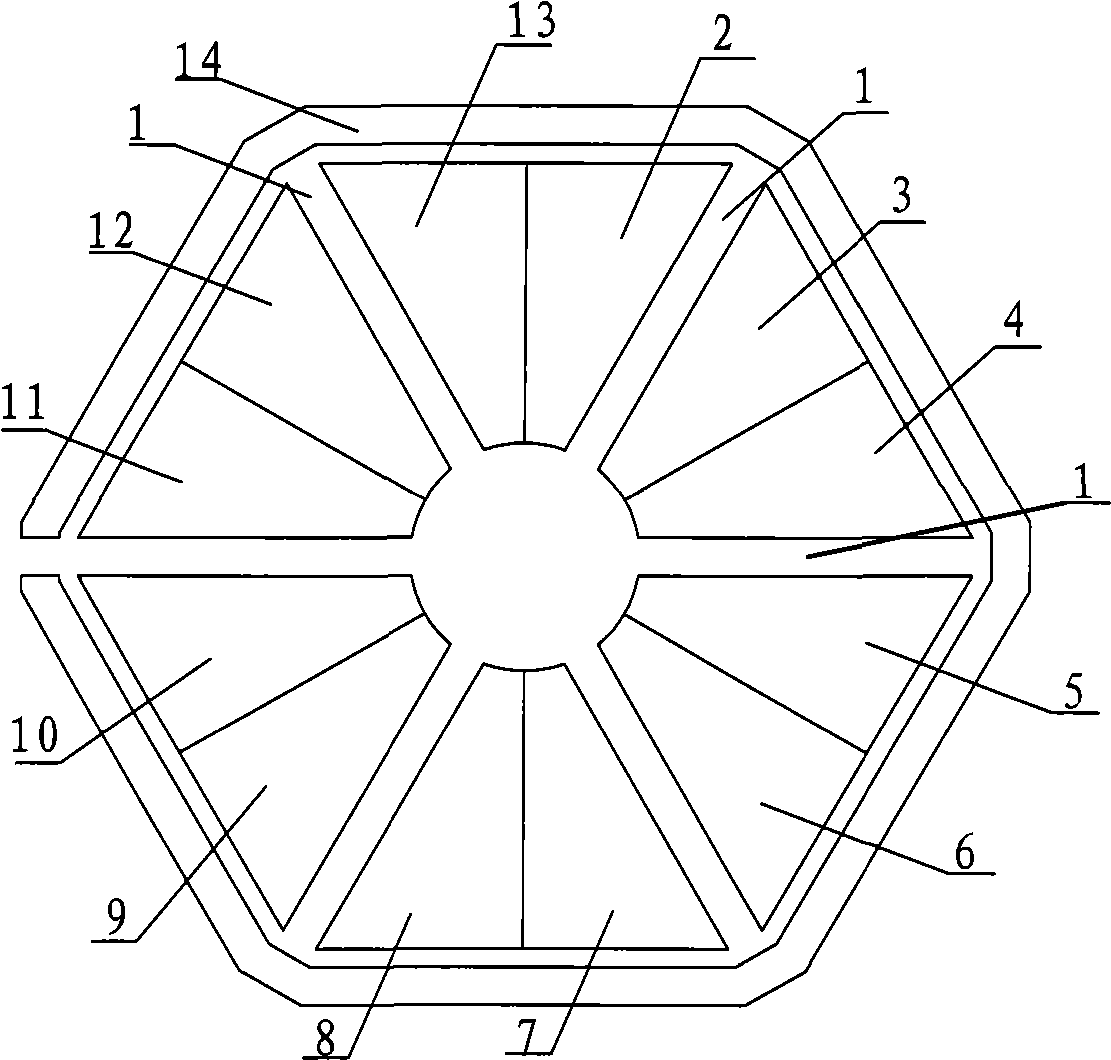

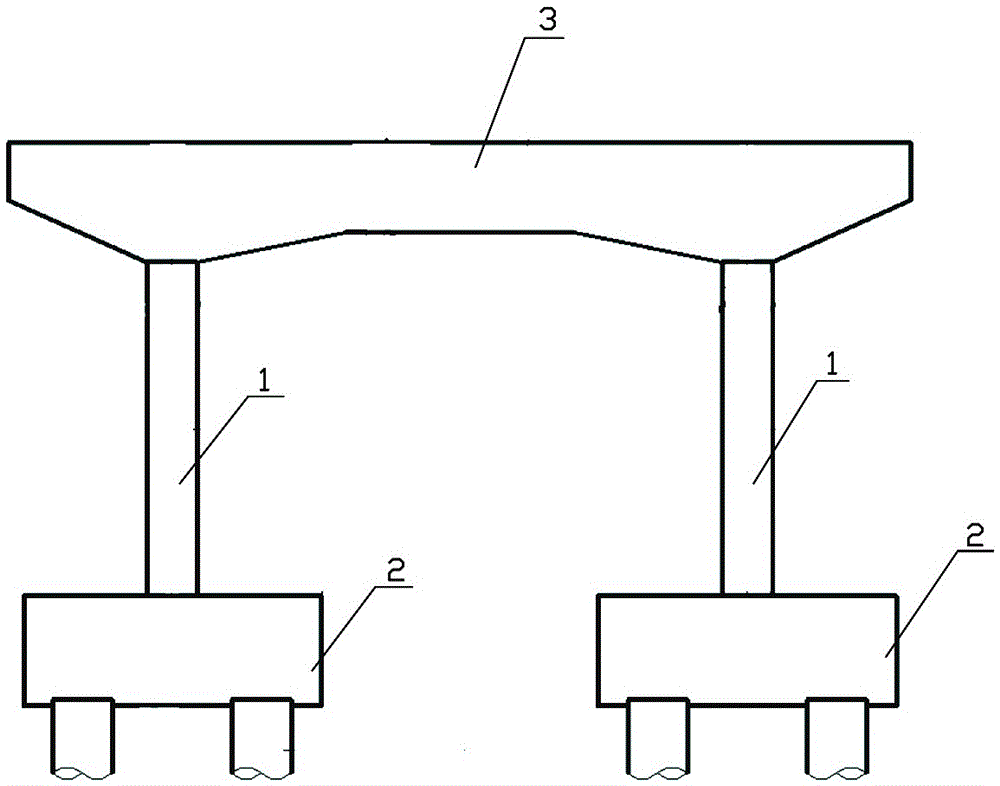

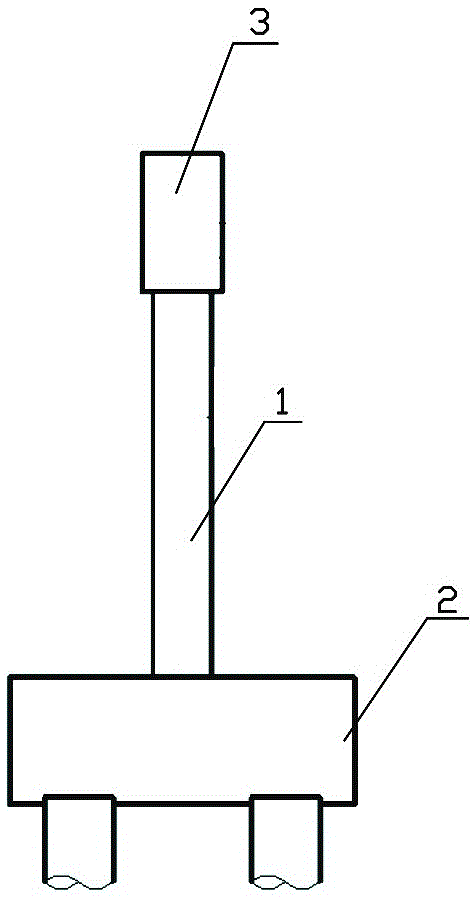

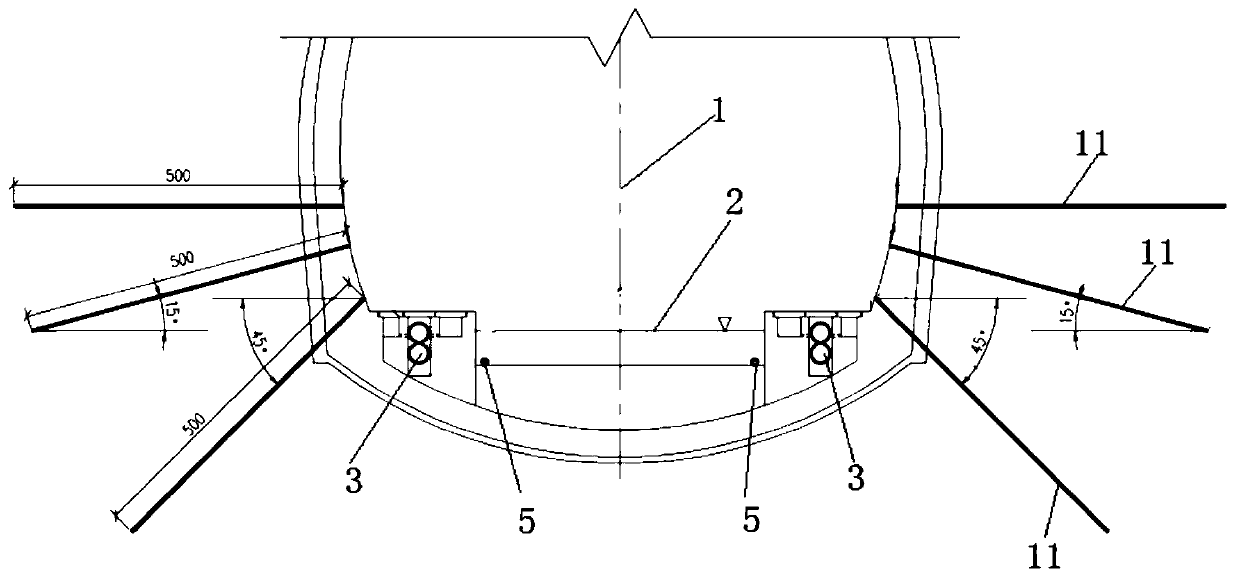

Urban rail transit overhead station and section steel and concrete combined column thereof

InactiveCN105464458AImprove pressure resistanceImprove impact resistanceStrutsPillarsRebarSteel columns

The invention discloses a section steel and concrete combined column of an urban rail transit overhead station. The urban rail transit overhead station is applied on bridge structures and building structures combining bridges with buildings and comprises bearing platforms, the section steel and concrete combined columns and frame cross beams, each section steel and concrete combined column comprises a section steel column, constructional rebars, stirrups and a concrete wrapper, the constructional rebars and the stirrups are arranged on the periphery of the section steel column, each concrete wrapper wraps the outside of the corresponding section steel column, the corresponding constructional rebars and the corresponding stirrups, each section steel column comprises a first section steel portion, a second section steel portion and a third section steel portion, and a second web of each second section steel portion and a third web of the corresponding third section steel port are connected with two opposite sides of a first web of the corresponding first section steel portion respectively. The invention further discloses the urban rail transit overhead station. The section steel and concrete combined column has good pressure bearing performance and is high in deformation capability, resistant to fatigue and good in impact resistance, can meet structural safety and engineering economy and relates to feasibility and process arrangement of site construction.

Owner:中铁五局集团路桥工程有限责任公司 +1

Construction method of concrete packing light pipeline

InactiveCN102776950APrevent floatingAvoid location movementSewer pipelinesRebarMechanical engineering

The invention discloses a construction method of a concrete packing light pipeline. The construction method comprises the steps of: correspondingly embedding a plurality of L-shaped steel bars with a certain length at each of the two sides of the light pipeline mounting position, wherein the upper ends of the steel bars are exposed out of the surface of a concrete layer by a certain height; mounting a light pipeline between two rows of L-shaped steel bars; arranging packing strips on the light pipeline, wherein the two ends of the packing strips are respectively connected to the two L-shaped steel bars corresponding to the two sides of the light pipeline and the packing strips press on the outer surface of the light pipeline; and casting the concrete layers on the left and right side surfaces and the top of the light pipeline to form the structure of the concrete packing light pipeline meeting technical requirements. By adopting the construction method, the upward floatation of the light pipeline can be effectively prevented, the translocation of the light pipeline is prevented, construction quality reaches design requirement, and the quality problem formed by the upward floatation of the light pipeline is eradicated completely; and the construction method is simple and reliable, spot operation is convenient, and operators can easily master the construction method.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Serum protein mass spectrum model for screening pancreatic cancer and construction method thereof

InactiveCN102128876AThe construction method is reasonableEasy to operateMaterial analysis by electric/magnetic meansPancreas CancersProtein composition

The invention discloses a serum protein mass spectrum model for screening pancreatic cancer and a construction method thereof. The serum protein mass spectrum model mainly comprises human serum proteins, the cytoplasm-nuclear ratios (M / Z) of which are positioned at 4,976+ / -380Da, 6,857+ / -737Da, 4,407+ / -726Da, 5,488+ / -963Da, 7,068+ / -142Da, 3,250+ / -591Da, 4,753+ / -360Da, 6,885+ / -572Da, 5,644+ / -382Da, 2,892+ / -299Da, 3,281+ / -348Da, 4,292+ / -289Da, 2,678+ / -208Da and 5,364+ / -126Da in human serum protein mass spectrums. The construction method is reasonable, feasible and simple and convenient in operation, and can be used for batch processing.

Owner:ZHEJIANG UNIV

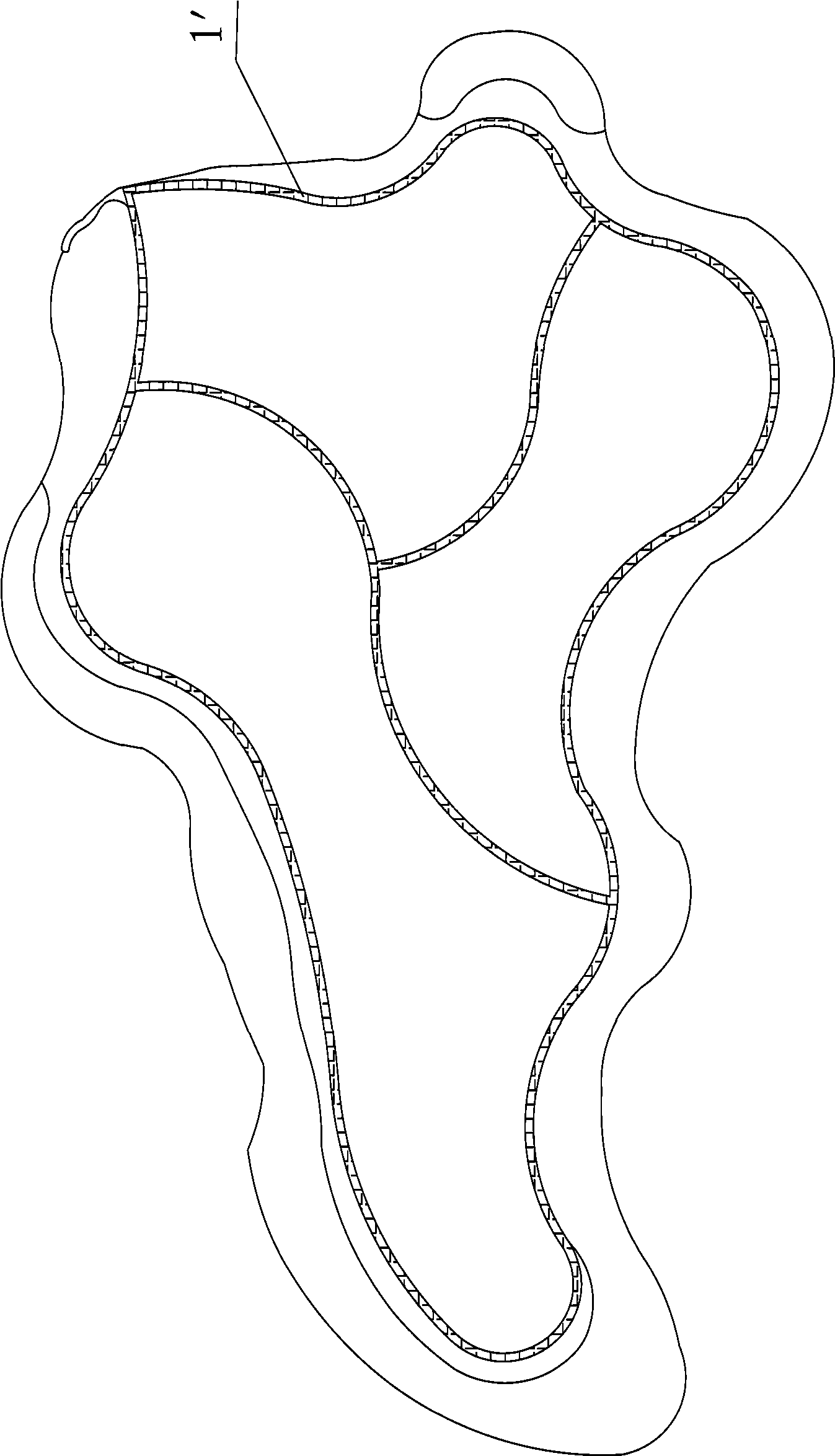

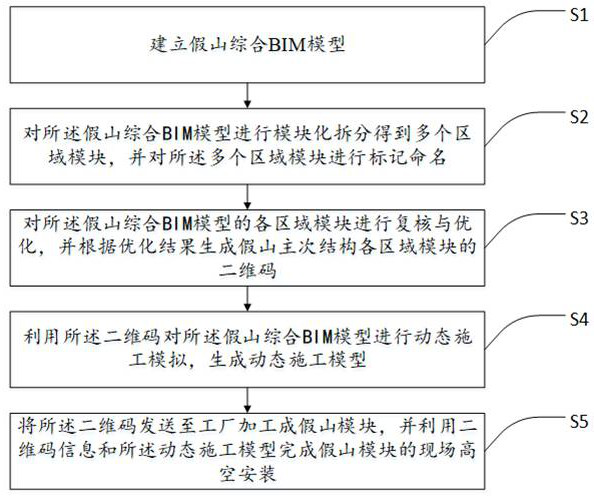

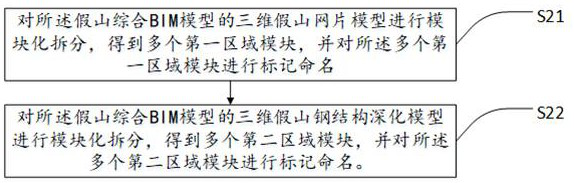

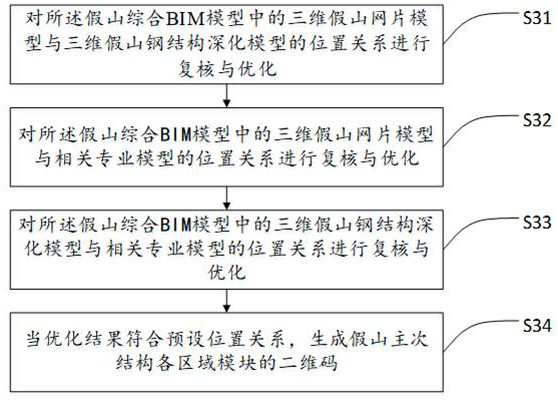

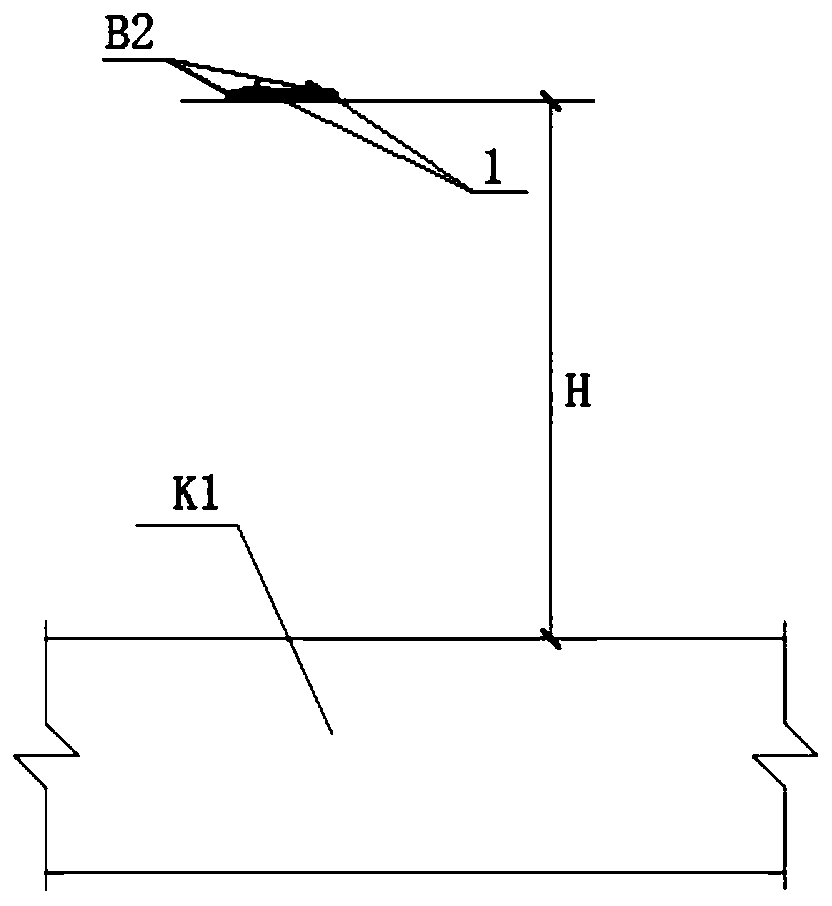

BIM-based rockery modular construction method and device and storage medium

ActiveCN112163264ANovel construction methodThe construction method is reasonableGeometric CADDesign optimisation/simulationSoftware engineeringModularity

The invention discloses a BIM-based rockery modular construction method and device and a storage medium, and the method comprises the steps: building a rockery comprehensive BIM model, carrying out the modular splitting of the rockery comprehensive BIM model to obtain a plurality of region modules, marking the region modules, and carrying out the rechecking and optimization of the primary and secondary structures of the rockery comprehensive BIM model, generating a two-dimensional code of each region module of the primary and secondary structures of the rockery according to an optimization result, performing dynamic construction simulation on the comprehensive BIM model of the rockery by utilizing the two-dimensional codes to generate a dynamic construction model, and sending the two-dimensional codes of the primary and secondary structures of the rockery to a factory to be processed into rockery modules; and completing field installation of the rockery module by utilizing the two-dimensional code information and the dynamic construction model. According to the method, the rockery components are modularly disassembled through the BIM technology, the field installation difficulty isreduced, the technical support is provided for field rockery assembly through the two-dimensional codes, the high-altitude operation is reduced, meanwhile, all professional construction procedures can be reasonably arranged through animation simulation, and the efficiency is higher.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

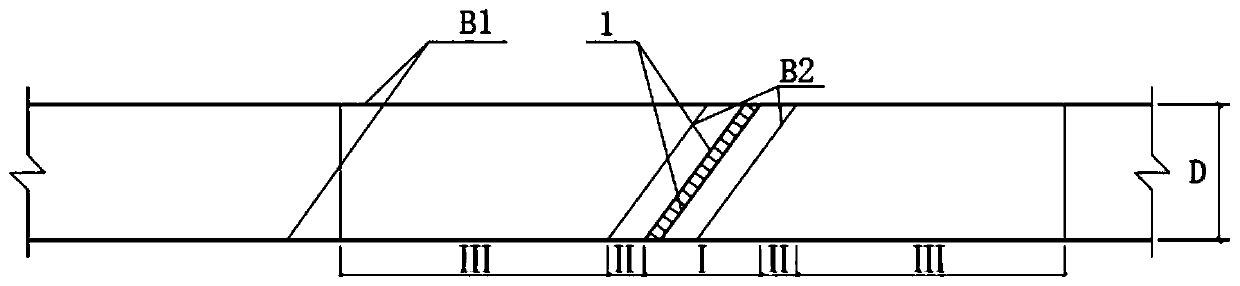

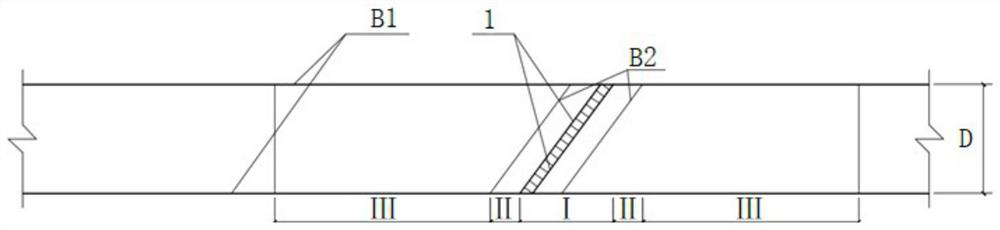

Non-span-reduction construction method for close-spaced underpass operating railway for loess tunnel with oversized cross section

ActiveCN111396062AShorten the closed loop distanceQuick closureUnderground chambersTunnel liningStructural engineeringConductor pipe

The invention discloses a non-span-reduction construction method for a close-spaced underpass operating railway for a loess tunnel with an oversized cross section. The method comprises steps as follows: firstly, the influence range of the underpass operating railway for the loess tunnel with the oversized cross section is divided into three support grade areas including an I area, an II area and an III area, then construction of a pipe shed working chamber, construction of a pipe shed, backfilling of the pipe shed working chamber and reinforcement by advanced small pipes are performed in sequence, and finally, a three-step and two-step temporary inverted arch method is adopted for hole body excavating and supporting. According to the method, equipment passes through the underpass operatingrailway area safely and rapidly, construction cycle is shortened, cost input is reduced, safety, economic efficiency and reasonability are combined, reference is provided for construction of the sametype of close-spaced underpass operating railway for the loess tunnel with oversized cross section, and construction efficiency of the close-spaced underpass operating railway for the loess tunnel with oversized cross section is further increased, and safety risks of the construction are reduced.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

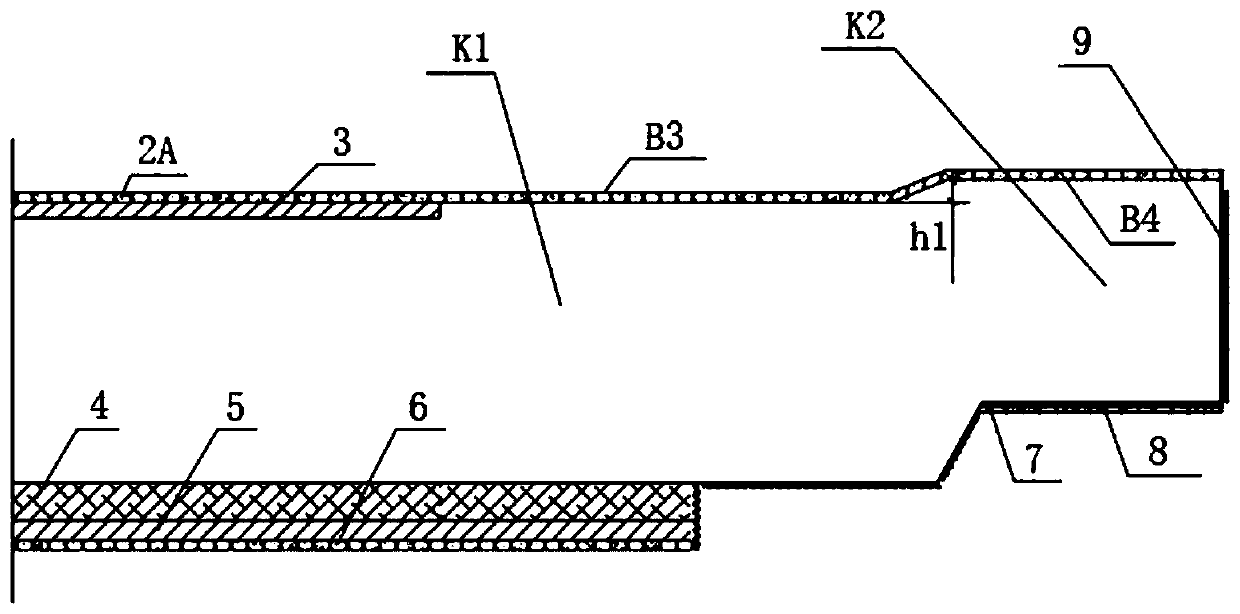

Rapid pushing and replacing construction method for ballastless track structure of passenger special line

InactiveCN111576106AImprove construction efficiencySpeed blockBallastwayRailway track constructionTrackwayPre stress

The invention discloses a rapid pushing and replacing construction method for a ballastless track structure of a passenger special line. The method comprises the process of renovating a disease area by adopting a detachable inverted arch structure. The process is divided into three stages of a preparation stage, a key stage and a recovery stage. The key stage at least comprises the steps of chiseling away grooves and roadbed slabs in a segmented mode, erecting temporary steel beams, laying wooden sleeper track panels, excavating a bottom of a tunnel, disassembling and replacing inverted archesand filling layers, carrying out end prestress anchoring and reinforcing, and carrying out roadbed pouring. In the process of chiseling away the grooves and track plates in the segmented mode, the track plates are pushed out of the grooves in a segmented and blocked mode, construction efficiency is high, a speed is high, and safety is good; and construction skylight is used for operation and railway operation line construction, influences of factors such as traffic safety, construction boundaries, technological processes and the like are considered, and the construction method and steps are reasonable in arrangement.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Test device for cavern body excavation model

PendingCN110967463AFlexible disassemblyThe construction method is reasonableEarth material testingPressure cellStrain gauge

The invention discloses a test device for a cavern body excavation model. The test device comprises a base, a sample arrangement mechanism, a test system and at least one upper computer. The sample arrangement mechanism is composed of stand columns vertically and fixedly connected with the base, pressure plates inserted between the stand columns and forming a cuboid cavity, and a pressure device or a counter-force device arranged on the outer sides of the pressure plates. The testing system comprises a steel wire pressure box and a resistance strain gauge which are arranged on a pre-excavatedsection; an upper computer used for receiving output signals of the steel wire pressure box and the resistance strain gauge, and the upper computer forms cavern body excavation stress and strain dataaccording to data changes generated by the steel wire pressure box and the resistance strain gauge. According to the device, chamber excavation of various section forms can be carried out in rock-soilbodies with different properties by adopting different construction methods, so that a reasonable, safe and efficient construction method can be selected in chamber excavation of rock-soil bodies with different properties.

Owner:EAST CHINA UNIV OF TECH

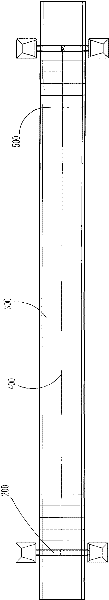

Construction method for repeated pile-sinking of inner pile casing

InactiveCN111364470AGuaranteed entry depthThe construction method is reasonableBulkheads/pilesStructural engineeringDrill bit

The invention discloses a construction method for repeated pile-sinking of an inner pile casing. The construction method includes the following steps that a dismantling drill bit and a dismantling drilling rig are lifted, and the drilling rig is lifted to a deck and tied firmly; a pile stabilizing platform is lowered, and then the pile stabilizing platform is re-leveled; an S2000 hydraulic pilinghammer is used for pile-sinking of the inner pile casing, the inner pile casing is continuously driven downwards, and the perpendicularity of the inner pile casing is measured and adjusted at any timein the construction process; and after the pile-sinking of the inner pile casing, the drilling rig is reinstalled and debugged for hole drilling. The construction method is reasonable and simple. First, the pile stabilizing platform is lowered, then the inner pile casing is subjected to repeated pile-sinking by the S2000 hydraulic piling hammer, and the perpendicularity of the inner pile casing is measured and adjusted at any time in the construction process, so that the inner pile casing is steadily subjected to pile-sinking and the depth of the inner pile casing into mud is ensured, and thestability is greatly improved.

Owner:JIANGSU LONGYUAN ZHENHUA MARINE ENG

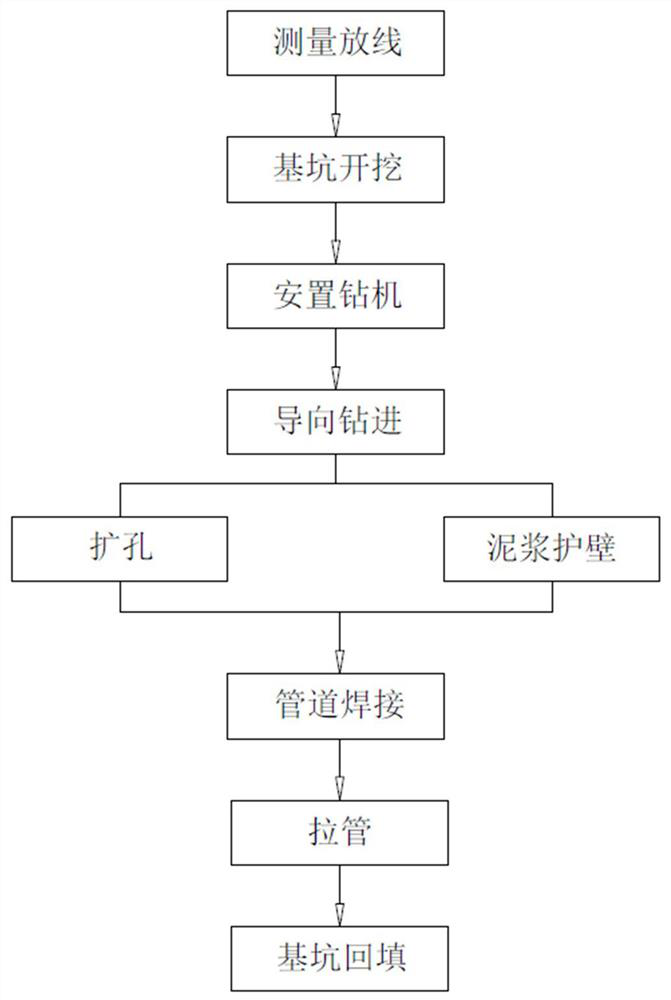

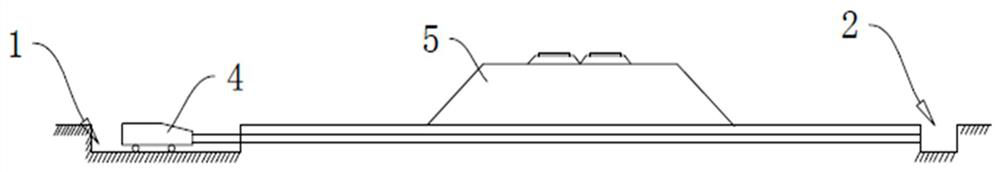

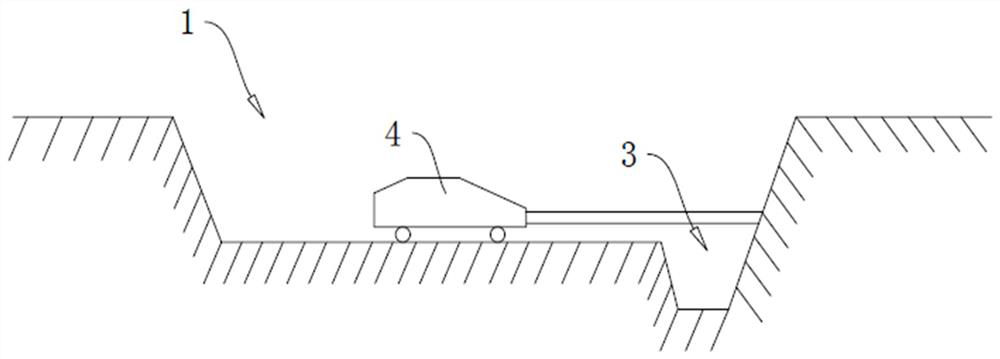

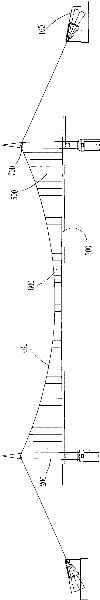

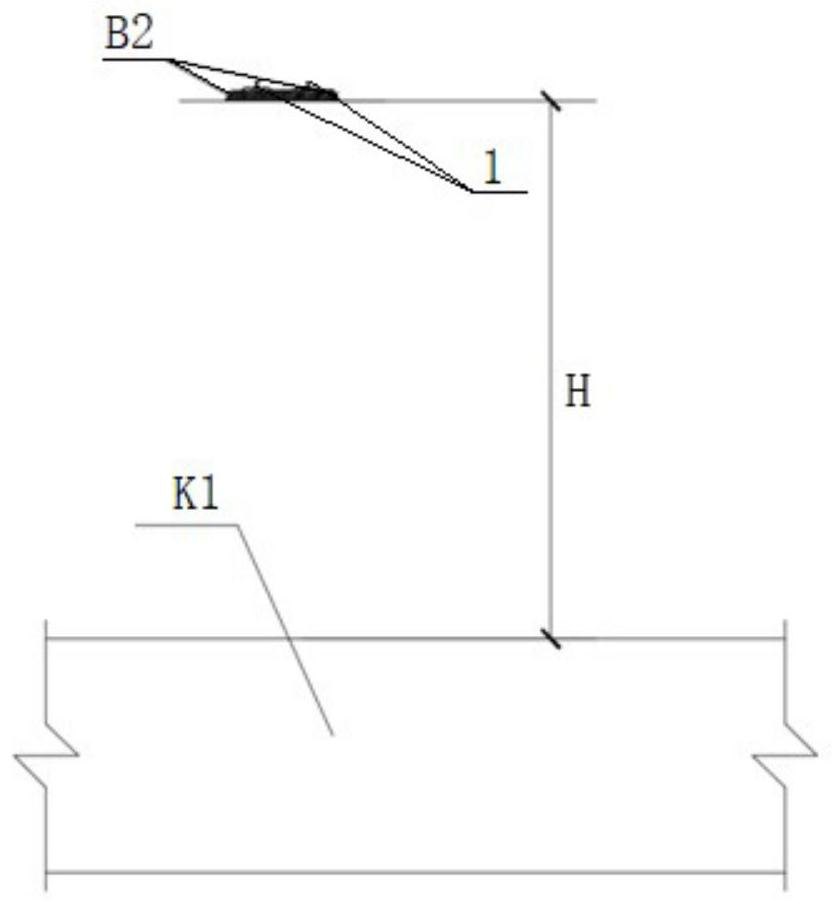

Construction method for non-excavation horizontal directional drilling of underneath passing existing railway

ActiveCN112727365AHigh crossing accuracyReduce the reinforcement processPipe laying and repairDerricks/mastsButt jointTotal station

The invention relates to a construction method for non-excavation horizontal directional drilling of underneath passing an existing railway. The construction method comprises the following steps that S1, surveying and setting out are conducted, specifically, a total station is used for setting out the center line of a pull pipe; S2, foundation pits are excavated, specifically, the foundation pits are excavated in the two sides of the existing railway; S3, drilling machines are arranged, specifically, the drilling machines are arranged in the working pits; S4, guiding drilling is conducted, specifically, after the drilling machines are arranged, guiding rods of the drilling machines are adjusted to the positions higher than the center elevation of the designed pipe position, and the drilling machines horizontally drill into soil; S5, chambering is conducted, specifically, after guiding drilling holes drill into receiving pits from the working pits, guiding drill bits are dismounted, and then back-expanding heads are mounted for repeated chambering; S6, pipelines are welded, specifically, the pipelines are fixed, and then hot melting butt joint is conducted; S7, the pipe is pulled, specifically, pipe heads of PE pipes are sealed through PE pipe sealing sleeves, then the back-expanding heads are connected to the rear ends of the pipe heads, and then the pipe is pulled; and S8, the foundation pits are backfilled, specifically, after construction is completed, the working pits are backfilled with fine soil. The construction method has the effects that the cost is saved, and the construction period is shortened.

Owner:BEIJING RAILWAY CONSTR OF CHINA RAILWAY SIXTH GROUP +1

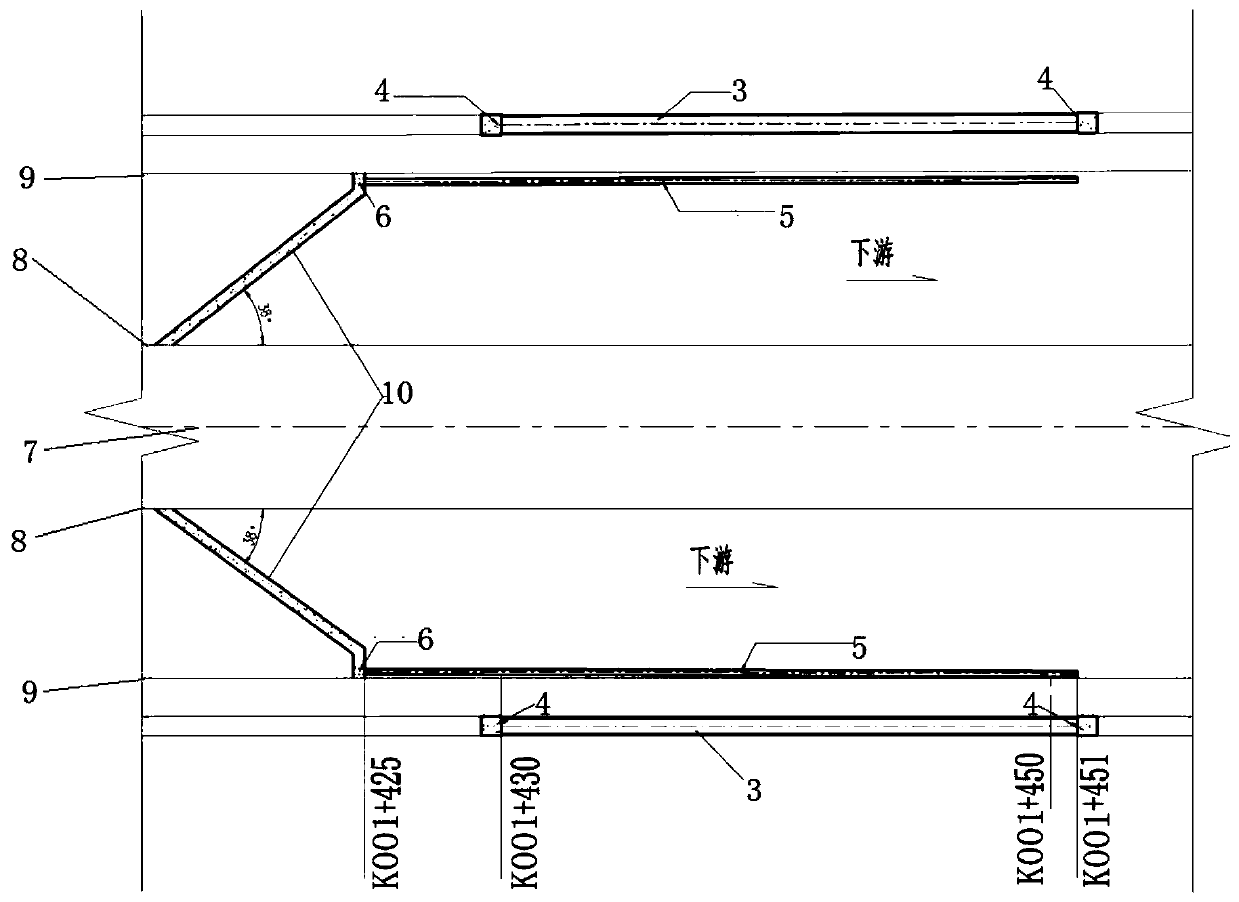

Construction method of single main cable inclined-suspender earth anchored suspension bridge

InactiveCN101914897BConstruction safetyGuarantee the quality of the projectSuspension bridgeFoundation engineeringTowerSteel box girder

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

A non-span-reducing construction method for a super-large-section loess tunnel close to the underlying operating railway

ActiveCN111396062BReduce the reinforcement processEliminate security risksUnderground chambersTunnel liningStructural engineeringCatheter

The invention discloses a non-span-reducing construction method for a super-large-section loess tunnel close to an underlying operating railway. Firstly, the influence range of the super-large-section loess tunnel passing under the operating railway is divided into three support level areas-I area, II area and III area. , and then carry out the construction of the pipe shed studio, the construction of the pipe shed, the backfilling of the pipe shed work room, and the reinforcement of the small conduit in advance, and finally adopt the three-step + two-step temporary inverted arch method to excavate and support the cave body. The invention is used to safely and quickly pass under the operating railway area, shorten the construction period, reduce the cost input, achieve the combination of safety, economy and rationality, and provide the same type of super-large section loess tunnels for the construction of the same type of super-large section loess tunnels close to the under-passing operating railway. Based on the reference, the construction efficiency of super-large-section loess tunnels passing under the operating railway can be further improved, and the construction safety risk can be reduced.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Building roof construction process

InactiveCN103362254BSimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

Owner:陕西建工集团有限公司 +1

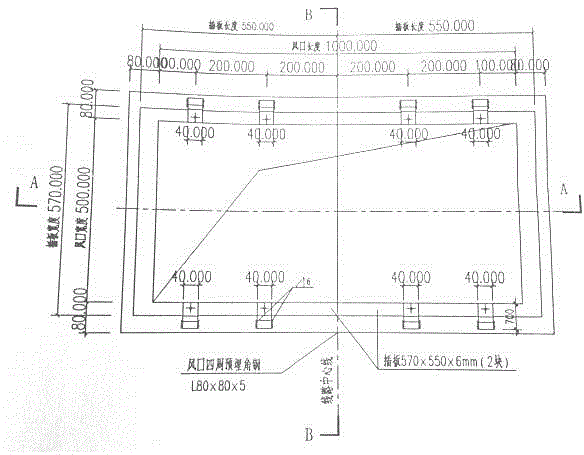

Rail top air port modification for subway stations

The invention relates to rail top air port modification for subway stations. According to the modification, air port louver windows are arranged on the lower sides of rail top air channel air ports and the upper ends of overhead line systems, an up and down rail running area is divided into four identical areas according to the station starting point, the station center line and the station terminal point, one of the four areas starts from the up starting point to the station center line, the subway rail top air channel air ports are located right above the overhead line systems of the rail running area, and the construction method needs to be reasonable and reliable due to the special position. Installing and debugging of the rail top air channel pull plate type air ports of the stations of double-layer island type structures are introduced in the article; compared with other installing modes, the installing mode of the pull plate type air ports has the advantages that installing is reliable, debugging is convenient and the safety is higher though the direct economic value is not obvious and is innovative for installing of rail top air channel air ports.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

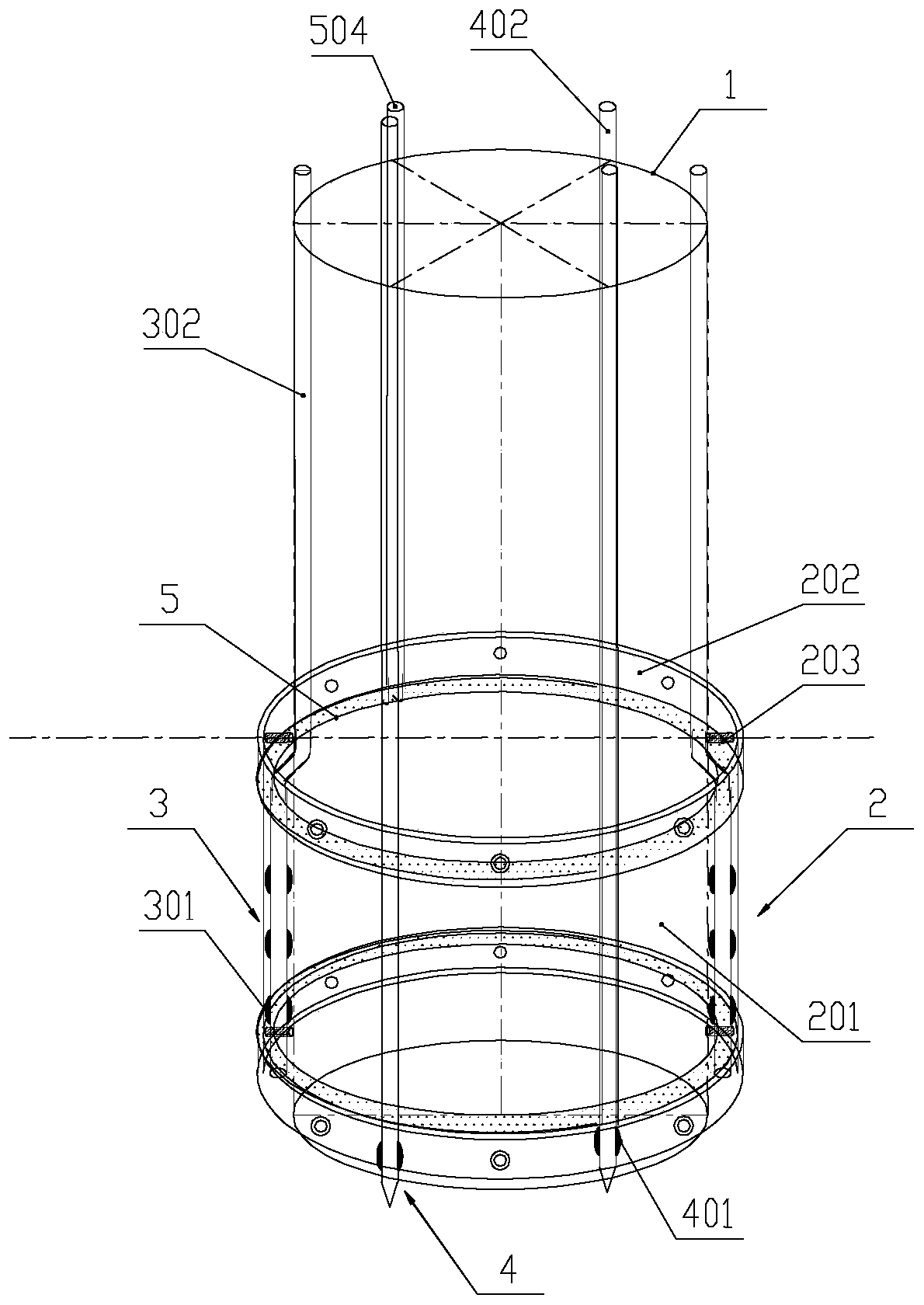

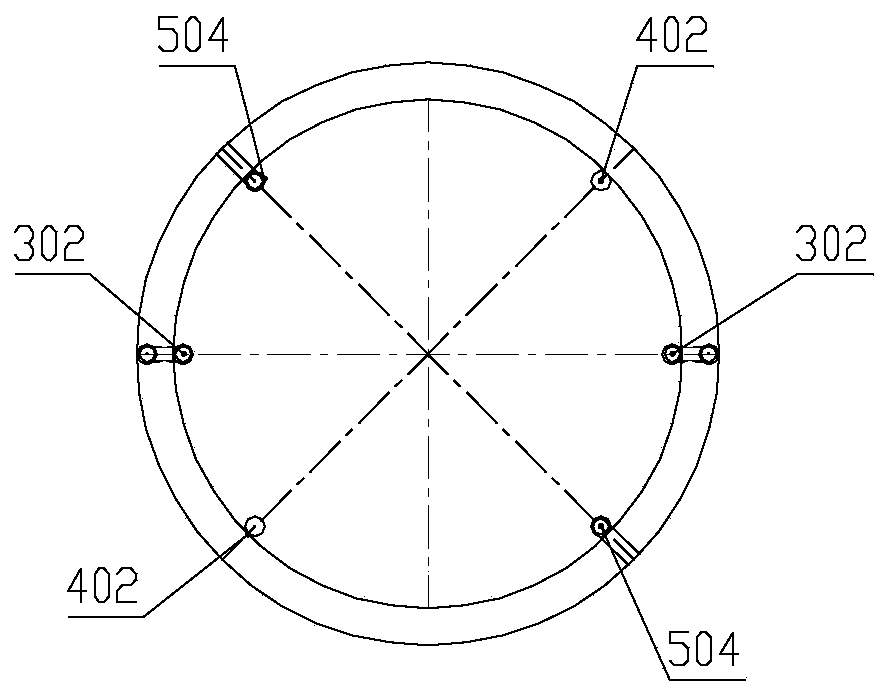

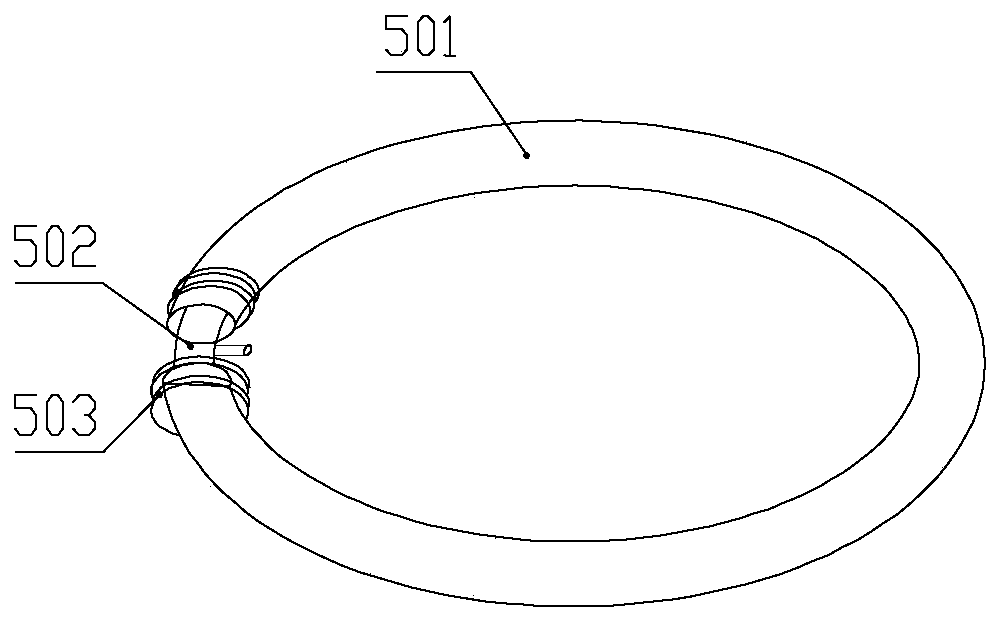

Post-combination grouting device and construction method of cast-in-situ pile pile end and pile side

ActiveCN107034877BAvoid uncertaintySolve the problem that the ideal geometric plasma bubble cannot be formedBulkheads/pilesRebarBearing capacity

The invention discloses a post-grouting device for a pile end and pile side combination of a cast-in-place pile. The device comprises a reinforcement cage, a lateral elastic cavity which wraps the outer side of the lower part of the reinforcement cage, a side grouting device which is fixed to the reinforcement cage and used for grouting the lateral elastic cavity, and an end grouting device for grouting the end part of the reinforcement cage, wherein the lateral elastic cavity comprises an elastic film, and double-layer steel rings which are positioned at the upper end and the lower end of the elastic film and used for clamping the elastic film; the double-layer steel rings are fixedly connected to the reinforcement through steel bars, and a clearance is formed between the lateral elastic cavity and the reinforcement cage; the reinforcement cage is sleeved with a rubber air bag device; the elastic film sleeves the rubber air bag device; the rubber air bag devices are arranged close to the upper and lower double-layer steel rings in a sleeving manner. With the adoption of the device, the bearing capacity of a pile foundation can be effectively improved; the settling amount of the pile foundation is decreased; and the cost is greatly decreased. The device is simple in structure, reasonable in construction method, convenient to operate, safe, reliable, suitably mounted at a construction site, and convenient to popularize and apply.

Owner:SOUTHEAST UNIV

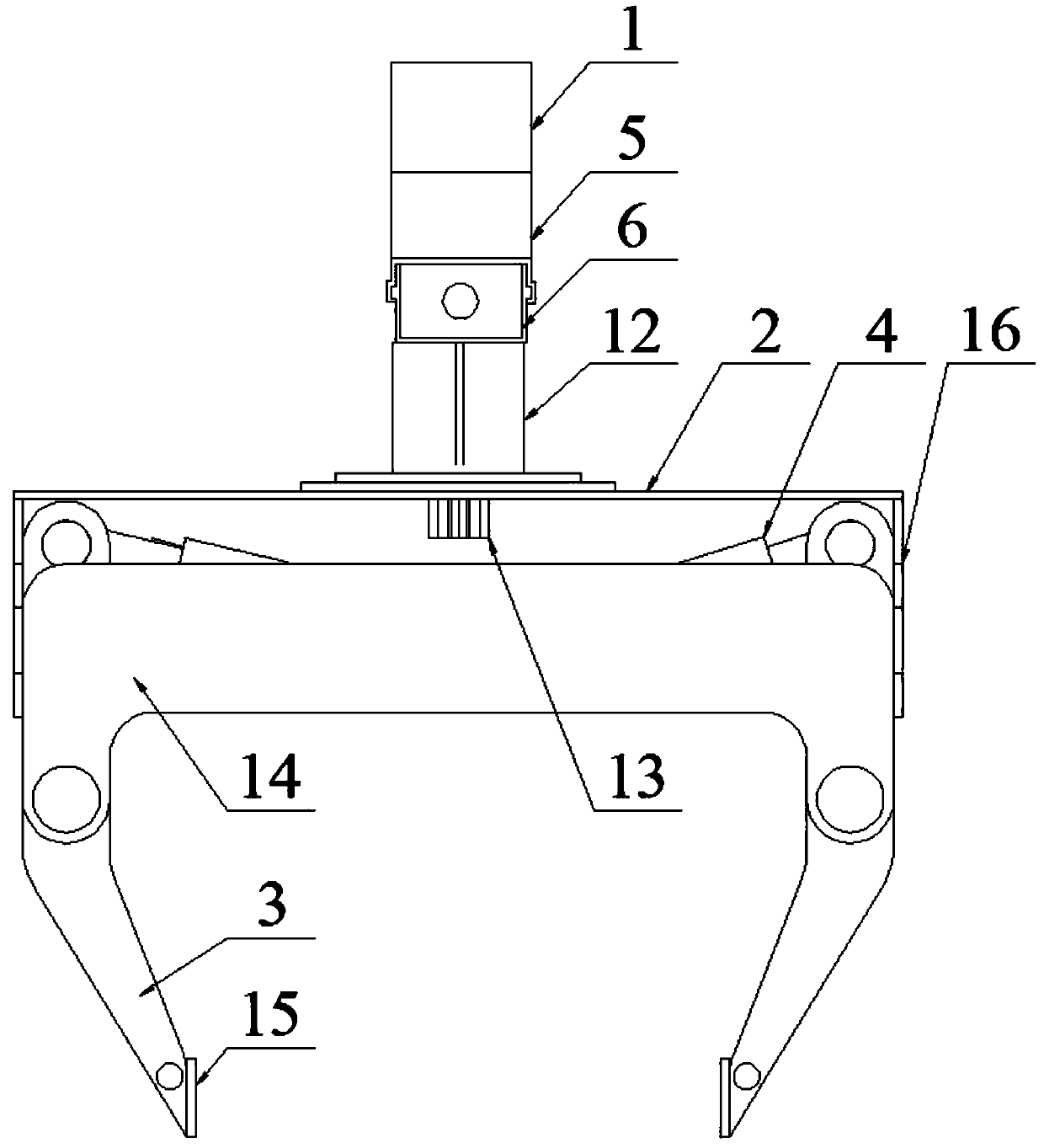

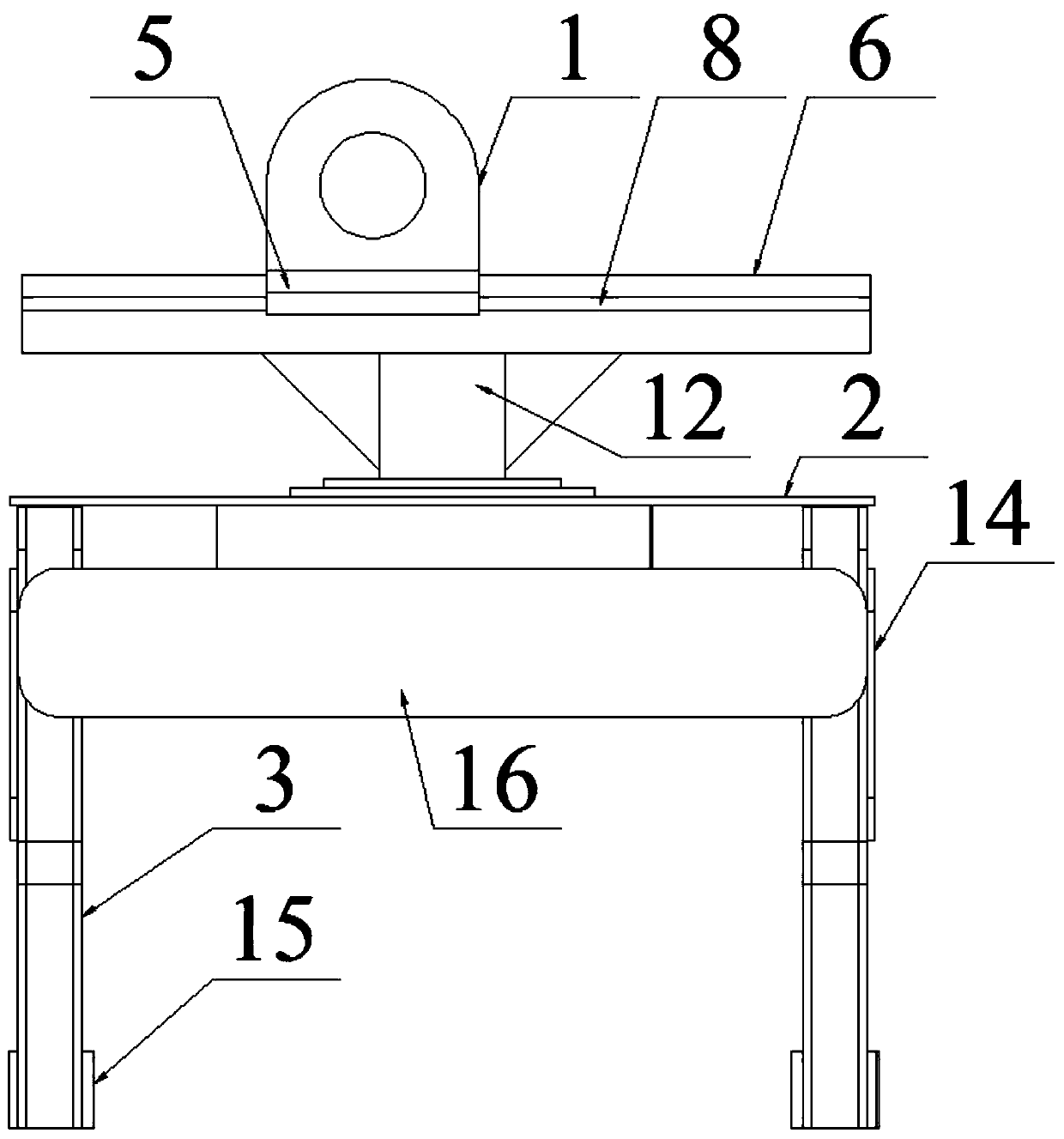

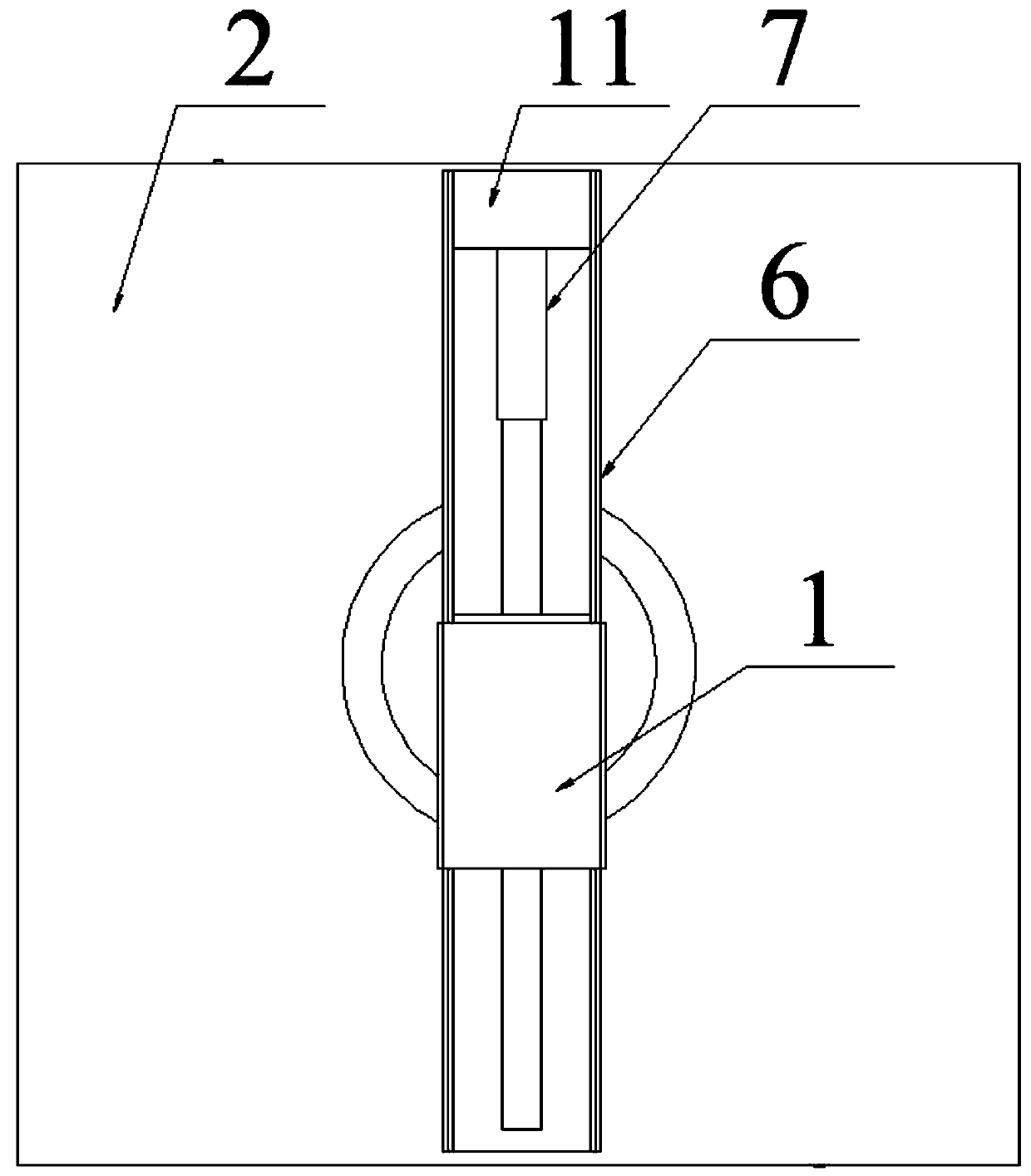

A construction method for breakwater protection block

ActiveCN109987509BAdjust postureSimple construction methodLoad-engaging elementsArchitectural engineeringSupport point

The invention relates to the technical field of port engineering strengthening construction device structures, in particular to a breakwater amour block construction method. A lifting lug connected with lifting equipment is involved. The method is characterized in that a cover plate and grippers are further involved; the grippers are rotationally hinged to the cover plate and driven by gripper oilcylinders on the cover plate to rotate around hinge supporting points correspondingly, so that a breakwater amour block is taken and placed; and a first adjusting structure used for adjusting the horizontal position of the cover plate and a second adjusting device used for adjusting the vertical rotating angle of the cover plate are arranged between the cover plate and the lifting lug. Accordingto the breakwater amour block construction method, the structure is simple, safe and reasonable, operation is convenient, the amour block can be rapidly arranged in a designated position under the condition that the amour block is not damaged, the amour block is directly gripped, the efficiency is high, the amour block posture can be adjusted, and the arranging precision is improved.

Owner:CCCC SECOND HARBOR ENG +1

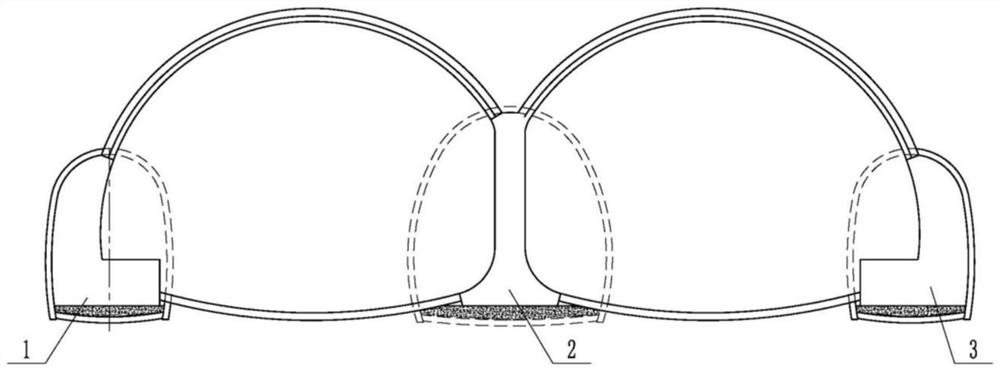

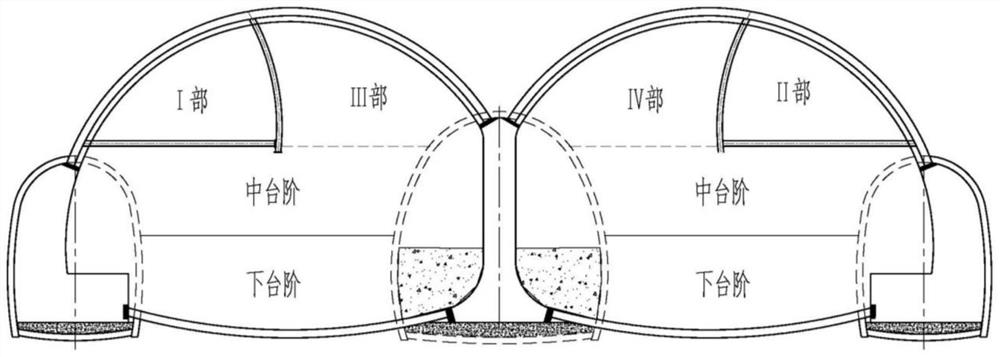

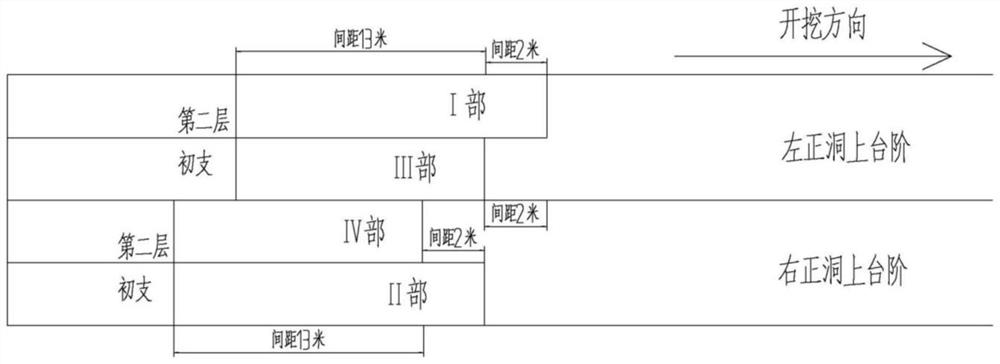

Large-span double multi-arch tunnel excavation method in urban complex environment

PendingCN113622941AExcavation has little impactThe construction method is reasonableUnderground chambersTunnel liningArchitectural engineeringSupport point

The invention discloses a large-span double multi-arch tunnel excavation method in the urban complex environment, which comprises the steps of: excavating three pilot tunnels, i.e., excavating the three pilot tunnels in a mode of firstly excavating a middle pilot tunnel and following up excavation of left and right pilot tunnels by opening the step pitches; after excavation of the third pilot tunnels is completed, pouring a left side wall of the left pilot tunnel, a right side wall of the right pilot tunnel and a middle partition wall of the middle pilot tunnel; and after the left side wall, the right side wall and the middle partition wall are poured, excavating a main tunnel of the double multi-arch tunnel in the mode that an upper step is firstly constructed by a CD construction method in a penetrating mode and then a middle step and a lower step are constructed, wherein supporting points of primary supporting are all located on the left side wall, the right side wall and the middle partition wall when the main tunnel is excavated. The construction method of firstly penetrating the upper step of the main tunnel, carrying out the primary supporting at the same time to form a multi-arch cover tunnel structure and then excavating the middle step and the lower step is reasonable, and construction safety is guaranteed.

Owner:中铁一局集团第五工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com