Rapid pushing and replacing construction method for ballastless track structure of passenger special line

A technology of ballastless track and construction method, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of disturbing normal transportation order, short skylight time, hidden safety hazards, etc., and achieves reasonable construction method and step arrangement and high construction efficiency , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

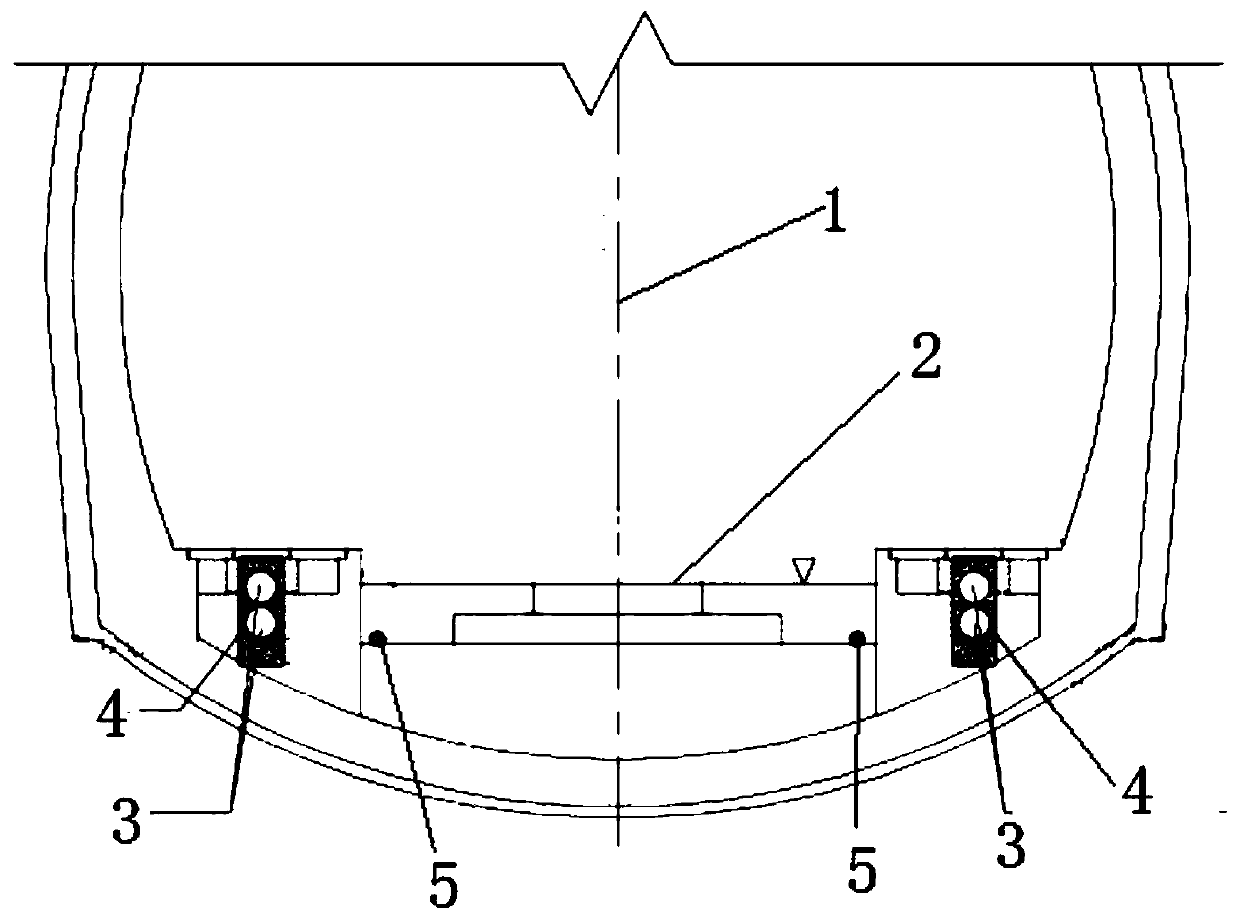

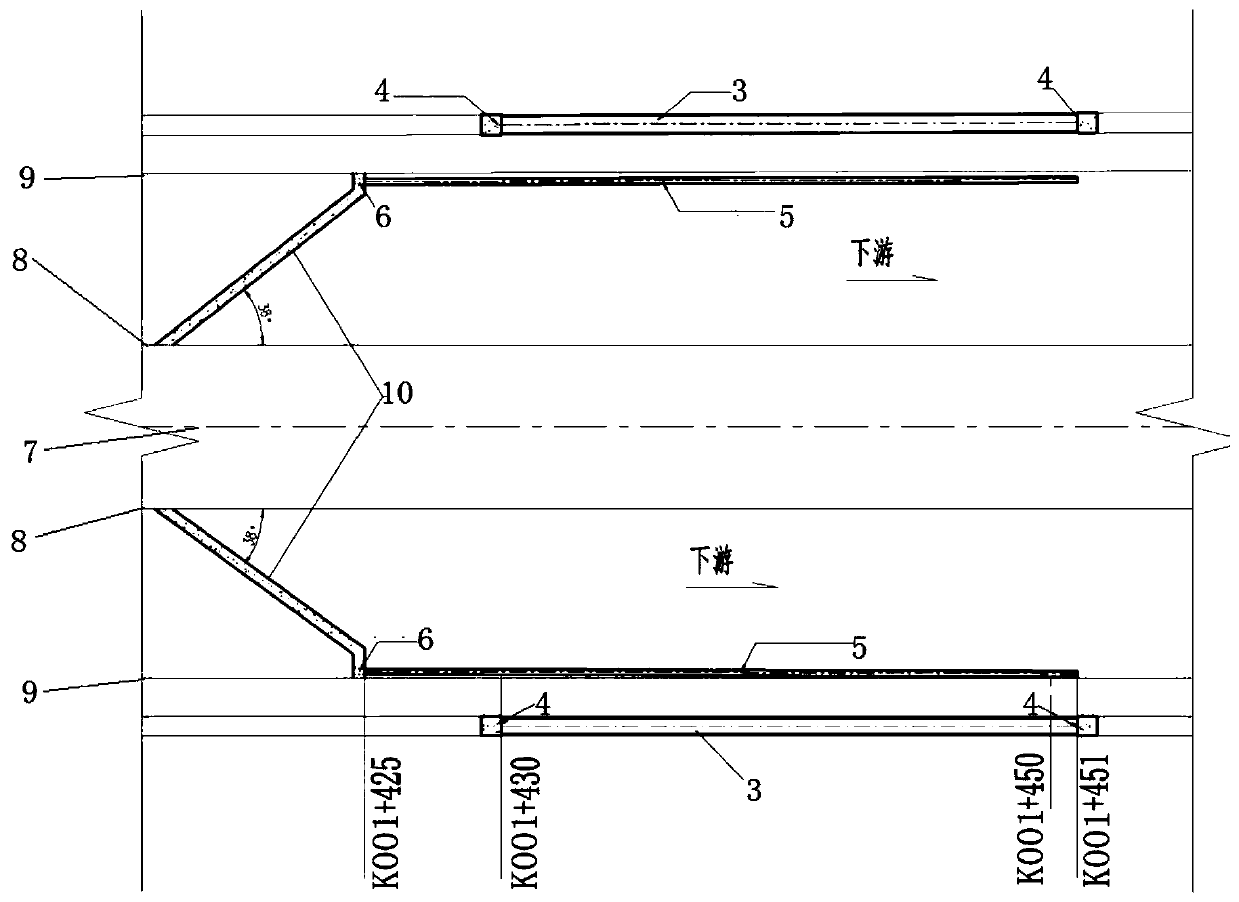

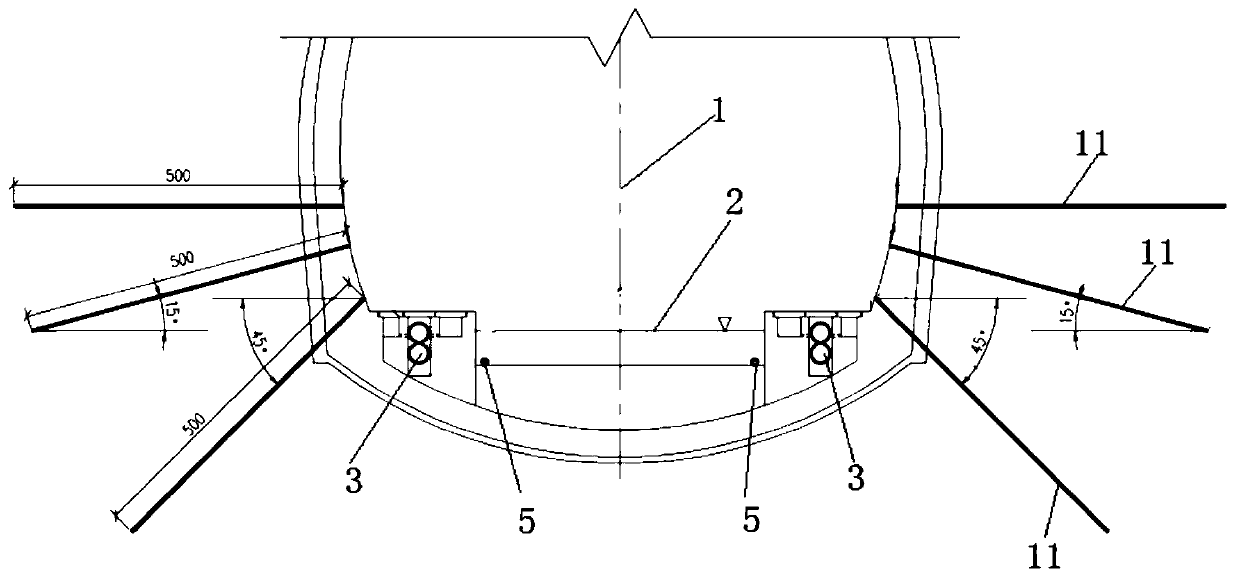

[0041] A construction method for quickly moving and replacing ballastless track structures of passenger dedicated lines, the construction method includes the process of removing and replacing the inverted arch structure and reinforcing the diseased area, which is divided into three stages: preparation stage, critical stage and recovery stage;

[0042] The preparation stage at least includes the steps of construction preparation, temporary works, reinforcement of lining side wall bolts, anchorage of ballast slab pins, reinforcement of steel plates, unlocking and cutting of rails in the work area, stress relief and joint connection;

[0043] The key stage at least includes the steps of excavating grooves and ballast bed slabs in sections, erecting steel beams, laying wooden sleepers and rail rows, excavating and replacing inverted arches and filling layers at the bottom of the tunnel, end prestressed anchoring and reinforcement, and pouring the ballast bed;

[0044] The restorati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com