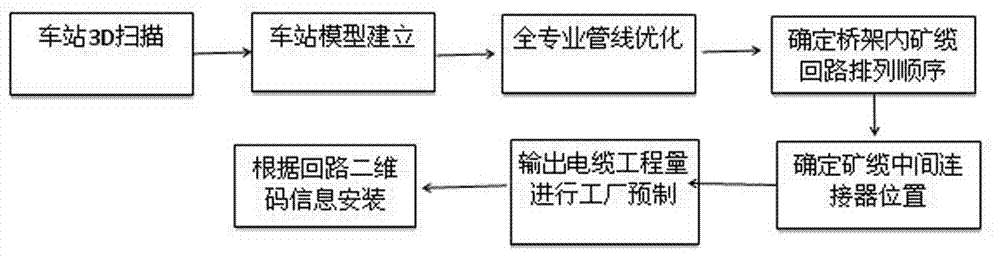

Mineral substance insulated cable factory-like pre-configuration processing method based on BIM technology

A technology of insulated cables and processing methods, which is applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of BIM technology introducing mineral insulated cables, etc., and achieve the effects of shortening the construction period, reducing labor costs, and solving limited conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

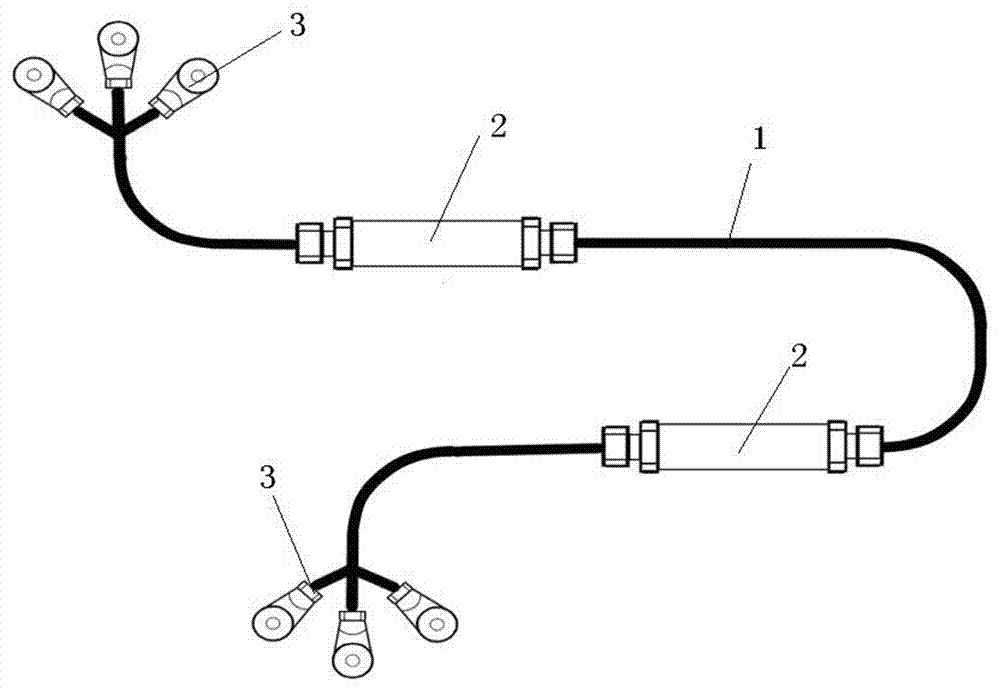

Method used

Image

Examples

Embodiment

[0031] The Hefei Rail Transit Line 2 project starts from Changning Avenue Station and extends eastward along Changjiang West Road, Changjiang Middle Road, and Changjiang East Road to the terminal Dazhong Road Station. The starting and ending points are reserved for line conditions extending to both ends. The total length of the line is 27.764km, all of which are underground lines, with a total of 24 stations. The maximum station spacing of the line is 1.665km, located between Yulan Avenue and Shufeng Road; the minimum station spacing is 0.714km, located between Wanggang Avenue and Dazhong Road; The average distance between stations is 1.182 km.

[0032] The eight bid sections of the mechanical and electrical general contract that the applicant is responsible for construction include Longgang Avenue Station, Wanggang Avenue Station, Dazhong Road Station, and are located at the intersection of Changjiang Road and Wanggang Road, Longgang Road, and Dazhong Road. The three-station min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com