Post-combination grouting device and construction method of cast-in-situ pile pile end and pile side

A technology for cast-in-place piles and pile sides, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problem that the amount of grouting and the grouting pressure cannot be effectively controlled, the vertical bearing capacity of cast-in-place piles is discrete, and cannot be formed. Ideal geometric slurry bubbles, etc., to achieve the effect of reducing uncertain factors, facilitating popularization and application, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

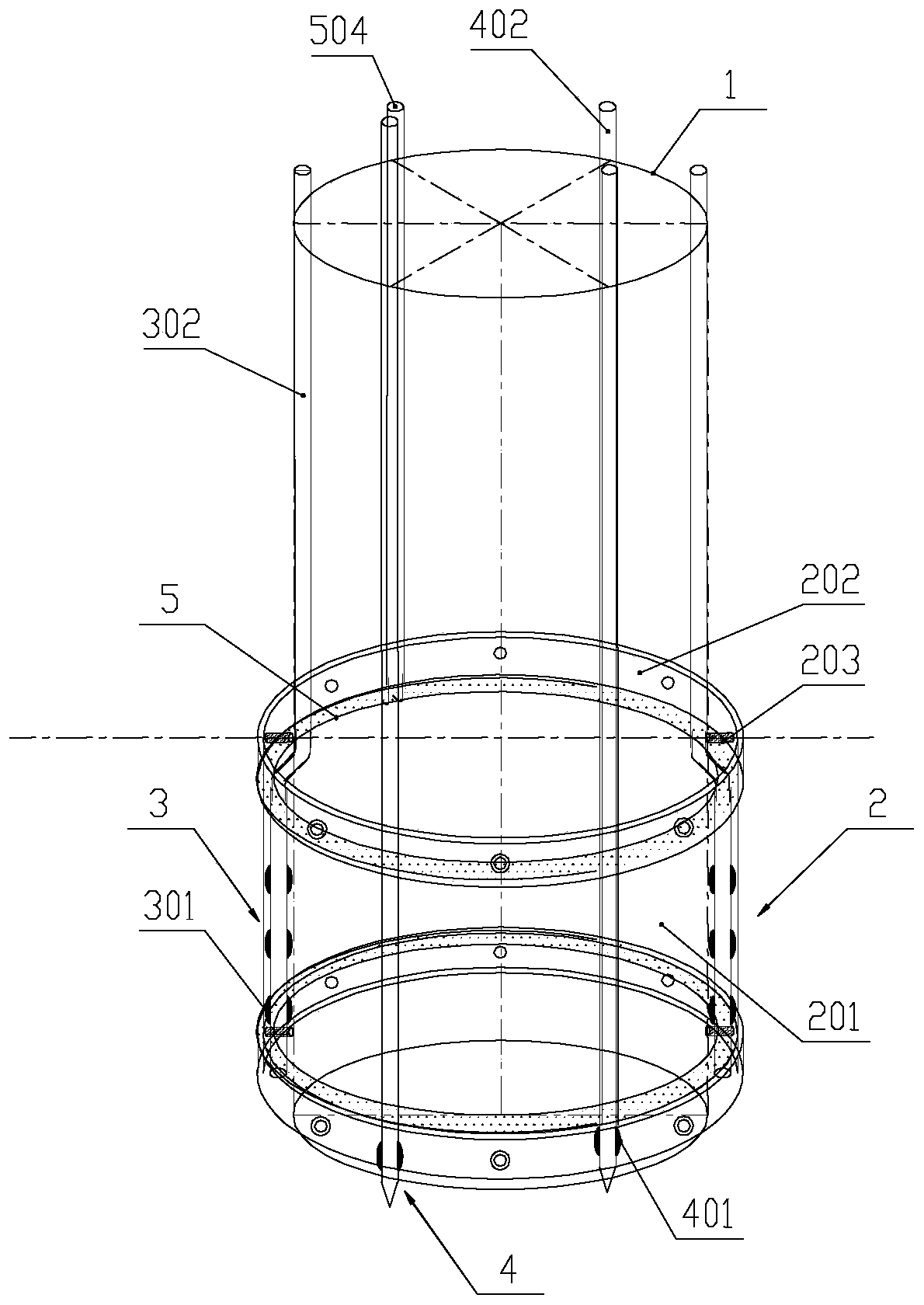

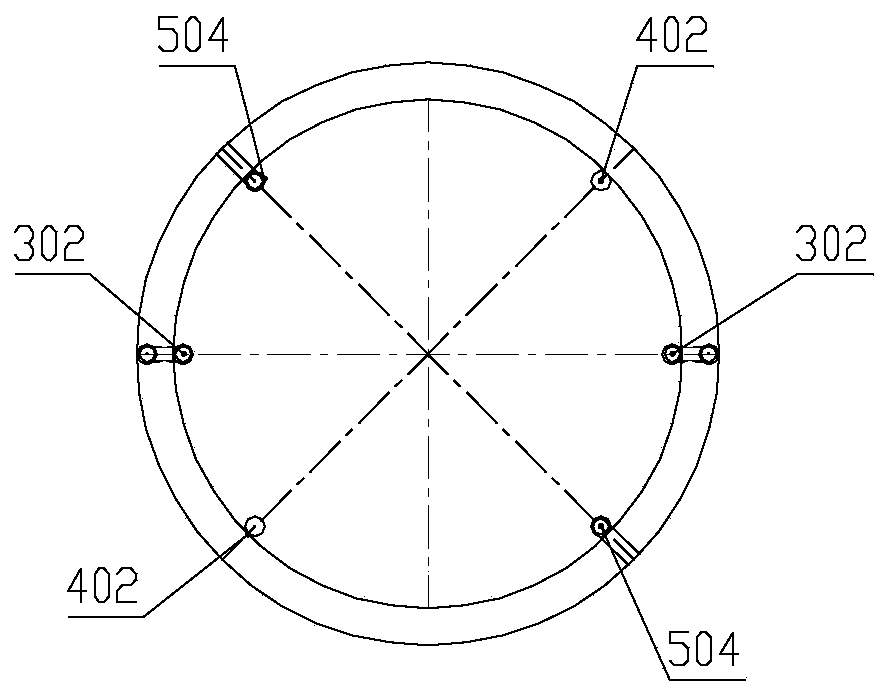

[0034] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

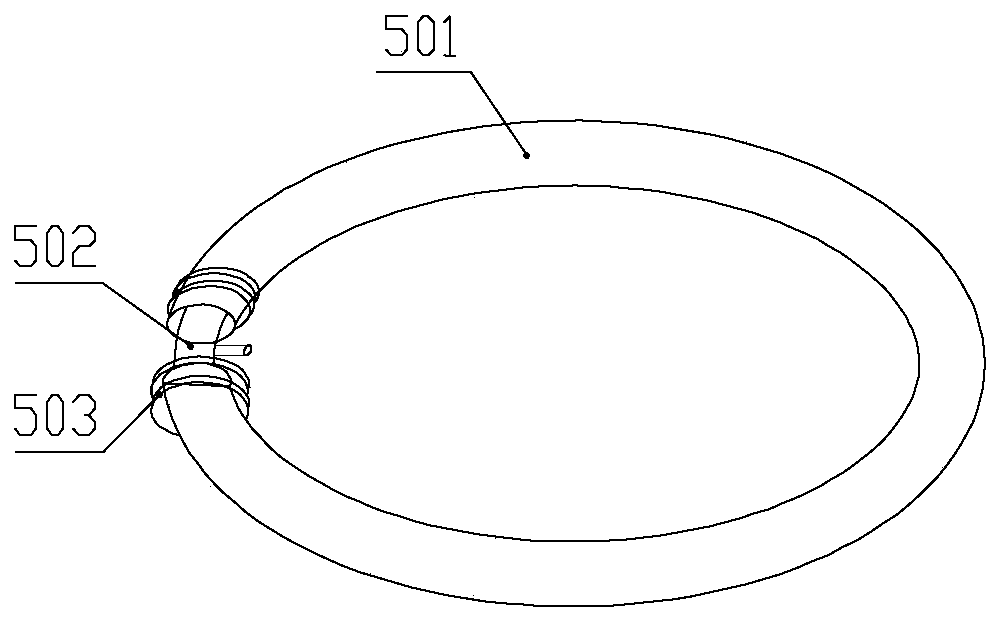

[0035] Such as figure 1 and figure 2 As shown, a post-combination grouting device for cast-in-place piles according to the present invention includes a steel cage 1 , a lateral elastic cavity 2 , a side grouting device 3 , an end grouting device 4 and a rubber airbag device 5 . Such as Figure 4 As shown, the lateral elastic cavity 2 is covered on the outside of the lower part of the steel cage 1, and the lateral elastic cavity 2 includes an elastic film 201 and a double-layer steel ring that is located at the upper and lower ends of the elastic film 201 and clamps the elastic film 201 202, the double-layer steel ring 202 is fixedly welded to the steel cage 1 through the steel bar 203, and forms a gap between the lateral elastic cavity 2 and the steel cage 1; the length of the steel bar 203 determines the size of the gap, and the steel The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com