Detection method for automatically identifying and detecting weld defects

A technology for automatic identification and detection methods, applied in measurement devices, image data processing, instruments, etc., can solve the problems of slow detection speed, inability to meet real-time industrial requirements, high overhead, etc., to improve detection speed, avoid inefficiency and Uncertainty and the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

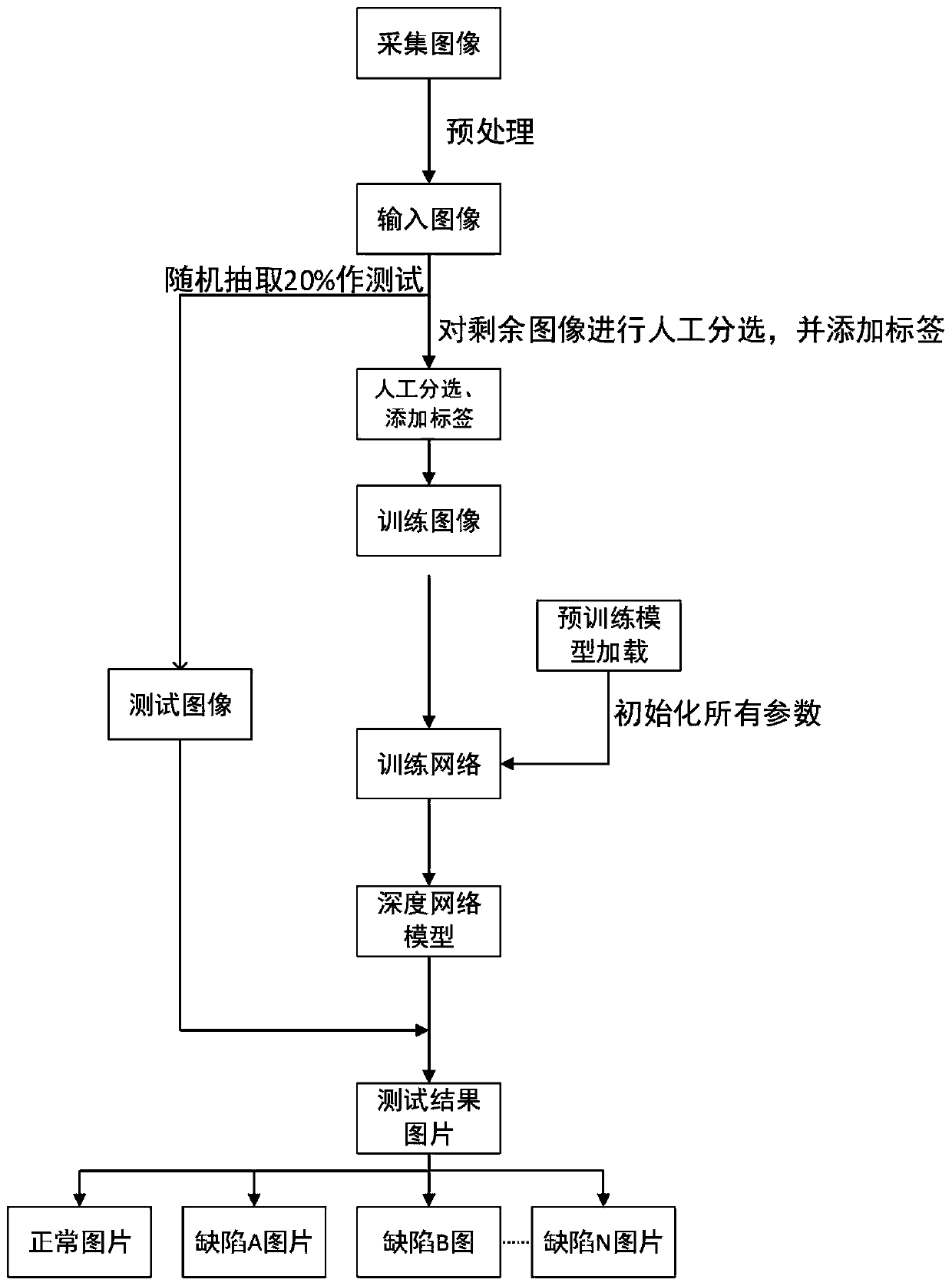

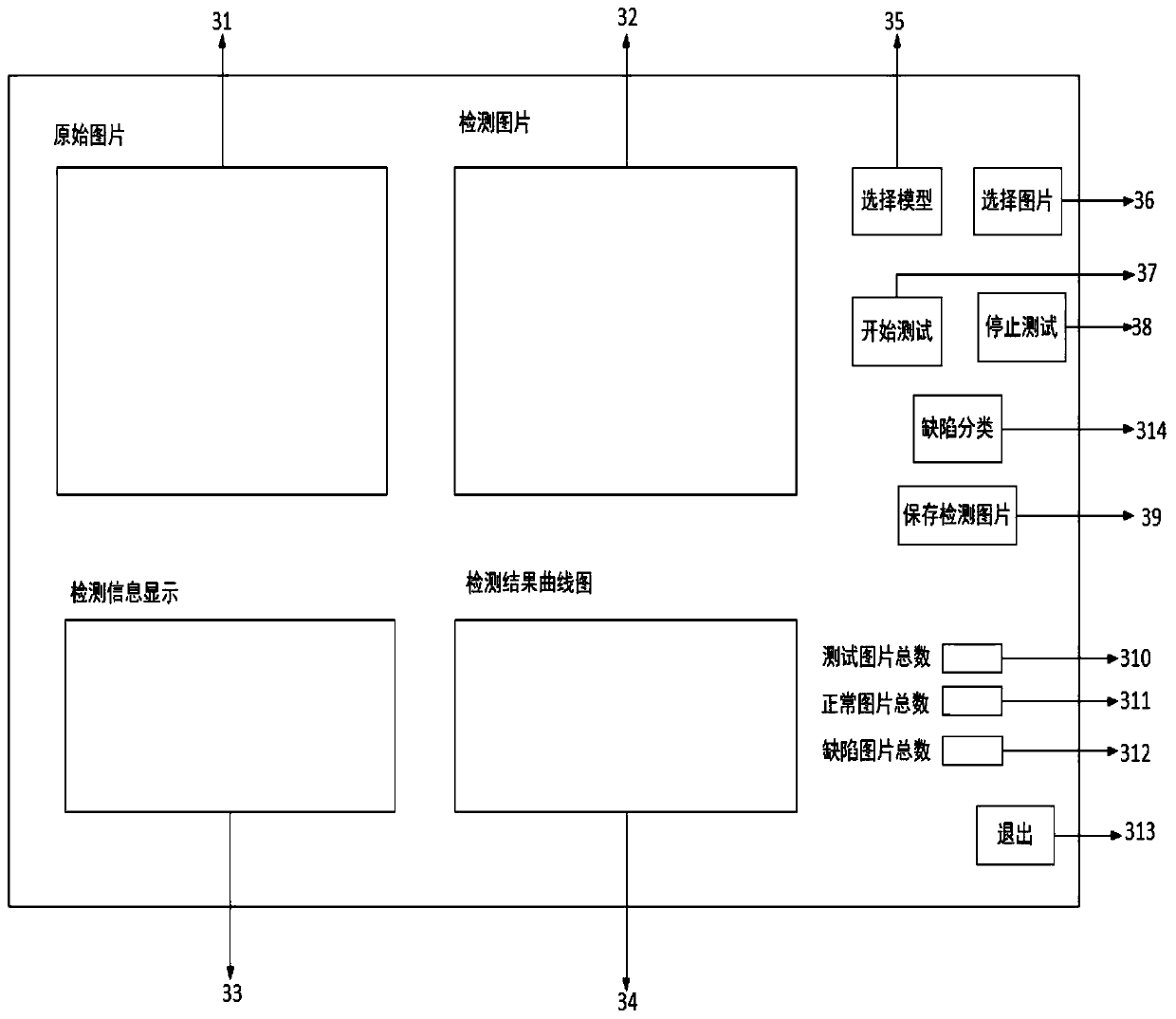

[0058] In this embodiment, a detection method for automatically identifying and detecting weld defects, which is used for the detection of weld defects, includes the following steps:

[0059] 1. Image preprocessing

[0060] Image acquisition: Obtain weld seam images through X-ray machine;

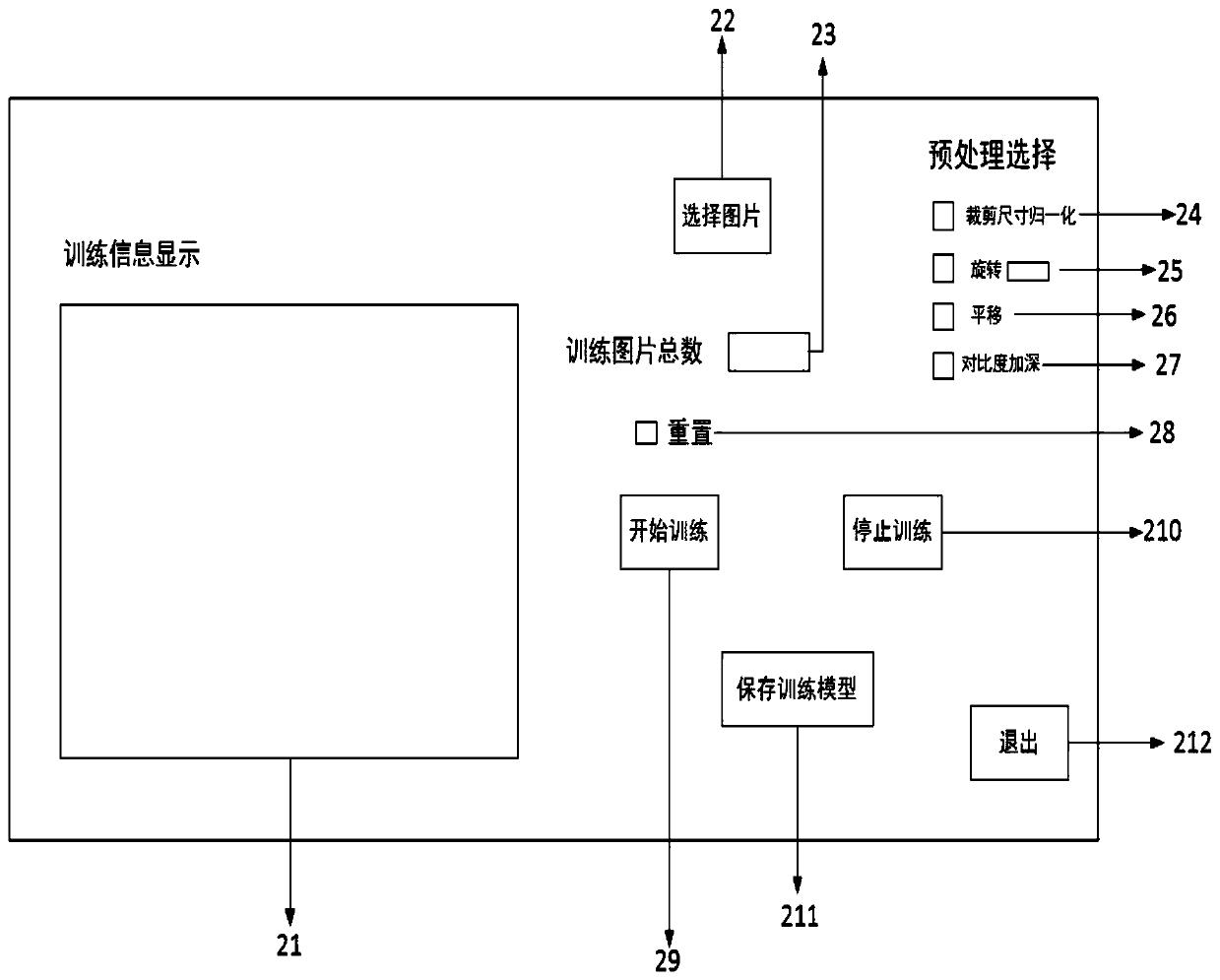

[0061]Image shape adjustment and edge processing: Firstly, the collected weld defect images are preprocessed. Since the number of collected weld defect images is significantly less than that of normal area images, in order to expand the weld defect database, the collected weld image The preprocessing methods include at least image cropping size normalization, rotation, translation, contrast deepening, etc.; the object of the label is a weld defect, and LabelImg is used to manually label the defect area; the unnecessary part of the image is removed by regional morphological processing , the edge of the weld image in the image is extracted and fitted by the least squares method, and the curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com