Construction method for non-excavation horizontal directional drilling of underneath passing existing railway

An existing railway and horizontal directional technology, applied in directional drilling, drilling equipment and methods, excavation, etc., can solve the problems of many personnel and mechanical equipment, complicated and tedious procedures, and high construction costs, and achieve high efficiency, improved effect, The effect of small construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

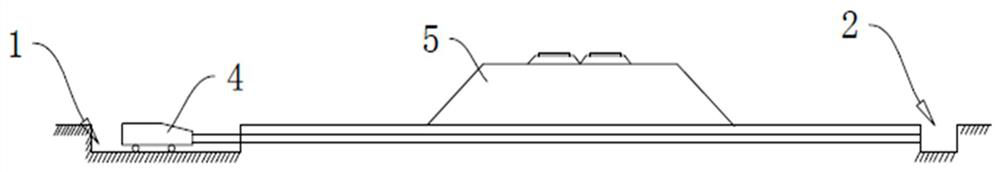

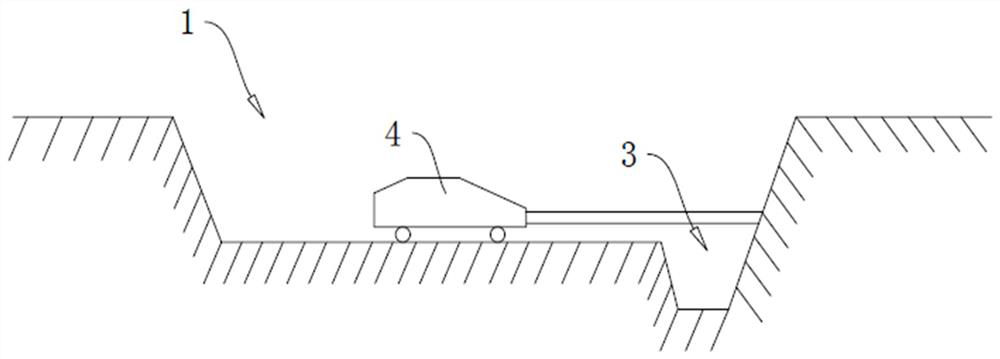

[0039] The following is attached Figure 1-3 The application is described in further detail.

[0040] There is an existing project, according to the planning requirements, combined with the intersection of highway and railway, due to the construction of the frame bridge, the rail cables and water supply pipelines need to be relocated, involving one 10KV high-voltage cable, one φ350mm water supply pipeline, four low-voltage cables, 13 communication cables.

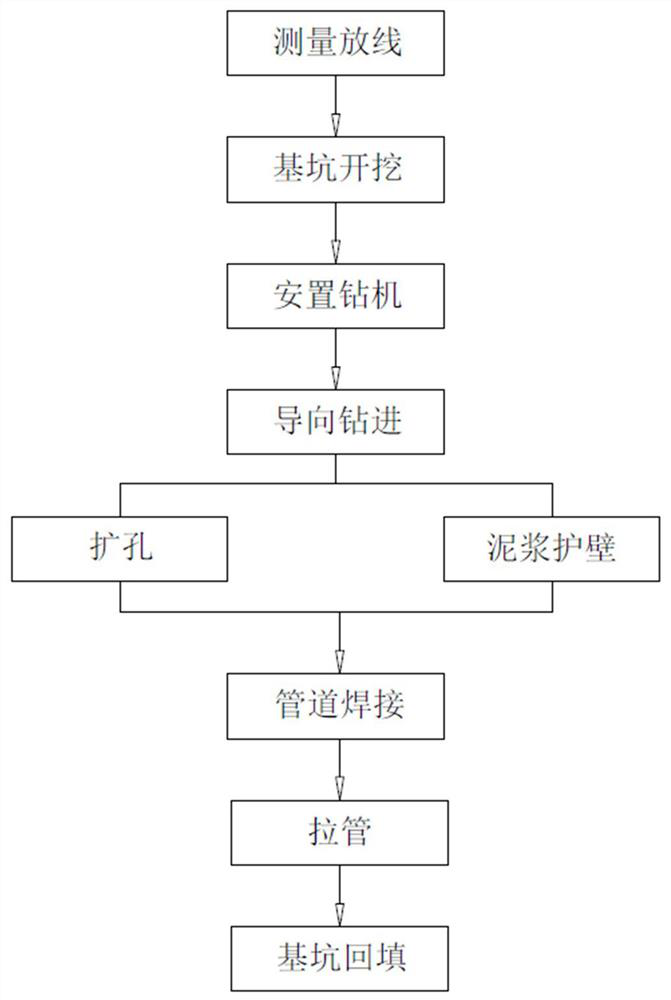

[0041] The embodiment of the present application discloses a construction method of trenchless horizontal directional drilling under an existing railway. A construction method for trenchless horizontal directional drilling under an existing railway, referring to figure 1 , including the following steps:

[0042] S1. Surveying and setting out: 1. Plane control setting out: according to the existing sidelines, the positioning points of the project are guided through the control points provided by the survey unit. The cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com