Line-to-line ditch plastic model construction method

A technology of plastic model and construction method, which is applied in the direction of waterway system, sewer system, water supply device, etc., can solve the problems of difficult operation of steel formwork construction, increase of workers and machinery, easy damage of bamboo plywood construction, etc., and achieve construction tasks Tough, reliable finished product quality, smooth surface without rough effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

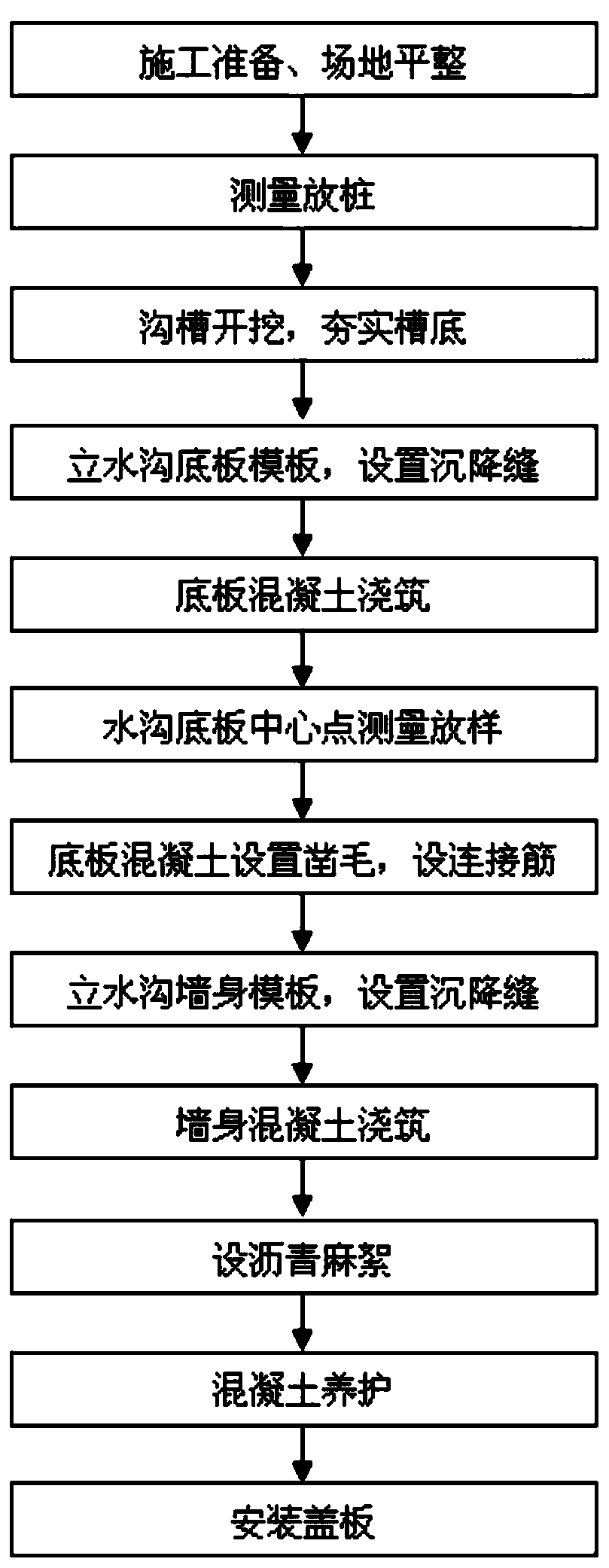

[0036] refer to figure 1 , the present embodiment provides a construction method for a plastic model of a trench between lines, specifically as follows:

[0037] 1) Measure and locate the center of the ditch, measure the center of the ditch according to the coordinate size of the design drawing, mark the measured pile position, sprinkle lime lines according to the size of the design drawing, and carry out excavation. When excavating the bottom of the tank, the mechanical excavation depth is controlled at a height of 10cm from the designed bottom of the tank. Soil, when there is virtual soil in the tank, use a small tamping machine to tamp the bottom of the tank.

[0038] 2) After the excavation of the foundation trench is completed and the bottom of the trench is tamped, the vertical formwork can be erected only after passing the acceptance inspection. Put a ditch floor elevation every 10m, and strictly control the longitudinal slope of drainage. Surveyors need to review se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com