Patents

Literature

84results about How to "Straight lines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

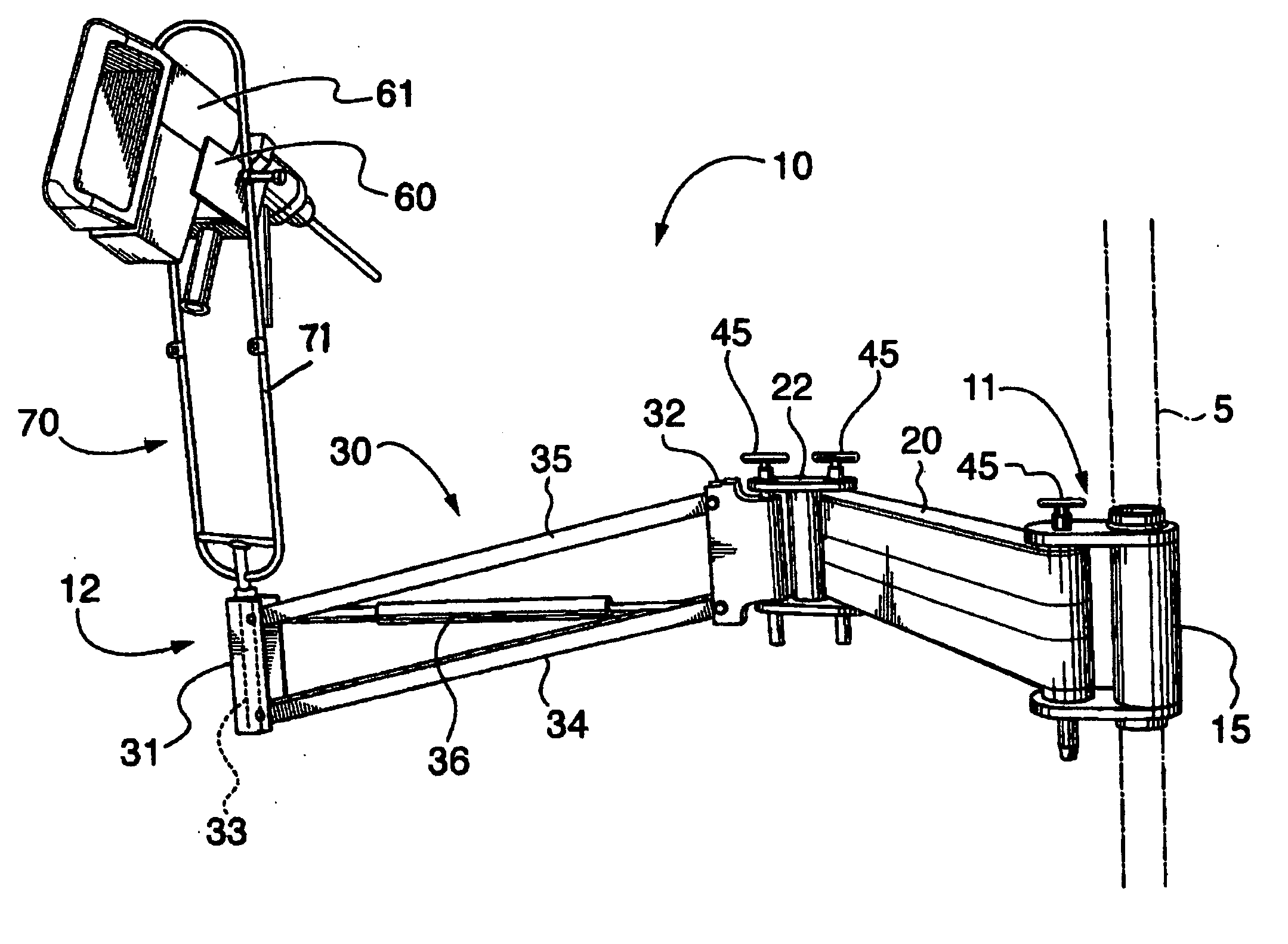

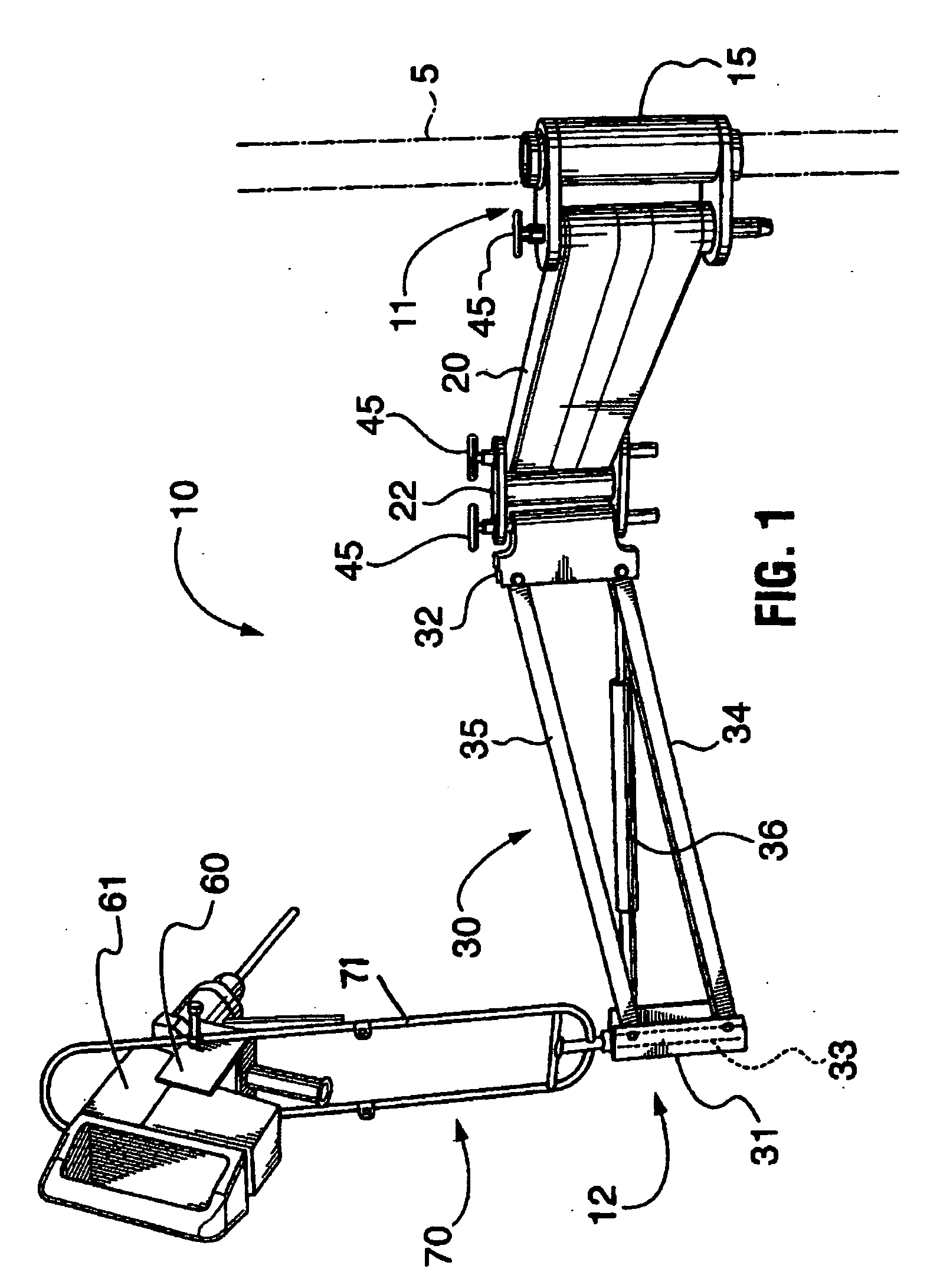

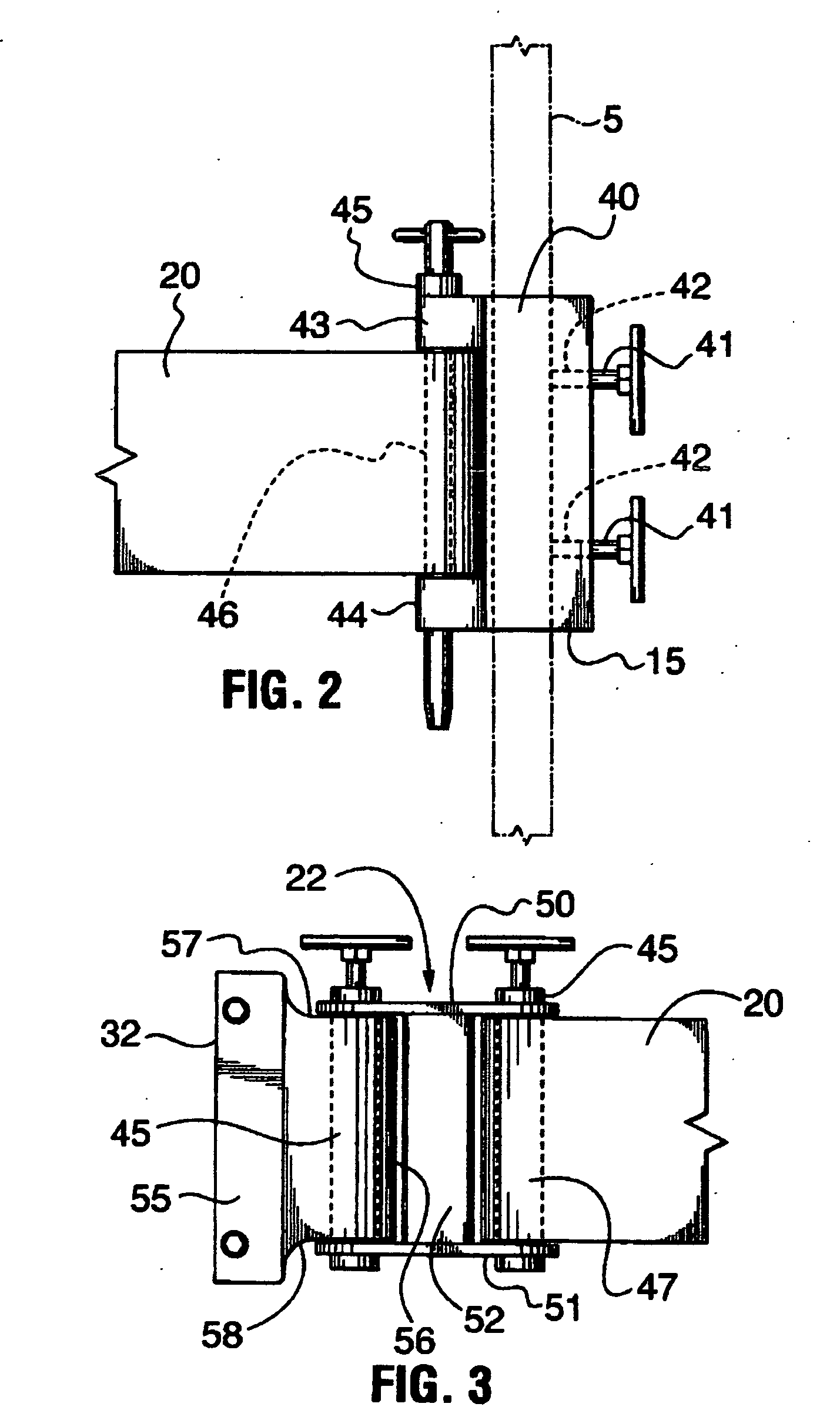

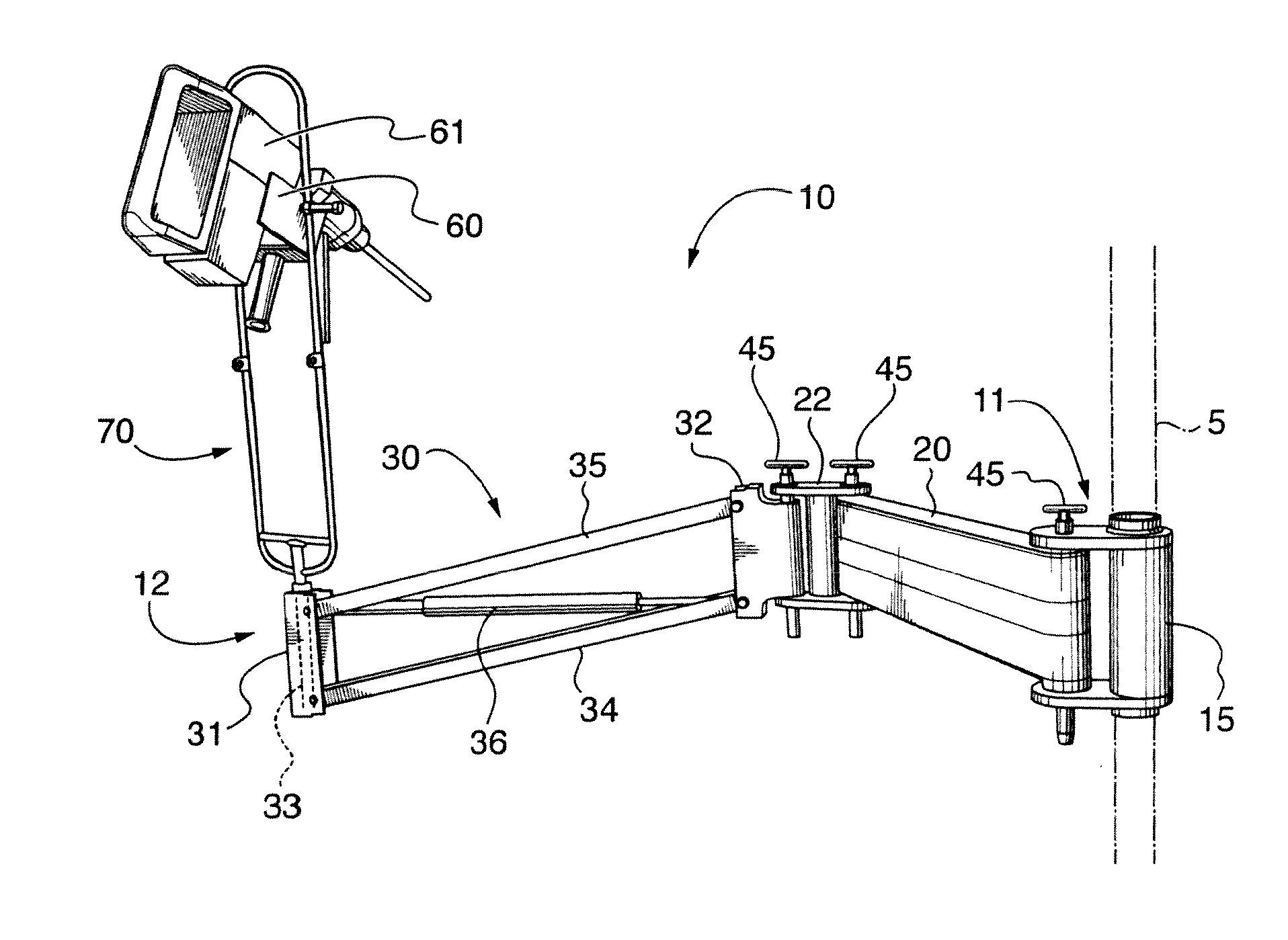

Portable articulating tool support

ActiveUS20060186281A1Improved ease of useQuickly assembleThread cutting toolsTransportation and packagingMultiple componentPower tool

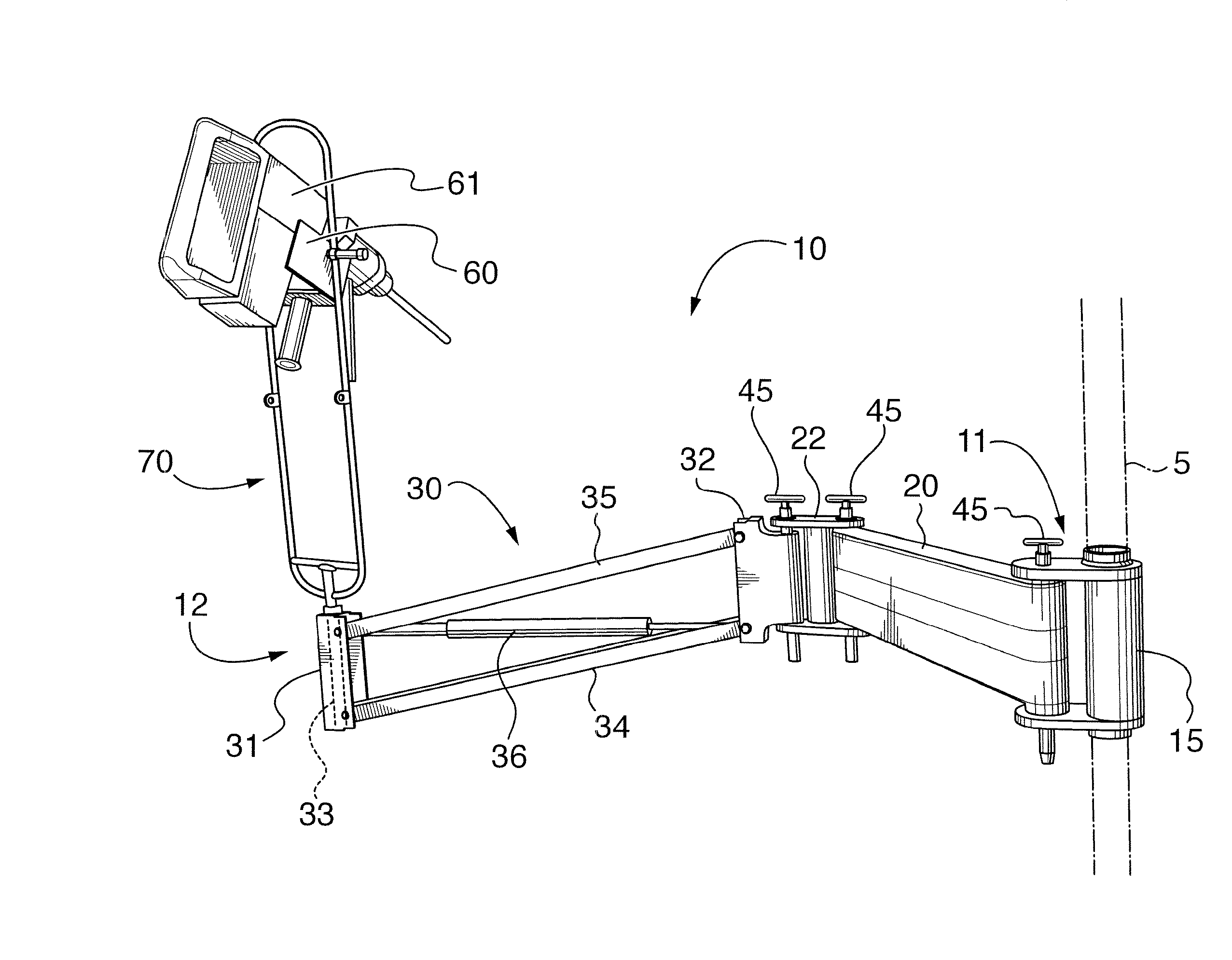

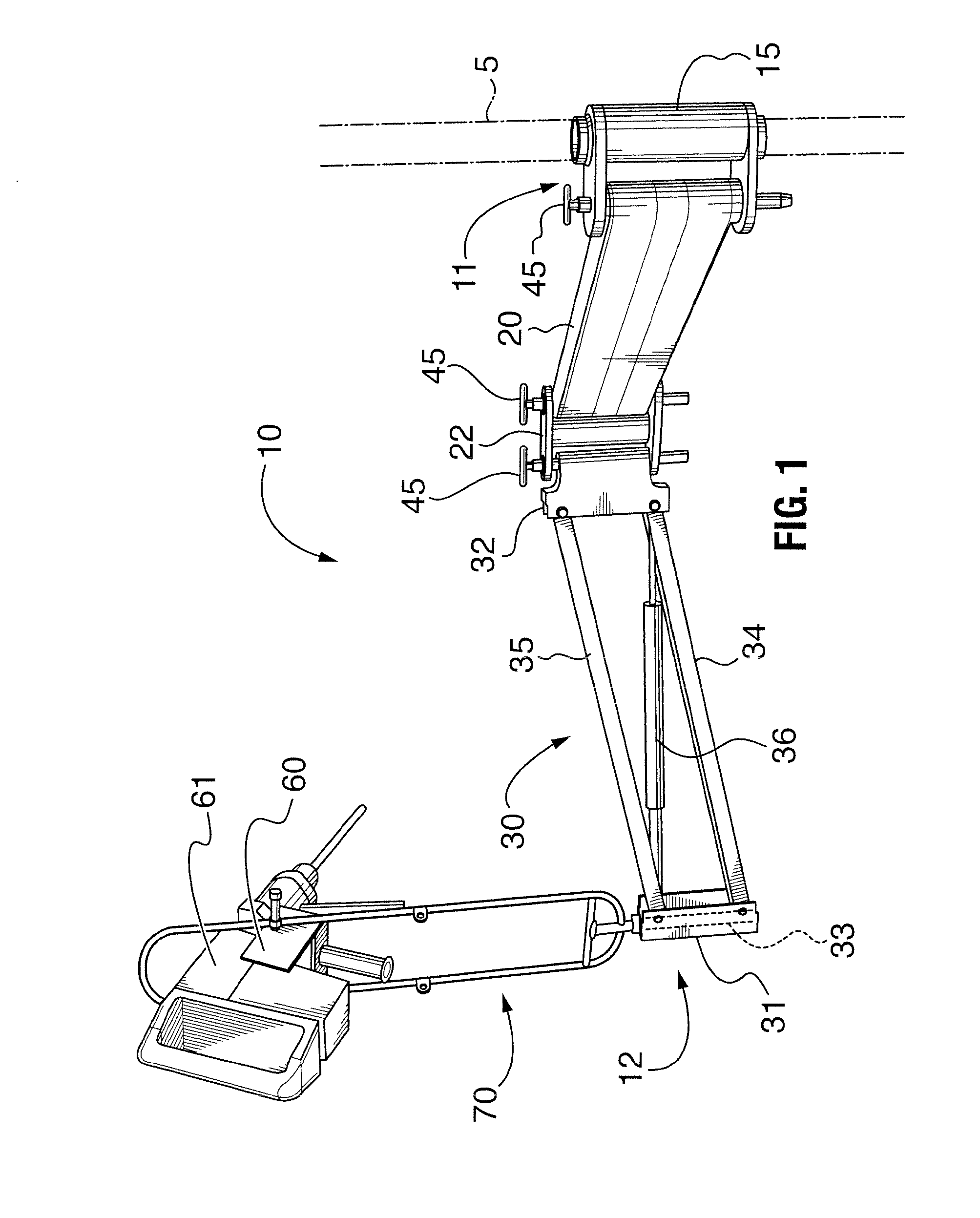

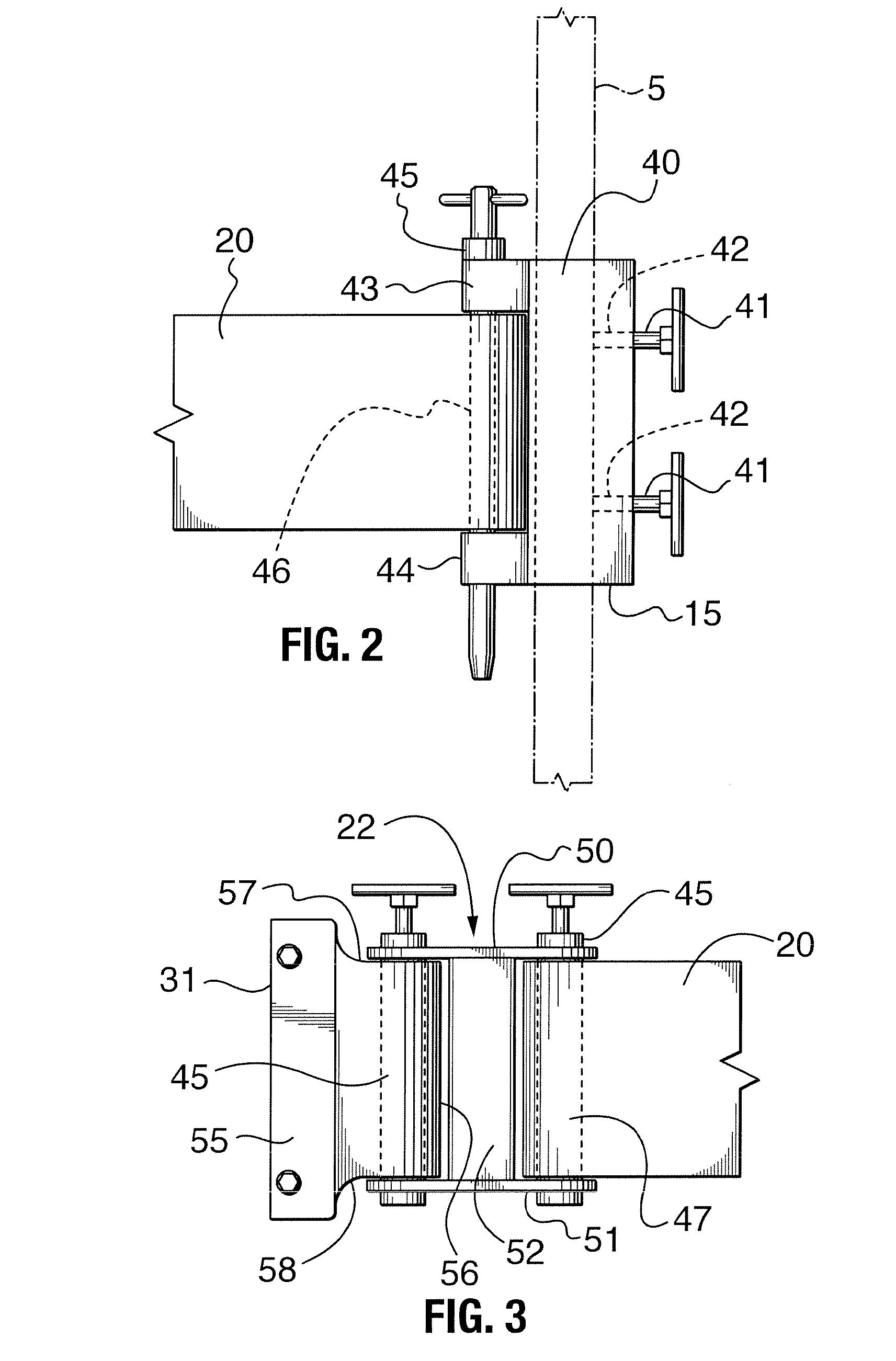

A portable multiple-component articulating support apparatus for engaging, moving, orientating and manipulating a hand-operated power tool within and throughout a three-dimensional workspace. The apparatus includes a clamping device for demountable engagement with a structural element, an elongate double-link hinge member, a spacer arm having opposite ends adapted for detachable engagement and rotational communication with the clamping device and the double-link hinge member, a vertically disposed pivotably connected counterbalance arm assembly adapted for detachable engagement and rotational communication with the double-link hinge member. The counterbalance arm assembly is equipped with a gas-charged cylinder for balancing the weight of hand-operated power tools. The clamping device, spacer arm, double-link hinge and counterbalance arm assembly are interconnected with removable hinge pins. A tool-mounting bracket is provided for gripping engaging a power tool. The tool-mounting bracket pivotably engages a power tool-bearing member which slidingly and rotatably communicates with the counterbalance arm assembly.

Owner:EKSO BIONICS

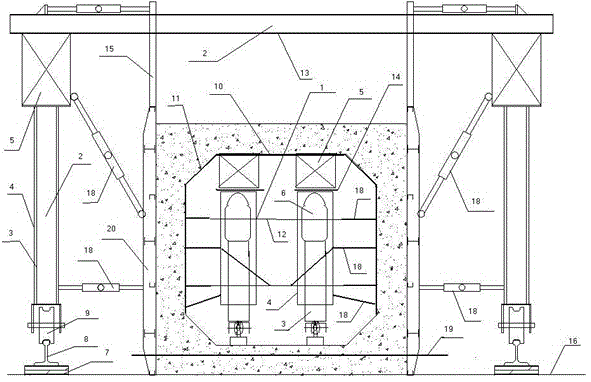

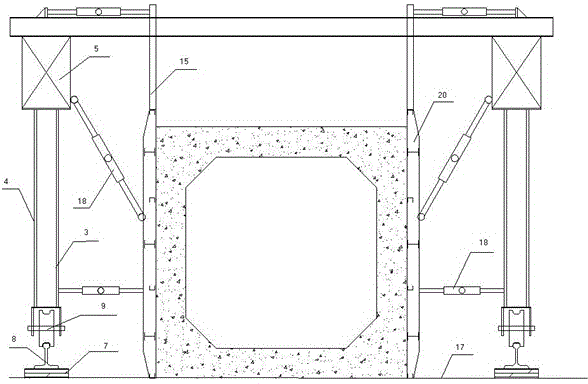

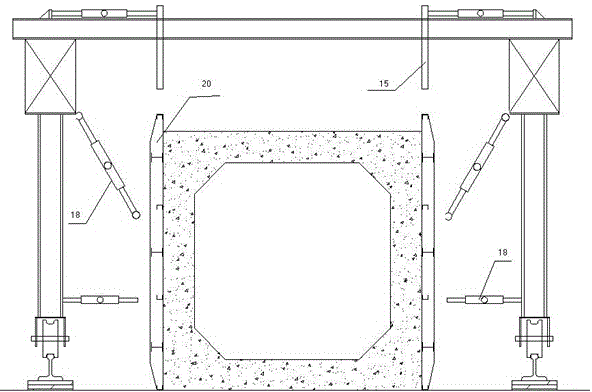

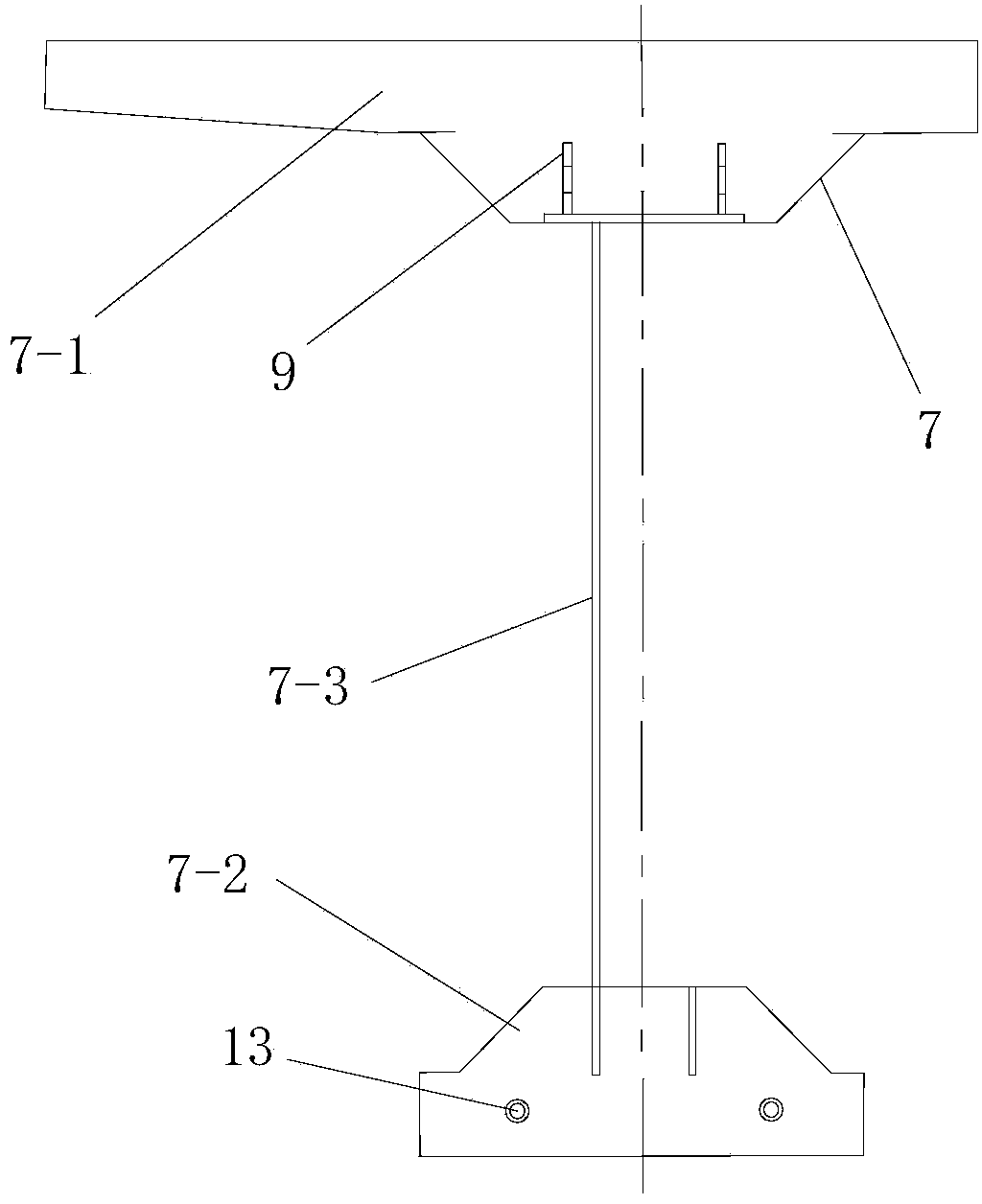

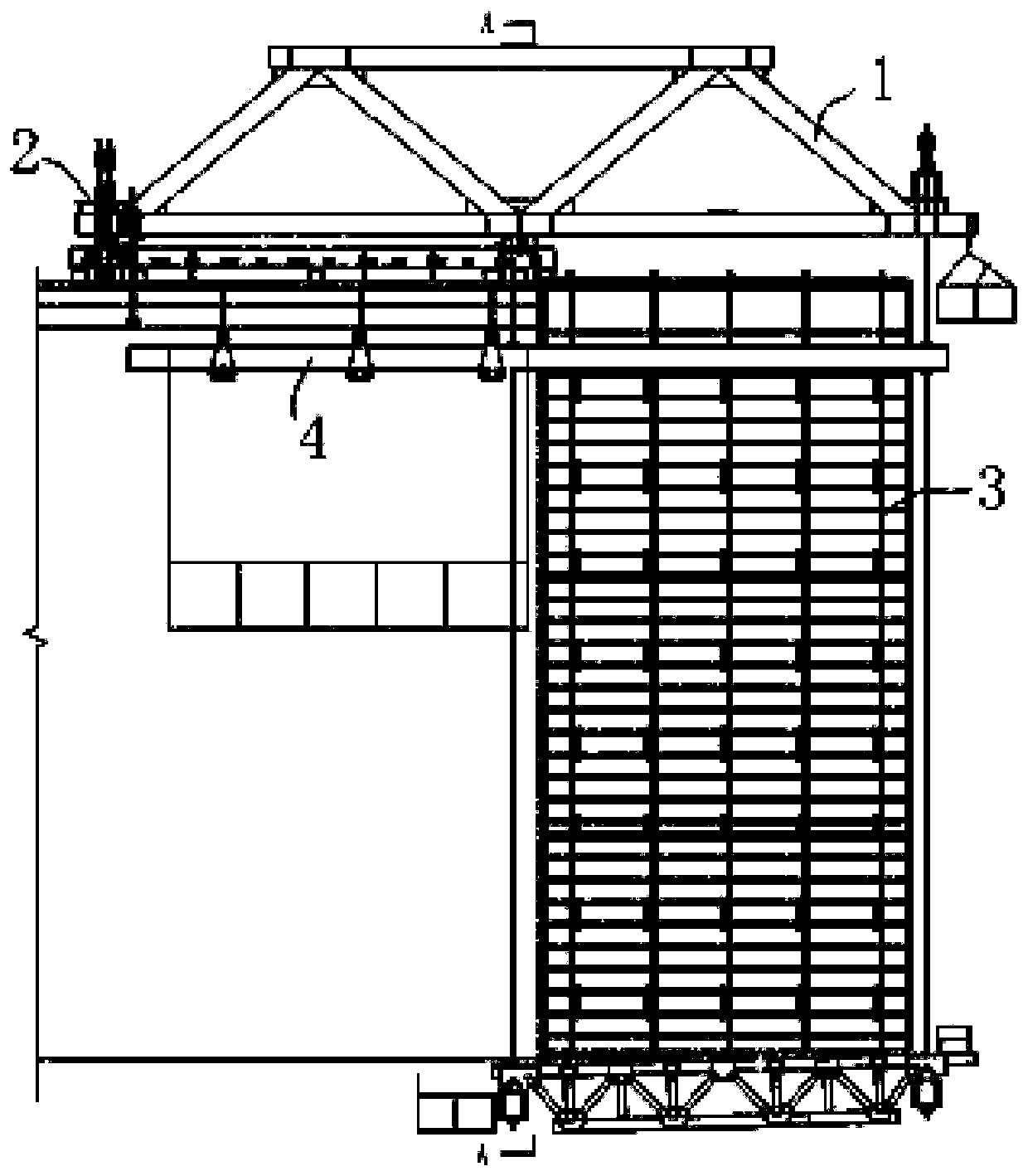

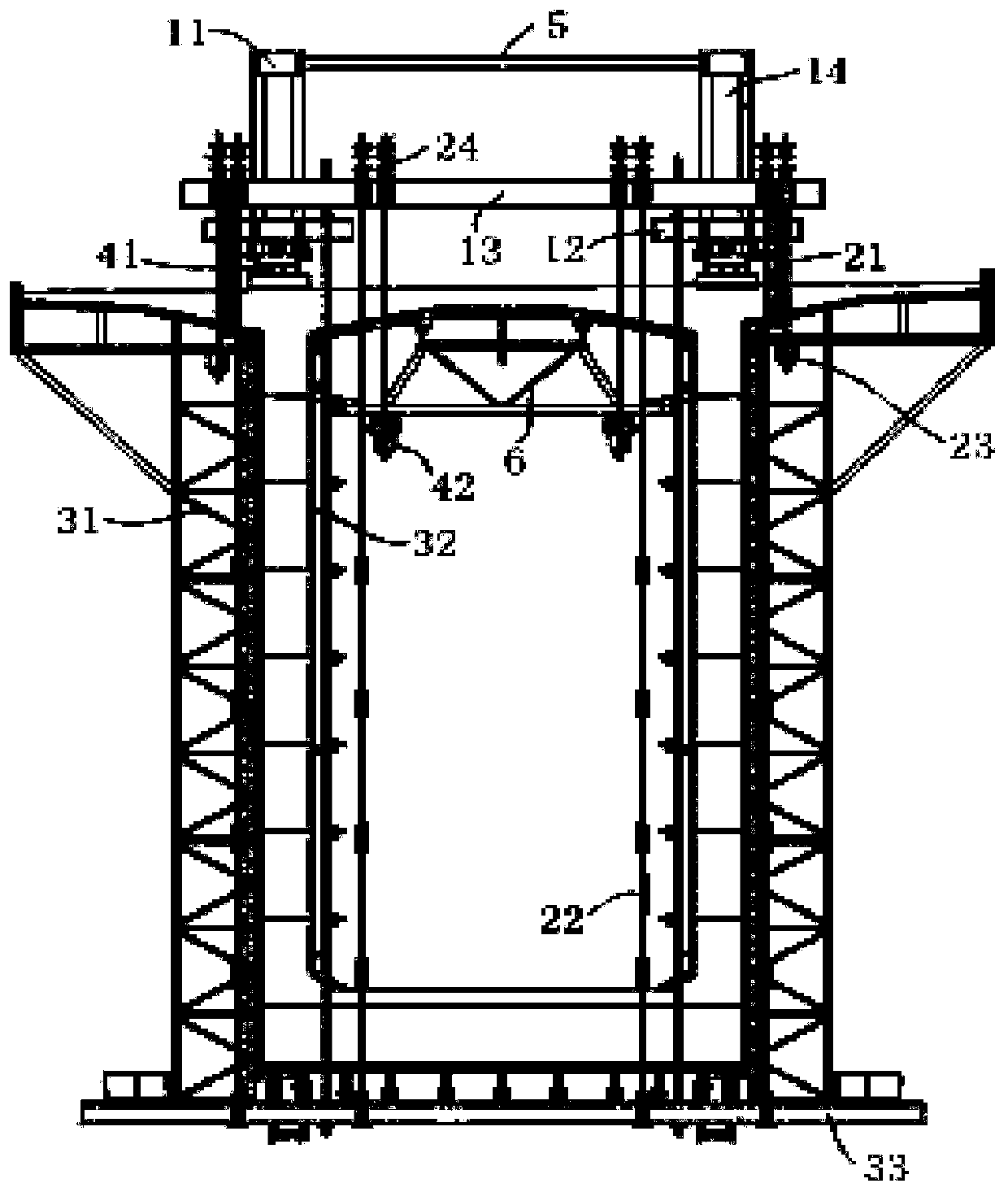

Modularization steel die trolley and construction process thereof

ActiveCN104895584AExcellent anti-rustEasy to remove formworkUnderground chambersTunnel liningSupporting systemEngineering

The invention provides a modularization steel die trolley and a construction process thereof. The trolley comprises an inner die trolley and an outer die trolley. The inner die trolley is of a semi-closed steel structure and comprises a support elevating system and a walking system. The outer die trolley also comprises the same support elevating system and the same walking system. The inner die trolley also comprises a support template. The outer die trolley also comprises a support system, an outer support template and a lead screw. According to the invention, one set of special outer die trolley door frame can be used with multiple sets of common template assemblies.

Owner:金中天建设集团有限公司

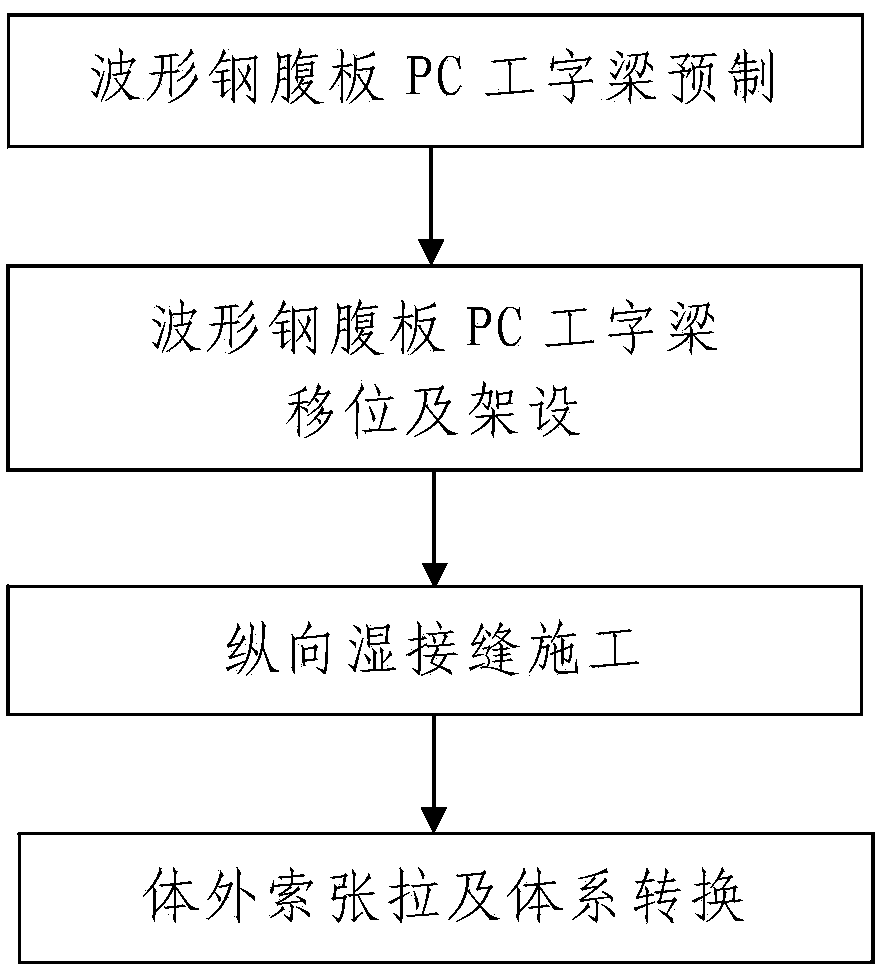

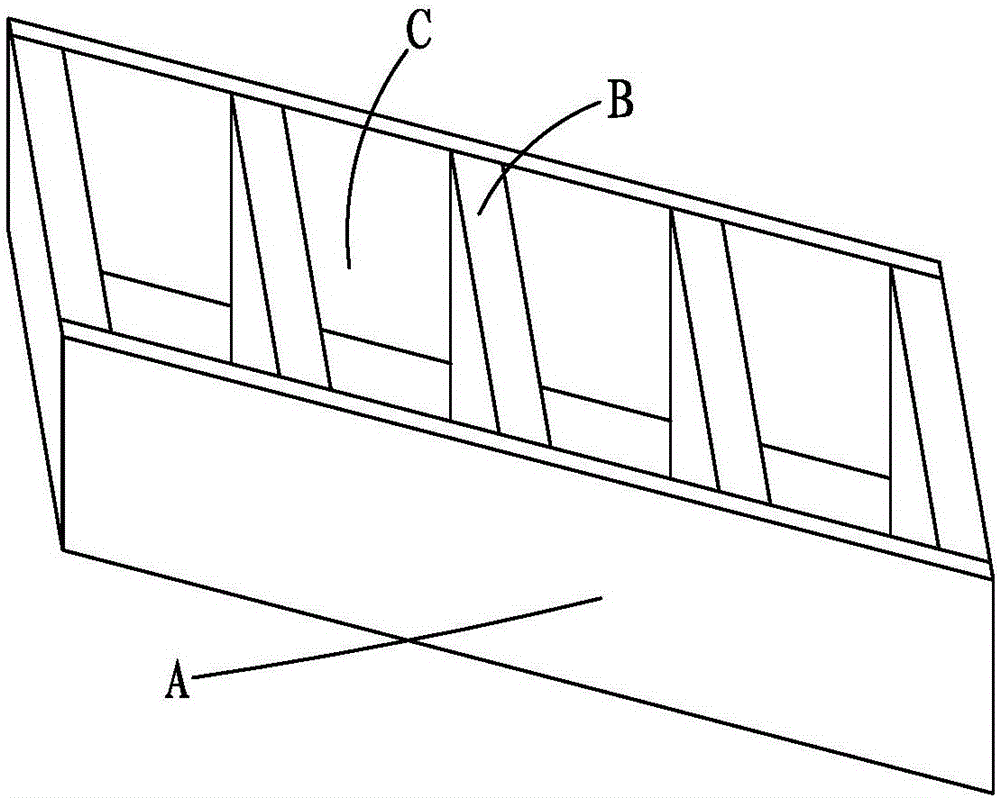

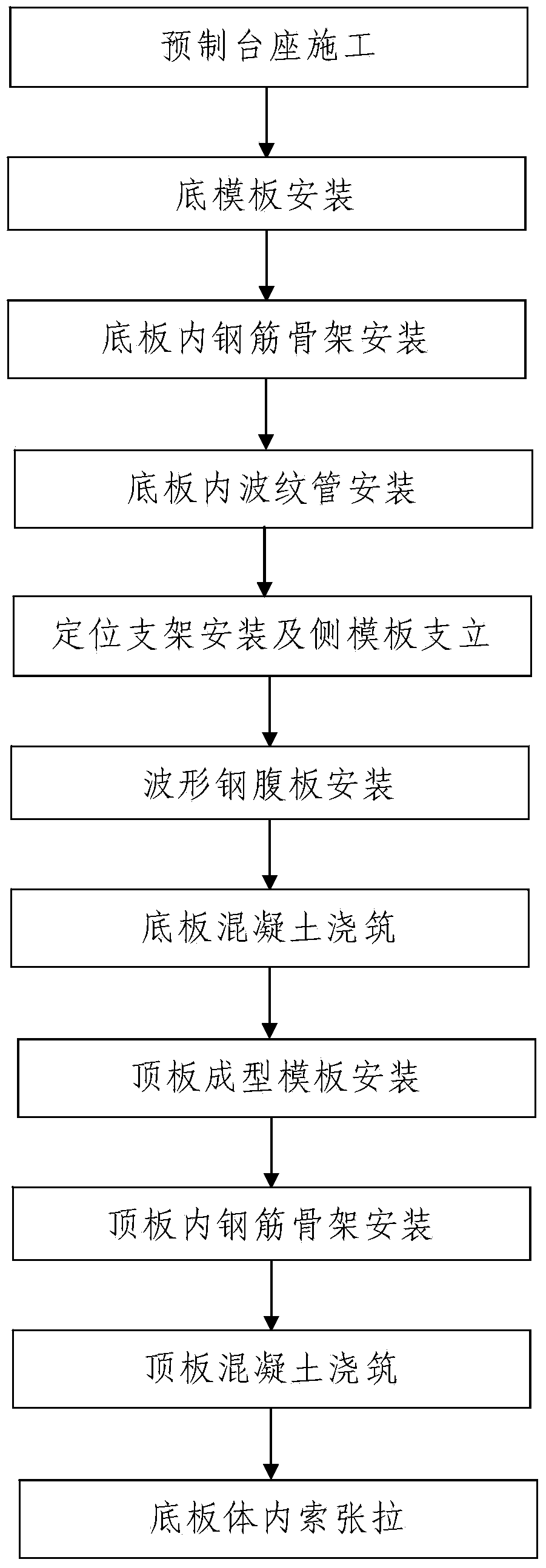

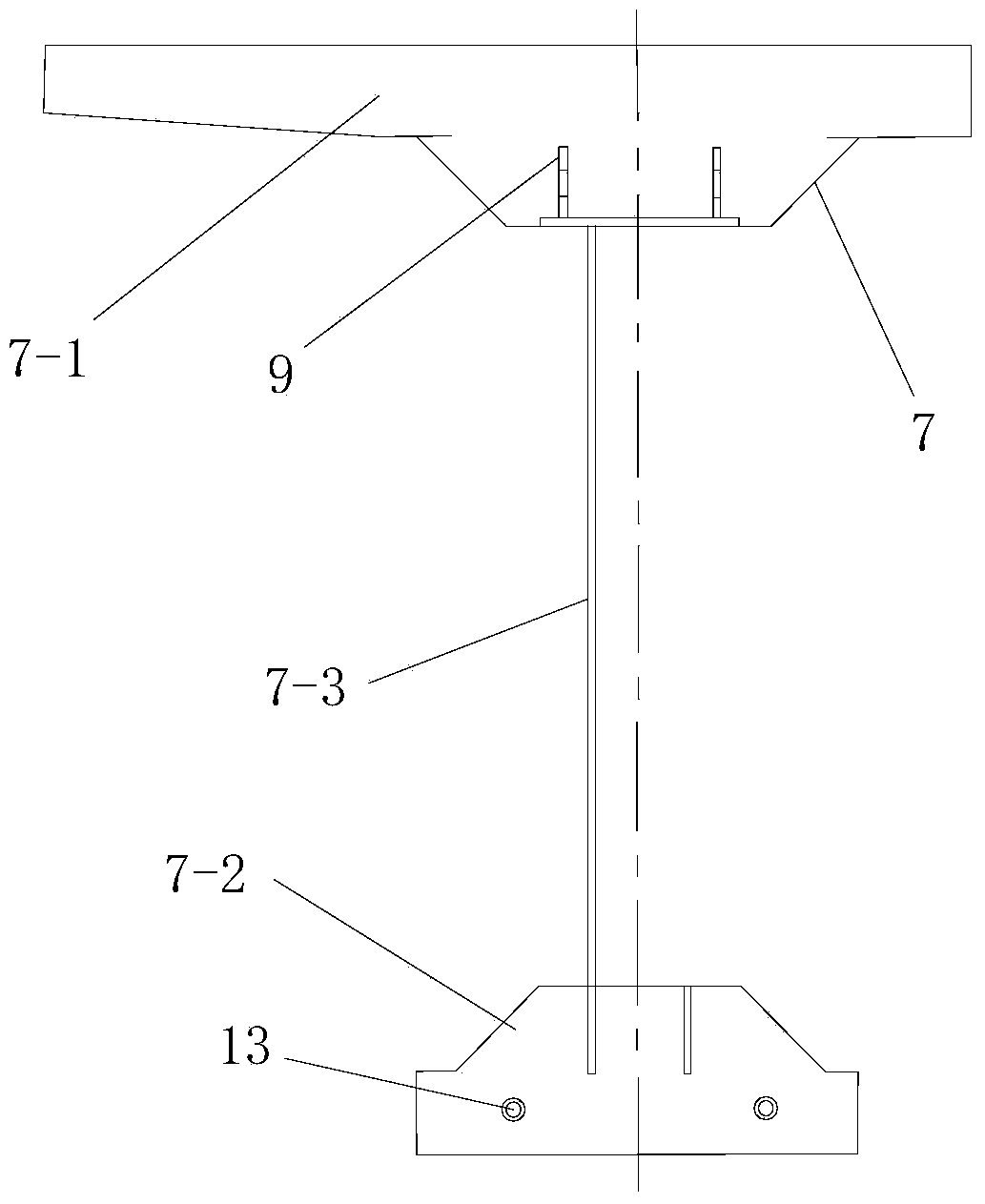

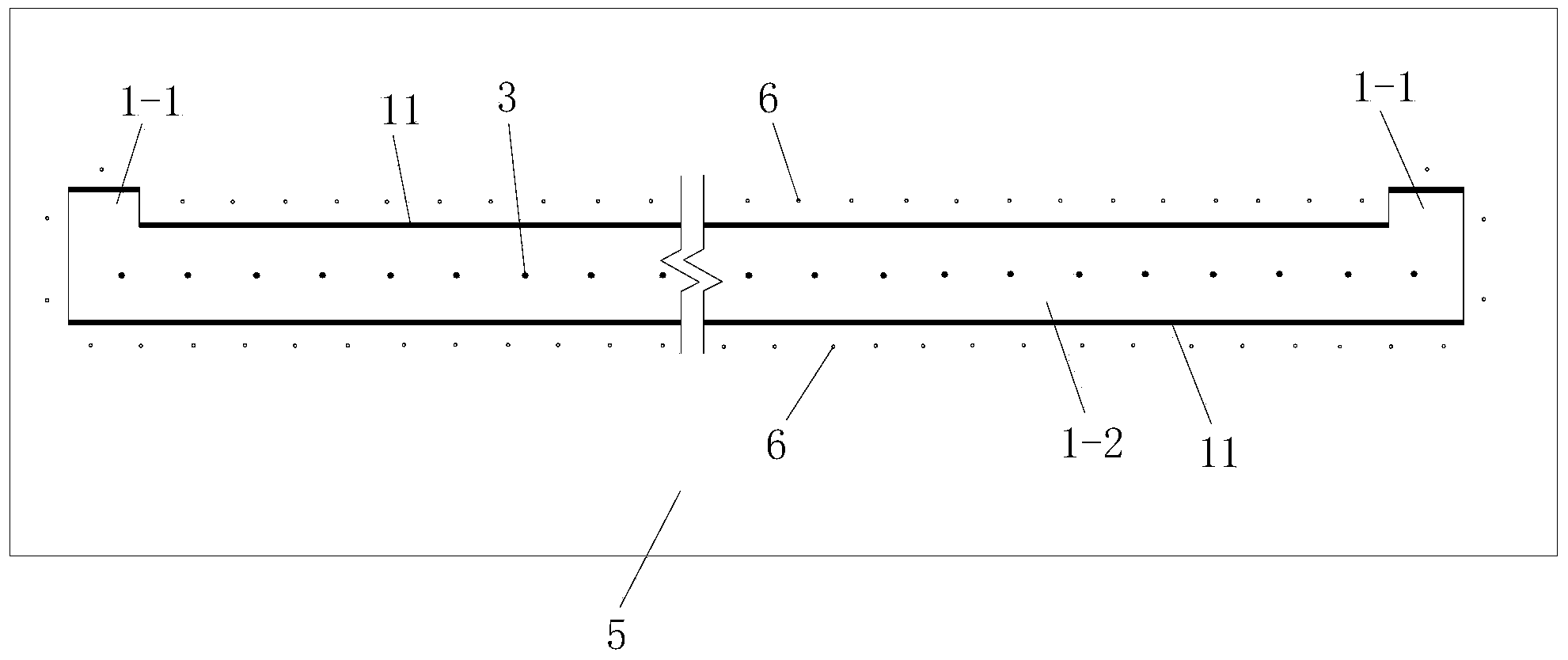

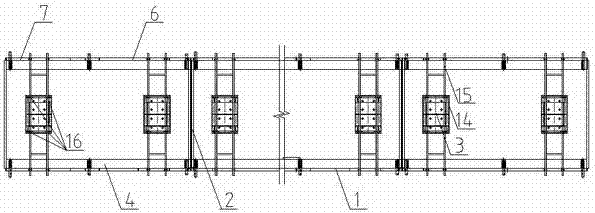

Construction technology for prefabricating a corrugated steel web PC I beam into combined box girder bridge

ActiveCN104195959ASimple structureEasy constructionBridge erection/assemblyBridge materialsEngineeringRebar

The invention discloses a construction technology for prefabricating a corrugated steel web PC I beam into a combined box girder bridge. Each combined box girder segment in a combined box girder of the combined box girder bridge is formed by connecting two corrugated steel web PC I beams. The construction technology comprises the following steps: Step I, prefabricating the corrugated steel web PC I beams: pedestal prefabricating construction, installation of a soffit formwork, installation of a reinforcement cage in a bottom plate, installation of a corrugated pipe in the bottom plate, installation of a positioning bracket and erection of a side formwork, installation of a corrugated steel web, pouring of concrete on the bottom plate, installation of a top plate molding template, installation of the reinforcement cage in a top plate, pouring of concrete on the top plate, and stretch-drawing of a cable in the bottom plate; Step II, displacement and erection of the corrugated steel web PC I beams; Step III, lengthways wet joint construction; Step IV, stretch-drawing of a cable out of the bottom plate and system conversion. According to the invention, the processing steps are simple, the design is reasonable, the implementation is convenient, the construction period is short, the construction quality is high, pedestal prefabricating and the positioning bracket are combined to complete bridge prefabrication, and the construction quality of the combined box girder bridge can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

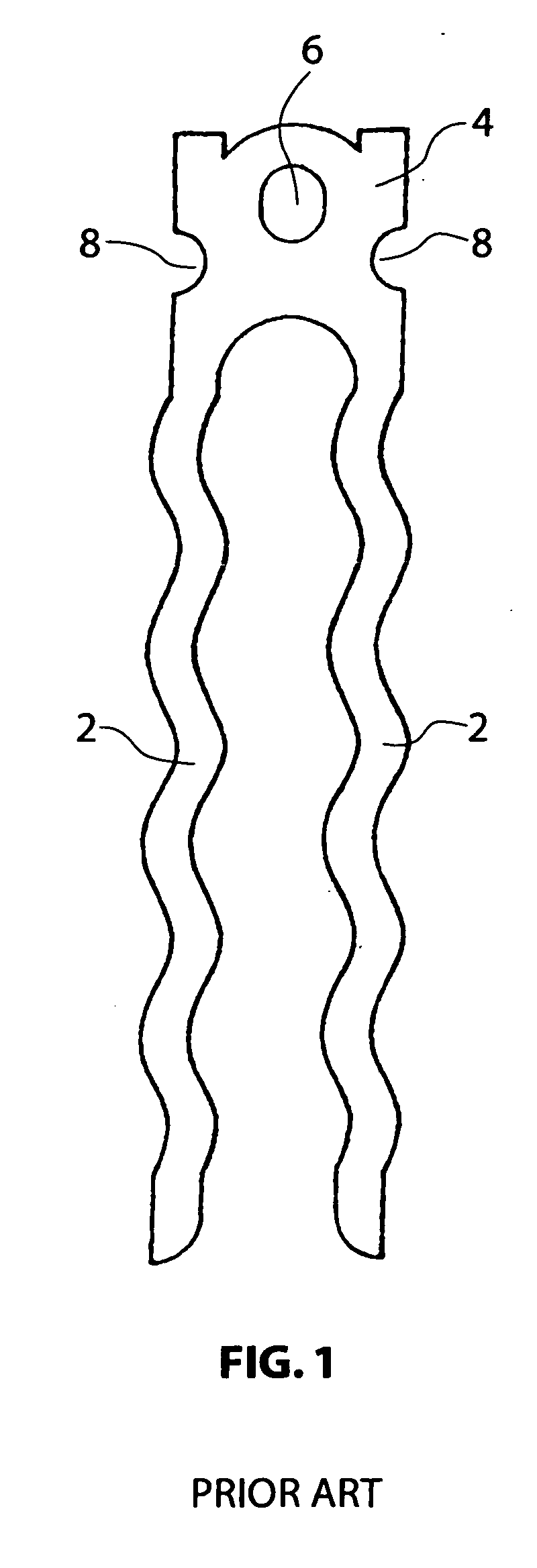

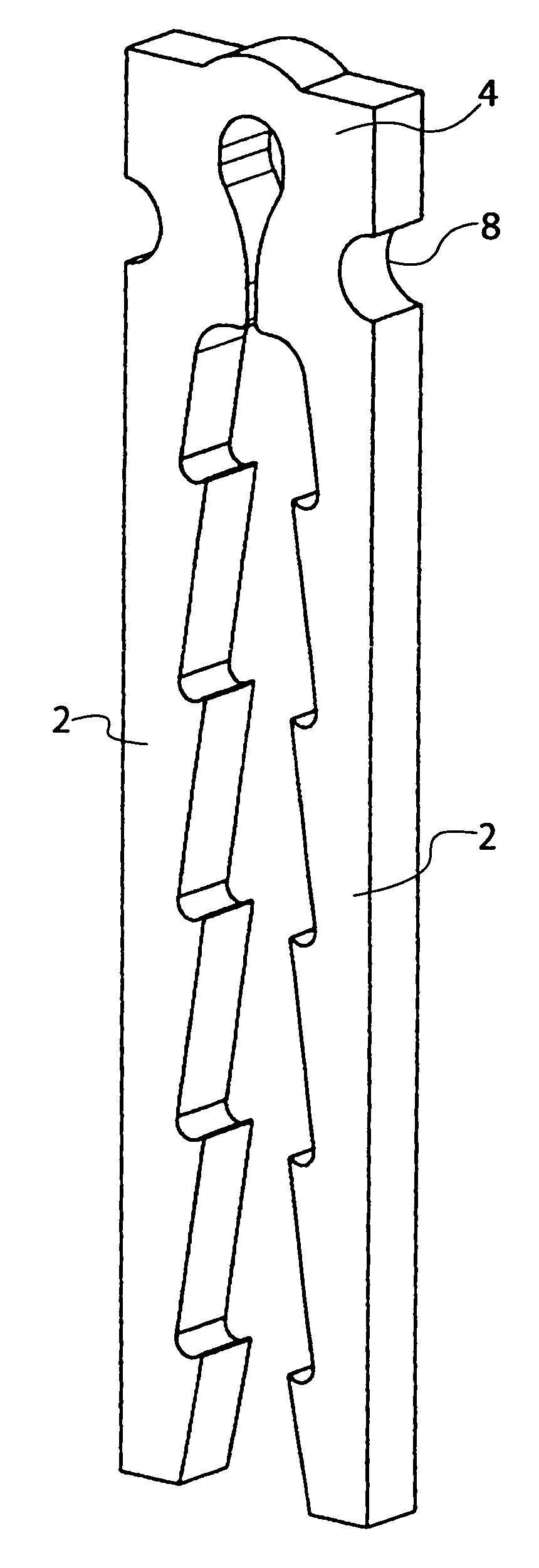

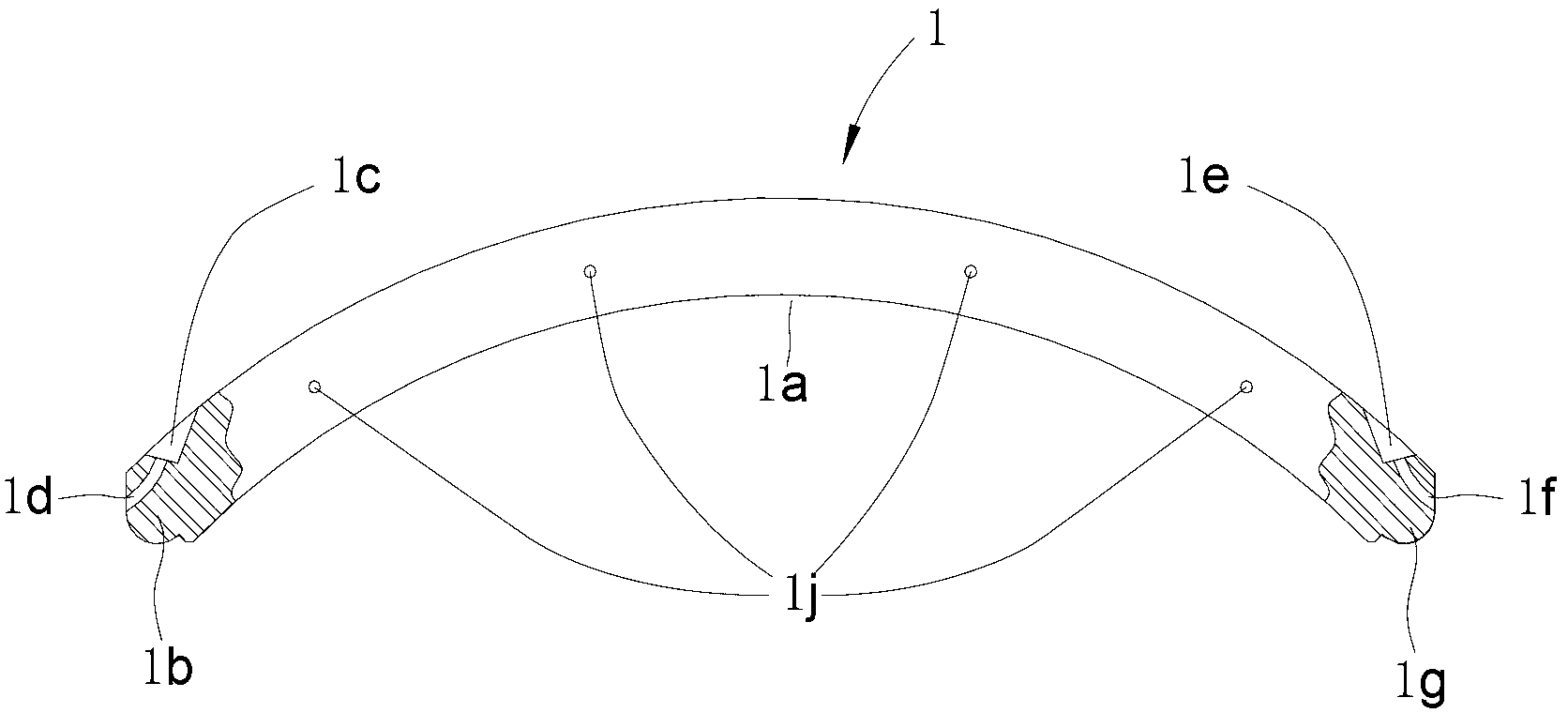

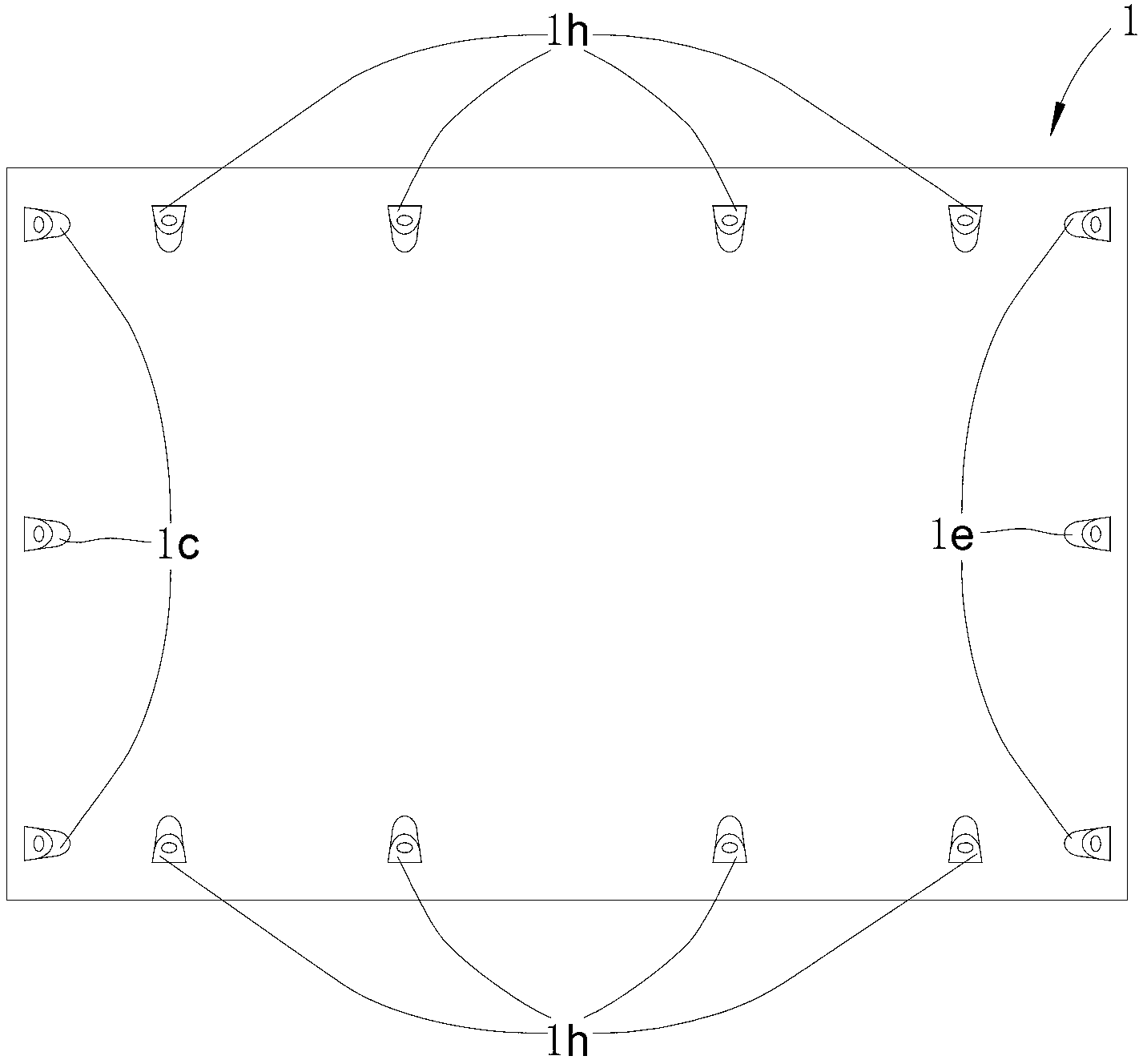

Cast-in anchors

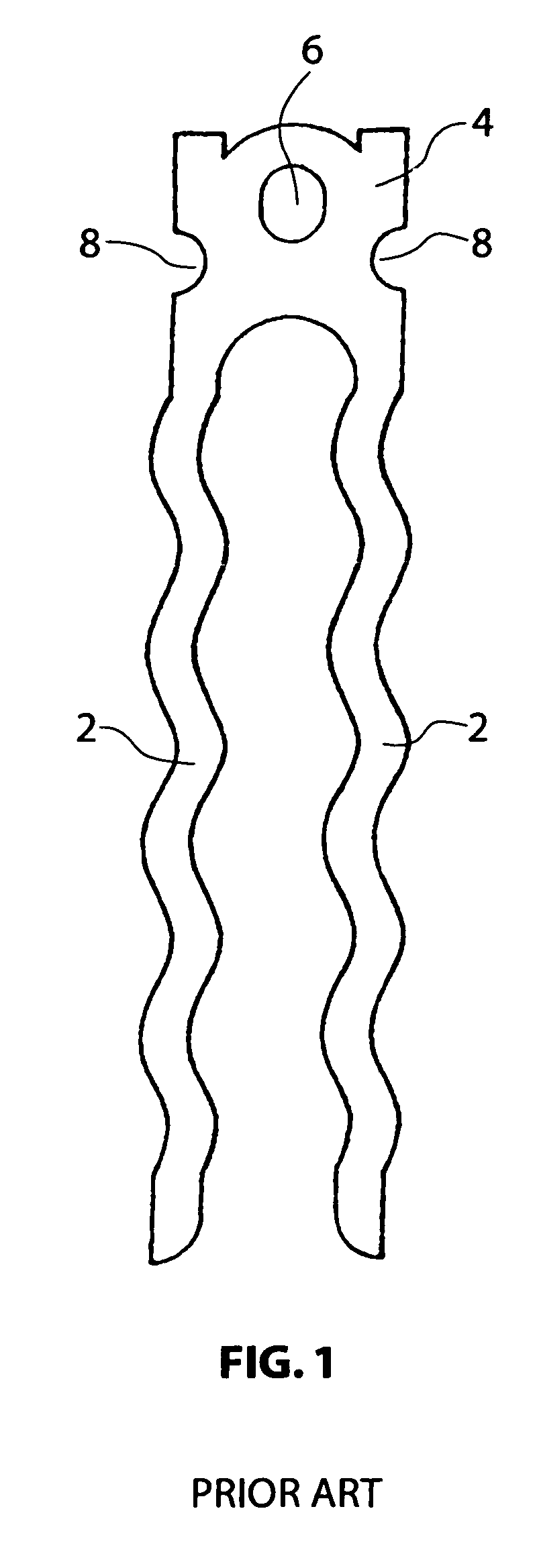

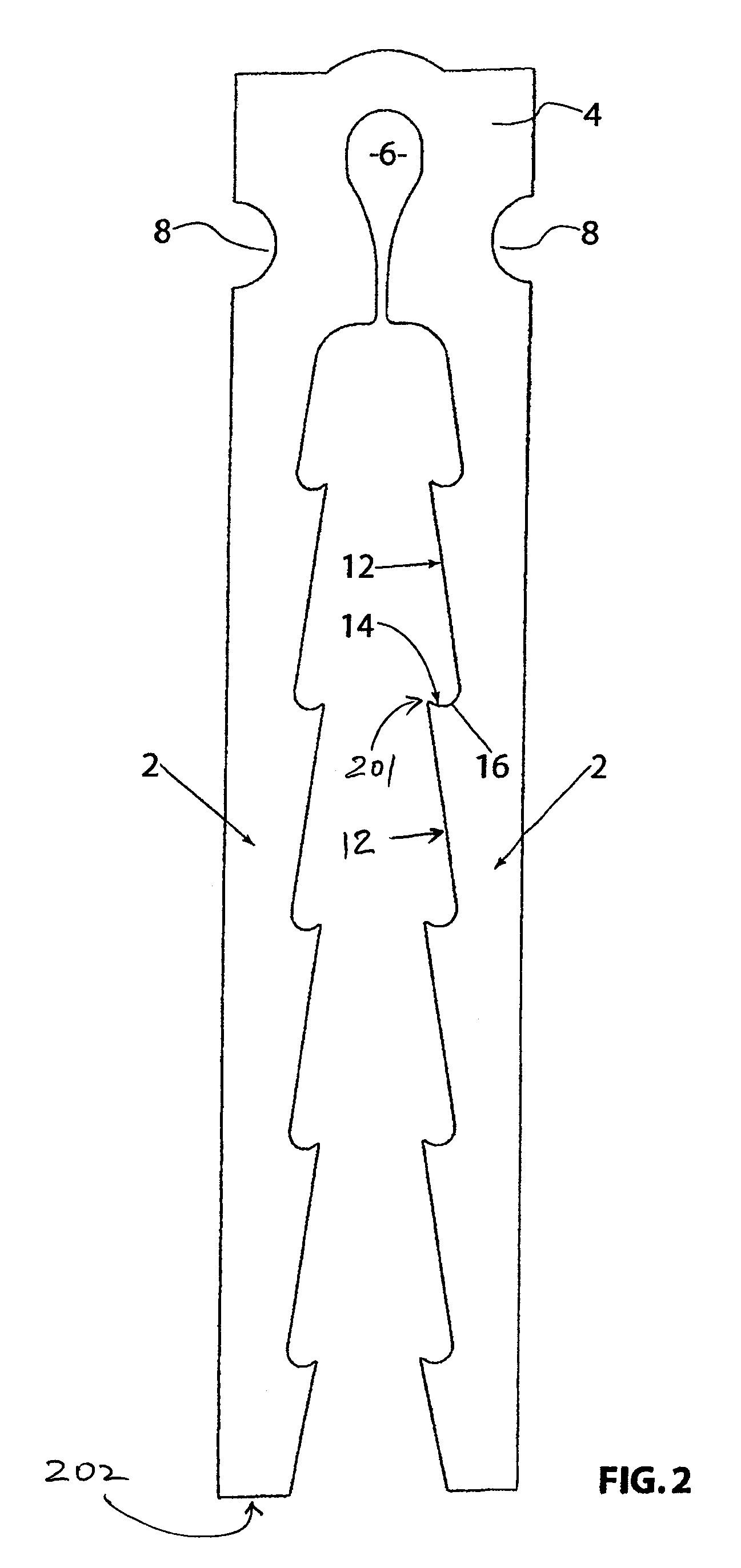

ActiveUS20060248813A1Quick cutAccomplished significantly more quicklyStaplesFoundation engineeringLeading edgeEngineering

An anchor for embedment into a concrete component, has a head via which load is applied to the anchor in use and an anchoring formation provided by at least one leg extending from the head and profiled along an edge thereof so as to lock into the surrounding concrete. The profile is formed by a series of longitudinally spaced formations each of generally saw-toothed shape with a leading edge of each formation inclining towards the head such that on application of a pulling load to the head the leg will lock tighter into the concrete with increasing load. In one form the anchor is a lifting anchor and having a pair of such legs extending from the head which is adapted for releasable engagement with lifting equipment, and the profile is formed along an inner edge of each of the legs. In an alternative form the anchor is a plate anchor in which the head of the anchor is formed by a plate and a set of such legs extends from each of two opposite sides of the plate transversely to the plane of the plate. Each set of legs comprises at least two parallel legs and the profile is formed along an inner edge of each of said legs.

Owner:ILLINOIS TOOL WORKS INC

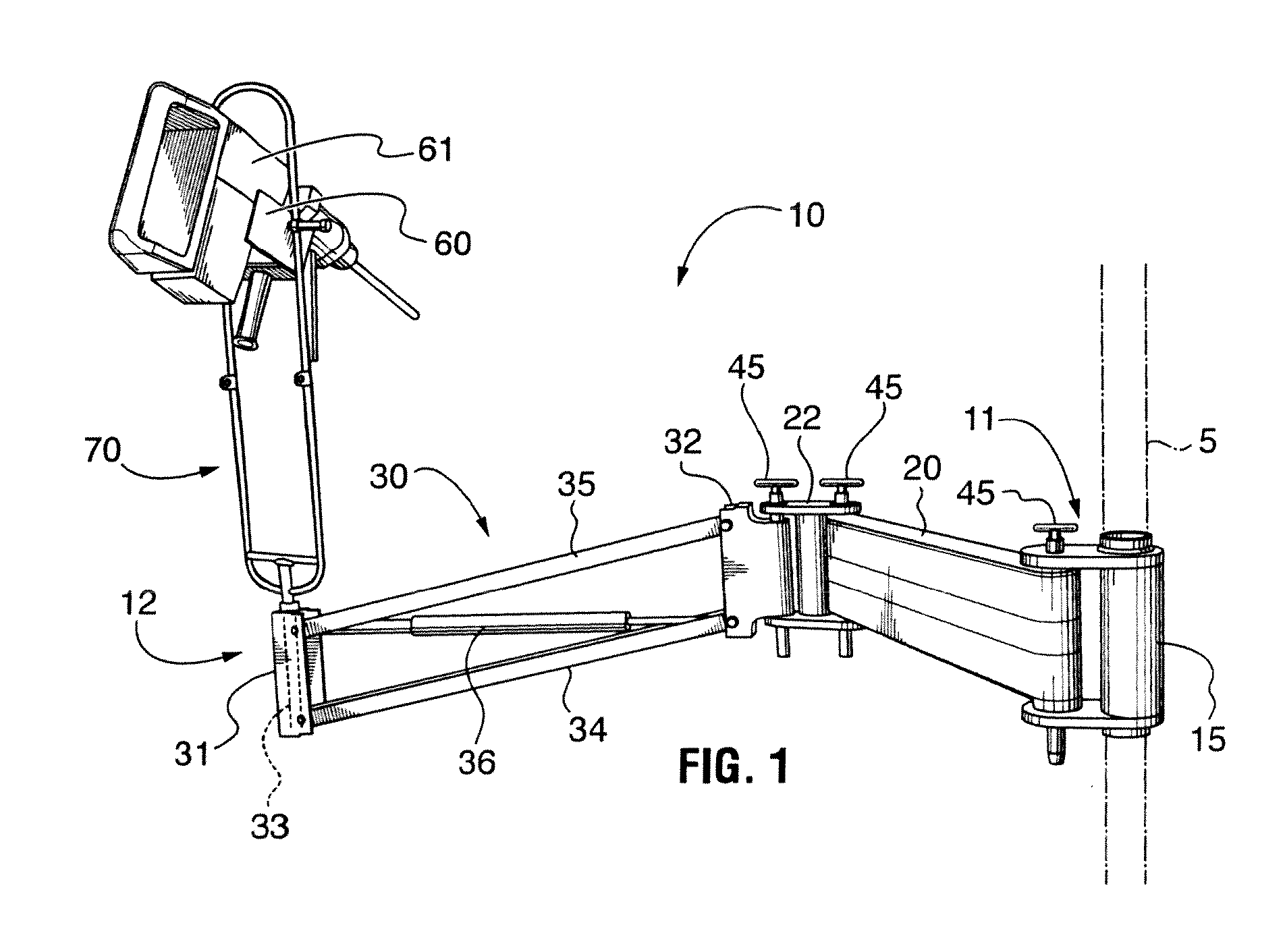

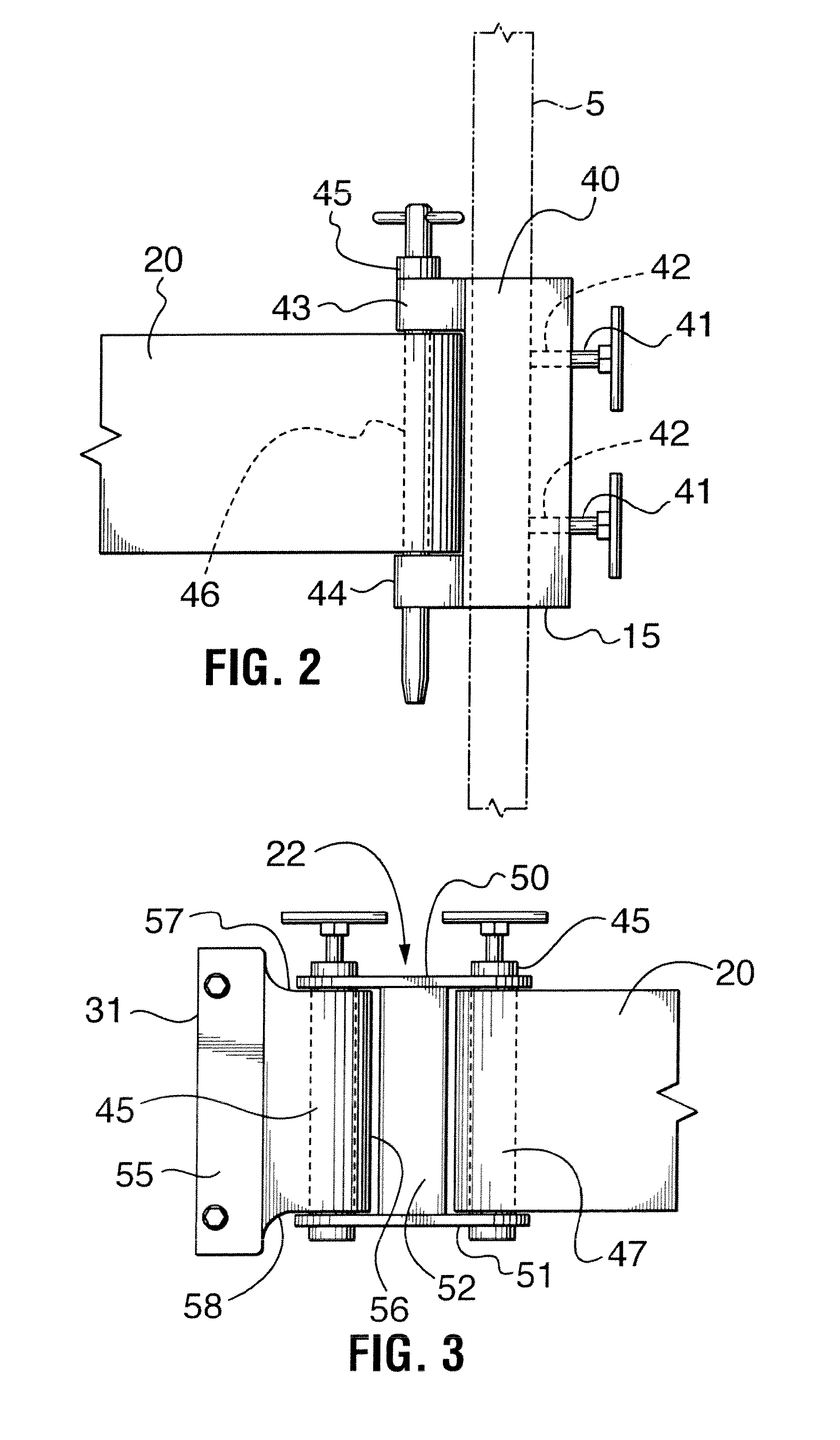

Portable articulationg tool support

InactiveUS20070237572A1Improve usabilityQuick assemblyYielding couplingCouplings for rigid shaftsEngineeringPower tool

A portable multiple-component articulating support apparatus for engaging, moving, orientating and manipulating a hand-operated power tool within and throughout a three-dimensional workspace. The apparatus includes a clamping device for demountable engagement with a structural element, one or more elongate double-axis hinge member, one or more spacer elements having opposite ends adapted for detachable engagement and rotational communication with the clamping device and the double-axis hinge member, a vertically disposed pivotably connected counterbalance arm assembly adapted for detachable engagement and rotational communication with the double-axis hinge member. The counterbalance arm assembly is equipped with a gas-charged cylinder for balancing the weight of hand-operated power tools. The clamping device, a counterbalance element, one or more spacer elements and one or more double-axis hinge elements alternating therebetween, are interconnected with removable hinge pins. A tool-mounting bracket is provided for grippingly engaging a power tool. The tool-mounting bracket pivotably engages a power tool-bearing member which slidingly and rotatably communicates with the counterbalance arm assembly.

Owner:BRITISH COLUMBIA INSTITUTE OF TECHNOLOGY

Composite building template compound system

InactiveCN106193582AReduce wasteLow costForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringButt joint

The invention provides a composite building template compound system. The composite building template compound system comprises a stair template and a closed type internal corner template. The stair template comprises blocking plates, pinking teeth, stair side plates, stair treads and stair risers. The stair treads and the stair risers are arranged sequentially from bottom to top in a staggered mode to form steps. The steps are installed between the stair side plates and the inner side faces of the pinking teeth. The outer side faces of the pinking teeth are arranged on a wall. The blocking plates are arranged at the bottoms of the pinking teeth, the stair side plates and the steps. A closed-opening type pouring space is formed among the blocking plates, the pinking teeth, the stair side plates, the stair treads and the stair risers. The upper end faces of the stair treads are provided with feed inlets. The closed type internal corner template comprises first end plates and first side plates which are connected mutually to form a cuboid. Any two adjacent first side plates are provided with a connection part and an operation part. The operation parts are connected in a butt joint mode in the intersections of the first side plates. The connection parts are provided with first connection holes. The operation parts are provided with operation holes. The composite building template compound system is a complete set of system.

Owner:郭榕来 +1

Construction method for ecological retaining wall built by self-embedded blocks

ActiveCN103774616AGood growth spacePromote ecological balanceCoastlines protectionEngineeringRetaining wall

The invention discloses a construction method for an ecological retaining wall built by self-embedded blocks. The method comprises the following steps of measuring a digging part, and digging grooves after the inspection acceptance; well doing the clearing work before the construction, and clearing surface soil and impurity soil; digging according to the requirements while clearing a field, wherein the digging comprises the following specific steps of: first clearing the surface soil, digging according to a construction operation surface needed by the retaining wall, reserving a construction platform with the width of 5m to be adjacent to an outer opening of a river, guaranteeing the smooth supply of the material needed by the construction, constructing a 40cm foundation of the retaining wall by adopting a soil mold, and building the retaining wall by utilizing self-embedded blocks. By adopting the method, not only can the ecological environmental protection effect be realized, but also a landscape function also can be realized, the factory-oriented production is realized, the labor consumption is less, the quality is easy to control, economical performance and reasonability can be realized, and the water and soil loss can be prevented.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

Low-caffeine black tea with flower fragrance and production method of low-caffeine black tea

InactiveCN102986962AReduce manufacturing costIncrease productivityPre-extraction tea treatmentTea extractionFragrance extractionBlack tea

The invention discloses a low-caffeine black tea with flower fragrance and a production method of the low-caffeine black tea, belongs to the technical field of tea processing and aims to provide a production method of the low-caffeine black tea. The production method of the low-caffeine black tea, provided by the invention, comprises the steps of fresh tea leaf rocking, rolling, fermenting, arranging-drying and fragrance extracting, wherein the rocked fresh tea leaves are rolled, fermented, arranged and dried and subjected to fragrance extraction after being subjected to high temperature desiccation.

Owner:中国测试技术研究院生物研究所

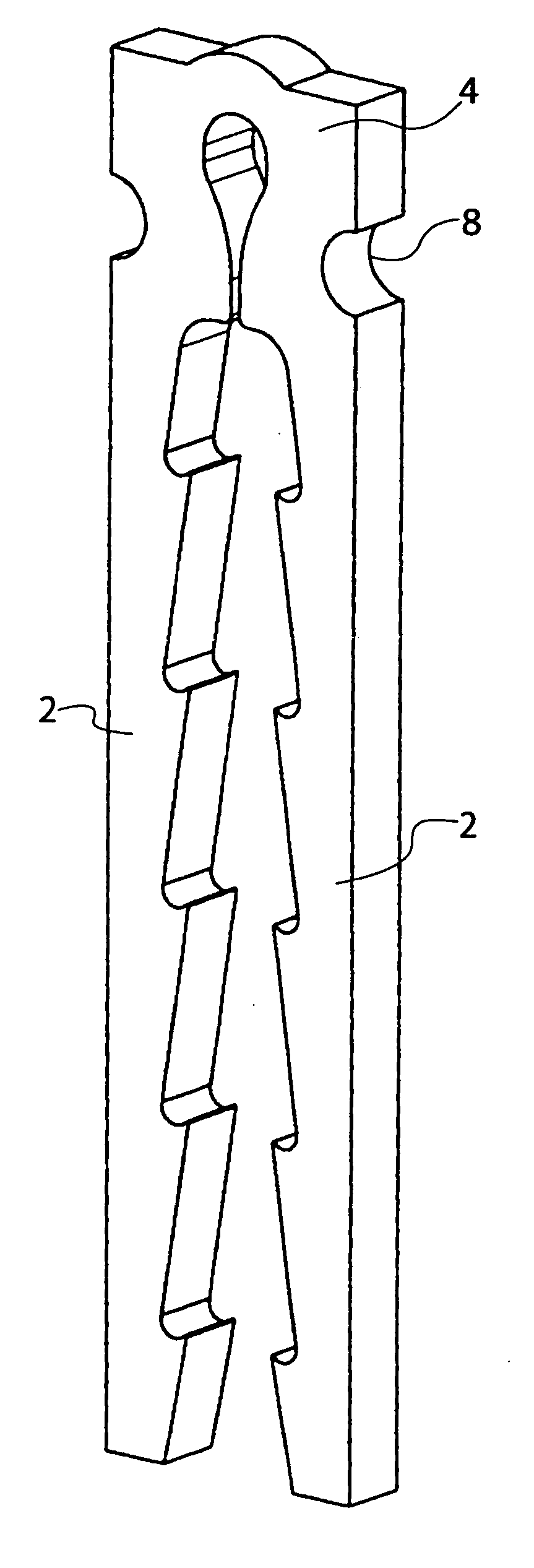

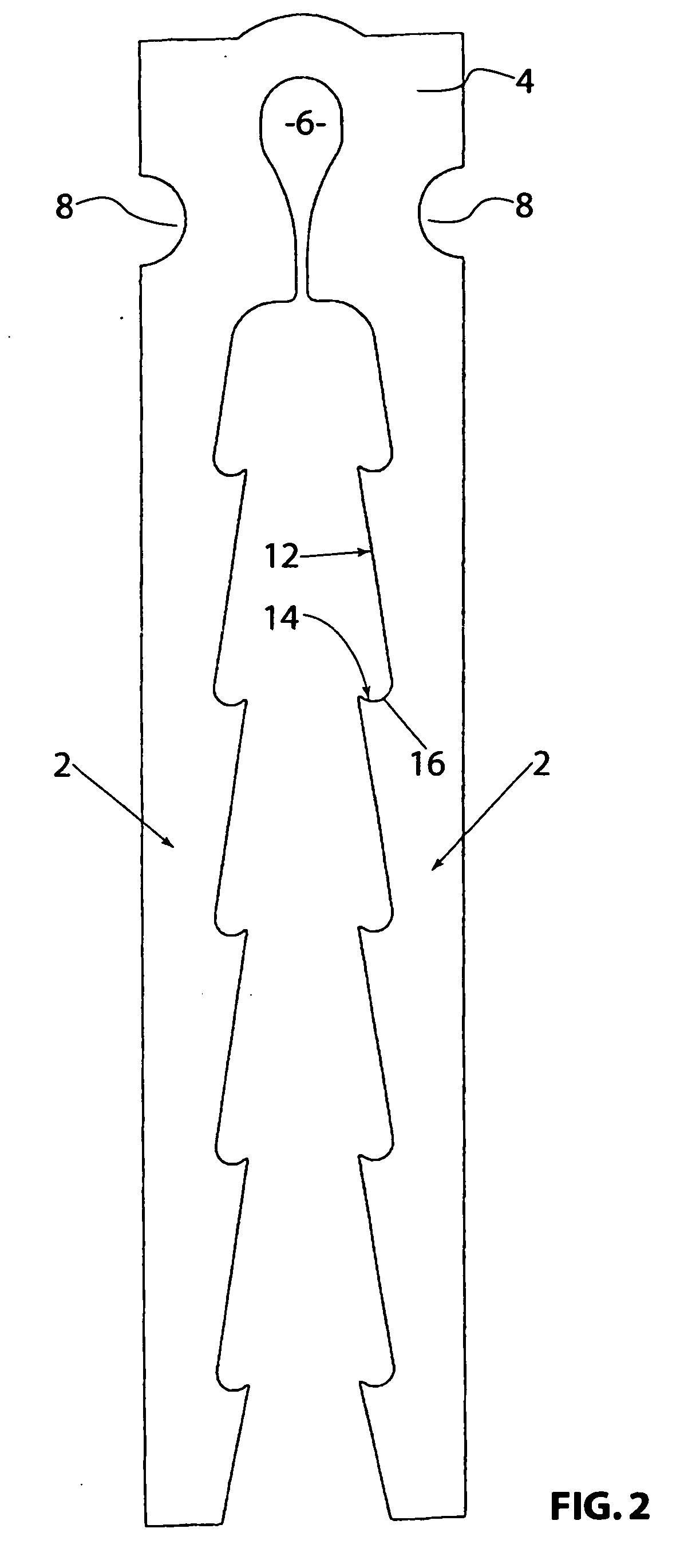

Cast-in anchors

ActiveUS7934343B2Accomplished significantly more quicklyStraight linesStaplesFoundation engineeringLeading edgeEmbedment

An anchor for embedment into a concrete component, has a head via which load is applied to the anchor in use and an anchoring formation provided by at least one leg extending from the head and profiled along an edge thereof so as to lock into the surrounding concrete. The profile is formed by a series of longitudinally spaced formations each of generally saw-toothed shape with a leading edge of each formation inclining towards the head such that on application of a pulling load to the head the leg will lock tighter into the concrete with increasing load.

Owner:ILLINOIS TOOL WORKS INC

Production method of striped stainless steel stripes

InactiveCN102000696AMeet the use requirementsImprove surface qualityRoll mill control devicesFurnace typesMetallurgySS - Stainless steel

The invention relates to a production method of striped stainless steel stripes. The production method is characterized by adopting the following process steps: grinding a general roll into a striped roll, carrying out a primary rolling process to a stainless steel stripe blank to roll the stainless steel stripe blank into a semi-finished stainless steel stripe; conveying the semi-finished stainless steel stripe into an annealing furnace and inflating protective gases, wherein the temperature in the annealing furnace is divided into six zones and a preheating section; carrying out a secondaryrolling process after finishing annealing and then annealing again; carrying out a tertiary rolling process to roll the semi-finished stainless steel stripe into a finished striped stainless steel stripe with the thickness of 0.2-0.5 mm; then, annealing the well-rolled stainless steel stripe for the last time; and finally cutting and packaging into a finished product. The invention has good surface quality, high yield, straight stripes and easily-controlled stripe depth and can satisfy the use requirements of users.

Owner:WUXI JIALIAN STAINLESS STEEL

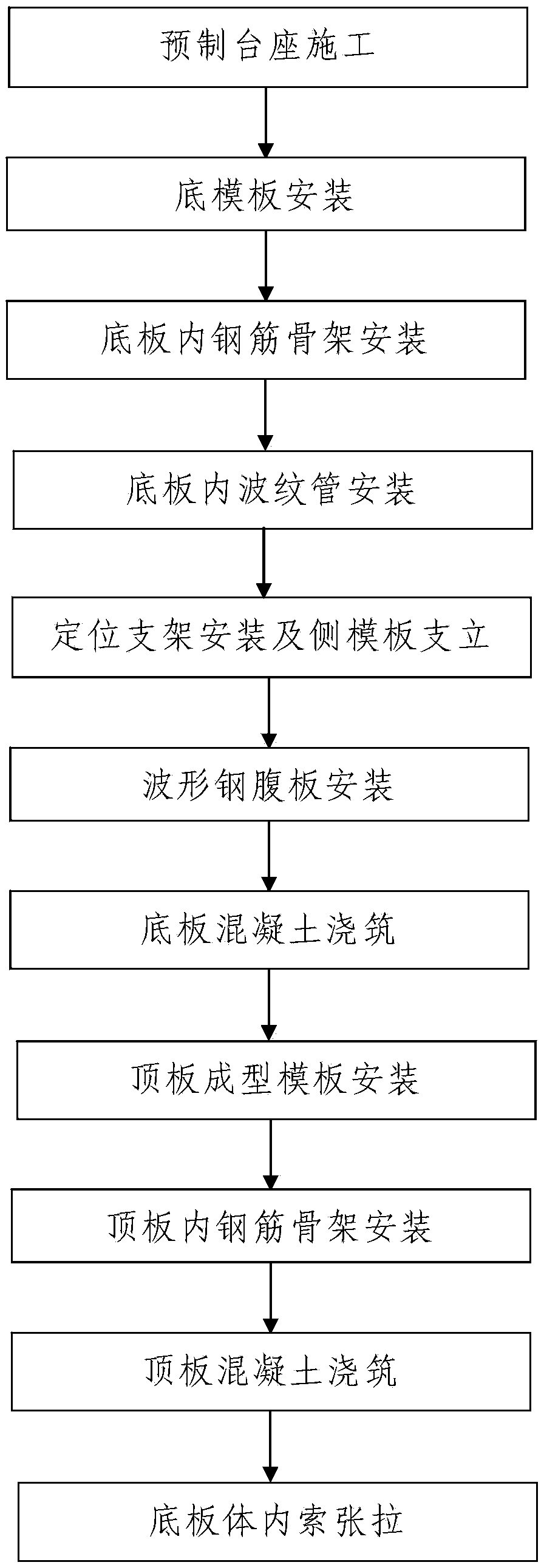

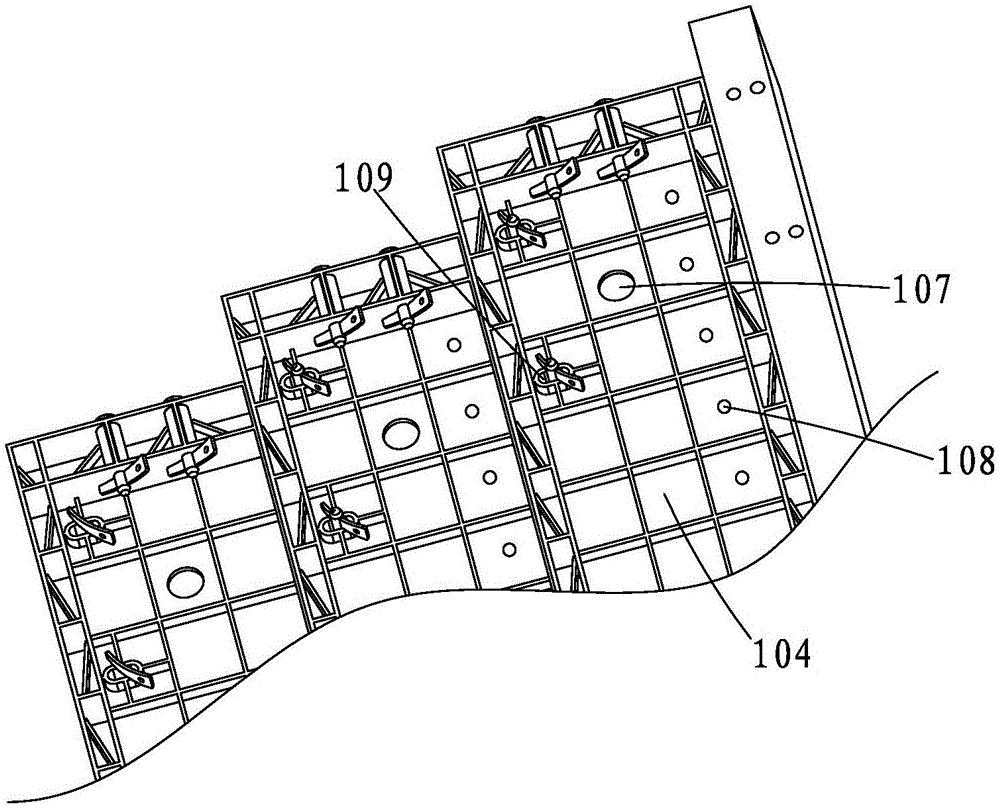

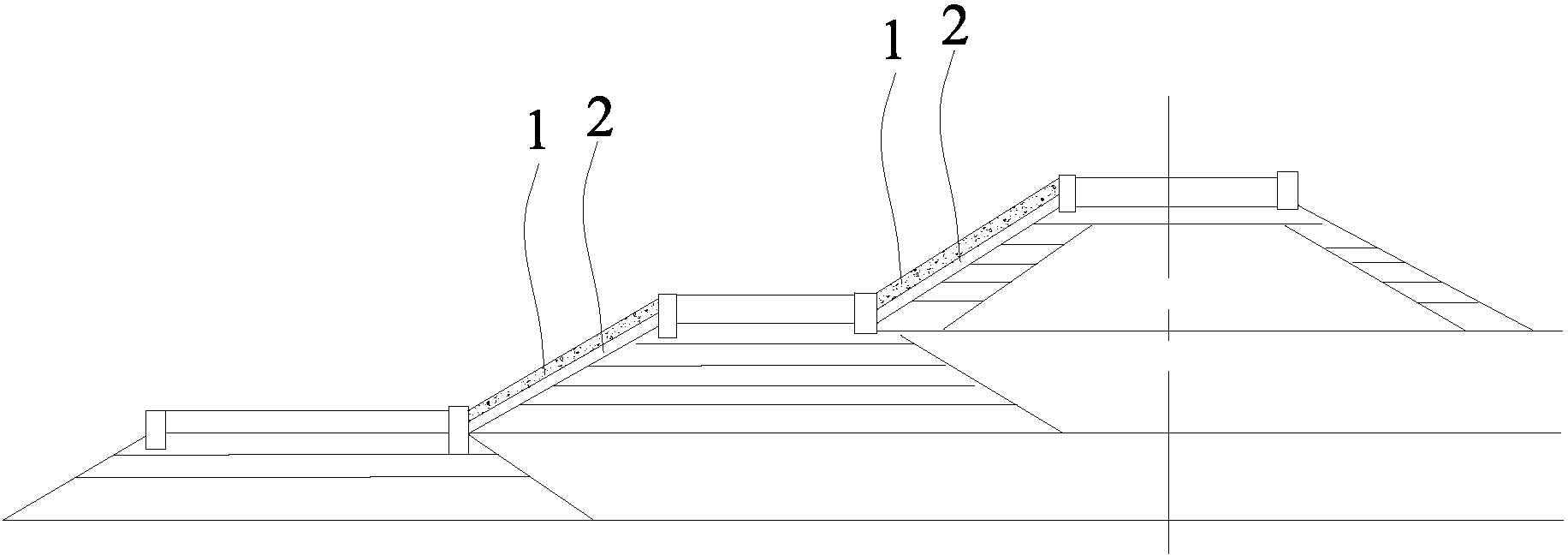

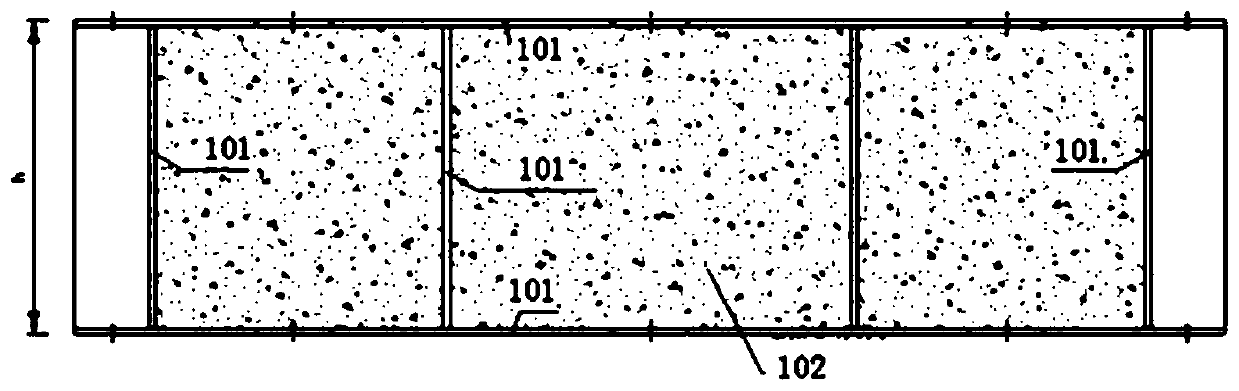

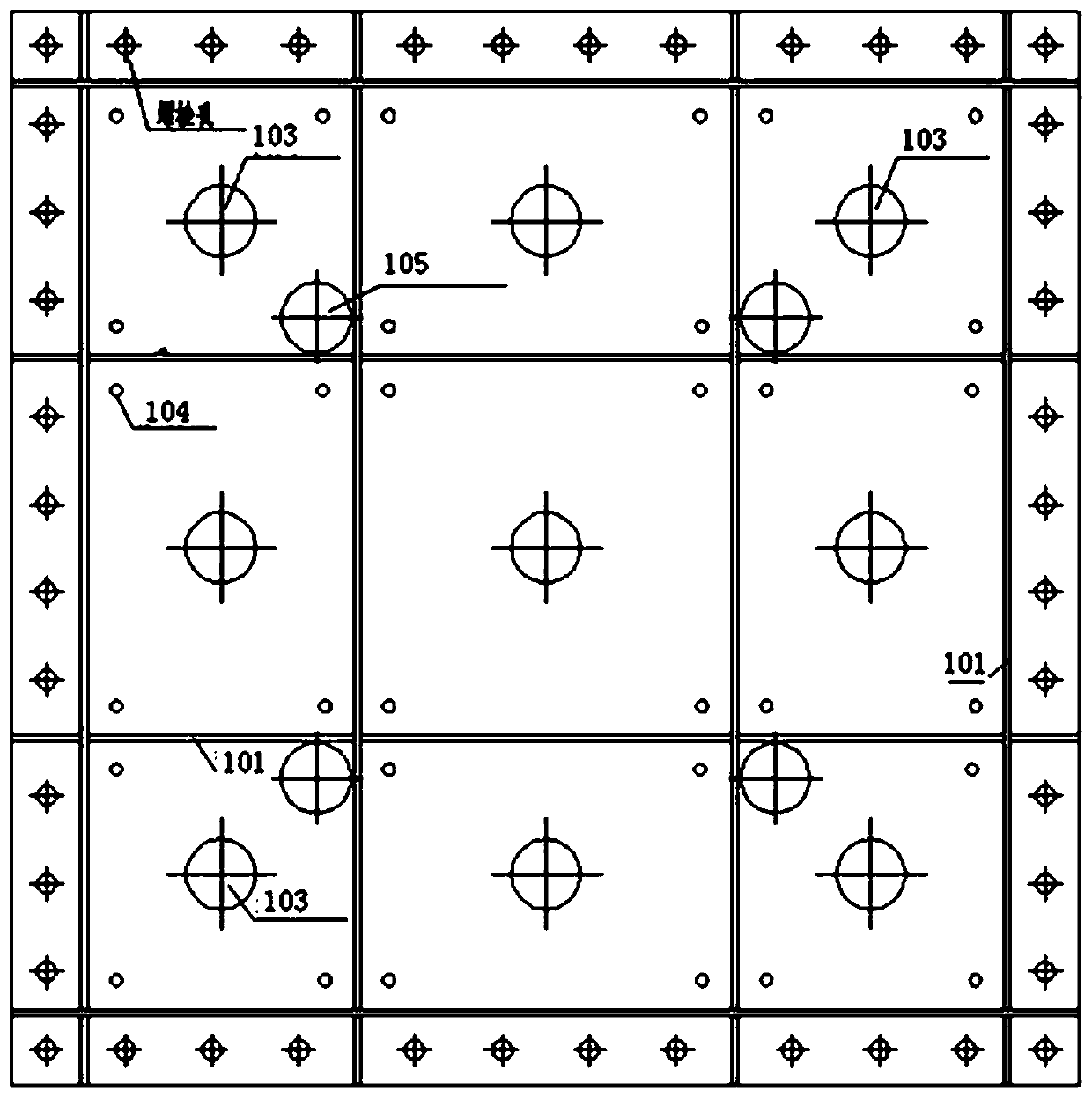

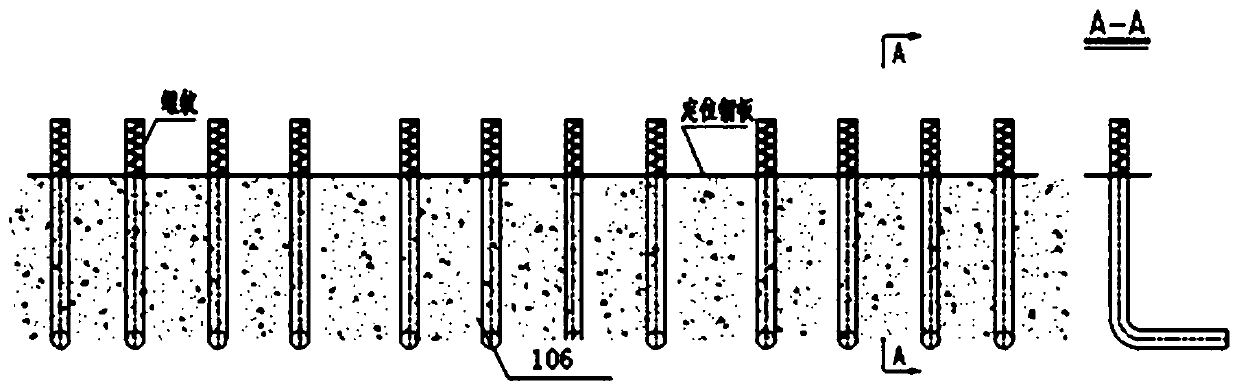

Prefabricating construction process for corrugated steel web prestressed concrete I-shaped beam

The invention discloses a prefabricating construction process for a corrugated steel web prestressed concrete I-shaped beam. The process comprises the following steps: 101, constructing a prefabricated pedestal; 102, mounting a bottom die plate; 103, mounting a reinforcement framework in a bottom plate; 104, mounting a corrugated pipe in the bottom plate; 105, mounting a positioning bracket and supporting a side die plate, wherein the positioning bracket comprises a supporting frame, and a plurality of positioning rods for positioning a corrugated steel web; 106, mounting the corrugated steel web, namely, mounting the corrugated steel web is mounted above the reinforcement framework in the bottom plate, and positioning through the positioning bracket; 107, pouring the concrete of the bottom plate; 108, mounting a top plate molding die plate; 109, mounting the reinforcement framework in a top plate; 110, pouring the concrete of the top plate; 111, stretching an inner cable in a bottom plate body. The prefabricating construction process is simple in steps, reasonable in design, convenient to implement, short in construction period, and high in construction quality; the prefabricated pedestal is matched with the positioning bracket to finish the prefabricating of a beam body, and the quality of a prefabricated beam body can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

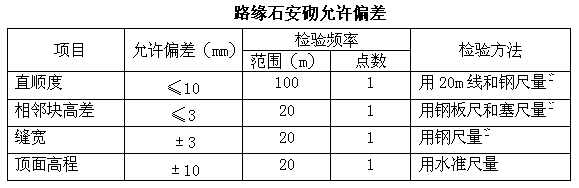

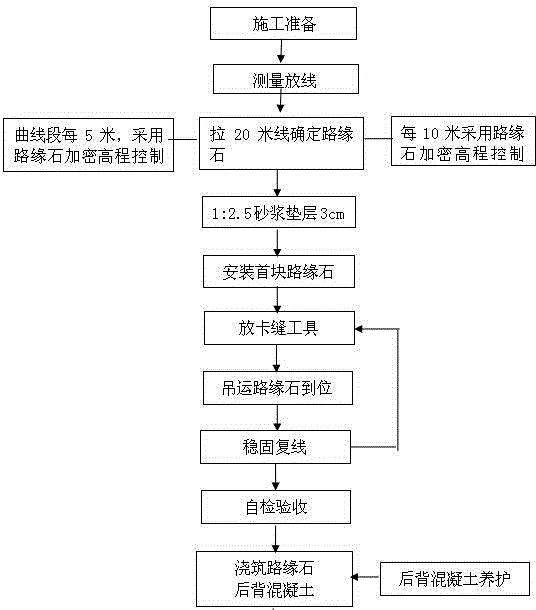

Curbstone mounting construction method

ActiveCN103233409AAvoid multiple adjustmentsImprove straightnessPaving gutters/kerbsClimate change adaptationArchitectural engineeringEconomic benefits

The invention provides a curbstone mounting construction method. According to the invention, first the curbstones are mounted with a double-line control method, curbstone backs are manufactured with a gantry-supported construction process, and then asphalt is paved. With the double-line control method, mounting speed is accelerated, adjustment is reduced, and curbstone straightness and appearance quality are improved. With the gantry-supported construction process, mounting speeds of the curbstone backs and concrete templates are accelerated, labor investment is greatly reduced, construction quality is improved, basic guarantee is provided for subsequent asphalt concrete construction, and pavement flatness is ensured. Good effects such as good pavement appearance, straight line, and comfortable driving are achieved. compared with prior art, construction control work load of steps such as measuring, checking, testing, and the like are reduced; working efficiency is improved; construction duration is shortened; and good social and economic benefits are provided. The method has wide application space in municipal project curbstone mounting projects, and has popularization value.

Owner:JINAN URBAN CONSTR GRP

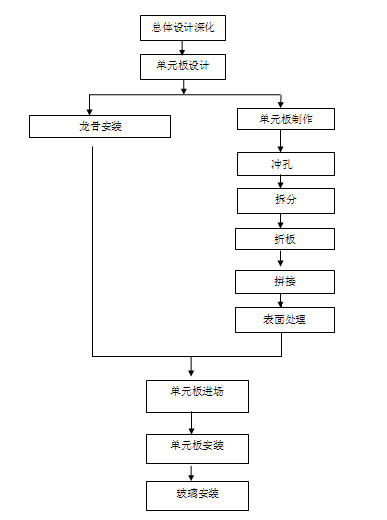

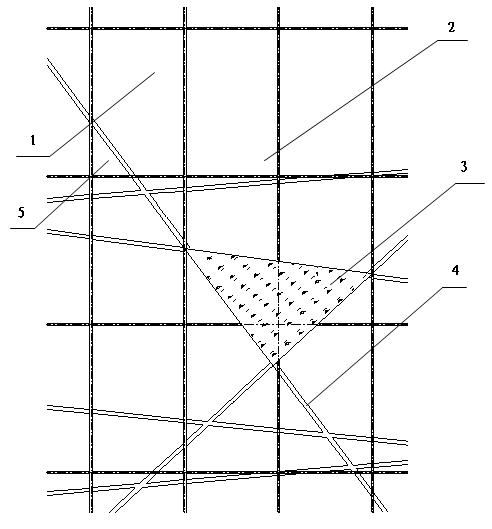

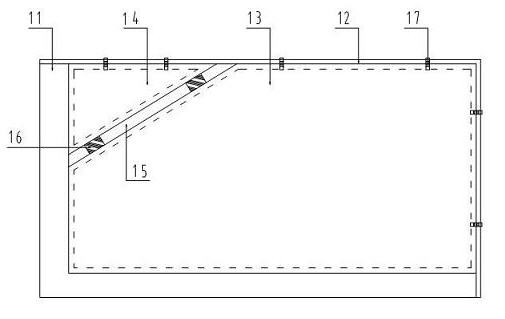

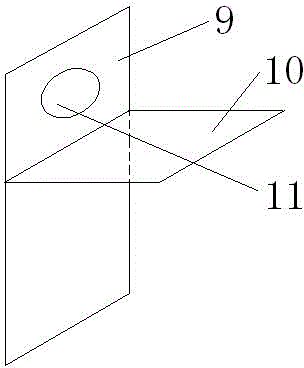

Construction method of complex puzzle unit type curtain wall

InactiveCN102661052AScientific and reasonable designAccurate block shapeWallsBuilding material handlingEngineeringUnit type

The invention relates to a construction method of a complex puzzle unit type curtain wall. The construction method comprises the following steps: using a computer to perform auxiliary design and calculation according to the overall design and the field actual situations of an elevation puzzle of the curtain wall, performing unit grid division, arrangement of a framework and unified numbering of unit plates, splitting the unit plates to puzzle plates according to puzzle lines and drawing a processing diagram of the unit plates; performing processing, shaping and splicing on the puzzle plates according to the processing diagram of the unit plates for forming the regular unit plates which are connected firmly; and finally performing field installation of the curtain wall. According to he construction method disclosed by the invention, the unit plates are scientific and reasonable in design, accurate in manufacturing, strict in installation process; the complex puzzle lines are straight and smooth, plate shape is accurate, falsehood and reality are combined smartly and the effect of the complex puzzle perforated curtain wall is given a full play. the construction method has the characteristics of advanced process, precision in manufacturing, convenience in installation, and high efficiency in construction.

Owner:常熟市华丽坚装饰工程有限公司

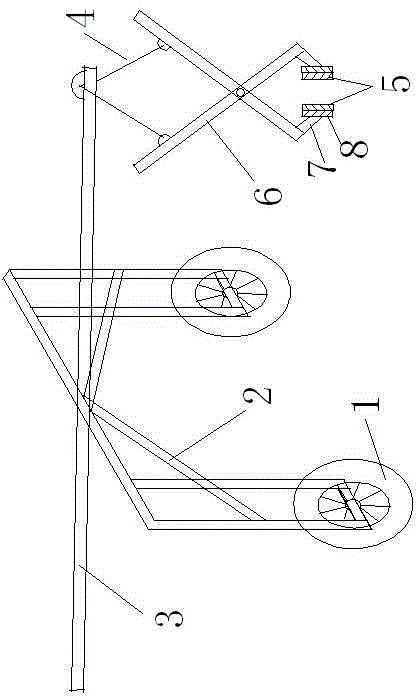

Kerbstone mechanical-hoisting and seam-spacing method-based construction method, hoisting tool and seam-spacing tool

InactiveCN104313984ASimple structureEasy to usePortable liftingRoads maintainenceEconomic benefitsCement mortar

The invention discloses a kerbstone mechanical-hoisting and seam-spacing method-based construction method, a hoisting tool and a seam-spacing tool. The kerbstone mechanical-hoisting and seam-spacing method-based construction method comprises the following steps of 1, preparing construction, 2, carrying out measurement and line laying, 3, bracing 10-20m of a line and determining a kerbstone directional line and elevation line, 4, arranging a 1: 2.5-3 cement mortar cushion layer having thickness of 3cm, 5, installing first kerbstone, 6, arranging the seam-spacing tool, 7, hoisting kerbstone to a designated position by the hoisting tool, 8, carrying out complex line stabilizing, 9, carrying out self-inspection checking, 10, pouring back concrete of the kerbstone, 11,maintening the back concrete and 12, carrying out inspection and acceptance by a supervisor. The method provided by the invention has strong operationality and simple installation method with low technical difficulty, reduces kerbstone manual-carrying labor intensity, improves efficiency, saves a labor cost and has economic benefits better than those of the traditional construction method.

Owner:JINAN URBAN CONSTR GRP

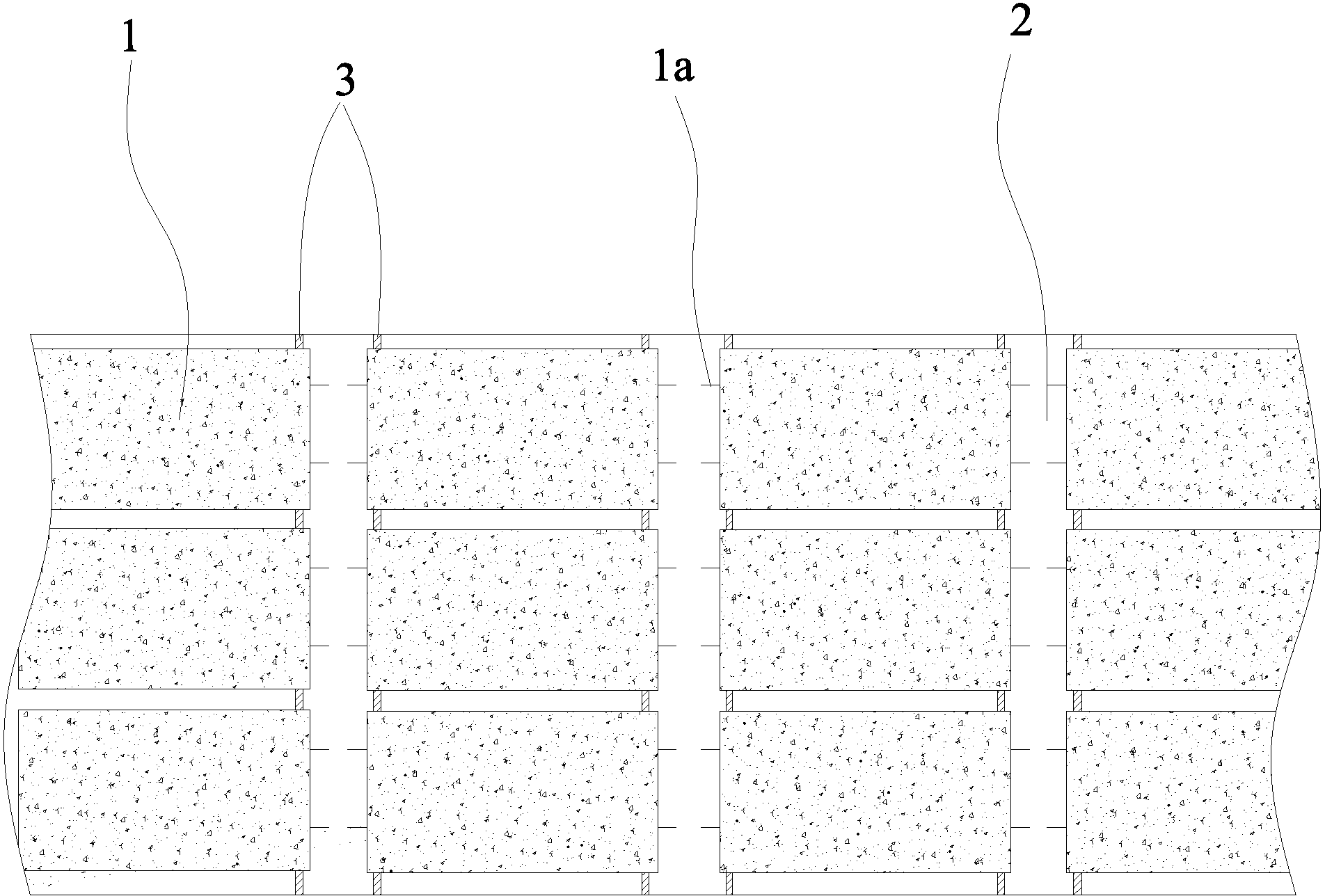

Large-aperture assembly-type reinforced concrete culvert member

ActiveCN103243664AProduction quality is easy to controlReduce the impactGround-workRebarReinforced concrete

The invention provides a large-aperture assembly-type reinforced concrete culvert member. The culvert member is provided with a left side wall, a right side wall and an arch-shaped top plate, and two ends of the top plate are connected with upper ends of left and right side walls respectively to form a culvert unit. The top plate, the left side wall and the right side wall form a reinforced concrete member, and a plurality of reinforced concrete members are installed sequentially, so that the large reinforced concrete culvert is assembled by modular reinforced concrete members, the production process and the production quality can be controlled easily, effects of weather factors on culvert engineering construction are reduced, and the engineering cost is reduced; member line production is performed, the construction technology is simple, and the inherent quality and the appearance quality of the installed solid structure are improved greatly; and a factorization prefabrication mode of members is performed, so that waste of raw materials of concrete is reduced, pollution caused by covering of membrane curing is reduced, and the molded solid structure is smooth in line type, attractive in appearance and provided with good visual effects.

Owner:安徽水利开发有限公司

Precast fence plate dam reinforcing method

The invention relates to a precast fence plate dam reinforcing method. The method comprises the following steps of: firstly precasting a fence plate, and conserving the precast fence plate until 75% of the design strength standard value is achieved; paving a layer stone blocks on a dam surface to be constructed, manuacturing a screed strip underlayer on the stone blocks, conveying the precast fence plate to a to-be-reinforced dam, manually regulating the position so that the fence plate is placed on the screed strip underlayer, and performing edge beam form erecting after placement is finished; then binding edge beam steel bars, pouring concretes, vibrating, trowelling, conserving until the dam is qualified, and then dismounting a template, thus finishing dam reinforcing construction. The fence plate dam reinforcing construction method is high in efficiency, low in cost, easy for formation of multiple parallel working surfaces and less in influence of tide water on construction; and furthermore, fence plates are connected by virtue of the steel bars and are poured by the concretes, a molded dam reinforcing structure has two advantages of reliable protective property and good wave eliminating effect, and is less in wave overtopping amount and long in service life.

Owner:ANHUI WATER RESOURCES DEV

Cloth fixing and line-drawing mechanism

The invention discloses a cloth fixing and line-drawing mechanism, which comprises a rack. An upper support frame and a placement block are fixed on the top surface of the roof of the rack. There is alower inner cavity in the middle of the bottom surface of the placement block. The side wall of the lower inner cavity is connected with a suction pipe, and the suction pipe is communicated with thelower inner cavity. An installation groove is formed in the top surface of the placement block, and a porous plate is inserted into the installation groove in a sleeved manner. Multiple suction through holes are formed in the bottom surface of the installation groove, and the suction through holes are communicated with the lower inner cavity. The porous plate covers all the suction through holes.Cloth to be processed is placed on the top surface of the porous plate. Connecting plates are respectively fixed on the left and right sides of the bottom surface of the roof of the upper support frame (11). The two ends of a transverse screw are hinged to the two connecting plates through bearings. A main mobile motor is fixed on the outer wall of one connecting plate, and the output shaft of themain mobile motor is a spline shaft. The cloth fixing and line-drawing mechanism can absorb and fix the cloth to be processed and then draw a line automatically. The drawn line is straight, the effect is good, and the efficiency is high.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

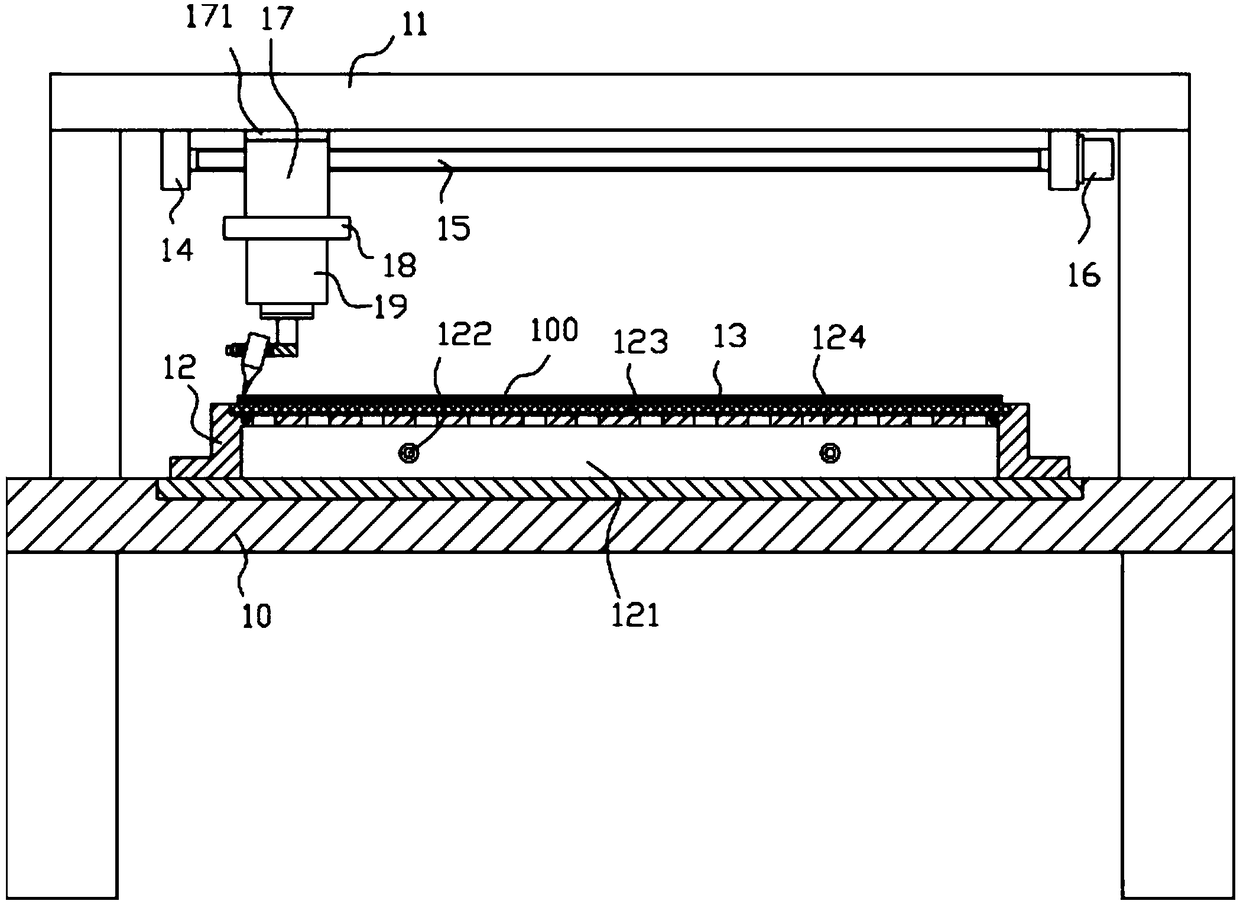

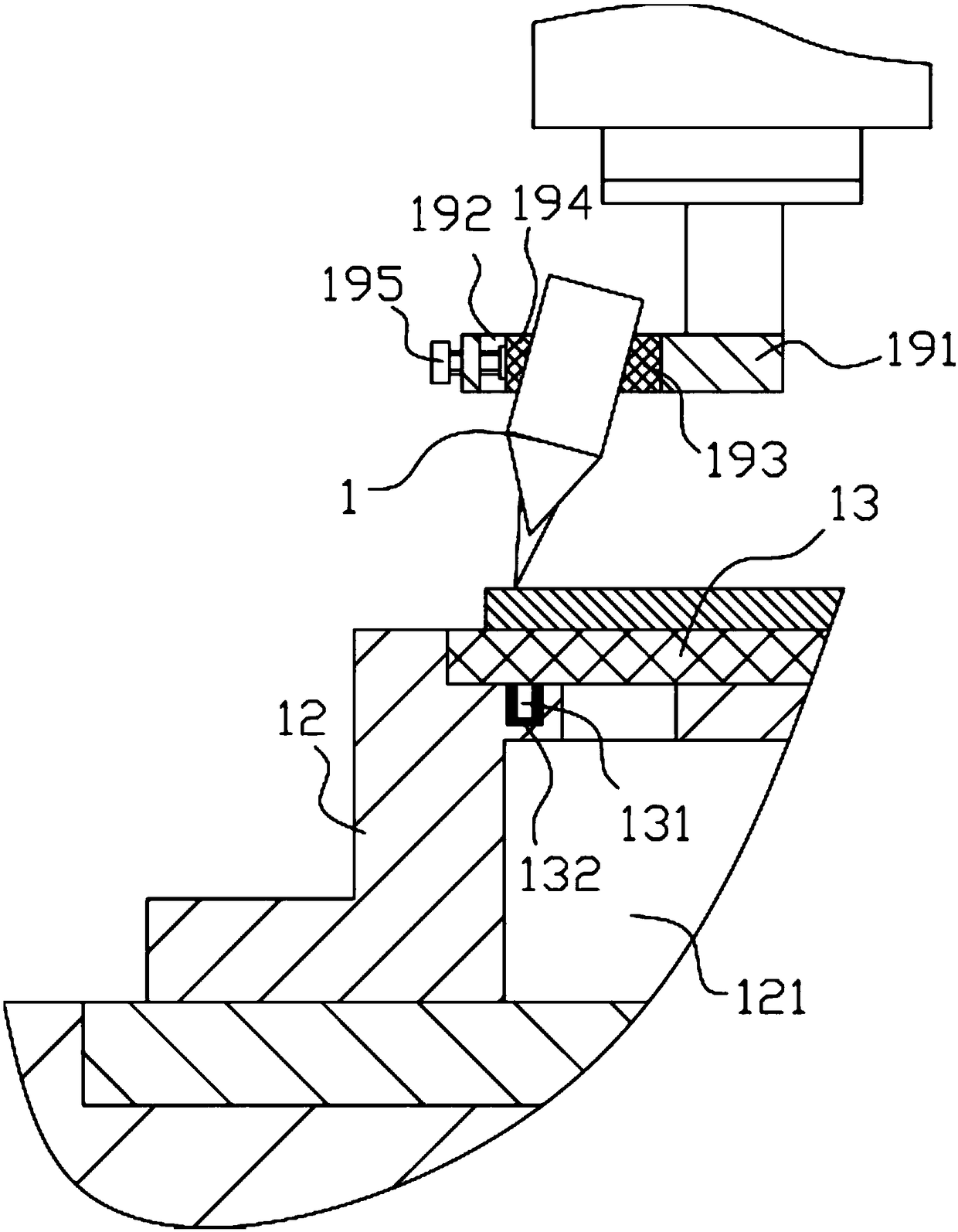

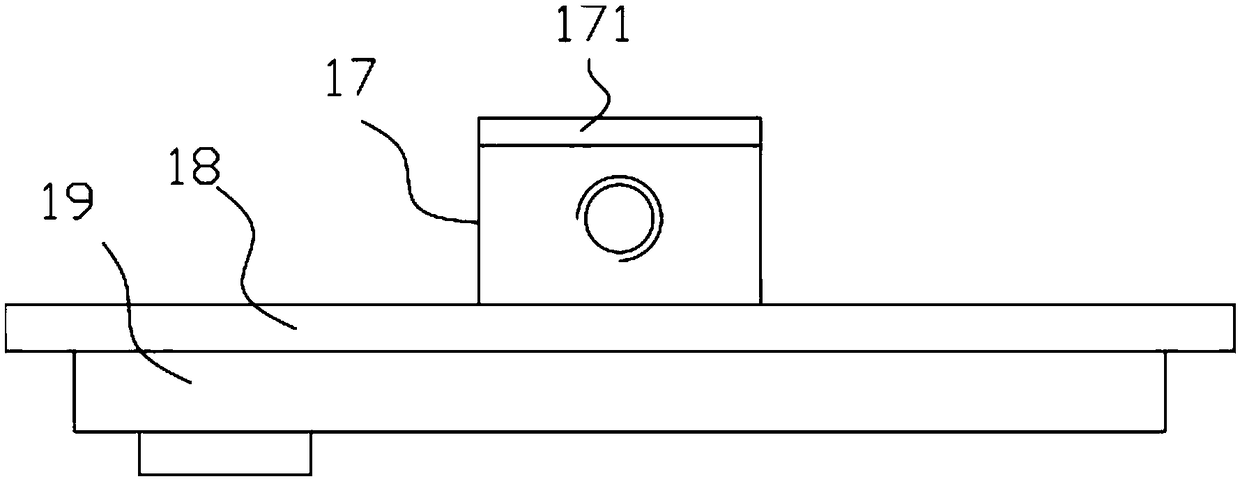

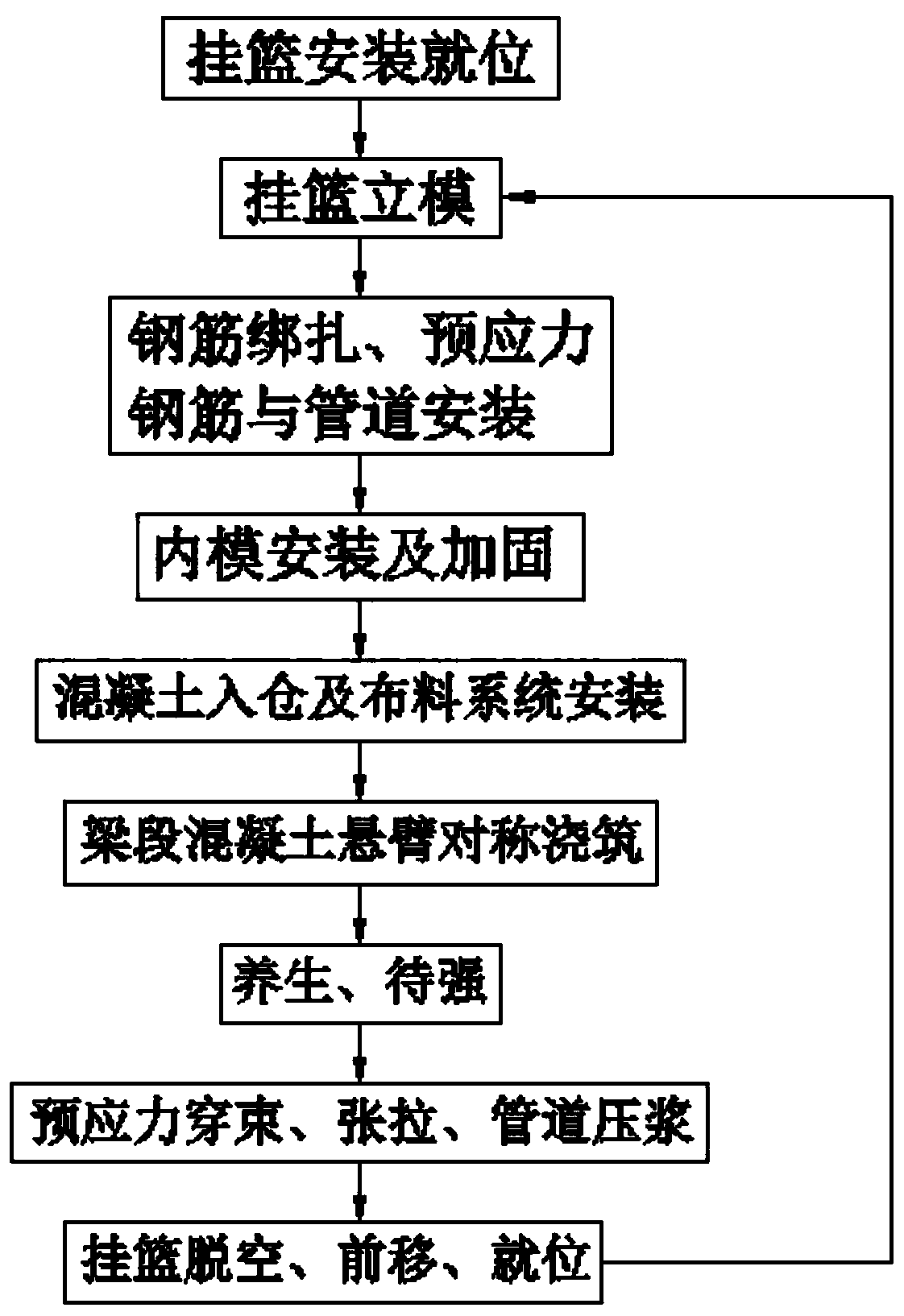

Large-span girder bridge box girder full-section one-time suspension pouring construction method

ActiveCN110453613AReasonable structureLight weightBridge erection/assemblyBridge materialsPre stressHanging basket

The invention discloses a large-span girder bridge box girder full-section one-time suspension pouring construction method, and belongs to the technical field of bridge construction. The large-span girder bridge box girder full-section one-time suspension pouring construction method comprises the steps of mounting of a hanging basket in place; hanging basket formwork erecting; steel bar binding, prestressed reinforcement and pipeline mounting; inner formwork mounting and reinforcing; concrete warehousing and distributing system mounting; symmetrical pouring of girder-segment concrete cantilevers; curing and reinforcing waiting; prestressing strand penetrating and tension, and pipeline grouting; and hanging basket disengaging, forward moving and taking place. According to the large-span girder bridge box girder full-section one-time suspension pouring construction method, the disadvantages that as for a previous fractional and layered pouring technology, interlayer construction joints need to be formed, and the construction period is excessive long are overcome, and the construction quality of a box girder is ensured.

Owner:湖南交通国际经济工程合作有限公司

Universal sweeping robot sweeping path planning method

InactiveCN110377014AReduce energy consumptionLess turnsPosition/course control in two dimensionsSimulationClosed loop

The invention relates to a universal sweeping robot sweeping path planning method comprising the following steps: (1) starting, pose control based on a closed loop of a robot; (2) finding objects witha laser reflection property; (3) extracting an area between the laser reflection substances and partitioning the area; (4) carrying out cleaning on each partition in sequence; (5) checking whether all the partitions are cleaned or not, entering the next step if yes, otherwise returning to the step (2); and (6) returning a charging point. The method in the invention has the beneficial effects thatin the solution of the invention, a mode of executing a cleaning task while collecting environment information is adopted in comparison with the mode of some sweeping robot products on the market that a target environment is traversed in advance so as to collect the environment information and then the cleaning task is executed.

Owner:SHANGHAI XPARTNER ROBOTICS +1

Construction technology for modeling special wall by utilizing cement mortar

The invention relates to a construction technology for modeling a special wall by utilizing cement mortar. A method that measures of a three-dimensional measurement instrument, a special plastic formwork tool, embedded plastic angle beads and the like are combined with cement mortar construction operation is adopted, so that excellent quality for modeling thin parts of the cement mortar has higher operability; a method that the plaster layer and skirting lines of the wall are surveyed and positioned by the three-dimensional measurement instrument is adopted, transverse, parallel, upright and foursquare modeling for the cement mortar is guaranteed; the special plastic formwork tool is adopted, so that the problems of modeling height of the cement mortar and thickness deviation of the wall are solved; a method that L-shaped plastic angle beads are embedded on upper modeling openings of the cement mortar in a through mode is adopted, the height and thickness of the wall are uniform after the skirting lines are activated, lines of the plastic angle beads of the upper openings are perfectly straight, and the boundary with the wall is clear.

Owner:CHINA AEROSPACE CONSTR GROUP +1

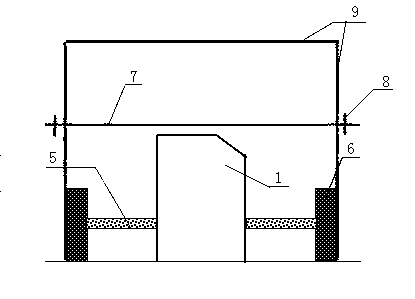

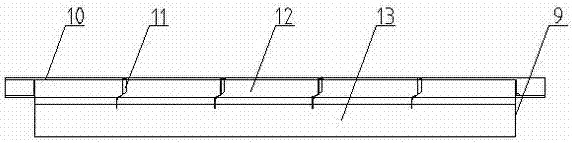

Curb prefabricating assembling side mold and construction technology thereof

PendingCN110424226AOptimizing Spatial RelationshipsImprove the stability of actionRoads maintainenceArchitectural engineeringAsphalt

The invention provides a curb prefabricating assembling side mold. The curb prefabricating assembling side mold is in a strip shape overall, and the cross section of the side mold is in an L shape. The curb prefabricating assembling side mold comprises a left portion, a lower portion and a right portion, wherein the left portion, the lower portion and the right portion are interconnected. A groovein the length direction is formed among the left portion, the lower portion and the right portion. The groove is in the middle and used for accommodating a curb. The left portion of the side mold ishigher than the right portion of the side mold. The inner side face of the left portion of the side mold is adopted as the rear backrest of the curb. The upper surface of the right portion of the sidemold is used for placing a square batten stone. The right portion of the side mold, the square batten stone and the curb are adopted as a road asphalt side mold simultaneously. The invention furtherrelates to a construction technology for the prefabricating assembling side mold. According to the curb prefabricating assembling side mold, time for pouring the rear backrest of the curb is saved; the curb is integrally prefabricated and molded in a factory; the problem of increasing of the cost and working procedures caused by secondary construction of the rear backrest of the curb in the laterperiod is solved; and the integral stability of the curb is improved.

Owner:JINAN URBAN CONSTR GRP

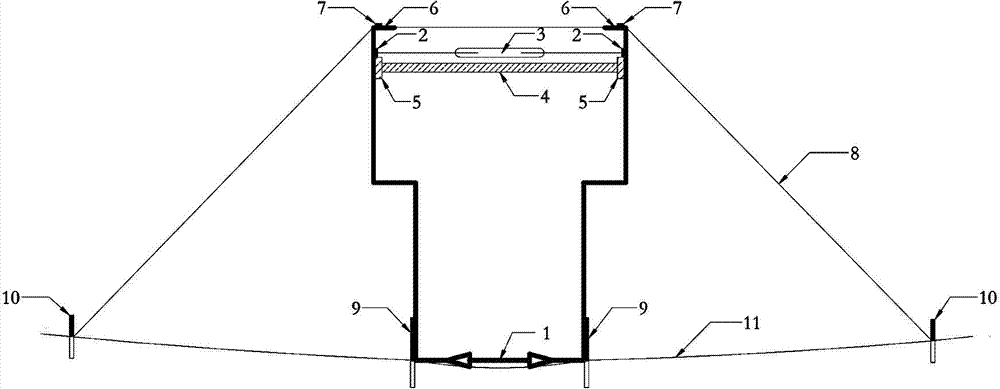

Three-way adjustable anti-seismic system of bridge crossing fracture zone

ActiveCN110331652AReduce earthquake responseReduction effectBridge structural detailsBridge materialsEngineeringFracture zone

The invention provides a three-way adjustable anti-seismic system of a bridge crossing a fracture zone. The three-way adjustable anti-seismic system of the bridge crossing the fracture zone is formedby adopting a dredging type anti-seismic measure and a blocking type anti-seismic measure, and arranging anti-seismic structures in the vertical direction, the longitudinal direction and the transverse direction of the bridge on the basis of each anti-seismic measure. According to the three-way adjustable anti-seismic system of the bridge crossing the fracture zone, the three-dimensional anti-seismic structures are adopted, so that the acceleration and the inter layer displacement of an upper structure during an earthquake can be reduced to a great extent, the earthquake response of the upperstructure is greatly reduced, the effect caused by earthquake force is dispersed and reduced, and the functions of reducing casualties and rapidly recovering the passage of vehicles are achieved.

Owner:CHINA HIGHWAY ENG CONSULTING GRP CO LTD

Portable articulating tool support

A portable multiple-component articulating support apparatus for engaging, moving, orientating and manipulating a hand-operated power tool within and throughout a three-dimensional workspace. The apparatus includes a clamping device for demountable engagement with a structural element, one or more elongate double-axis hinge member, one or more spacer elements having opposite ends adapted for detachable engagement and rotational communication with the clamping device and the double-axis hinge member, a vertically disposed pivotably connected counterbalance arm assembly adapted for detachable engagement and rotational communication with the double-axis hinge member. The counterbalance arm assembly is equipped with a gas-charged cylinder for balancing the weight of hand-operated power tools. The clamping device, a counterbalance element, one or more spacer elements and one or more double-axis hinge elements alternating therebetween, are interconnected with removable hinge pins. A tool-mounting bracket is provided for grippingly engaging a power tool. The tool-mounting bracket pivotably engages a power tool-bearing member which slidingly and rotatably communicates with the counterbalance arm assembly.

Owner:EQUIPOIS

Cashmere filling device for high quality hand-knitted down jacket

PendingCN108542031AEvenly filledAdjustable relative spacingClothes making applicancesEngineeringFill device

Owner:湖州林品服饰有限公司

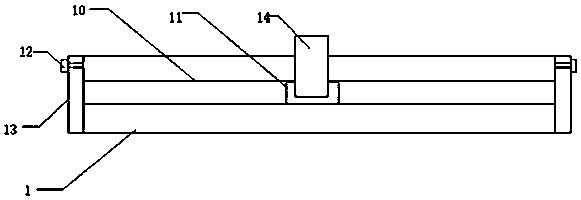

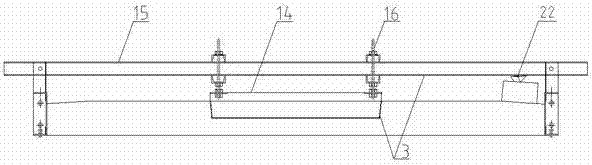

Complete tool for CRTSIII plate-type ballastless track base plate construction

PendingCN107119514AAvoid the problem of missing edges and cornersGuarantee the quality of finished productsRailway track constructionSupporting systemTrackway

The invention relates to a complete tool for high speed railway CRTSIII plate-type ballastless track base plate construction and belongs to the technical field of high speed railway construction. The complete tool can accurately control the gradient and top surface flatness of drainage slopes on the two sides of a base plate and comprises a base plate side mold, an expansion joint template, a limiting groove and support, a gradient adjusting plate and a supporting system. The base plate side mold comprises a standard section and an adjusting section; and the standard section is a foundation for template configuration, and a pre-buried casing pipe is arranged on the lower portion of the base plate side mold. The expansion joint template comprises a steel plate, a pressing plate and a G-shaped clamp. The expansion joint template clamps and fixes square steel and a caulking material to the steel plate through the G-shaped clamp. The caulking material is stored on the lower portion of the pressing plate and tightly attached to the steel plate. The complete tool has the effect of being capable of accurately controlling the top surface elevation and the drainage gradient of the CRTSIII plate-type ballastless track base plate.

Owner:ELECTROMECHANICAL DEVICE INSTALLATION OF CTCE GROUP

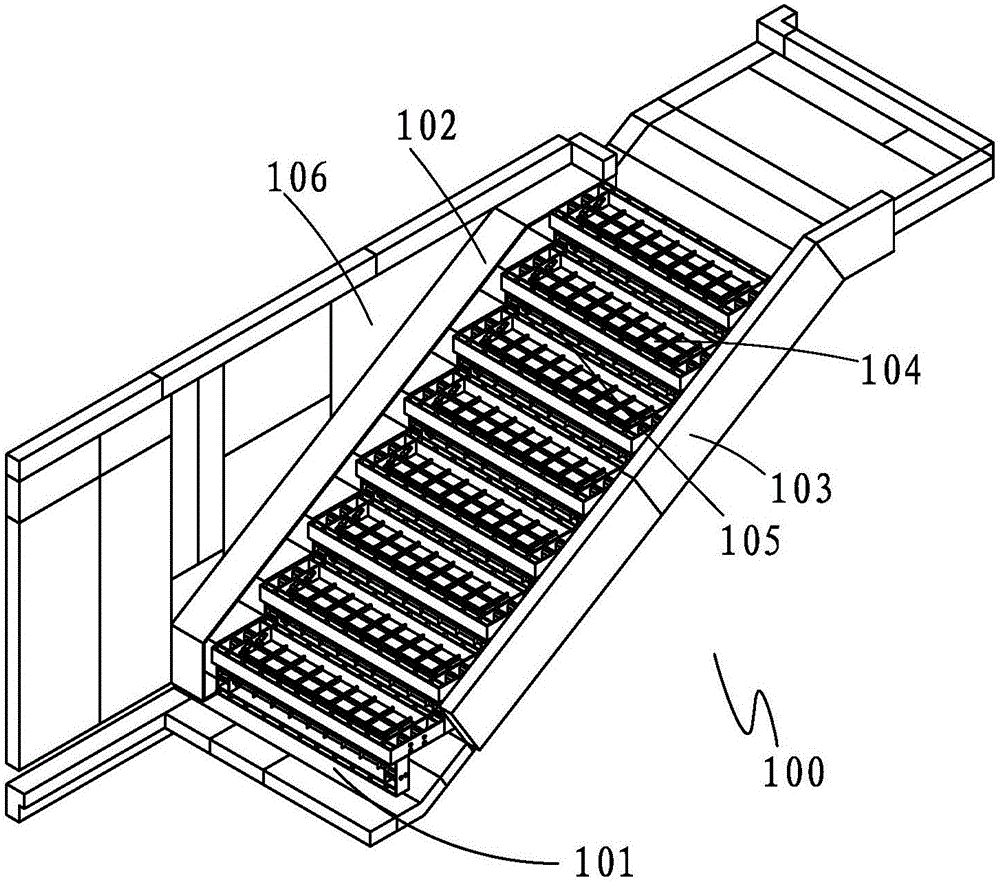

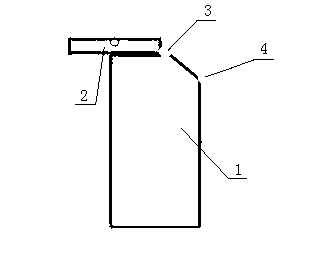

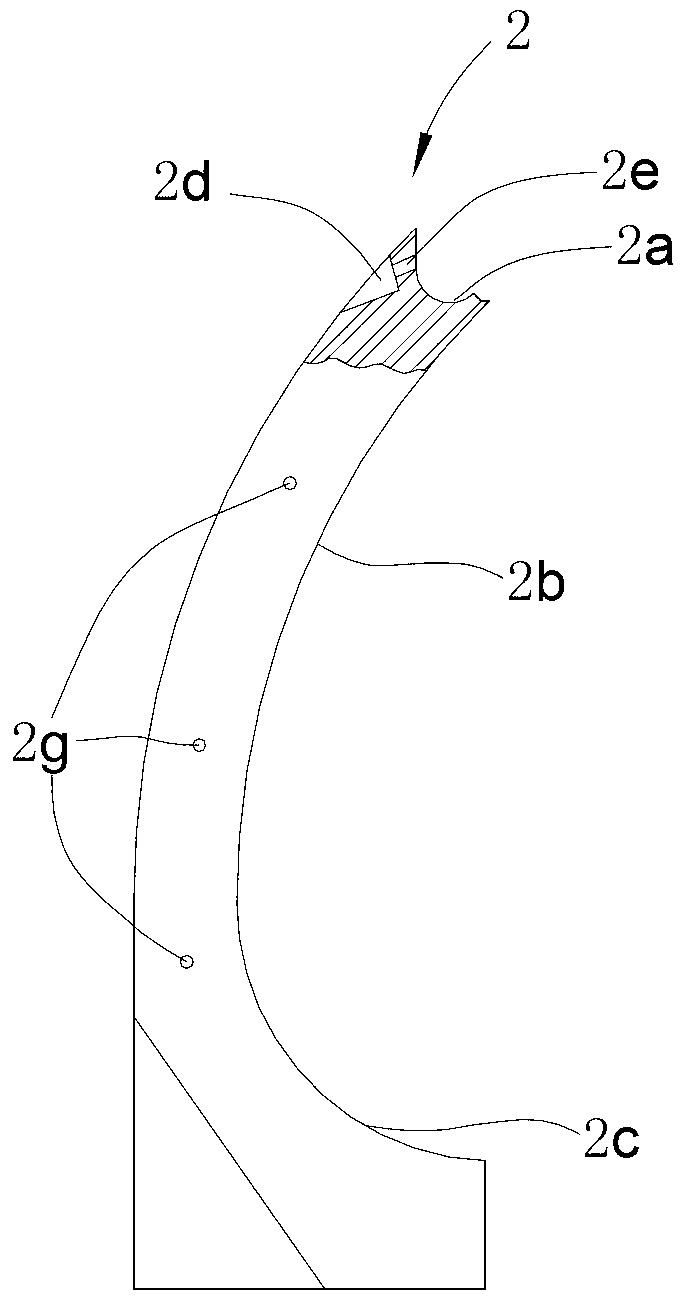

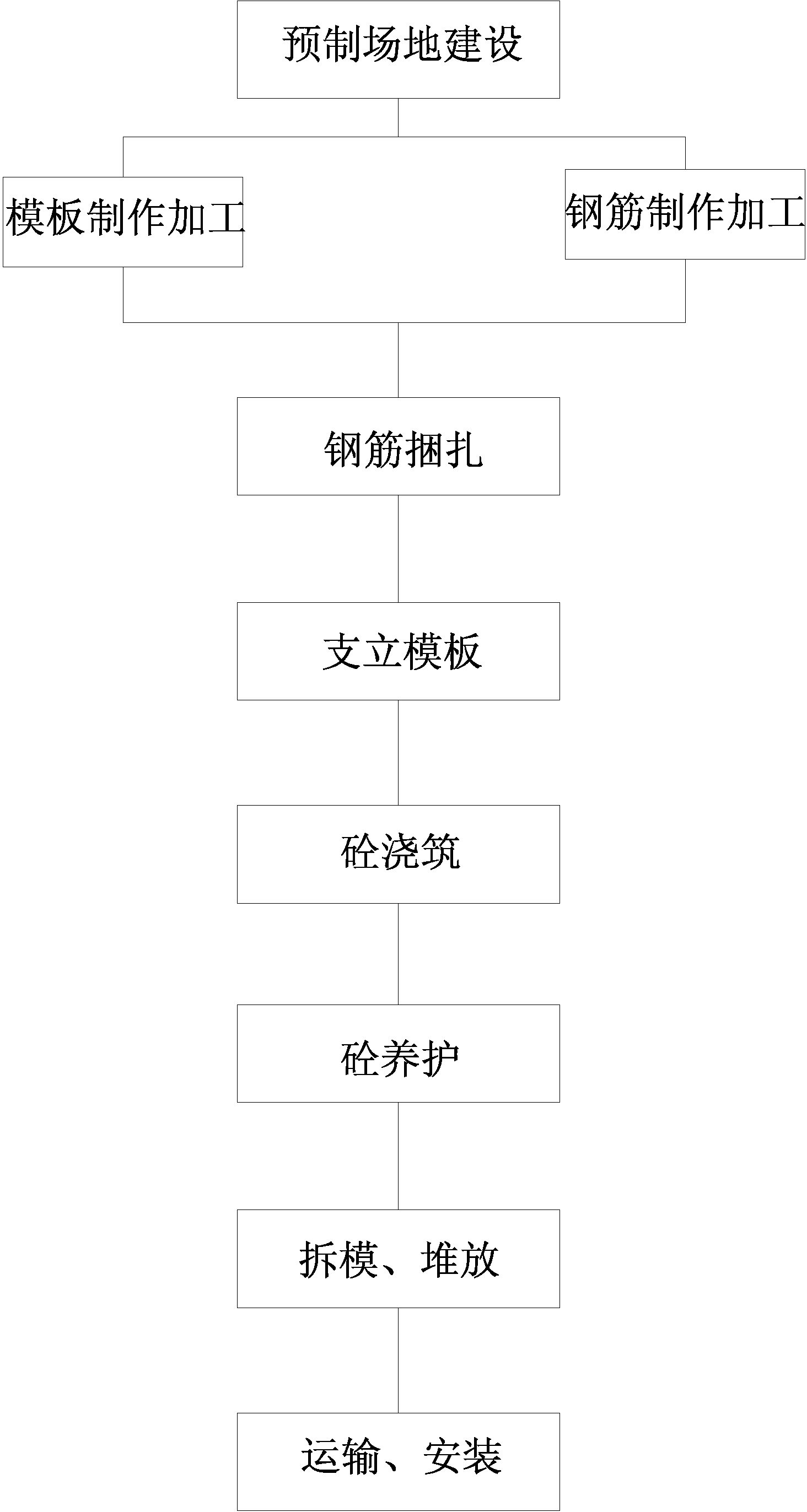

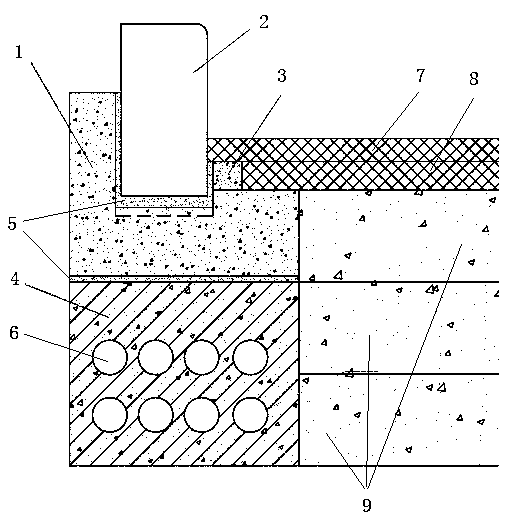

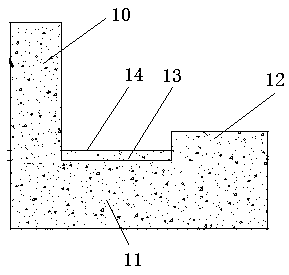

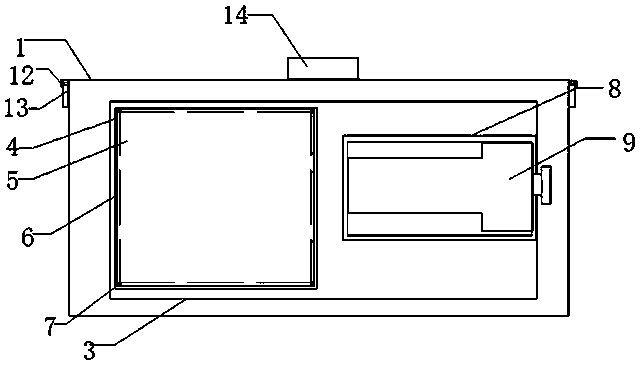

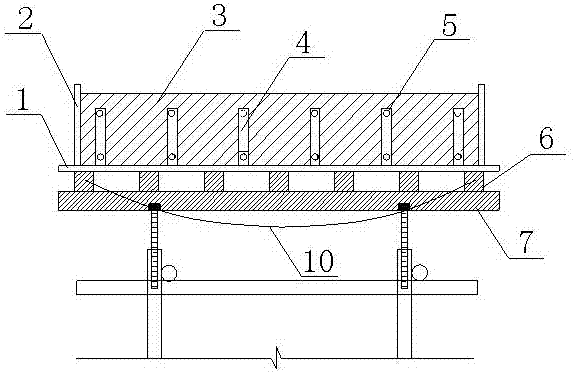

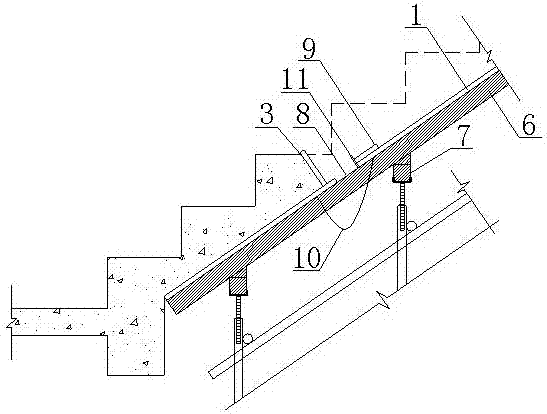

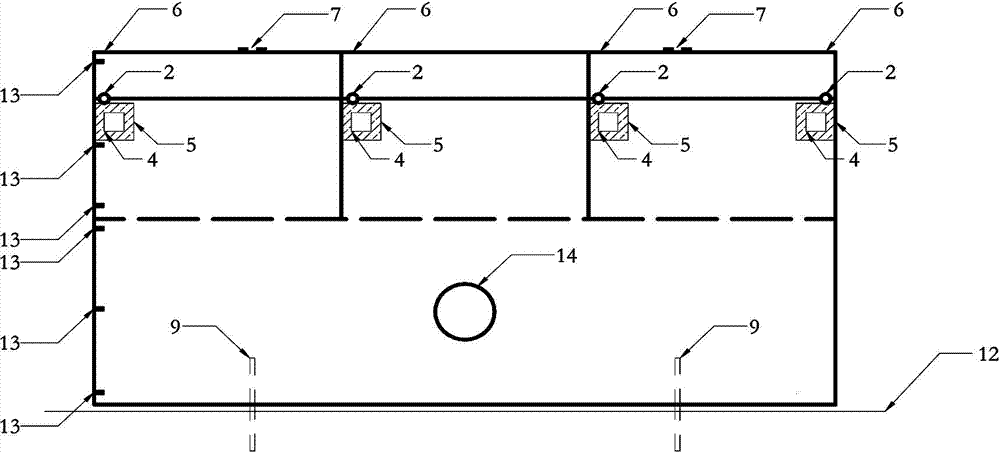

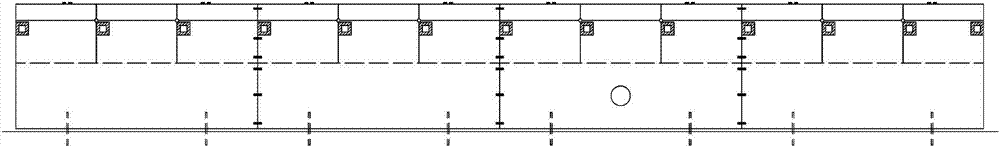

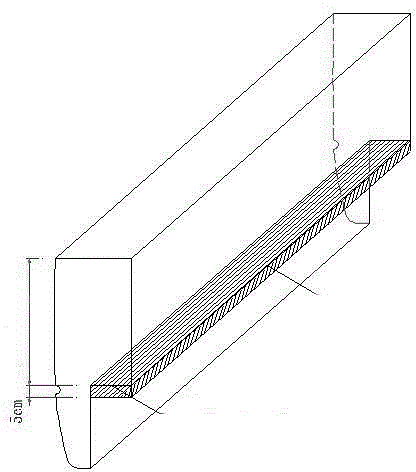

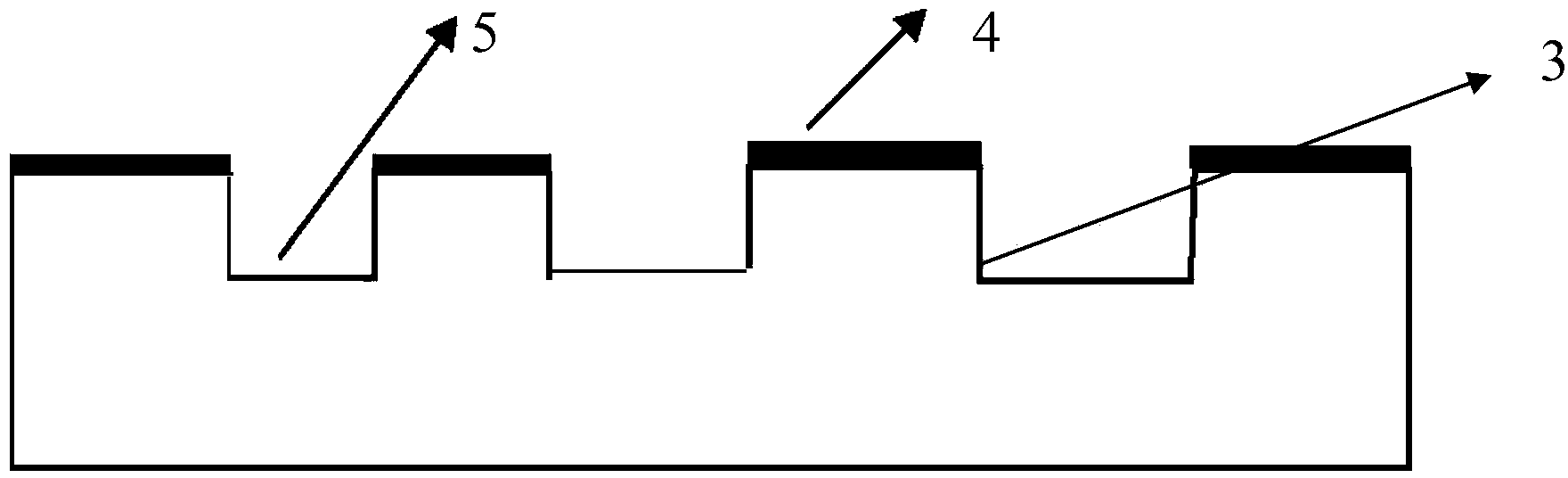

Template device for reserving concrete stair construction crack

PendingCN107514136AStraight linesEliminate chiseling processForms/shuttering/falseworksRebarBuilding construction

A template device for reserving a concrete stair construction crack includes a bottom die (1), lateral dies (2), and a sealing plate (3); the bottom die (1) is supported on secondary columns (6); the secondary columns (6) are supported on a primary column (7); a reserved plate crack (8) with the width of 10-12 cm is retained in a twice concrete construction crack position of the bottom die (1); the sealing plate (3) seals first poured concrete at the construction crack position in a manner of being perpendicular to the bottom die (1), and reserved gaps (4) are formed; stair longitudinal steel bars (5) pass through the reserved gaps (4); and the reserved gaps are formed according to the size and spacing of the stair longitudinal steel bars (5). The sealing plate is arranged on the construction crack position, the construction crack concrete surface is linear and straight; rubbish and sundries generated during construction can be discharged from the reserved plate crack, and cleaning work before concrete pouring is reduced; and a safe mesh fabric is hanged under the reserved plate crack, which can collect the rubbish and the sundries, and will not cause environment pollution.

Owner:MCC5 GROUP CORP SHANGHAI

Preparation method for clear water mirror surface concrete

Owner:HUAQIAO UNIVERSITY

Inserted convex integral central drainage ditch device in road tunnel

The invention discloses an inserted convex integral central drainage ditch device in a road tunnel. The inserted convex integral central drainage ditch device comprises steel templates, a movable hinge, a turnbuckle, square timber cross arms and skids, wherein the two steel templates are arranged symmetrically; the bottom ends of the two steel templates are connected through the movable hinge; the upper ends of the two steel templates are fixedly connected through the turnbuckle, the square timber cross arms and the skids. The concept of water prevention and drainage is implemented in a template, so that structural drainage is realized, the effects of 'combination of prevention and blockage and rapid drainage' are achieved, problems of a central ditch system are prevented fundamentally, the stability and durability of a tunnel structure are ensured, and the operation and all-life effect of the tunnel are enhanced.

Owner:GANSU ROAD&BRIDGE NO 4 HIGHWAY ENG

Continuous beam curtain board construction technology

InactiveCN105625636AStraight linesLinear smoothGirdersJoistsArchitectural engineeringContinuous beam

A continuous beam curtain board construction technology comprises the following steps: arranging and fixing a template bottom template; binding steel bars, and arranging an embedded part; arranging a side die; arranging a foam plate according to a foam plate installation instruction; flattening and straightening the foam plate, and reinforcing and firming the foam plate; pouring concrete; carrying out demolding curing on concrete; and storing: transporting a curtain board to a field according to installation schedule requirements before installing construction, and temporarily storing the transported curtain board for installation. The construction technology has the advantages of simple operation, cheap material and cost reduction. A continuous beam can be effectively smoothly connected with curtain boards at two sides of the continuous beam, so integral linear straightness is guaranteed. The height of a curtain board bearing platform of the continuous beam curtain board is increased in advance, so linear straightness of the continuous beam curtain board and the simply supported beam curtain boards at two sides in the installation process is guaranteed, thereby resource waste and construction period prolongation caused by unable normal use of curtain boards produced as designed on the continuous beam are avoided.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

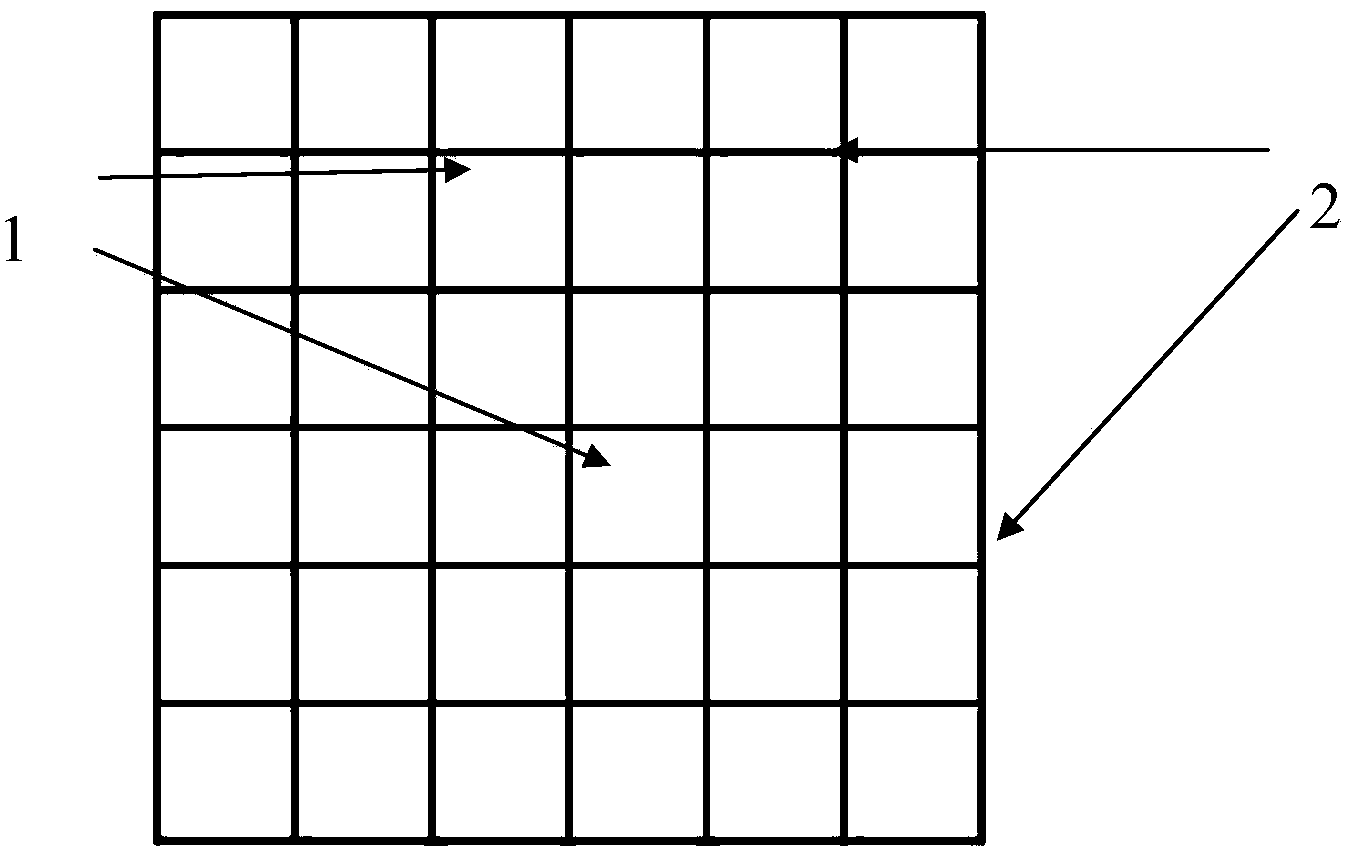

Metal grid type transparent conducting thin film and manufacturing method thereof

InactiveCN103545021AImprove photoelectric performanceHigh surface flatnessConductive layers on insulating-supportsCable/conductor manufactureTransparent conducting filmOptoelectronics

The invention relates to a metal grid type transparent conducting thin film and a manufacturing method thereof. The metal grid type transparent conducting thin film comprises a substrate and a metal layer, wherein the metal layer is a patterned metal conducting grid. The sum of the areas of the positions except for the metal conducting grid is more than 80% of the overall area of the thin film. According to the metal grid type transparent conducting thin film, grid patterns are printed on the flexible transparent substrate through conductive ink in a flexographic printing mode, and batch production is achieved in a reel-to-reel high-efficiency producing mode; meanwhile the flexographic printing mode not only guarantees that the metal grid type transparent conducting thin film has excellent photoelectric performance, but also guarantees that the thickness of the ink lay of the grid is smaller than 1 micron, excellent conductive performance is obtained, lines are flat, and surface flatness of the transparent conducting thin film is also improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com