Large-span girder bridge box girder full-section one-time suspension pouring construction method

A construction method and full-section technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of setting construction joints between layers and long construction period, and achieve fast formwork installation and dismantling and vertical formwork, reduce labor, and reduce deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

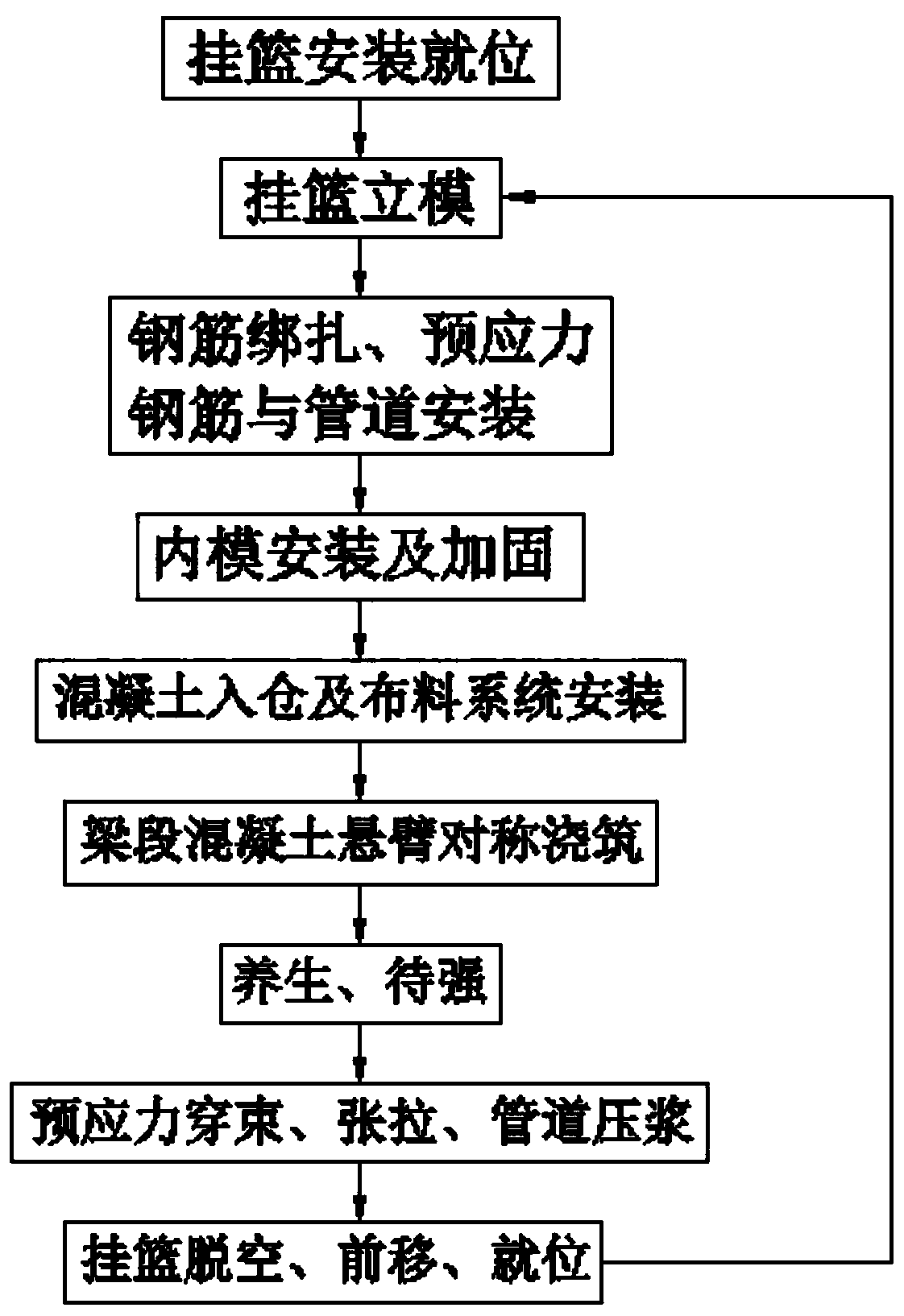

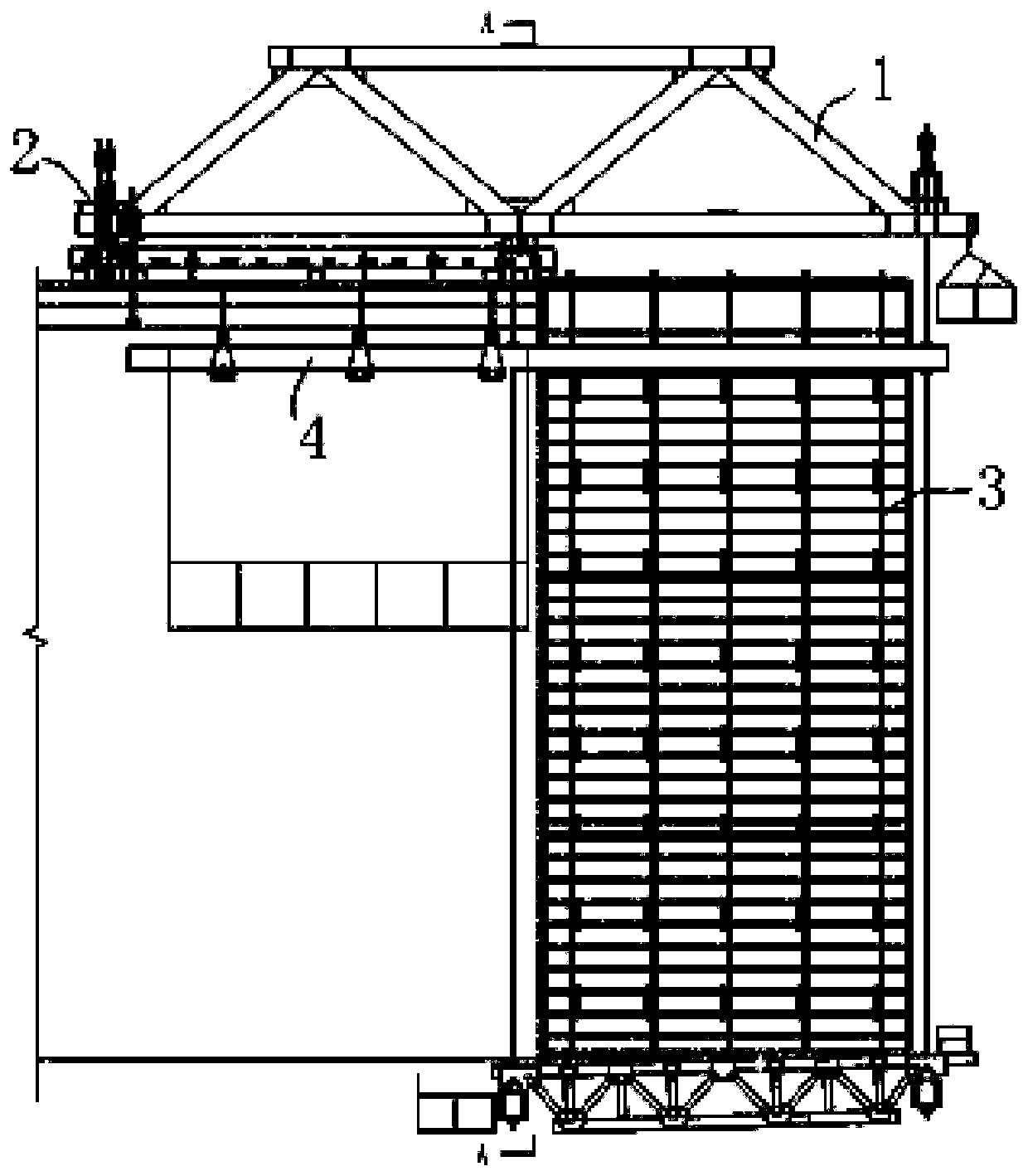

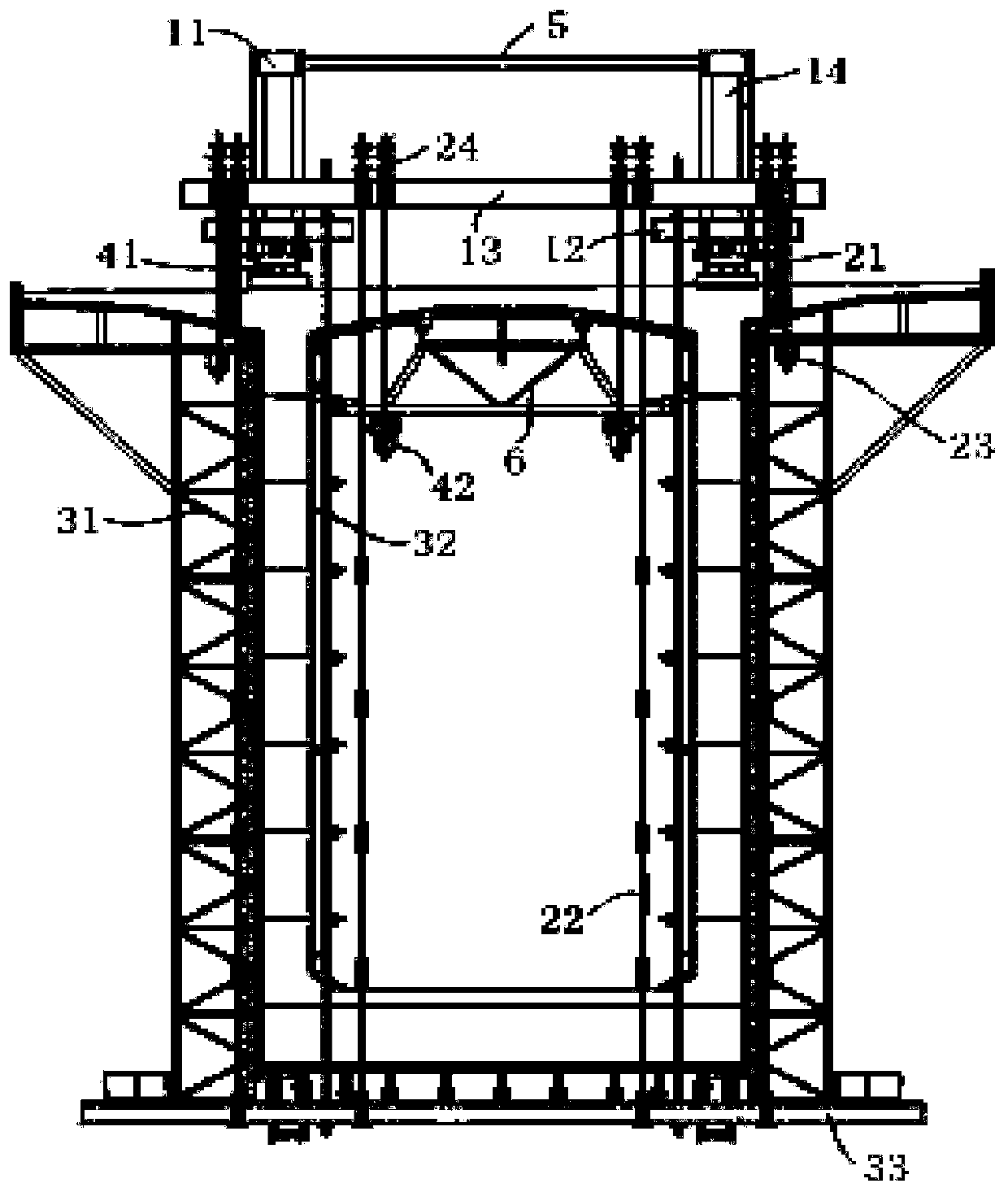

[0045] Embodiment: A kind of cantilevered construction method for the full section of the box girder of a long-span girder bridge, refer to figure 1 , 2 , 3, 4, 5, including the following steps:

[0046] a. The hanging basket is installed in place

[0047]The hanging basket is the main carrier of the load-bearing and formwork structure of the box girder full-section one-time cantilevered construction. The hanging basket includes the main truss 1, the suspension and anchoring system 2, the formwork system 3 and the walking system 4. Both the main truss 1 and the formwork system 3 move back and forth through the walking system 4 . The main truss 1 is the main load-bearing structure of the cantilever construction of the box girder. The main truss 1 is an isosceles trapezoidal truss structure. The diagonal brace 14 is located between the upper crossbar 11 and the lower crossbar 12, and the two ends of the diagonal brace 14 are respectively fixed to the upper crossbar 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com