Kerbstone mechanical-hoisting and seam-spacing method-based construction method, hoisting tool and seam-spacing tool

A construction method and technology for curb stones, applied in the field of construction engineering, can solve the problems of high labor intensity, uneven seam width, unsightly installation of curb stones, etc., and achieve the effects of reducing installation labor intensity, uniform seam width, and beautiful installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

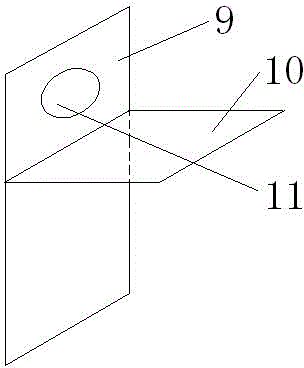

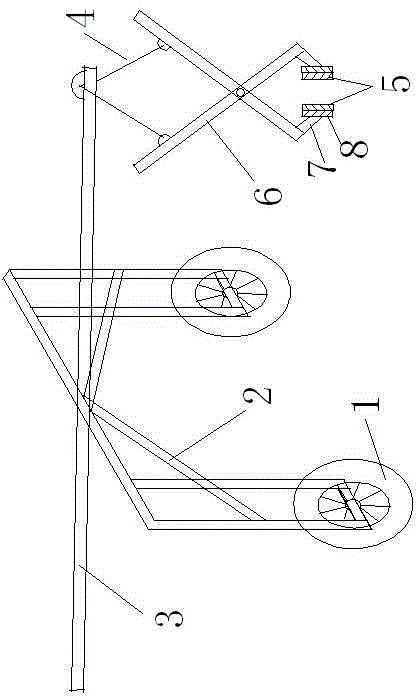

[0015] Accompanying drawing is a kind of specific embodiment of the present invention.

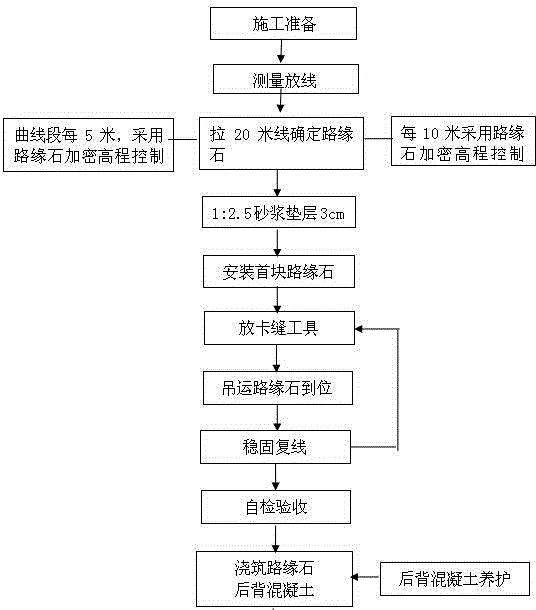

[0016] The curb mechanical lifting and construction method of the present invention includes the following steps: construction preparation → measurement and setting out → pulling 10-20 meters line to determine the direction line and elevation line of the curb → 1:2.5-3 cement mortar cushion 3cm→Install the first curbstone→Put the jamming tools→Elevate the curbstone in place with lifting tools→Fix the double track→Self-inspection and acceptance→Pouring the back concrete of the curb→Concrete maintenance on the back→Supervisor acceptance.

[0017] When measuring and setting out, when installing and constructing curbs, position and set out according to the plane position designed by the curb; 50m, the curve segment is 5-10 meters; this line is the upper level line of the curb and the side line inside the road, double control, so the control of the pull line must be accurate, tightened, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com