Curb prefabricating assembling side mold and construction technology thereof

A technology of prefabricated assembly and curbstones, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of multiple invalid working hours, back-to-back rework, etc., and achieve the effect of convenient prefabricated assembly, avoiding errors, and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

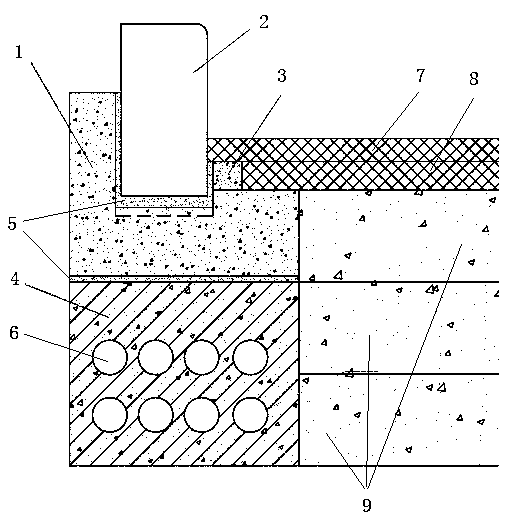

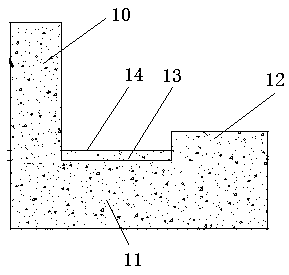

[0037] Accompanying drawing is a kind of specific embodiment of the present invention.

[0038] The curb prefabricated assembled side form of the present invention has a long strip shape as a whole and an L-shaped cross-section, including a left part 10, a lower part 11, and a right part 12 connected to each other. Form a groove 14 along the length direction, the groove is located in the middle, and the groove is used to accommodate curbstones; the left part is higher than the right part, the inner side of the left part is used as the backrest of the curbstone, and the upper part of the right part is used for pouring square Beading stone, right part, square beading stone and curb stone as road asphalt side formwork at the same time.

[0039] The curb stone is prefabricated and assembled with side forms, and the bottoms of the two ends of the groove are reserved with water grooves 13, which are used for taking out the spreader in the curb stone installation process.

[0040] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com