Metal grid type transparent conducting thin film and manufacturing method thereof

A technology of transparent conductive film and metal grid, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., to achieve the effect of excellent conductive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

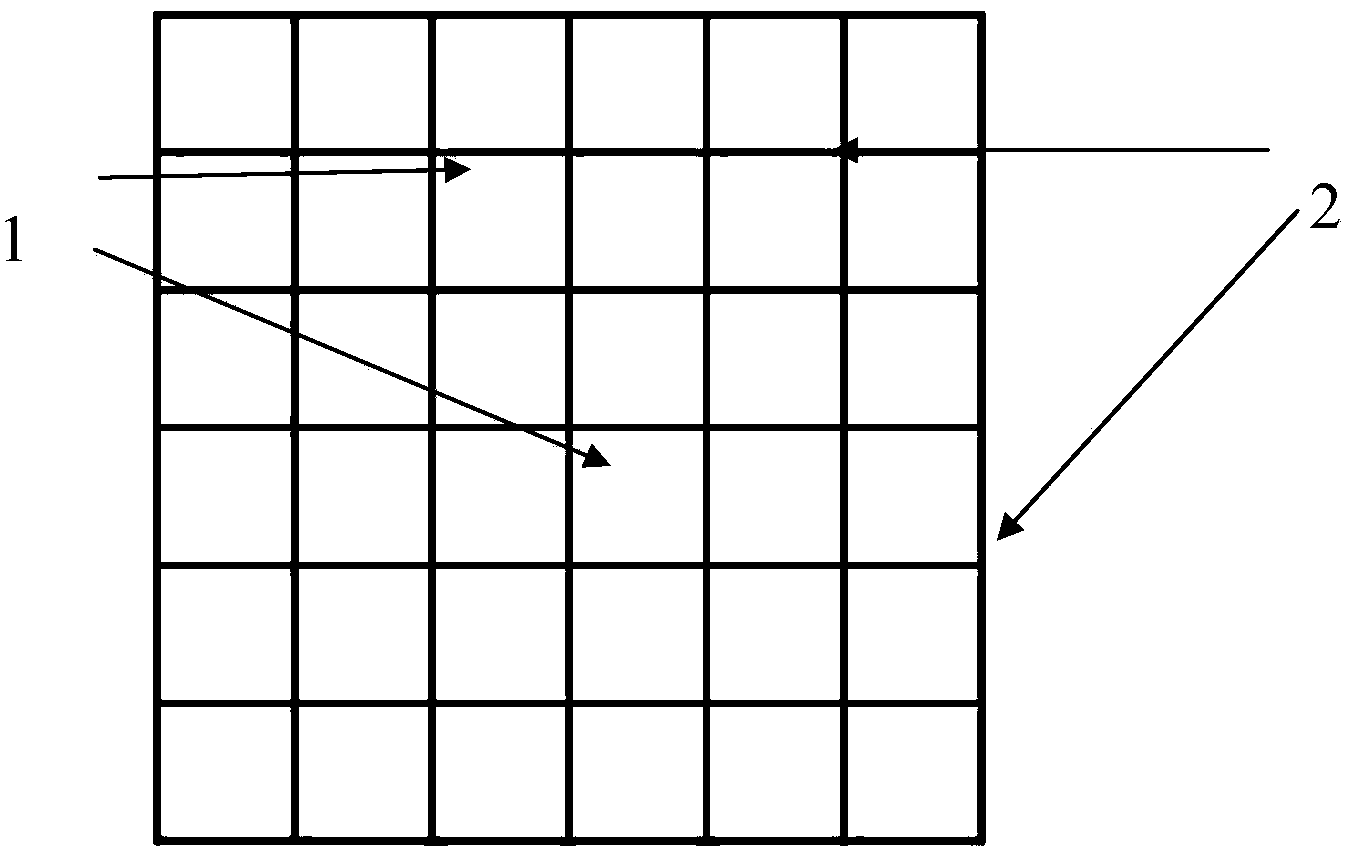

[0047] figure 1 It is a schematic diagram of the principle of the metal grid type transparent conductive film of the present invention; wherein, 1 is a blank space, and 2 is a metal silver conductive grid.

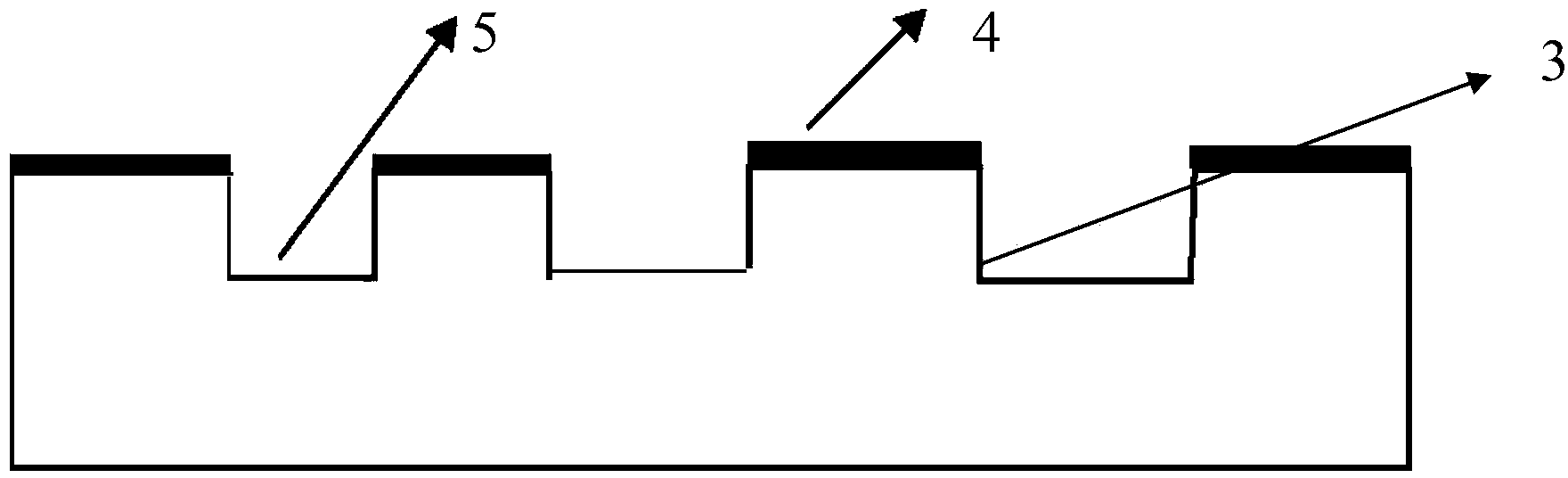

[0048] Such as figure 2 As shown, it is a schematic cross-sectional structure diagram of the metal conductive grid printing plate of the first embodiment; wherein the protruding part is the grid relief width of the printing plate. Among them, 3 is the grid relief height of the printing plate, 4 is the graphic part, and 5 is the blank part. The printing plate grid of the metal conductive grid is a square array, the side length of the square is 400 μm, and the relief width d of the printing plate grid is 17.8 μm. The printing material used is a commercially available flexible transparent PET with a thickness of 88 μm and a light transmittance of a=91%.

[0049] image 3 The scanning electron microscope image of the metal grid-type transparent conductive film prepared fo...

Embodiment 2

[0072] Others are the same as in Example 1, except that the nano-silver is changed to nano-copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com