Method for preparing graphene-phthalocyanin nano composite material by mercaptan-alkene clicking chemical method

A technology of nanocomposite materials and chemical methods, which is applied in the field of graphene-phthalocyanine nanocomposites prepared by thiol-ene click chemistry, achieving high product quality, wide application prospects and high input-output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

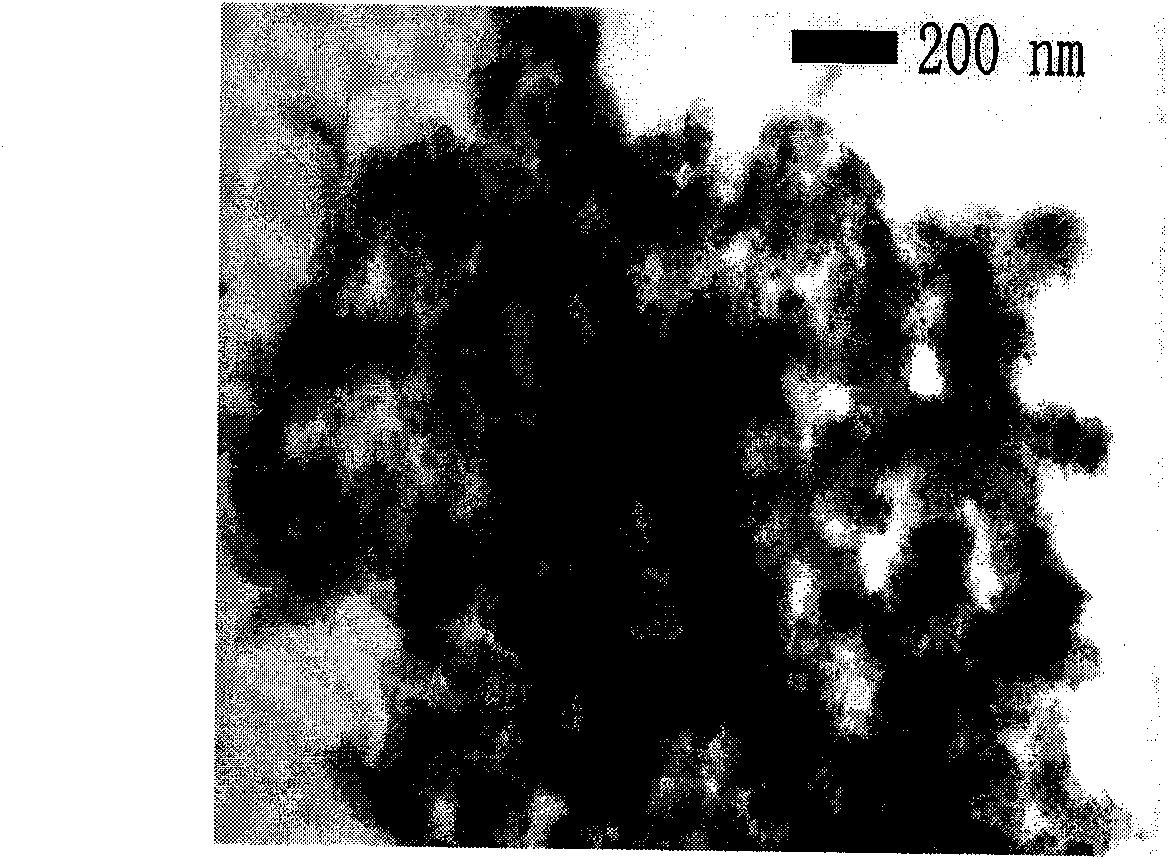

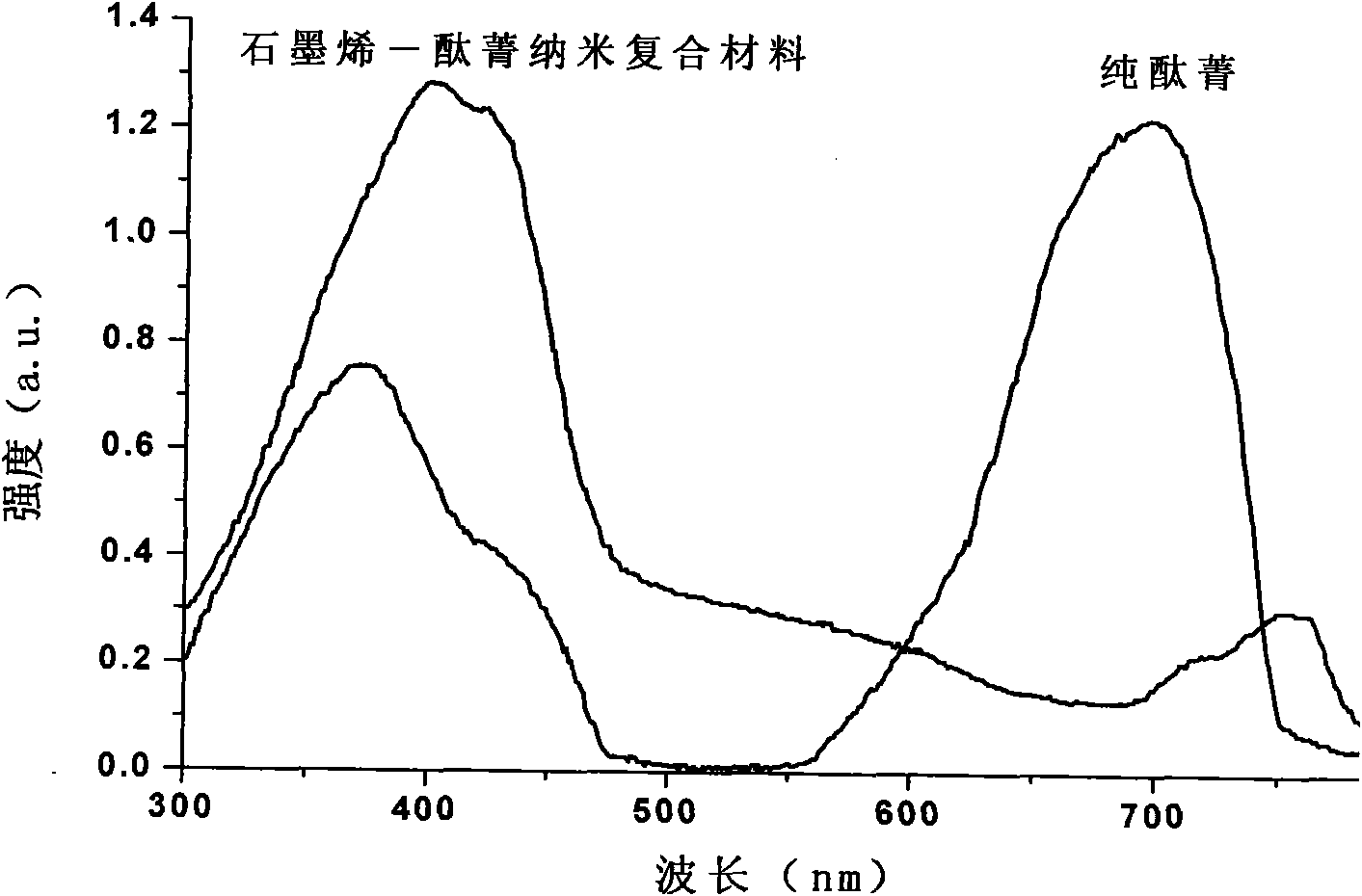

Image

Examples

Embodiment 1

[0025] Measure 50mL of 98% concentrated sulfuric acid and place it in an ice-water bath to keep it at 0-5°C. Add 4.0 g flake graphite and 2.0 g NaN0 while stirring 3 mixture, stir well. Slowly add 12g KMn0 4 , After the addition was complete, the ice-water bath was removed, and the reaction was stirred at room temperature for 24h. Then add 100 mL of deionized water, raise the temperature to 90°C, and continue stirring for 1 h. Lower the temperature to 55° C., add 30 mL of 30 wt % hydrogen peroxide, and continue stirring for 45 min. After the reaction is completed, the graphite oxide is obtained by high-speed centrifugation, filtration and repeated water washing to neutrality, ion exchange resin treatment, and finally low-temperature vacuum drying.

[0026] Disperse 2.0g of the above-mentioned graphite oxide in absolute ethanol, add 15mL of KH-570 ethanol solution with a concentration of 0.15g / ml dropwise in a water bath at 35°C, react continuously for 48 hours, centrifugally...

Embodiment 2

[0032] Same as Example 1, but the concentration of coupling agent KH-570 ethanol solution is changed from 0.15g / ml to 0.25g / ml.

Embodiment 3

[0034] Same as Example 1, but the coupling agent KH-570 is changed to titanate coupling agent 5S, and its dosage remains unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com