Ultraviolet detector manufacturing method

An ultraviolet detector and ultraviolet technology, applied in the field of photoelectric detection, can solve the problems of single wavelength response, serious problem of thin film phase separation, etc., and achieve the effect of reducing thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

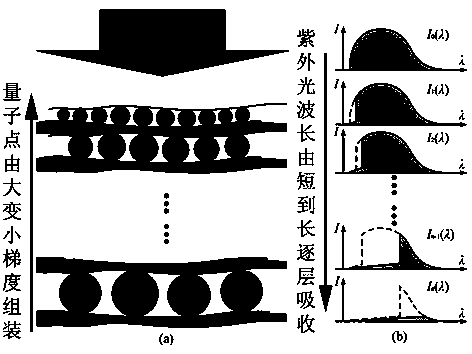

[0023] The following is a description of the specific implementation of the preparation of ZnO quantum dots in the present invention and the preparation of ultraviolet detection devices by gradient assembly in multi-layer graphene using it as an ultraviolet photoelectric response active material.

[0024] figure 1 (a) The ZnO quantum dots in (a) are prepared by colloid chemical method, and can also be prepared by other methods, but the size is required to be from large to small, and the absorption wavelength can be adjusted from near ultraviolet to deep ultraviolet (380-275nm), and It has good dispersibility; the specific preparation process of zinc oxide quantum dots in this example is as follows: dissolve 0.01 mol of zinc acetate in 100 mL of absolute ethanol and reflux at 80 ° C for 3 h as a precursor, then cool it to room temperature, and then Dissolve 0.01mol sodium hydroxide in 100mL absolute ethanol, slowly add the sodium hydroxide ethanol solution to the precursor, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com