System and method of operating low coupling efficiency optical source by dissipating cladding modes

a technology of optical source and cladding mode, which is applied in the direction of optics, instruments, optical light guides, etc., can solve the problems of affecting device reliability, significant temperature increase, and low coupling efficiency of ibc lasers compared to typical telecom lasers, so as to reduce thermal effects on respective devices or systems, dissipate optical power, and dissipate the generated heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

prior art;

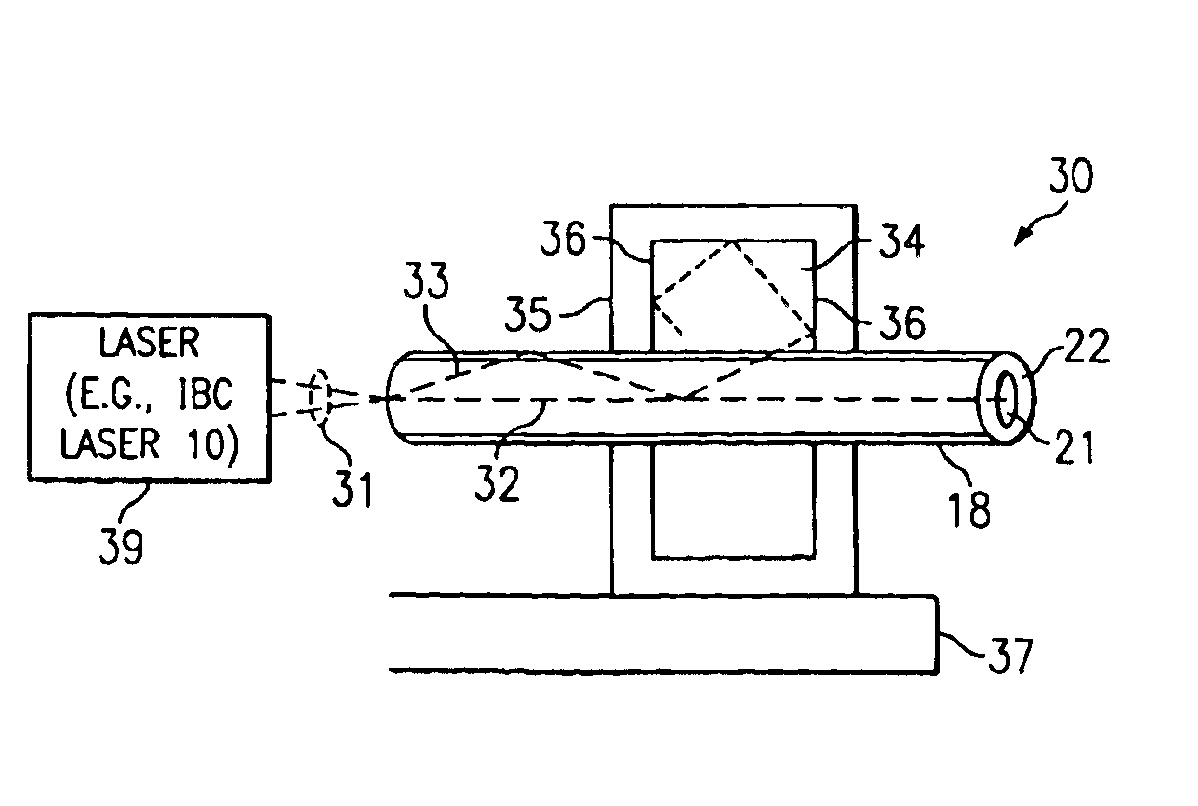

[0013]FIG. 2 depicts a single beam processed by an incoherently beam combined laser according to the prior art; and

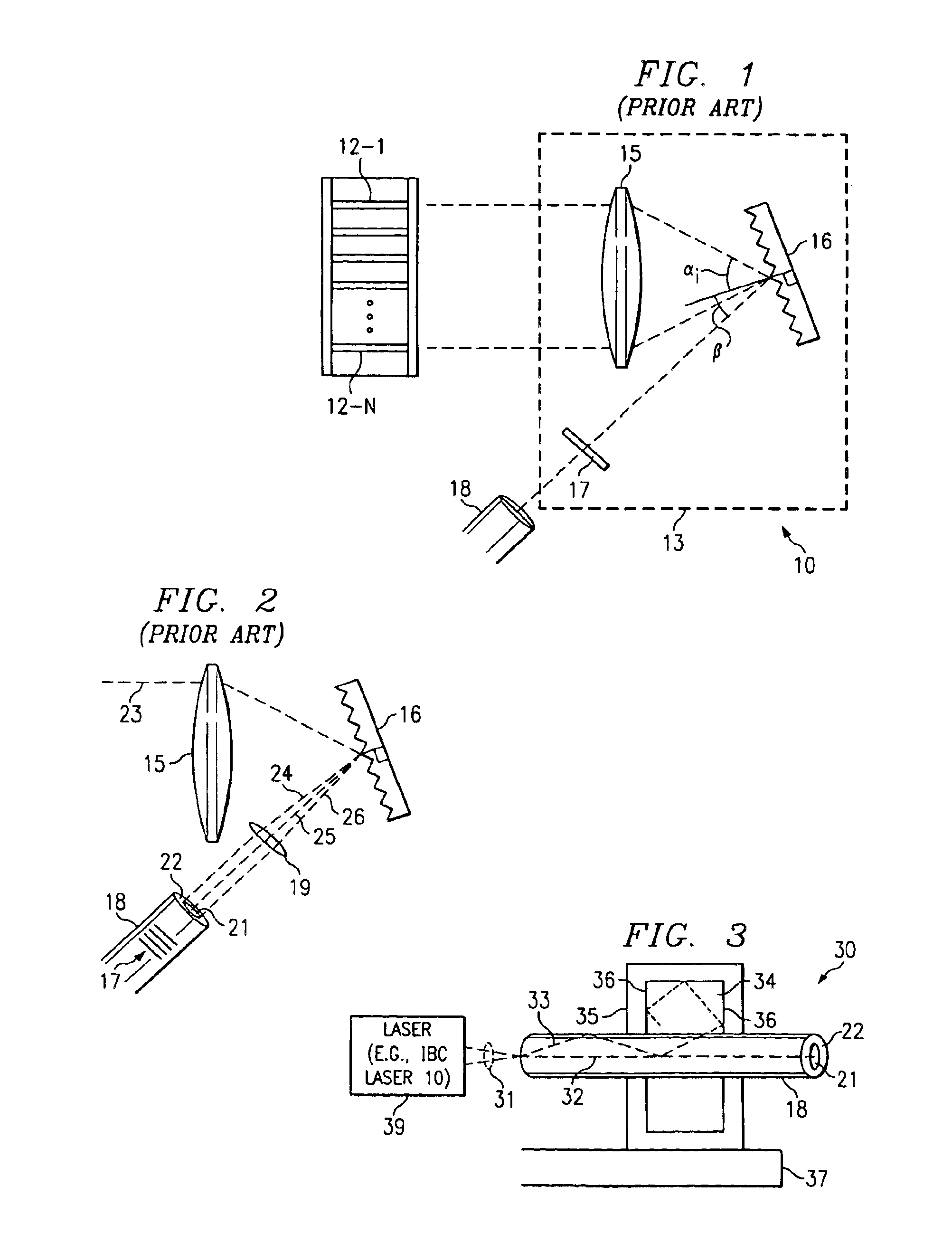

[0014]FIG. 3 depicts a system for dissipating cladding modes of a laser according to embodiments of the present invention.

DETAILED DESCRIPTION OF THE INVENTION

[0015]Before discussing the present invention in greater detail, it is appropriate to discuss the physical characteristics of IBC laser technology that may become problematic when relatively higher output powers are utilized. FIG. 2 depicts a portion of an IBC laser. It shall be appreciated that FIG. 2 is not drawn to scale or drawn according to an actual geometry for the purpose of illustrating the respective elements conveniently for the reader. The IBC laser generates beam 23 from one of its emitters 12-1 through 12-N (which are not shown in FIG. 2). Beam 23 may comprise several closely spaced Fabry-Perot modes. Accordingly, beam 23 does not consist of essentially one wavelength. It shall be appreciat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com