Method for performing microprocessing by utilizing laser cavitation micro jet flow

A micro-jet and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of processing accuracy and processing efficiency, workpiece thermal damage, etc., to achieve improved processing efficiency, high processing accuracy, and low thermal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below by accompanying drawing.

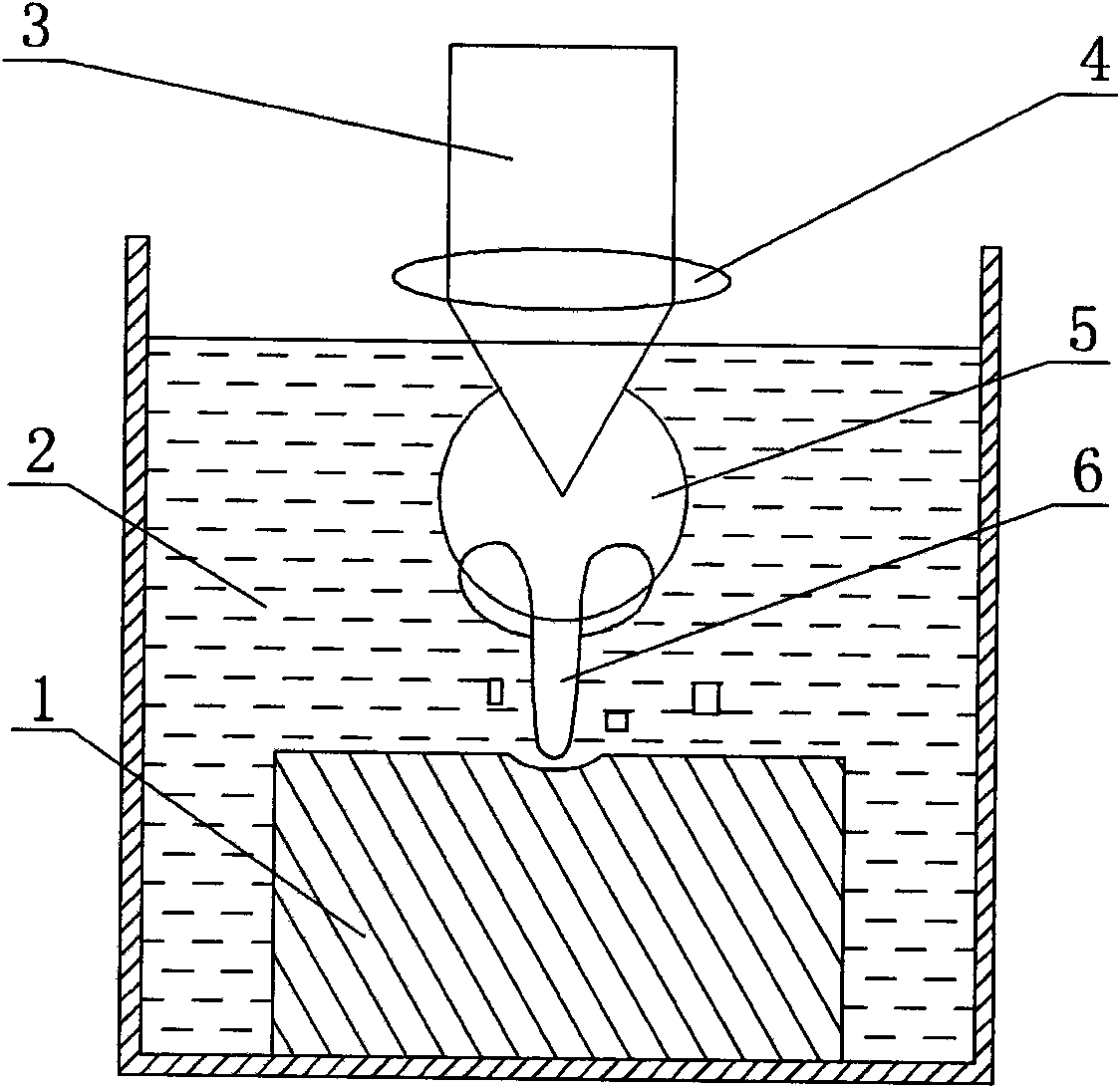

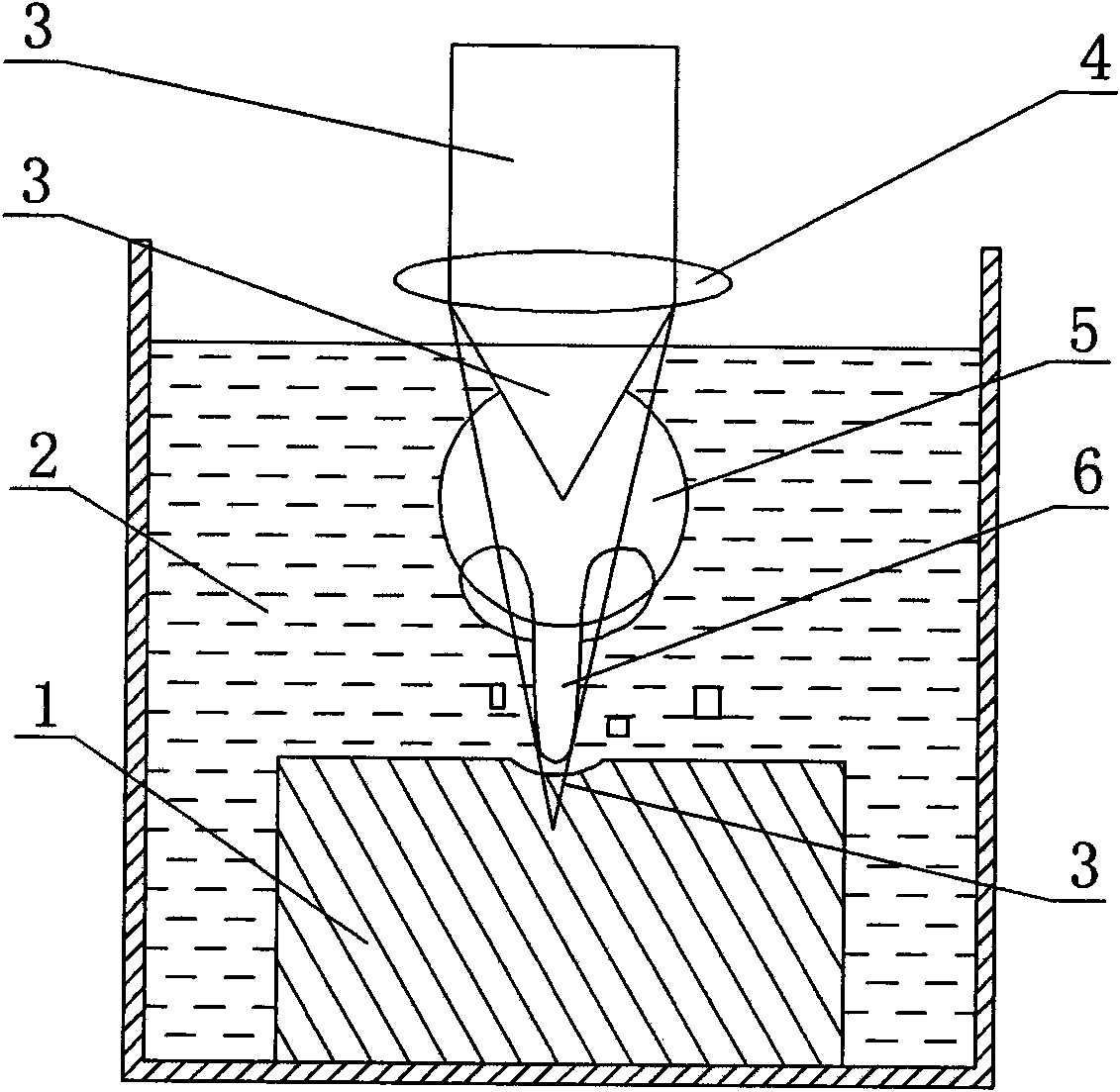

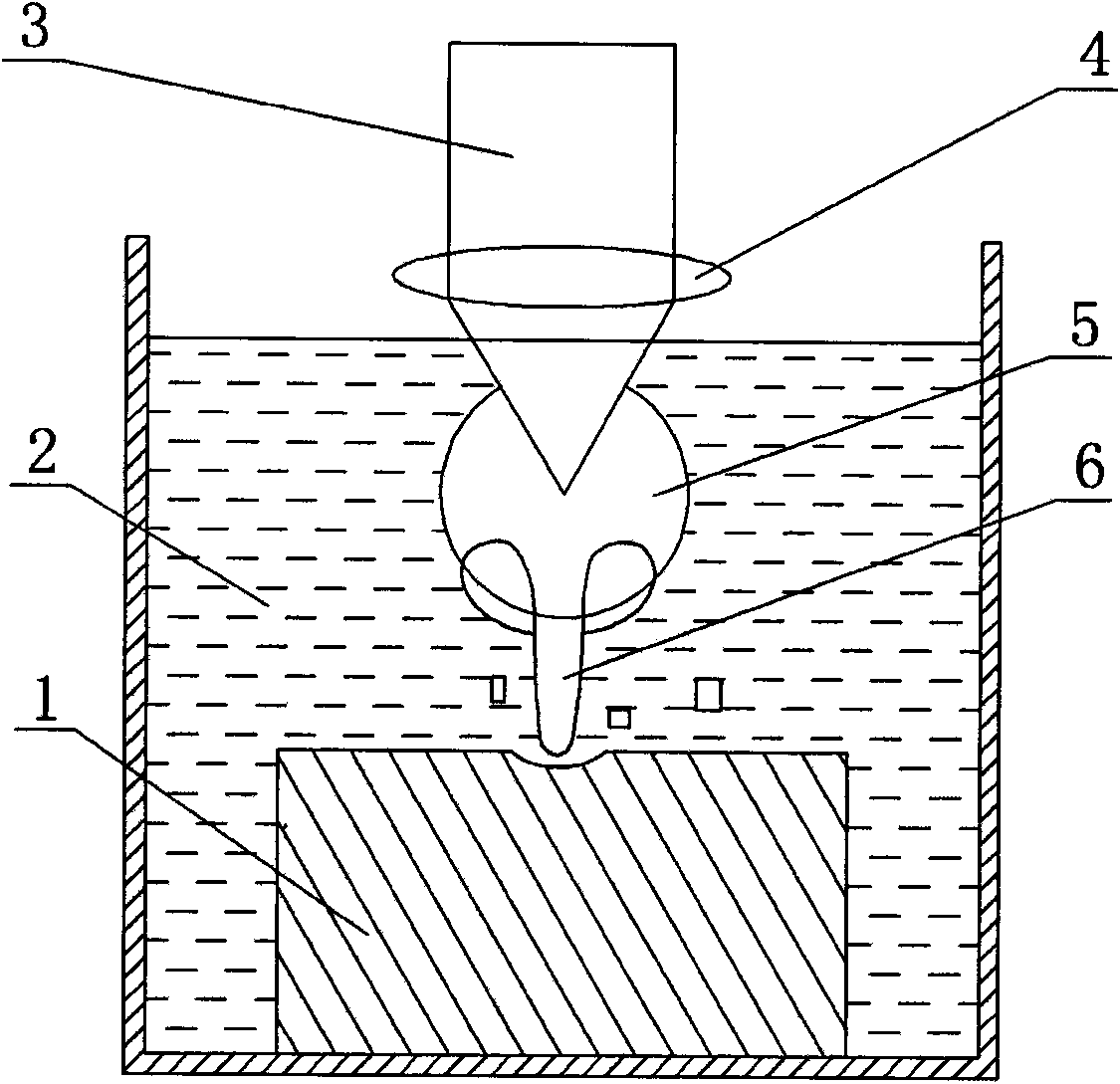

[0019] like figure 1 Shown, utilize laser cavitation microjet to carry out the method for microfabrication, comprise the following steps:

[0020] 1) Place the workpiece 1 to be processed in the liquid 2;

[0021] 2) The laser beam 3 is focused in the liquid 2 near the workpiece 1 through the lens group 4, and due to the optical breakdown effect, a cavity 5 is generated at the focal point;

[0022] 3) The cavity 5 expands-shrinks-collapses rapidly. Since the cavity 5 is adjacent to the surface of the workpiece 1, its contraction mode is asymmetrical shrinkage, which triggers the high-speed micro-jet 6 directed at the workpiece 1, and simultaneously generates high-intensity micro-shock waves;

[0023] 4) Depending on the energy of the laser pulse, the jet velocity can reach tens to thousands of meters per second. The high-speed micro-jet 6 hits the surface of the workpiece 1 to form an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com