Template device for reserving concrete stair construction crack

A technology of concrete and construction joints, which is applied to the preparation of formwork/formwork/work frame, building components on site, construction, etc., which can solve problems affecting work efficiency, falling garbage, affecting structural stress, etc., and reduce cleaning work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

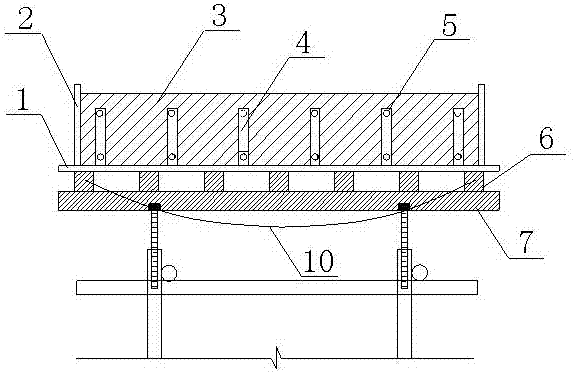

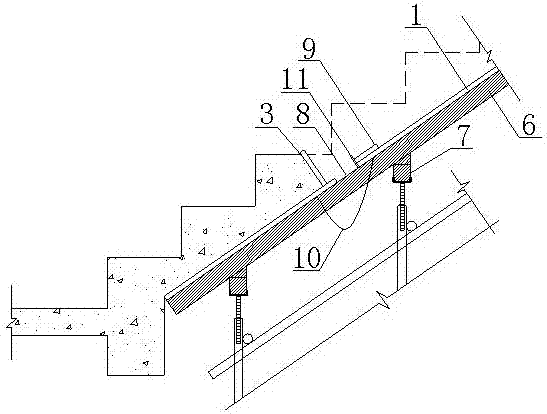

[0022] The formwork device for retaining construction joints of concrete stairs according to the present invention comprises a bottom form 1 , a side form 2 and a sealing plate 3 .

[0023] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the cross-section of the formwork device of the reserved concrete staircase construction joint in the embodiment of the present invention, figure 2 It is a schematic diagram of the longitudinal section of the formwork device for reserved concrete staircase construction joints according to the embodiment of the present invention. As shown in the figure, the bottom mold 1 is supported on the secondary flute 6, the secondary flute 6 is supported on the main flute 7, and a supporting scaffold is provided under the main flute.

[0024] The base form 1 leaves 10-12 cm reserved slab seam 8 at the construction joint position of the two concretes, and the rear installed plate 9 is placed on the upper opening of the reserved s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com