Patents

Literature

30results about How to "Linear smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

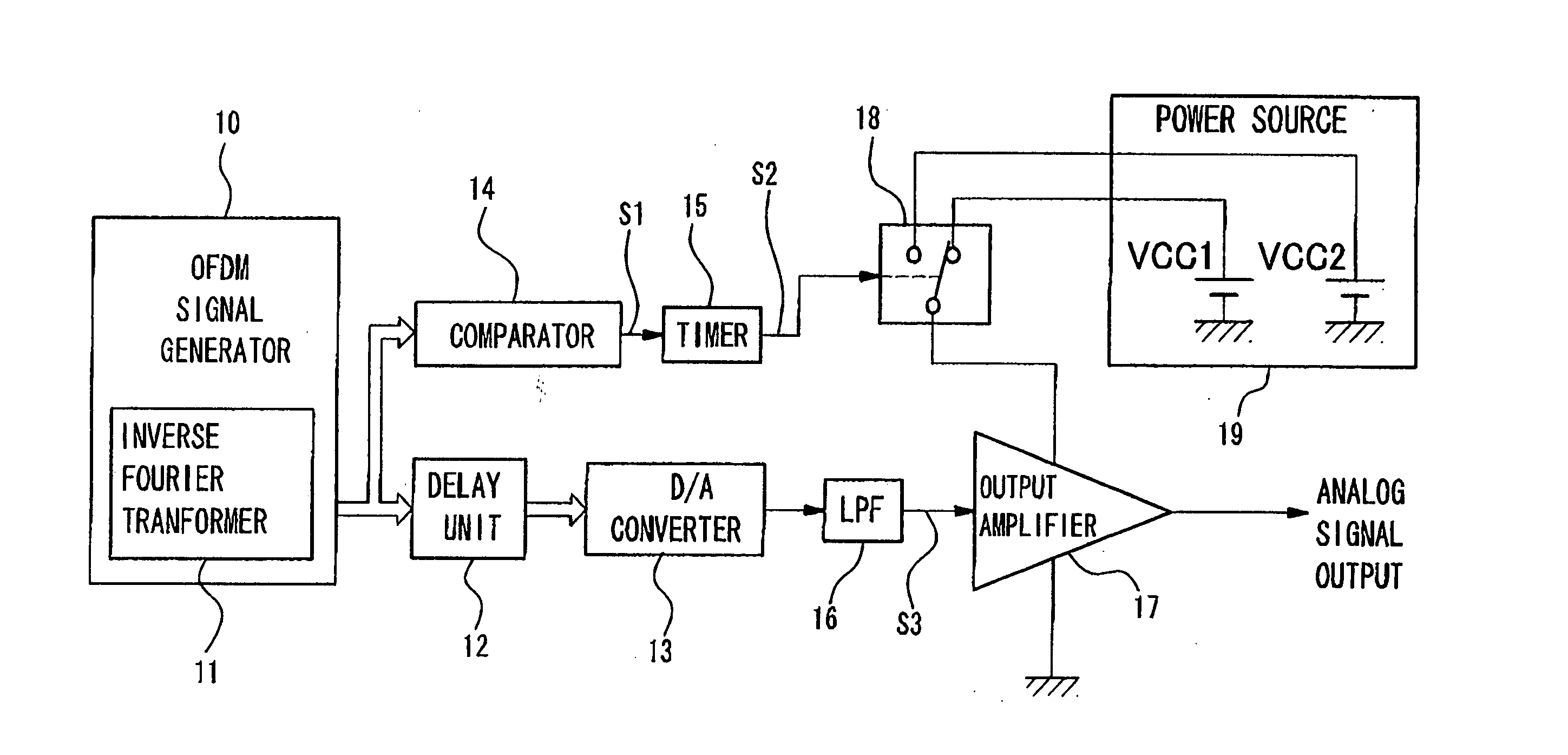

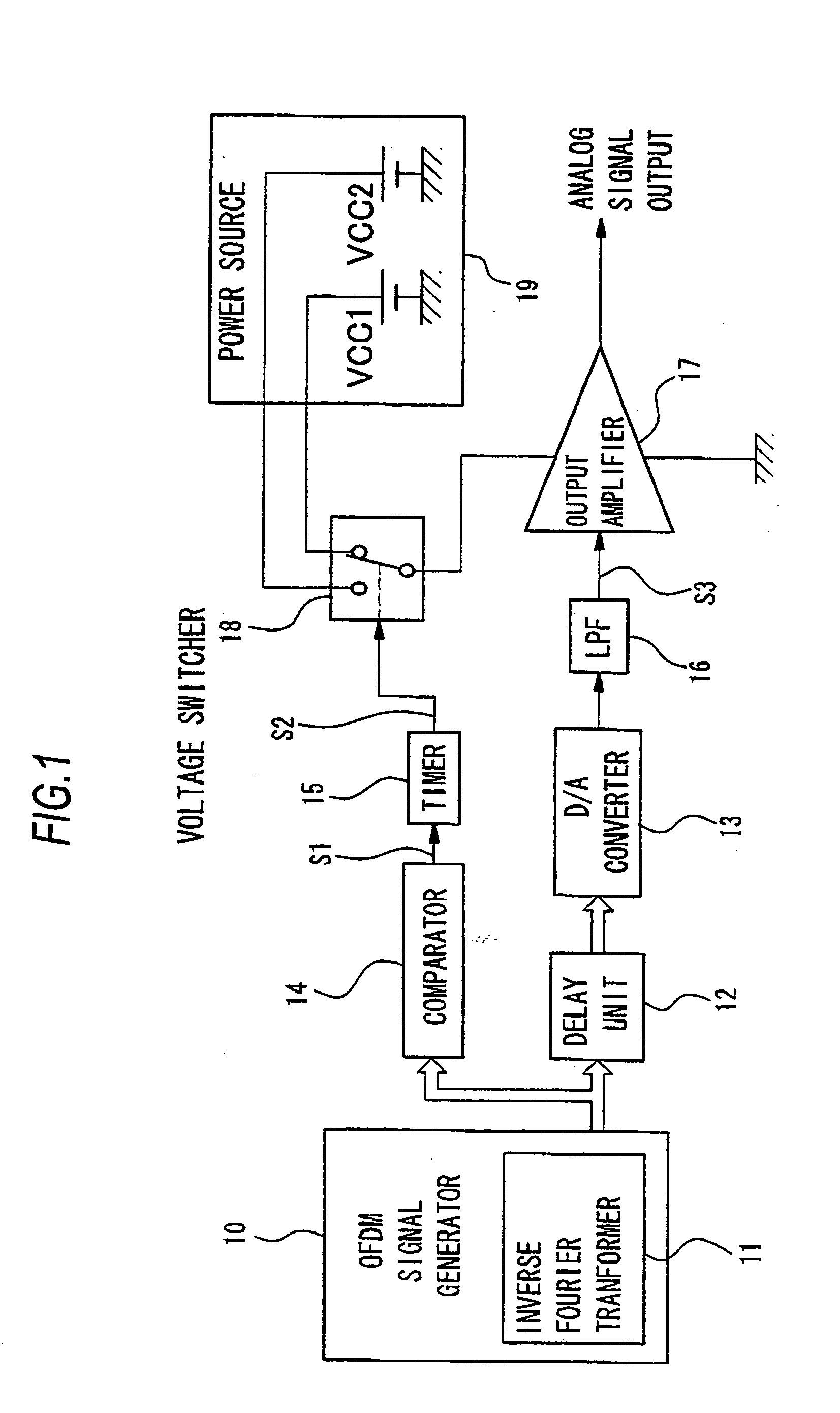

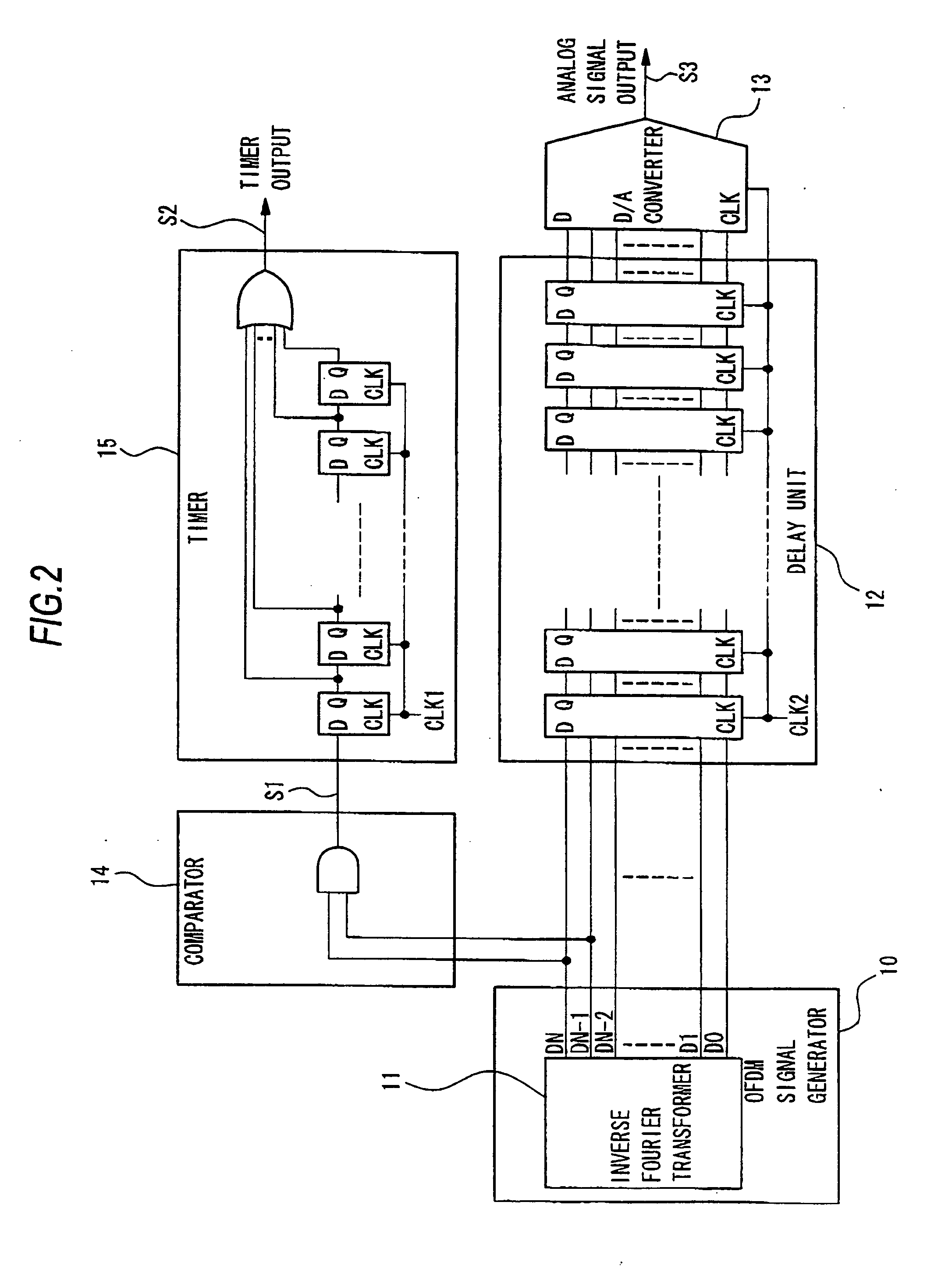

Signal output circuit, communication apparatus and signal output control method

InactiveUS20070223360A1Reduce power consumptionLinear smoothSystems using filtering and bypassingTransmission/receiving by adding signal to waveLow voltageHigh pressure

An OFDM signal generator performs inverse Fourier transform of frequency domain data of an OFDM signal, and generates and outputs time domain data. An output amplifier amplifies an analog signal transmitted via a delay unit and a D / A converter. Here, a comparator detects whether the amplitude of a signal has exceeded a predetermined value; and when the amplitude of the signal has exceeded the predetermined value, a timer outputs a timer output during a predetermined period. A voltage switcher switches a power voltage to be supplied to the output amplifier from low voltage power to high voltage power while a timer output is being generated; and increases the power voltage only during a predetermined period elapsed after the amplitude of a signal has exceeded a predetermined value.

Owner:PANASONIC CORP

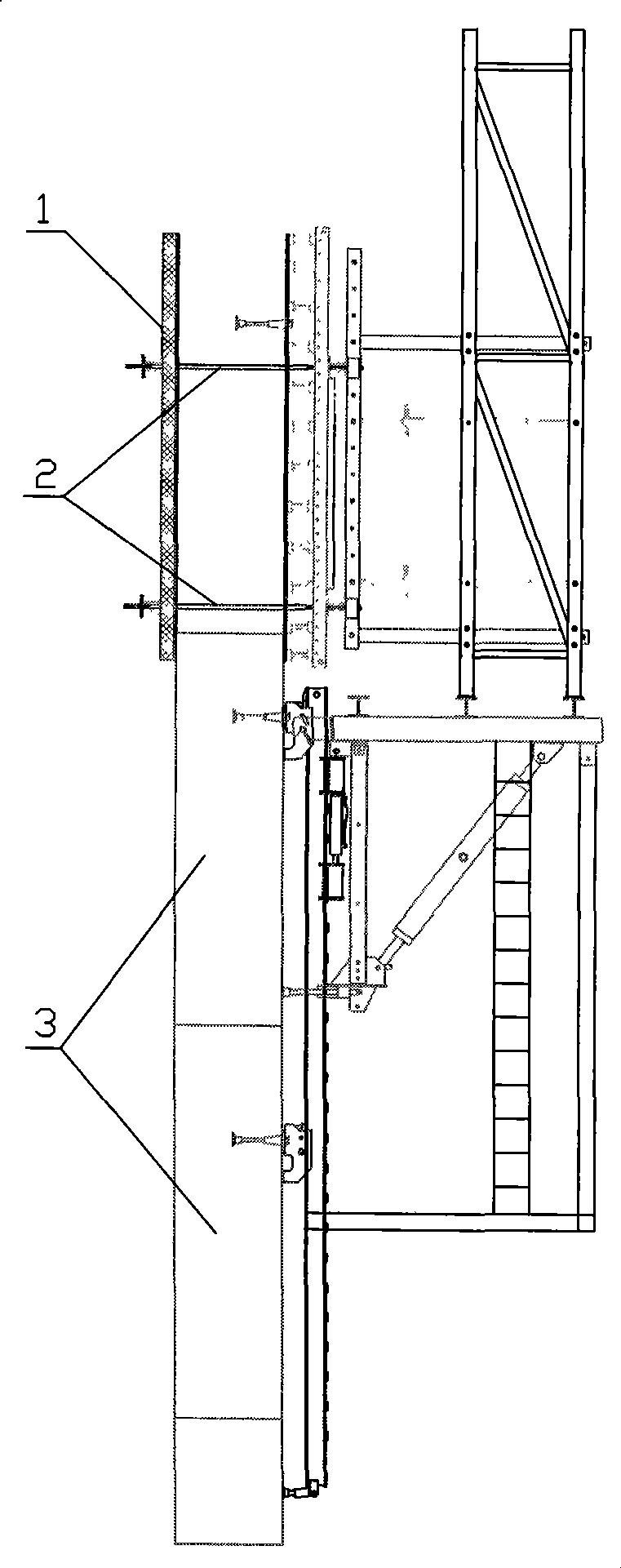

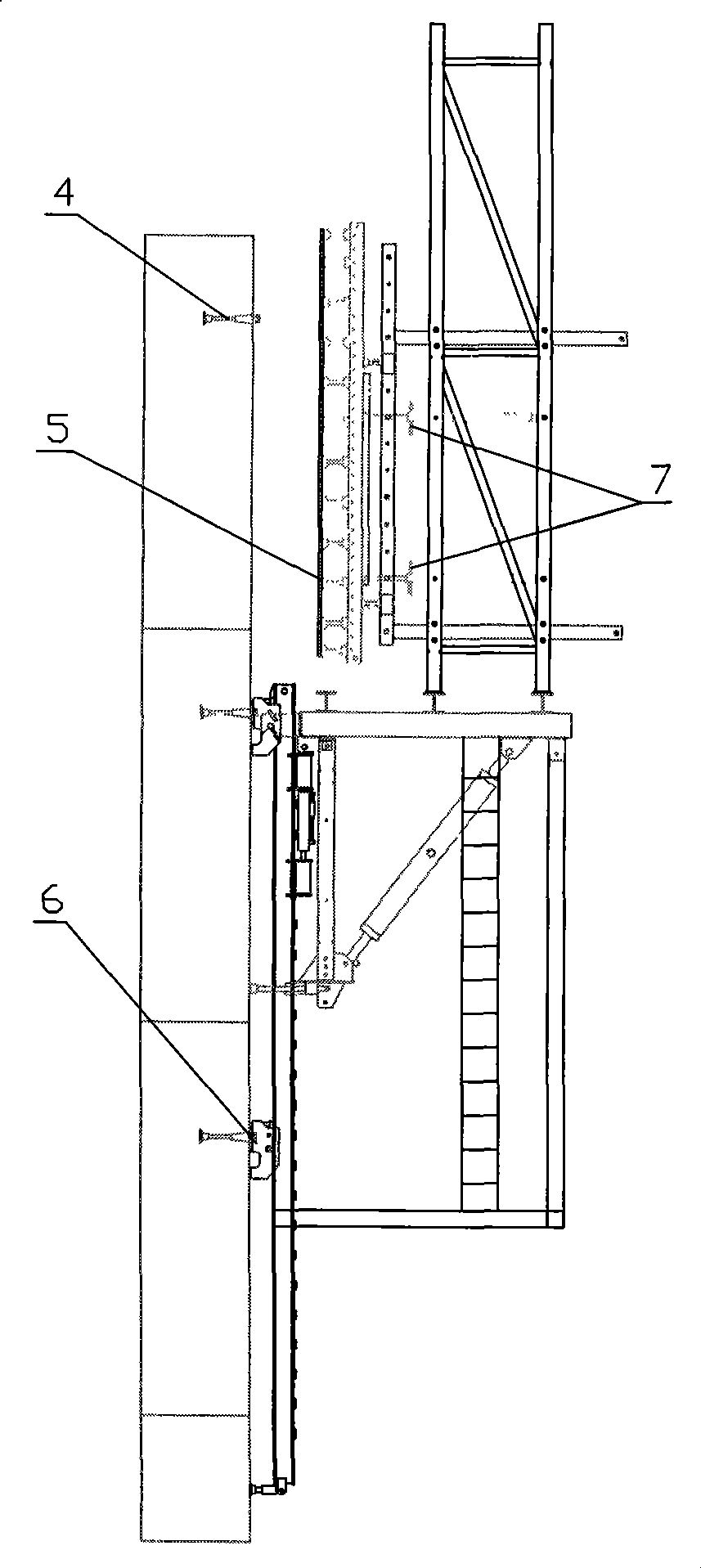

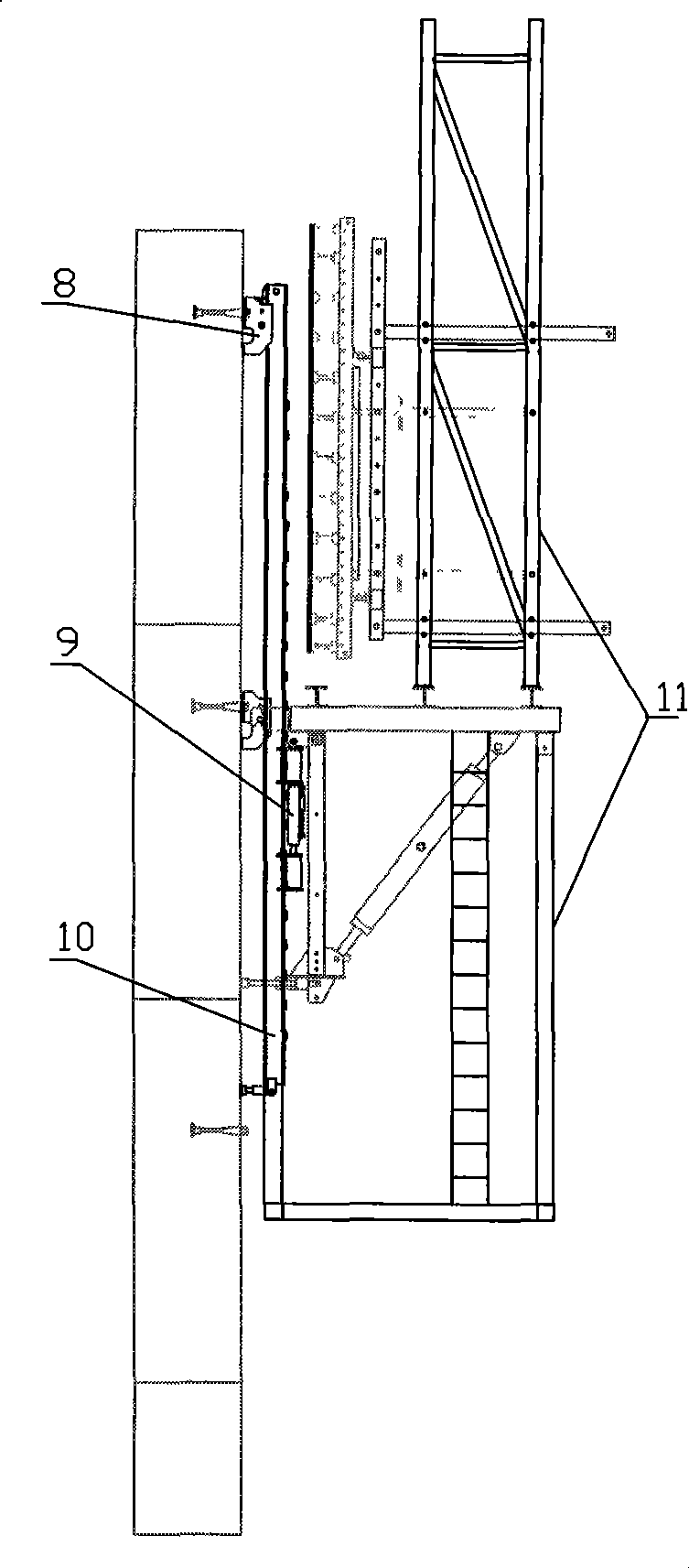

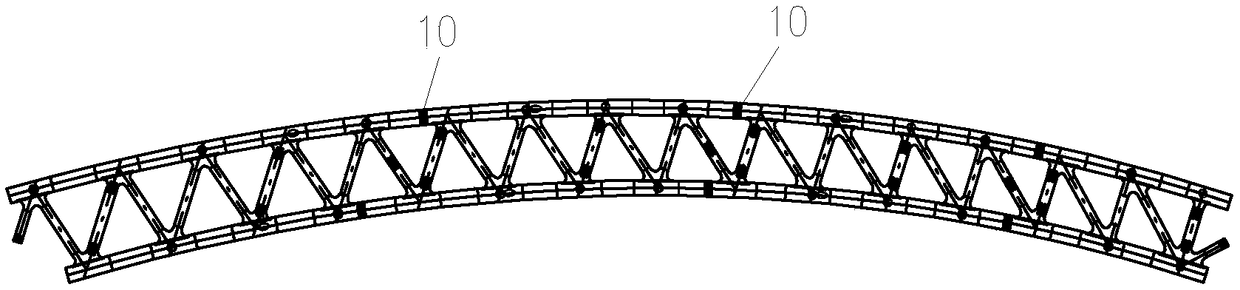

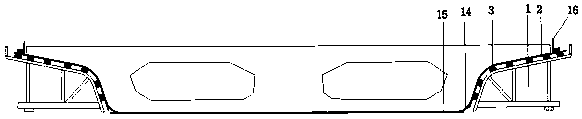

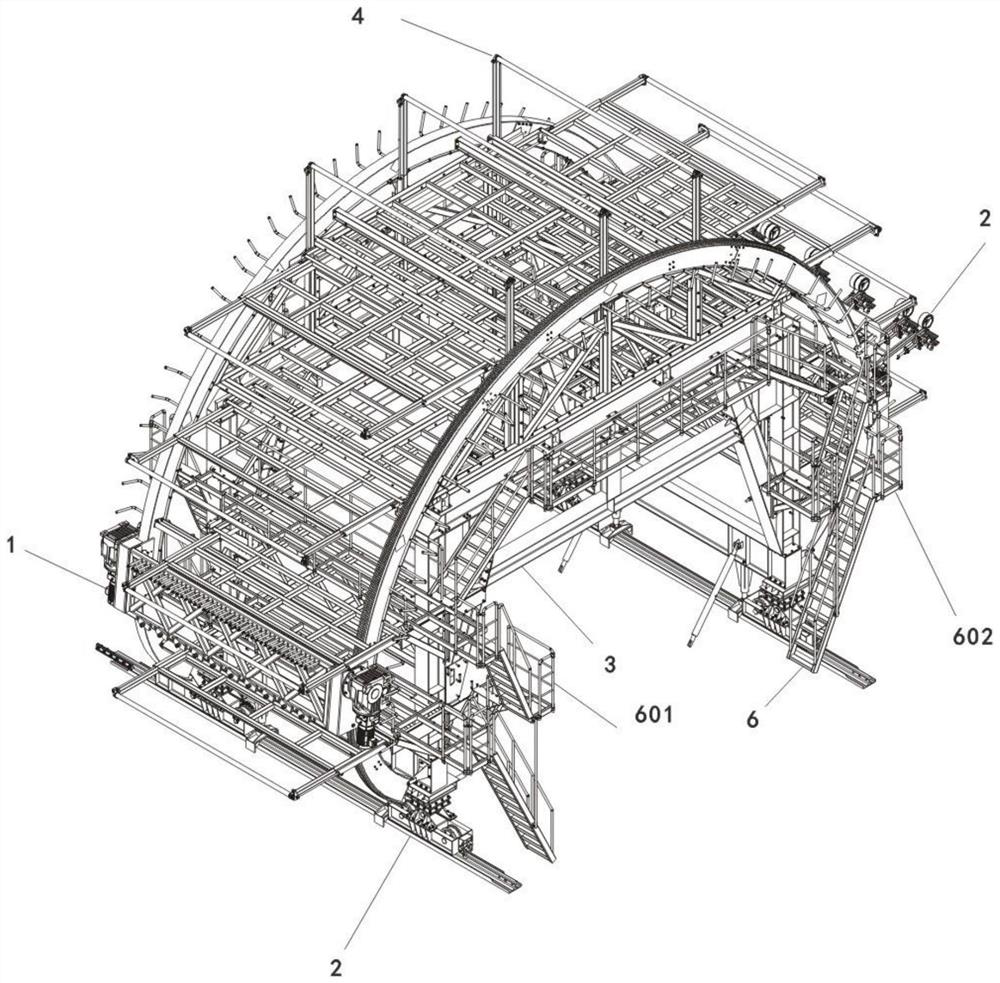

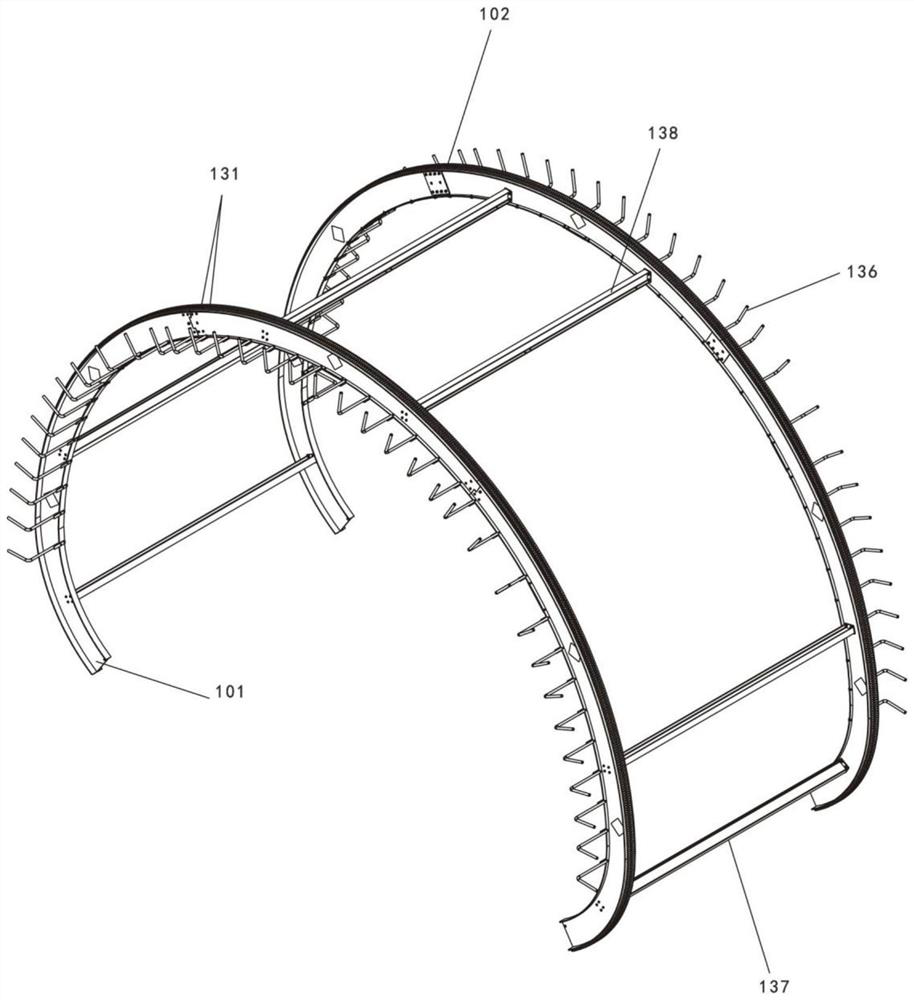

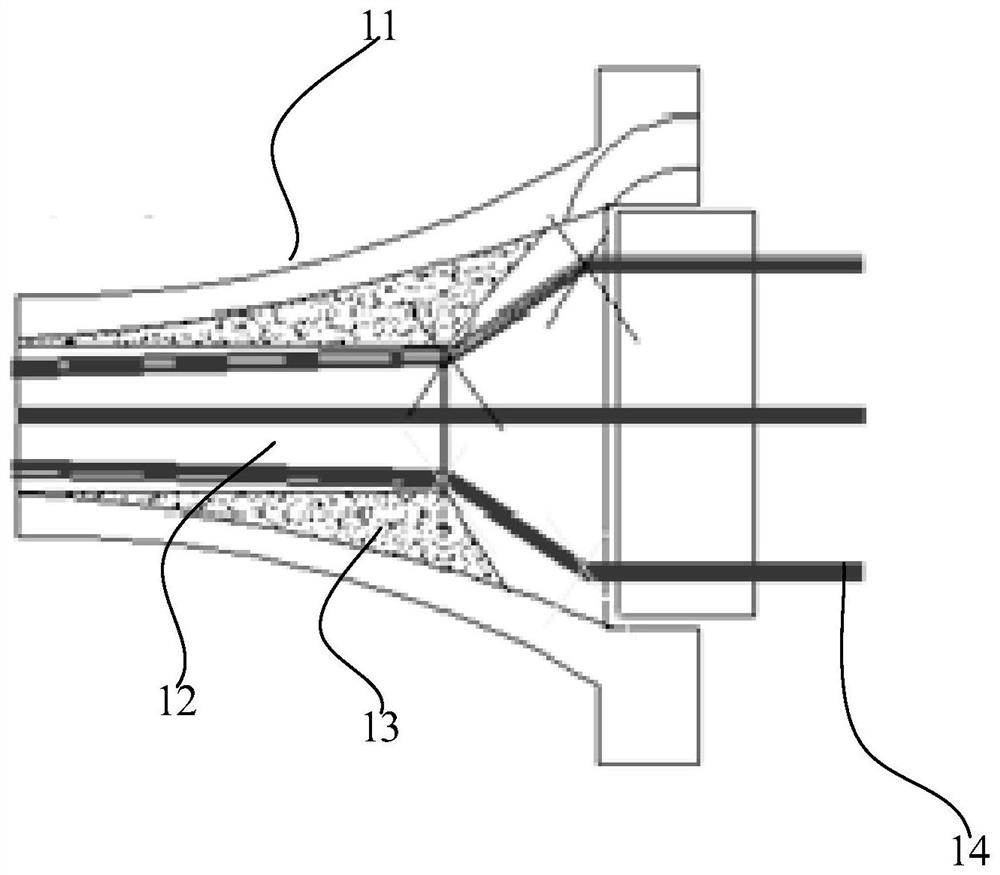

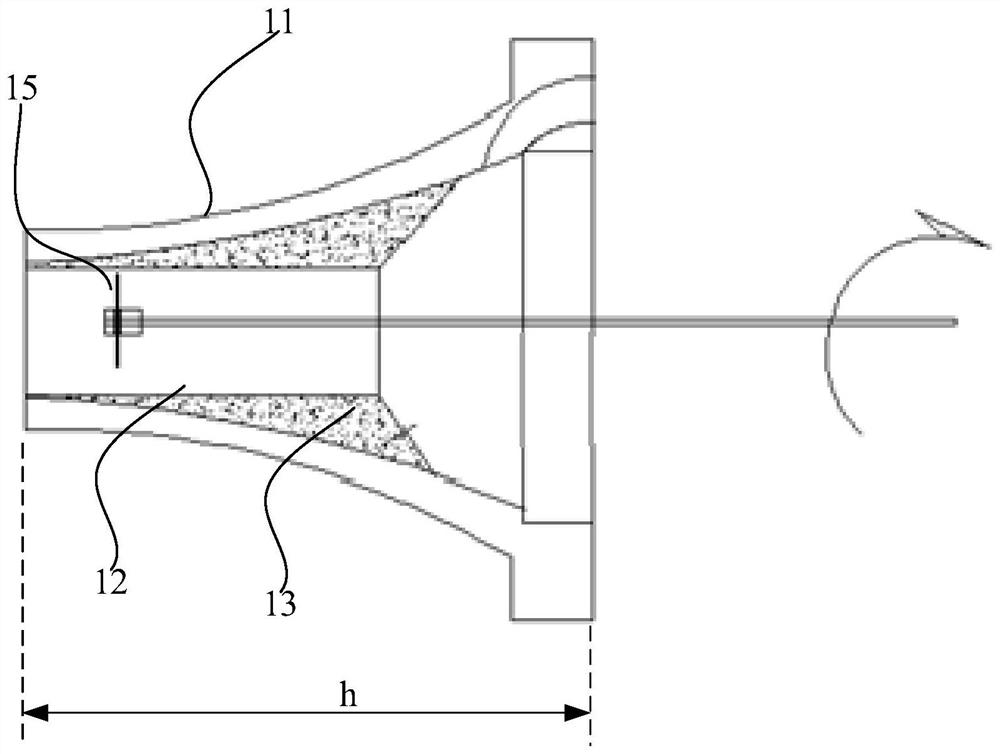

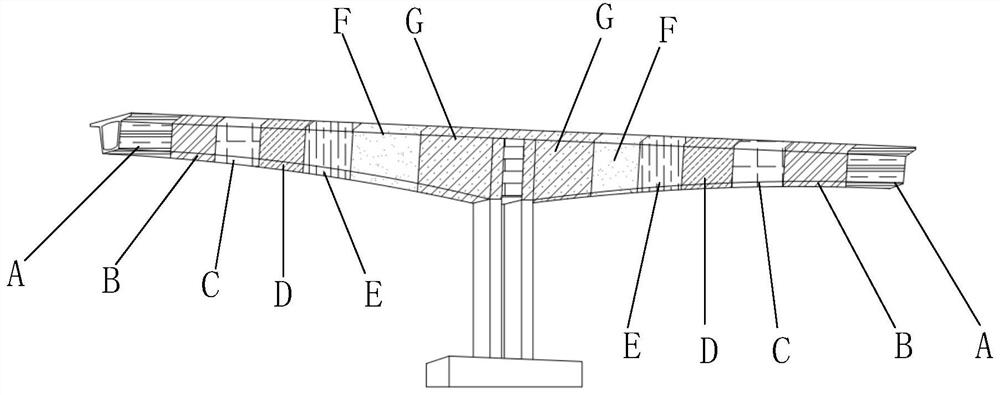

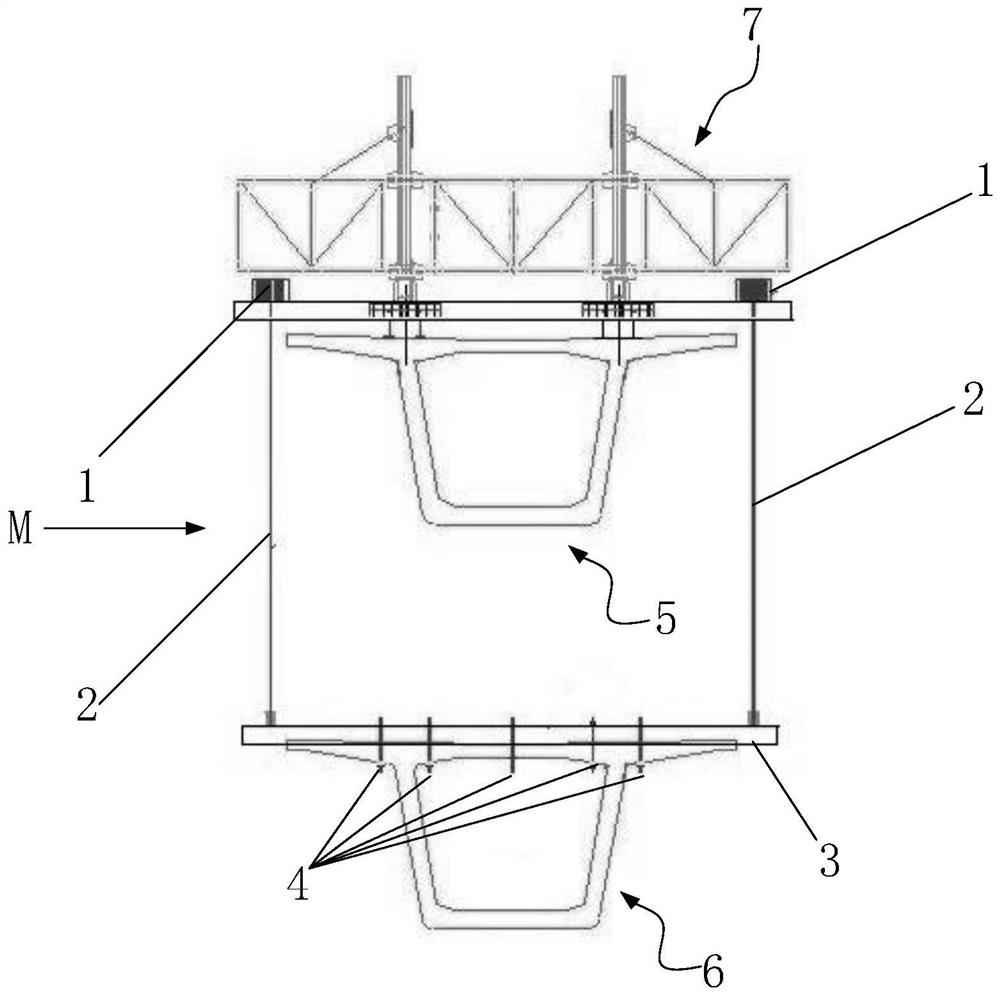

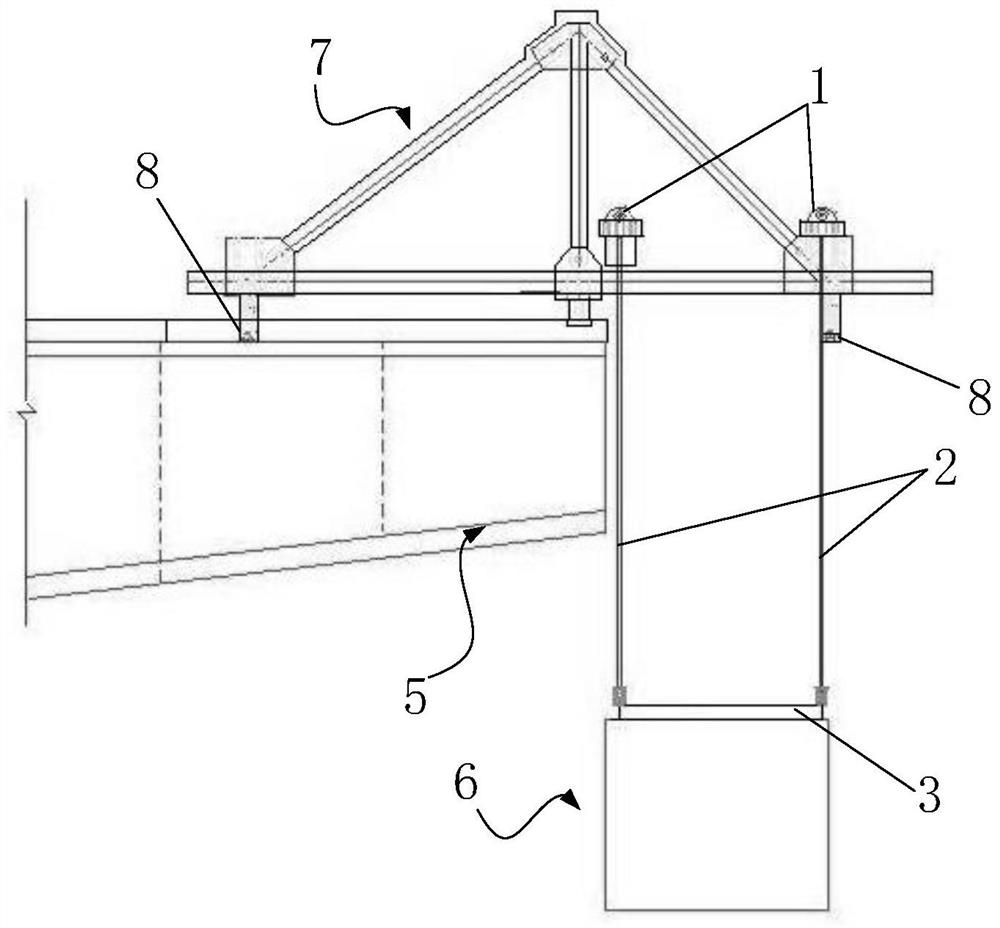

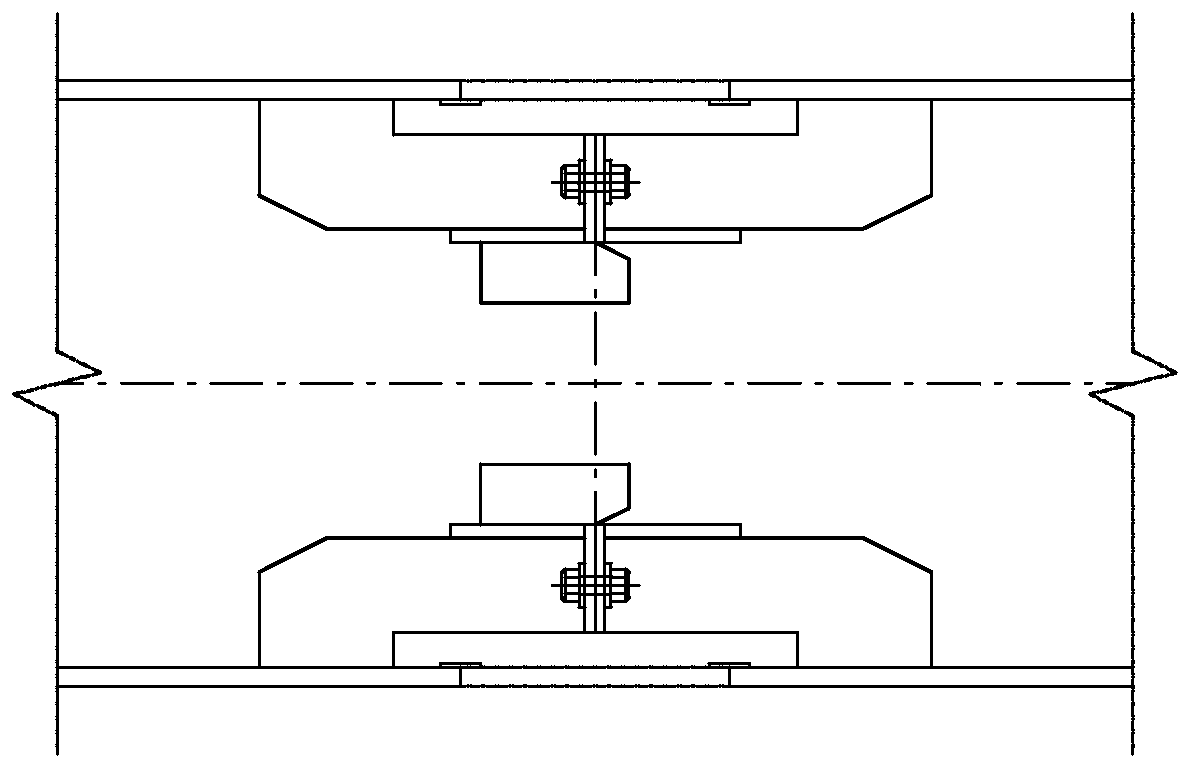

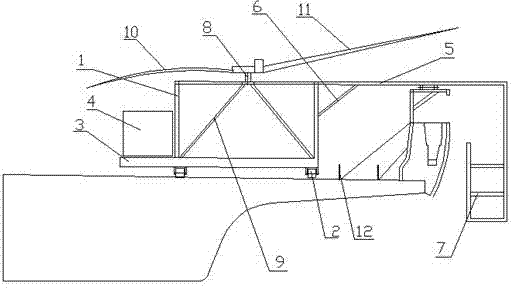

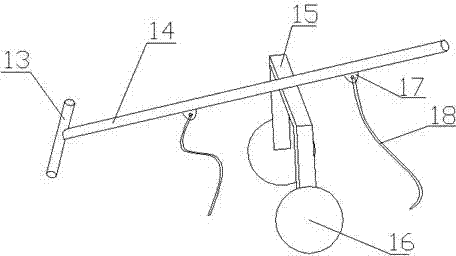

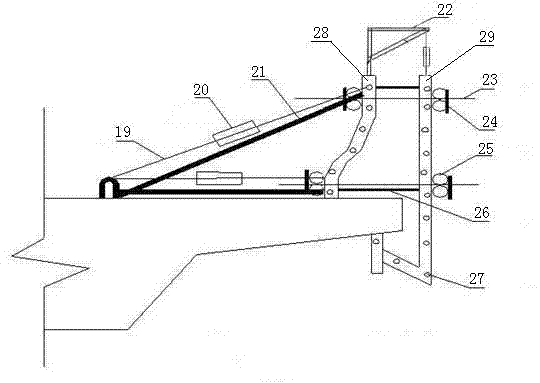

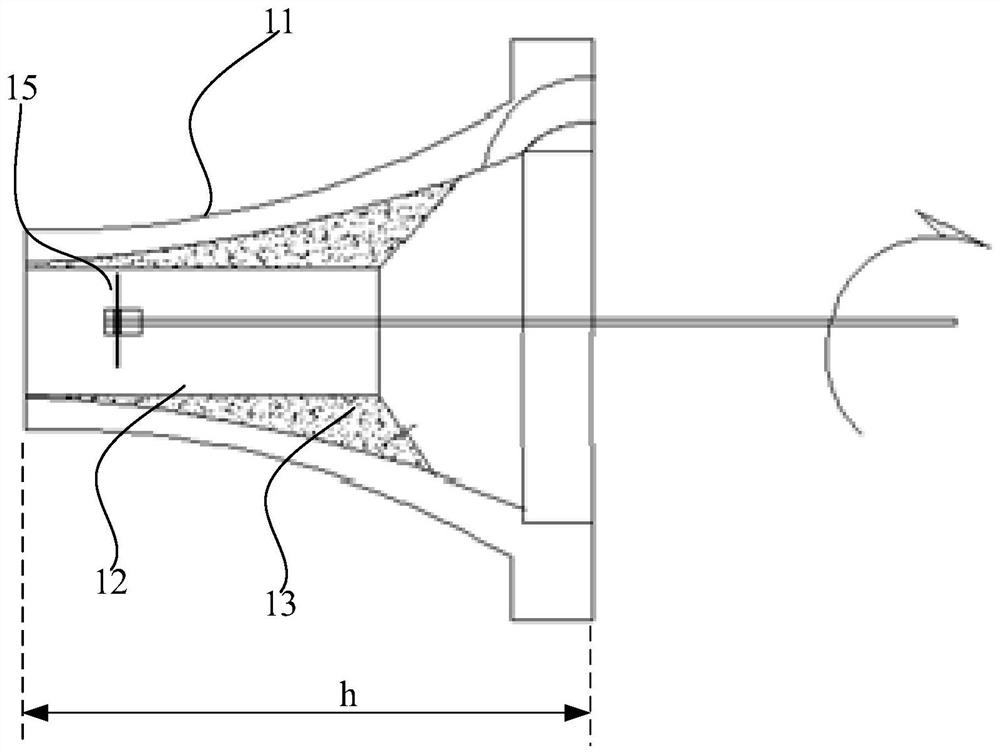

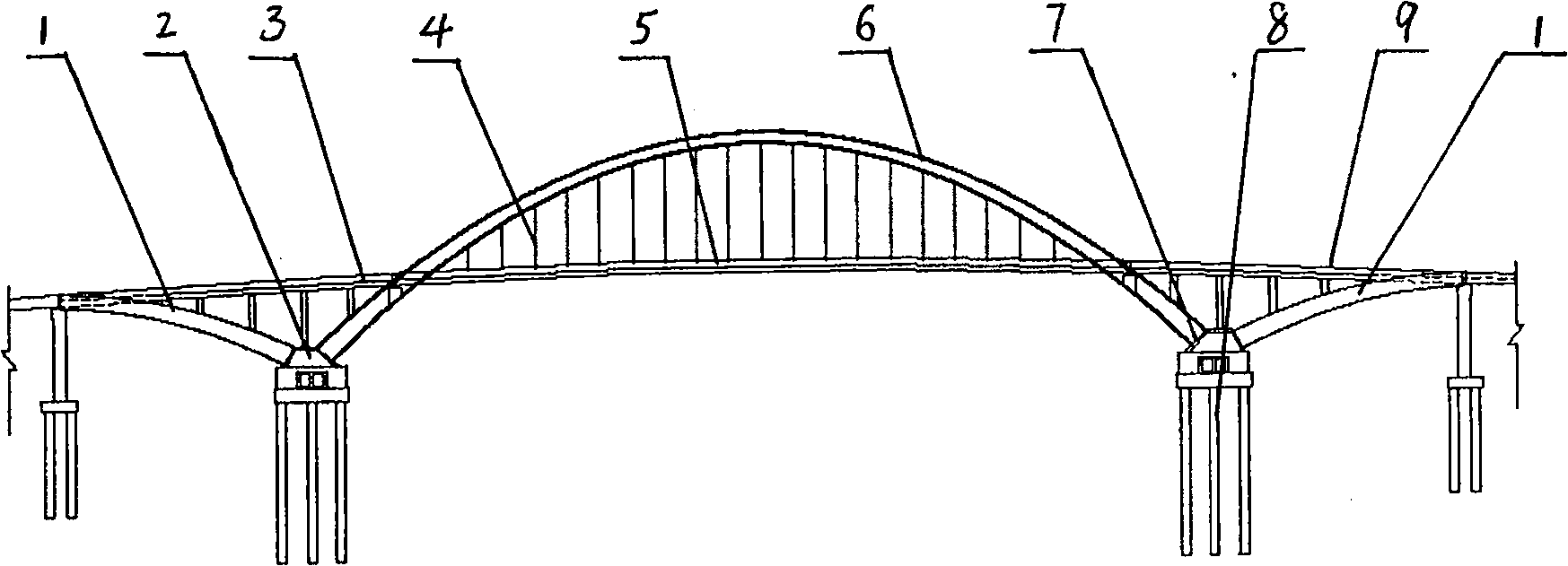

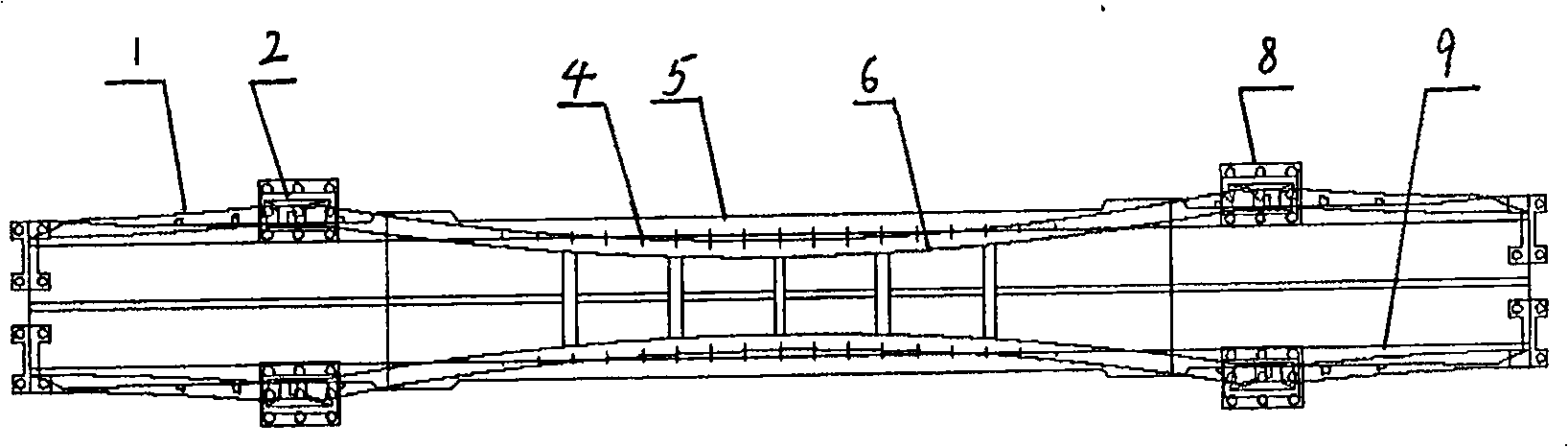

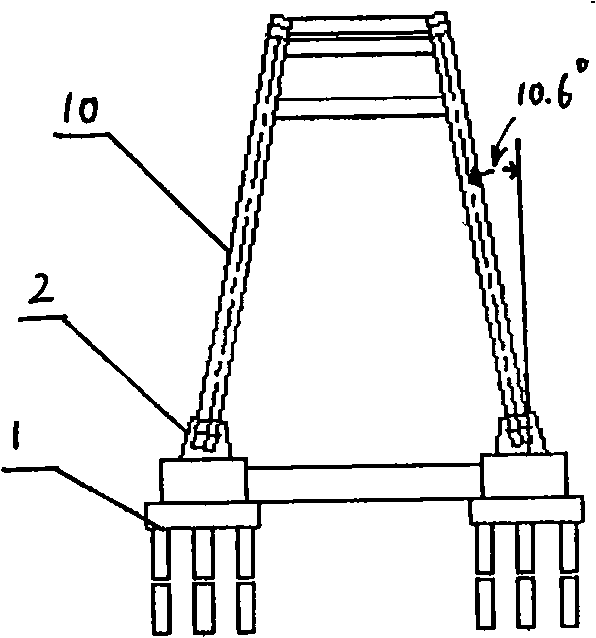

External inclined type concrete arch rib construction method and hydraulic self-creeping formwork equipment

InactiveCN101413248AThe deviation value of the three-dimensional coordinates of the structure is smallAccurate structure sizeForms/shuttering/falseworksBridge erection/assemblyShape deviationCantilever

The invention applies to the field of bridge construction, and provides a method for constructing camber-type concrete arch ribs, as well as a hydraulic self-ascending mold device. The method is to utilize the hydraulic self-ascending mold device for construction by adopting a self-ascending mold segmented cantilever casting mode. A rail and a template of the self-ascending mold device are both in the shape of a straight line or straight surface, or are both in the shape of a curve or a curved surface. The method constructs the camber-type concrete arch ribs by adopting the self-ascending mold segmented cantilever casting mode, wherein the guide rail and the template of the self-ascending mold device can be in the shape of a curve or a curved surface; as the template and a bracket of the device can be repeatedly used during the construction of the arch ribs, steel used for the template and the bracket can not be wasted; in addition, the method can greatly improve construction efficiency, shortens construction period, and realizes that a cast concrete arch rib is small in the deviation value of structural three-dimensional coordinate, accurate in structure size, smooth in line shape and clear in edge angle, and achieves the high-precision requirements on line shape deviation.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

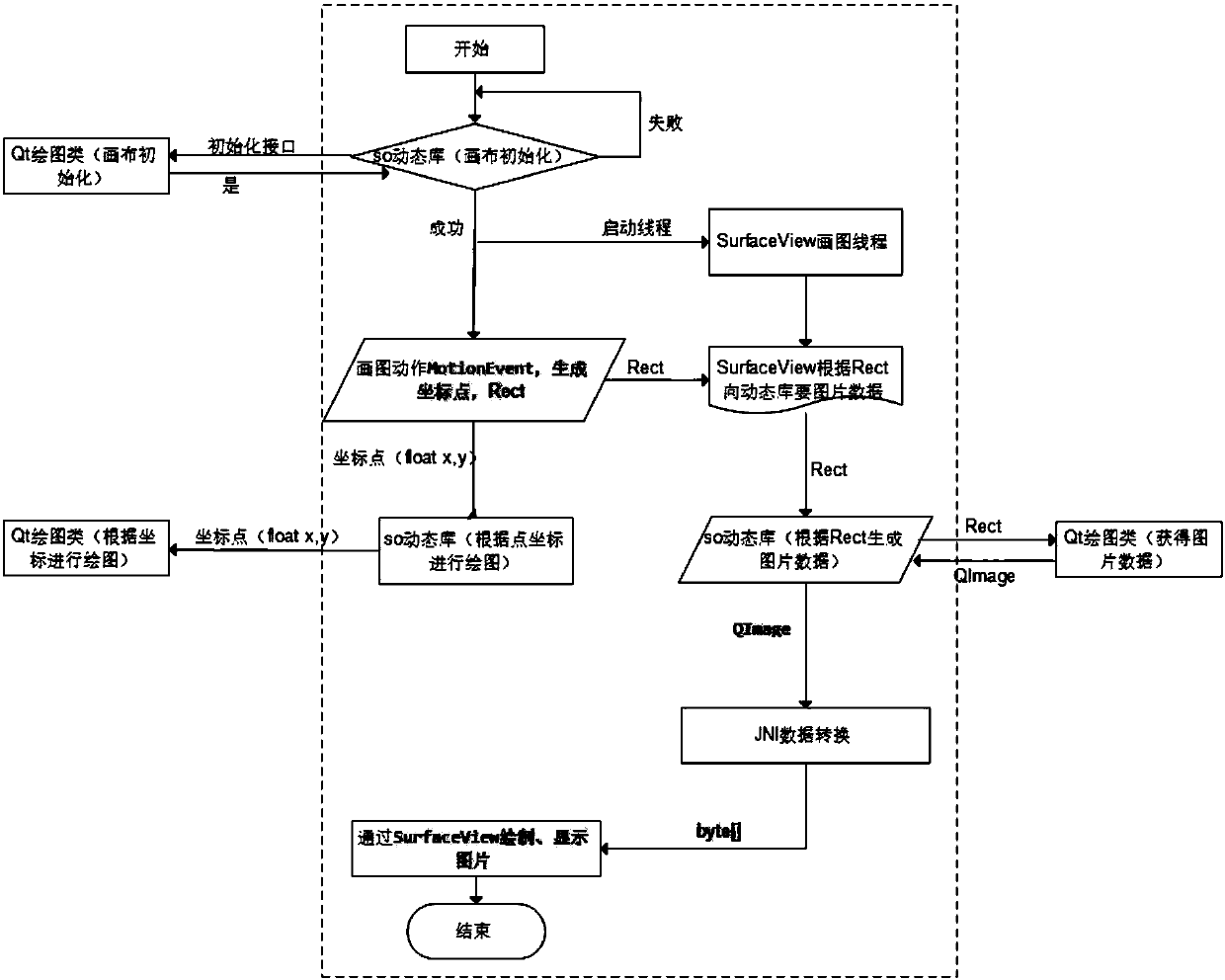

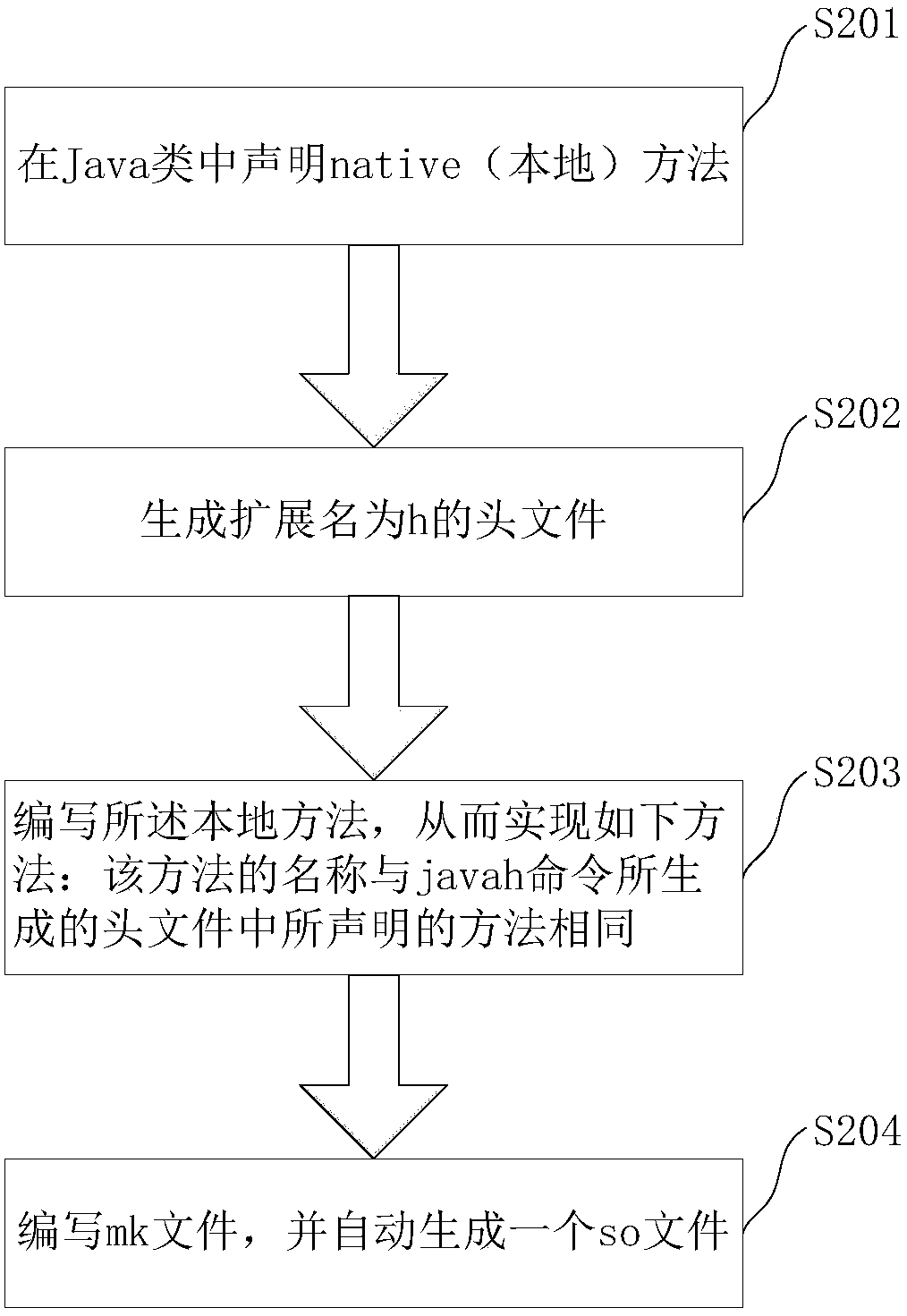

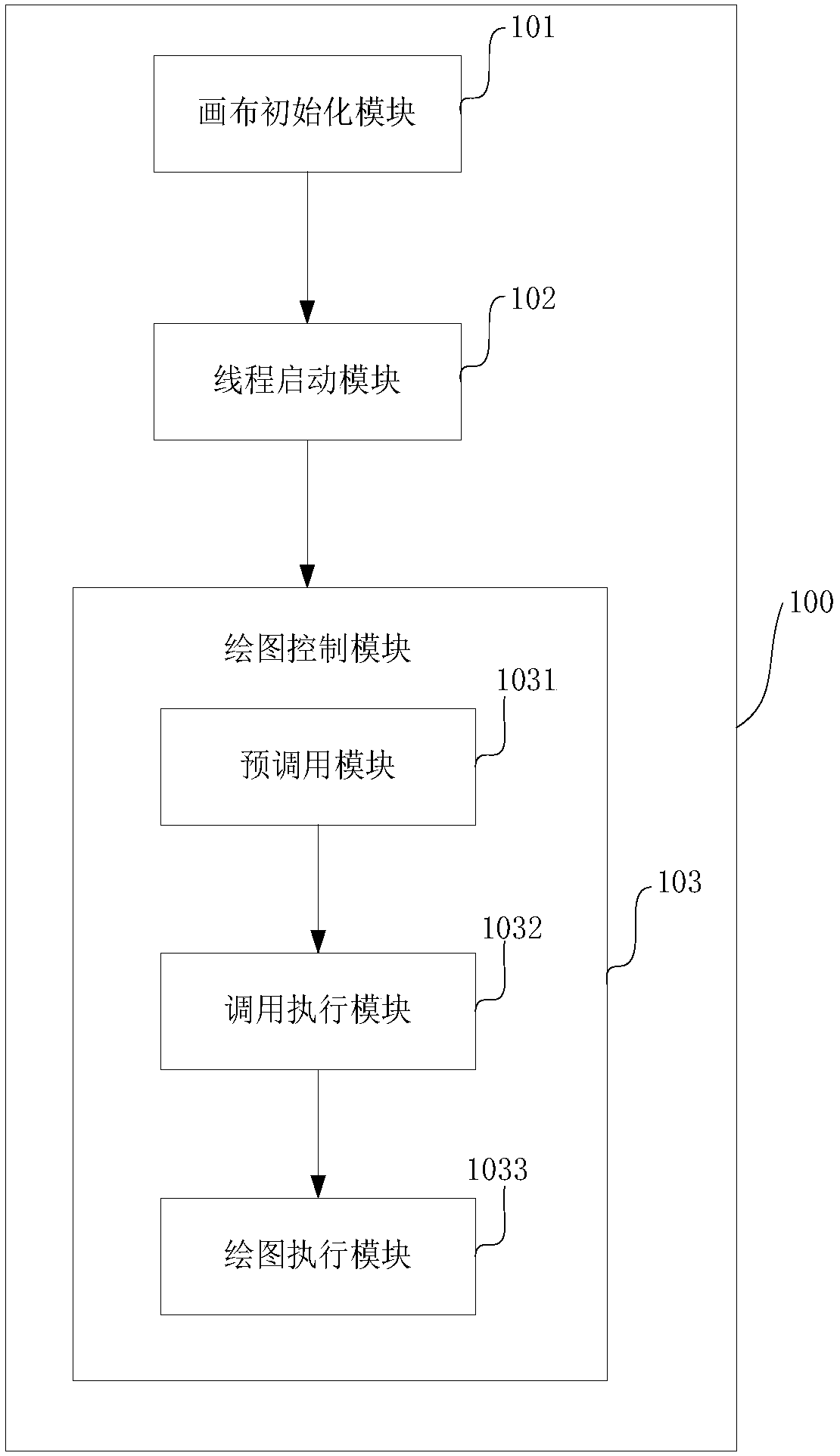

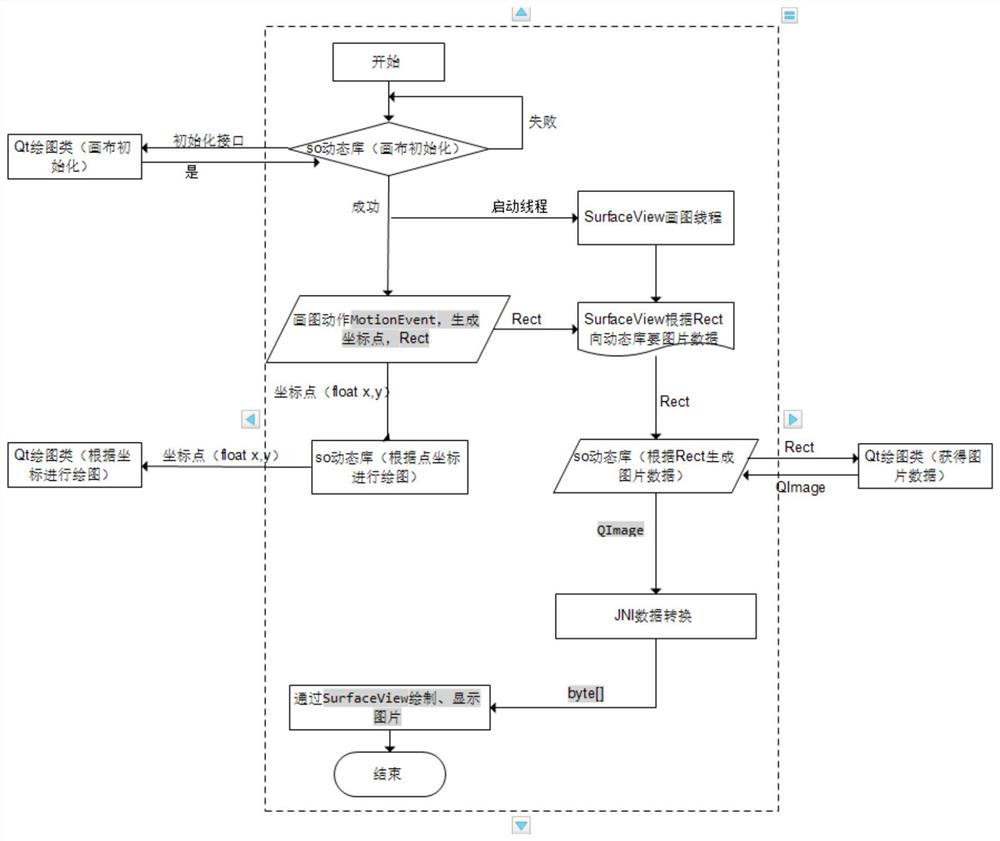

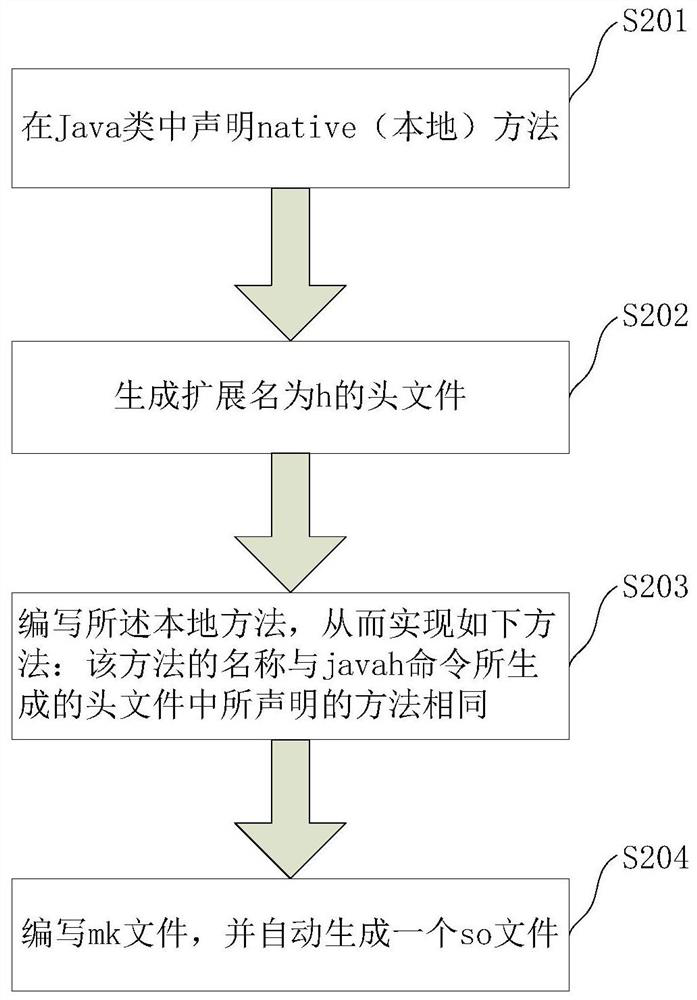

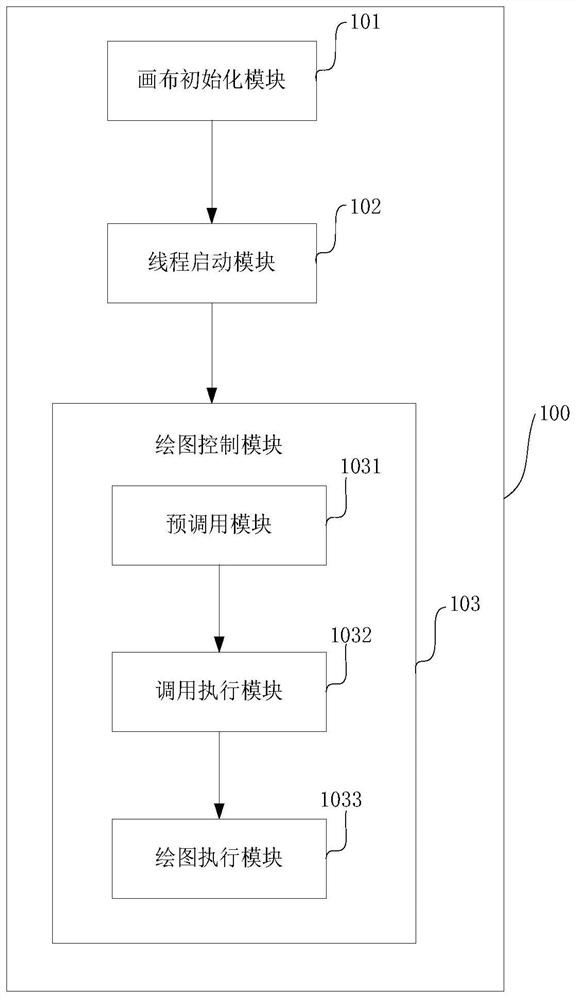

JNI-based apparatus and method for Android system to call Qt picture drawing system in multithread manner

ActiveCN107818588AImprove drawing speedDrawing speed is noticeableDrawing from basic elementsAnimationCross-platformComputer graphics (images)

The invention discloses a JNI-based apparatus and method for an Android system to call a Qt picture drawing system in a multithread manner. The method comprises the following steps: the Android systemis operated, system memory is cleared, painting canvas initialization is performed, and an so dynamic library is activated to do preparation work for calling the Qt picture drawing system; if the painting canvas initialization fails, the so dynamic library is activated again; after successful activation of the so dynamic library, an image data sampling thread and a SurfaceView drawing thread arestarted at the same time in a first language environment, operation of the image data sampling thread is performed, coordinate points are generated via a picture drawing MotionEvent, a rectangular frame is drawn according to the generated coordinate points via an Rect command, point coordinates float (x, y) are loaded to the so dynamic library, a picture is drawn by the Qt picture drawing system according to the point coordinates float (x, y), operation of the SurfaceView drawing thread is performed, the picture is drawn via SurfaceView built in the Android system, and the picture drawn via SurfaceView is displayed on a display device. Picture drawing speed is improved markedly, and cross platform calling is realized.

Owner:SHENZHEN HONGHE INNOVATION INFORMATION TECH CO LTD

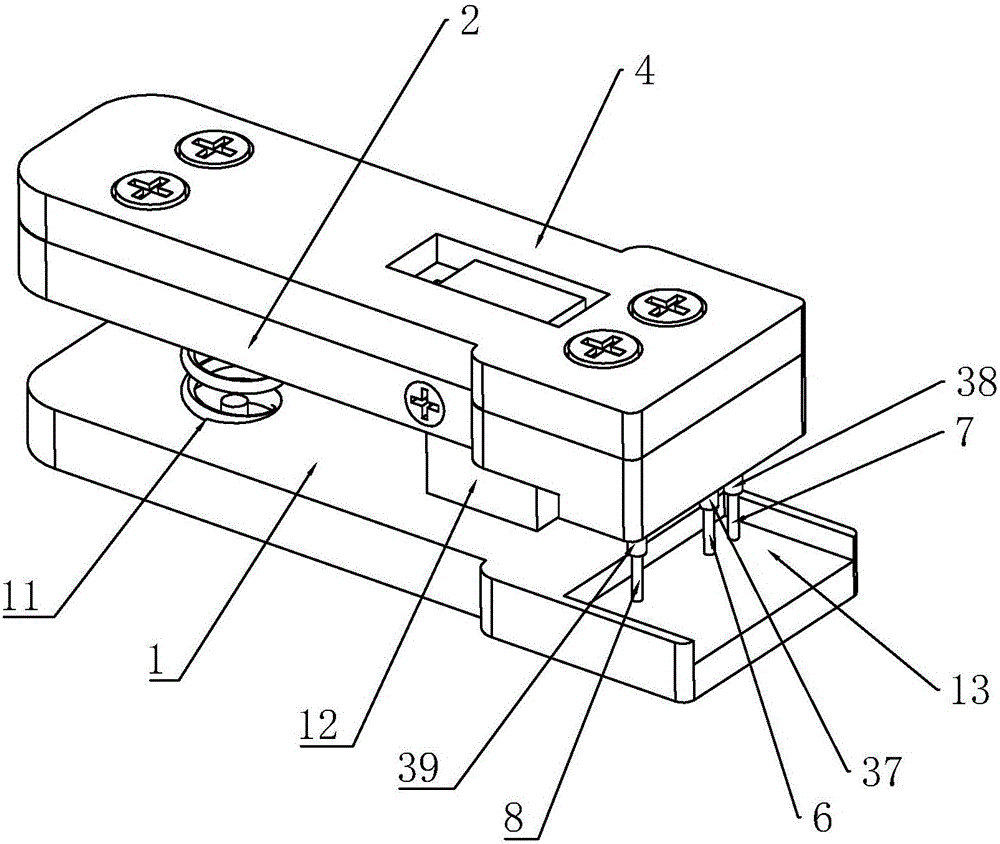

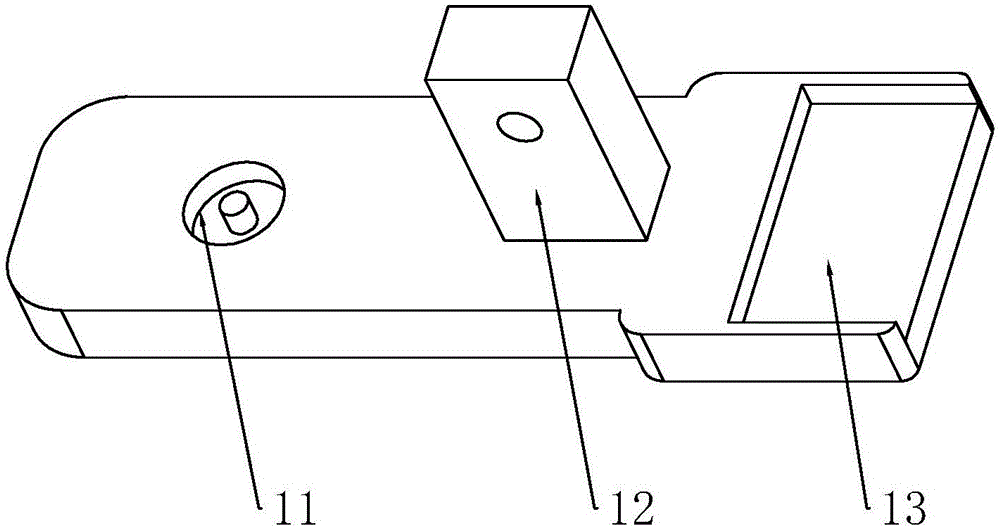

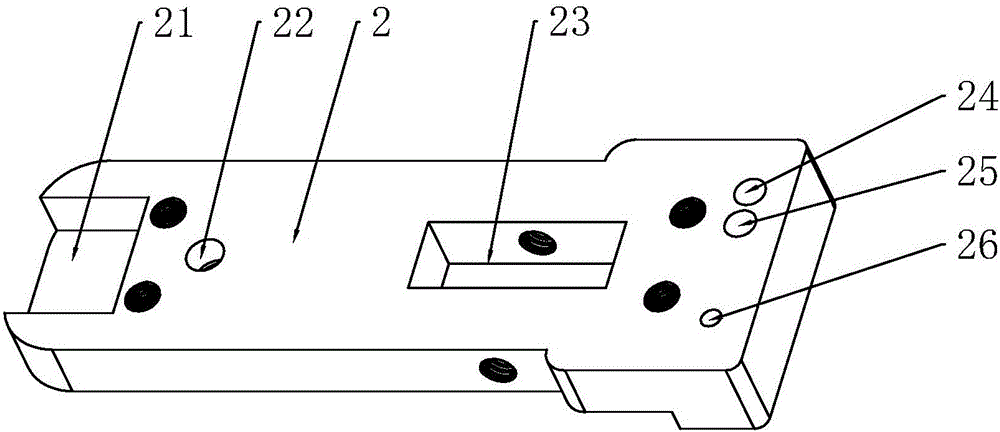

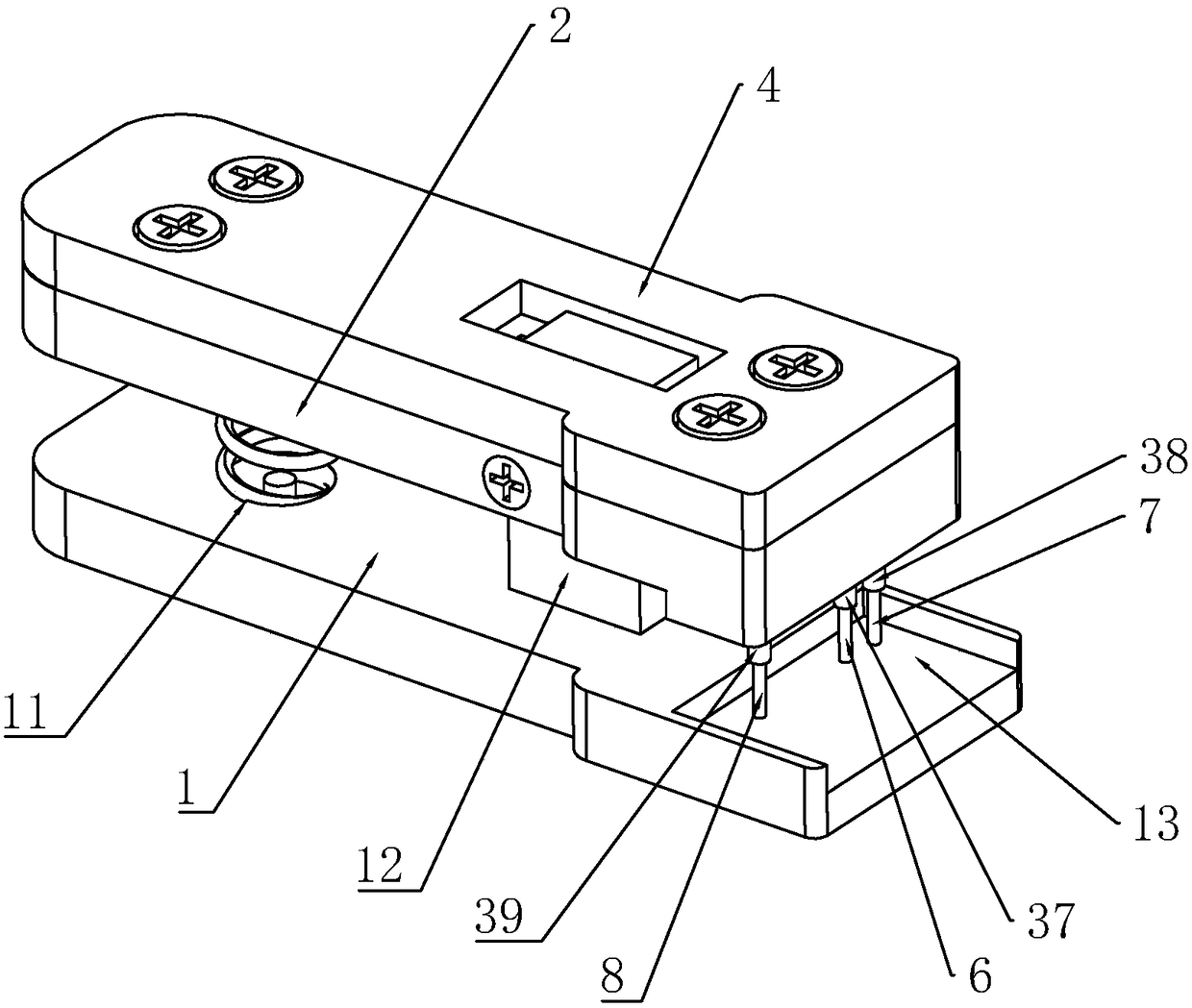

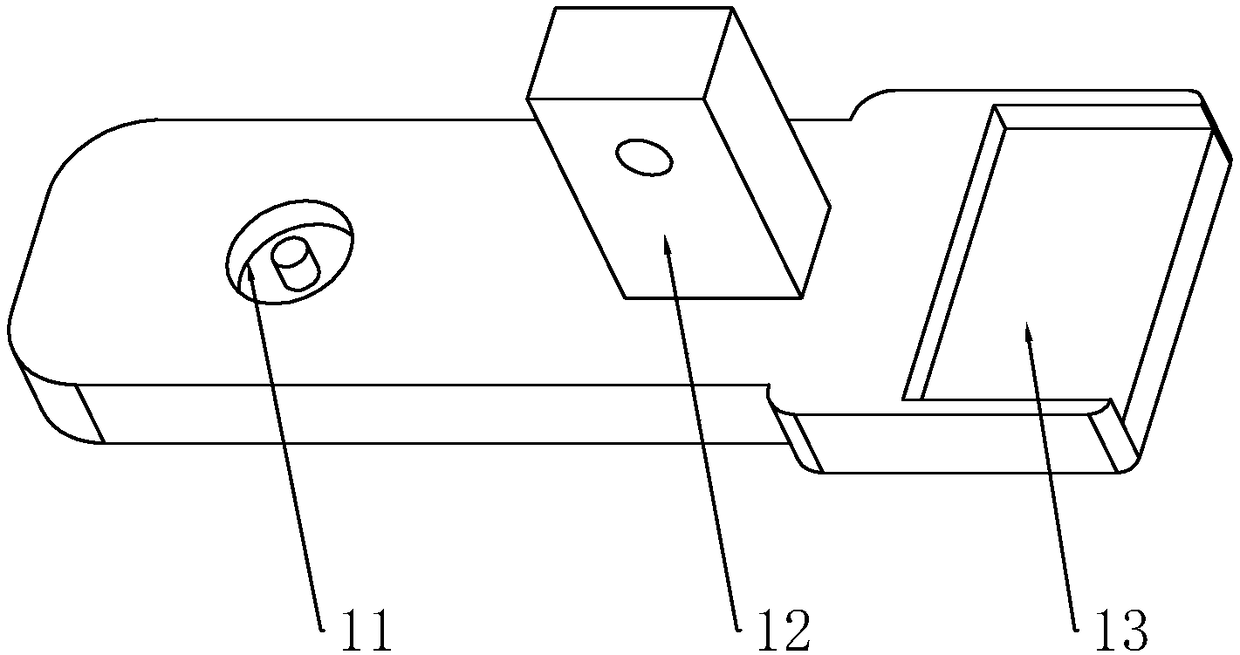

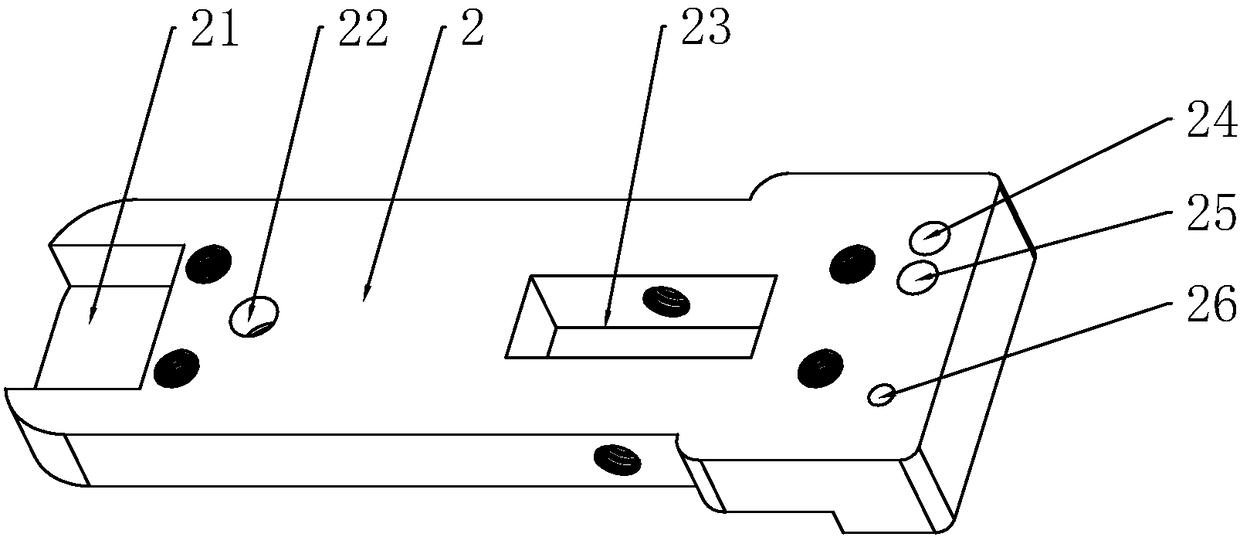

Electrical signal acquisition and transmission device for flat plate type working electrode

ActiveCN105954340AIncrease contactImprove compatibilityMaterial electrochemical variablesInterface layerData transmission

The invention belongs to the technical field of electrochemical detection, and aims to provide an electrical signal acquisition and transmission device for a flat plate type working electrode. The electrical signal acquisition and transmission device is simple in structure, easy to operate and high in sensitivity, improves the detection effect, and comprises a base, an interface layer, a transmission layer and a top layer; a data transmission interface slot is formed in the left side of the interface layer; three electrode joint positioning holes are formed in the right side of the interface layer; the transmission layer comprises a printed circuit board; three electrode joint welding holes are respectively formed in the printed circuit board; a data transmission interface element is fixed on the printed circuit board; the top ends of three electrode joints are respectively welded at three welding holes; the lower ends of the three electrode joints respectively penetrate three electrode joint positioning holes in the interface layer; the top ends of the three electrode joints are respectively connected with the data transmission interface element through signal transmission lines; the top layer, the transmission layer, the interface layer and the base are sequentially mounted together from top to bottom; the upper end and the lower end of a spring are respectively mounted in an upper spring fixing slot and a lower spring fixing slot.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

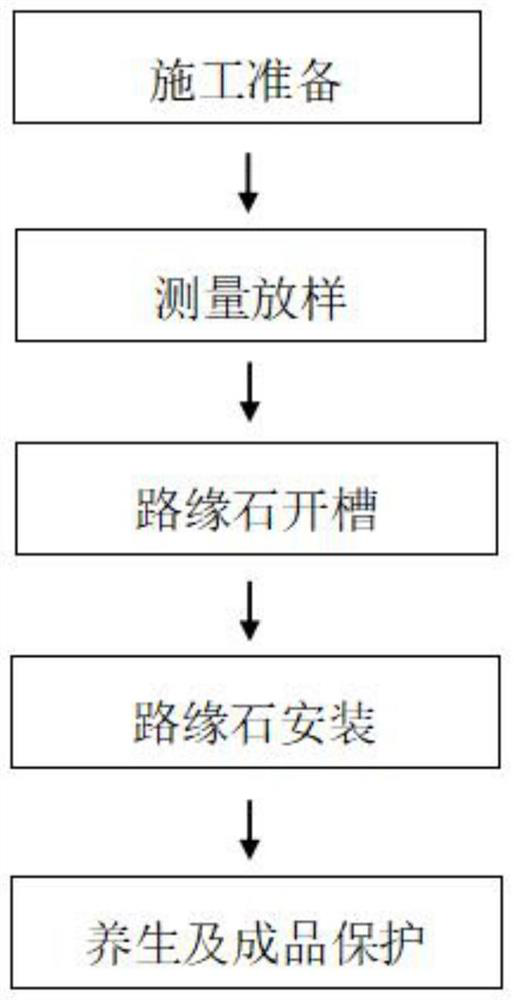

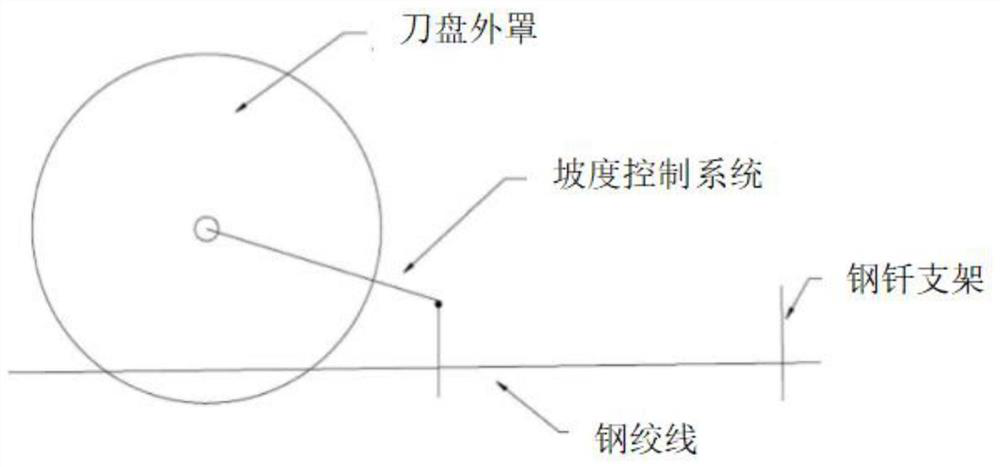

Kerb mechanized operation construction method

InactiveCN112064446AConstruction quality improvement and enhancementGuarantee the construction qualityPaving gutters/kerbsClimate change adaptationPlastic filmStructural engineering

The invention discloses a kerb mechanized operation construction method. The kerb mechanized operation construction method comprises the following steps that S1, construction preparation is carried out, and continuous and effective construction can be ensured; S2, measuring and setting out are carried out; S3, the kerb is subjected to slotting; S4, curb stone is installed, and the site is cleaned;and S5, curing and finished product protection are carried out, specifically, finished product protection and curing are conducted through plastic film covering, the curing period of the kerb is notshorter than 3 d, and collision should be strictly prevented in the period. According to the kerb mechanized operation construction method, a traditional construction method is reformed and innovated,the slotting depth is guaranteed through a longitudinal slope control system, the width of adjacent block joints is controlled through improved clamping pieces, construction is simplified through advanced instruments and equipment, the construction straightness of the kerb is guaranteed, full joint filling is guaranteed through small tools, and other measures are adopted, so that the constructionquality is effectively improved, the construction cost is saved, and the method has remarkable economic benefits and social benefits, and has very wide application prospects.

Owner:SHAANXI HUASHAN ROAD & BRIDGE ENG

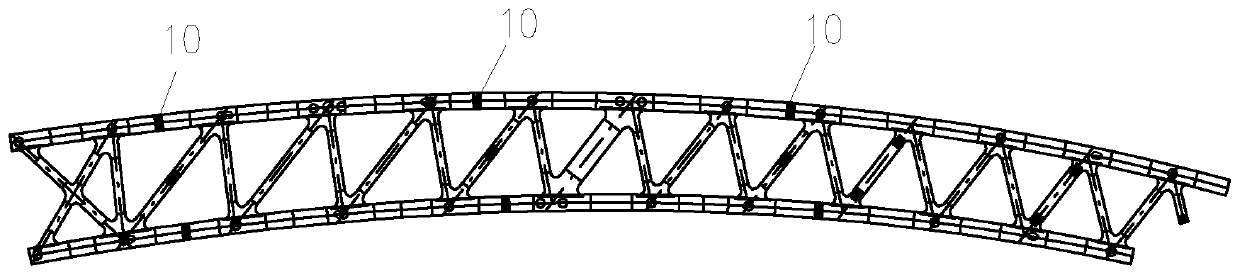

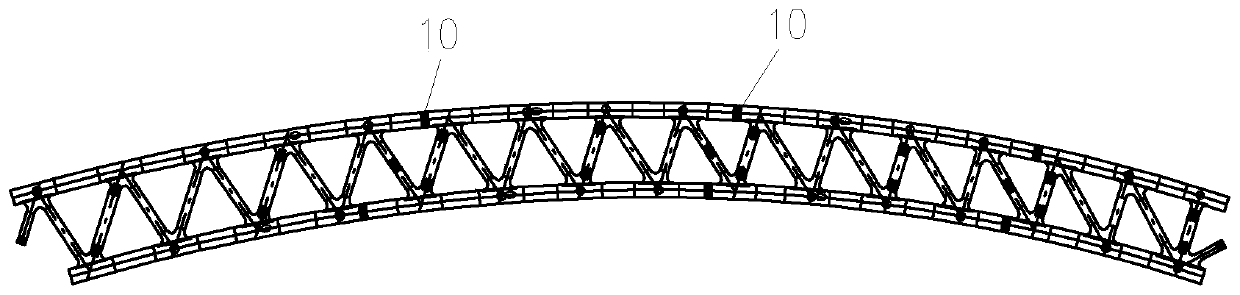

On-site horizontal splicing method of steel tube arch

ActiveCN109505266AHigh degree of mechanizationSmall footprintBridge erection/assemblyBridge materialsStress concentrationError prevention

The invention discloses an on-site horizontal splicing method of a steel tube arch, which adopts horizontal splicing in the form of '3+1' to meet the requirements of the alignment and can be processedand manufactured normally. The method adopts a mode of drawing a ground sample and then hanging a vertical line to lead the wire to be centered and aligned, is convenient and practical, and ensures horizontal splicing precision and linear smoothness. An inner flange is adopted to connect the two arch rib sections, the connection precision is high, the adjusting speed is high when a steel beam iserected in the later period, and the safety of the inner flange is high. The arrangement of a pre-arch degree is considered during horizontal splicing, so that the problem that the linear change caused by the pre-arch degree in the erection process cannot accurately align an inner flange bolt is avoided, and unnecessary trouble is caused. The on-site horizontal splicing method of the steel tube arch adopts the mode of steel component processing and on-site assembly separation, and is convenient for management and error prevention by batch entry and batch acceptance. The middle part is welded first, and then the two sides are welded to prevent stress concentration. After the arch rib is welded, welding the inner flange and the arch rib which are connected by bolts in advance; the deformation caused by the shrinkage of a welding seam cannot be prevented so that the inner flange cannot be accurately aligned.

Owner:中铁一局集团厦门建设工程有限公司 +1

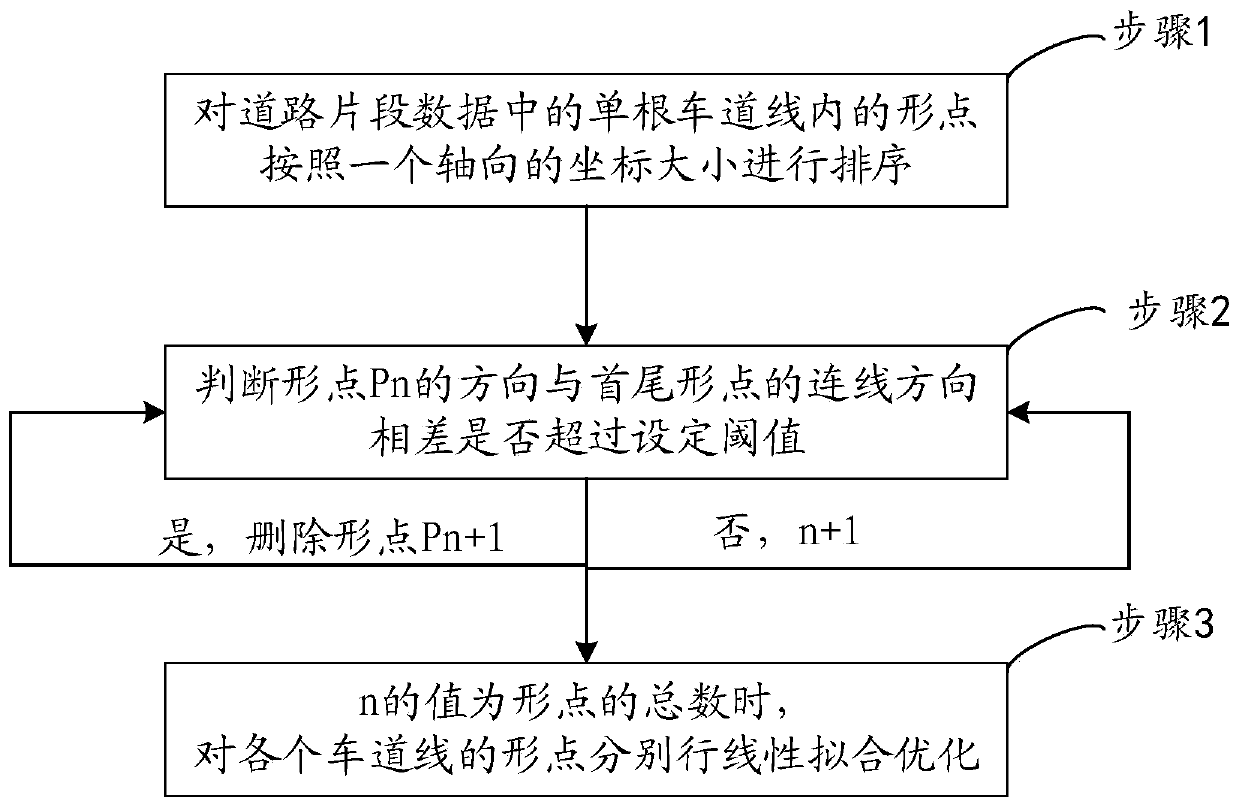

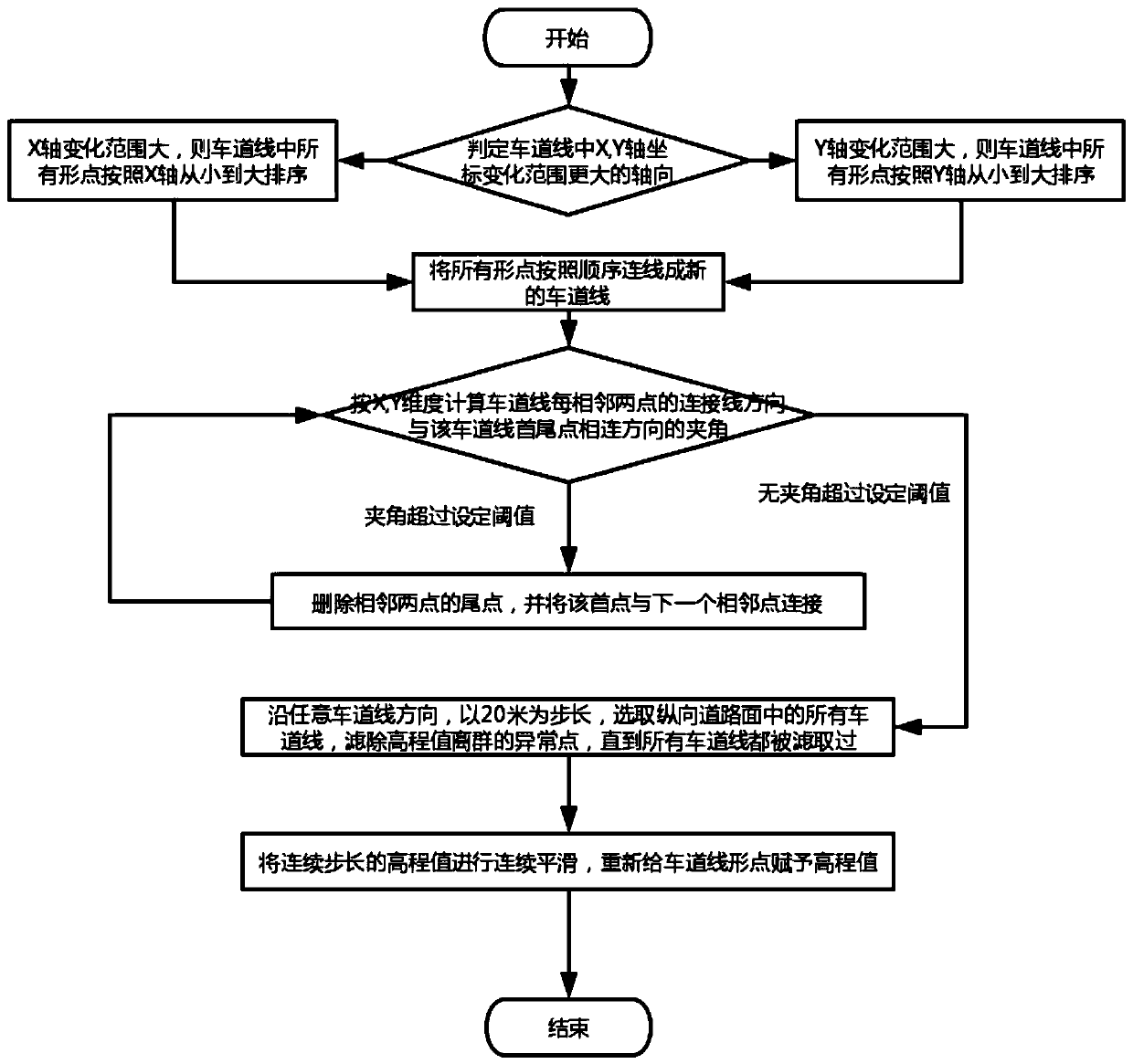

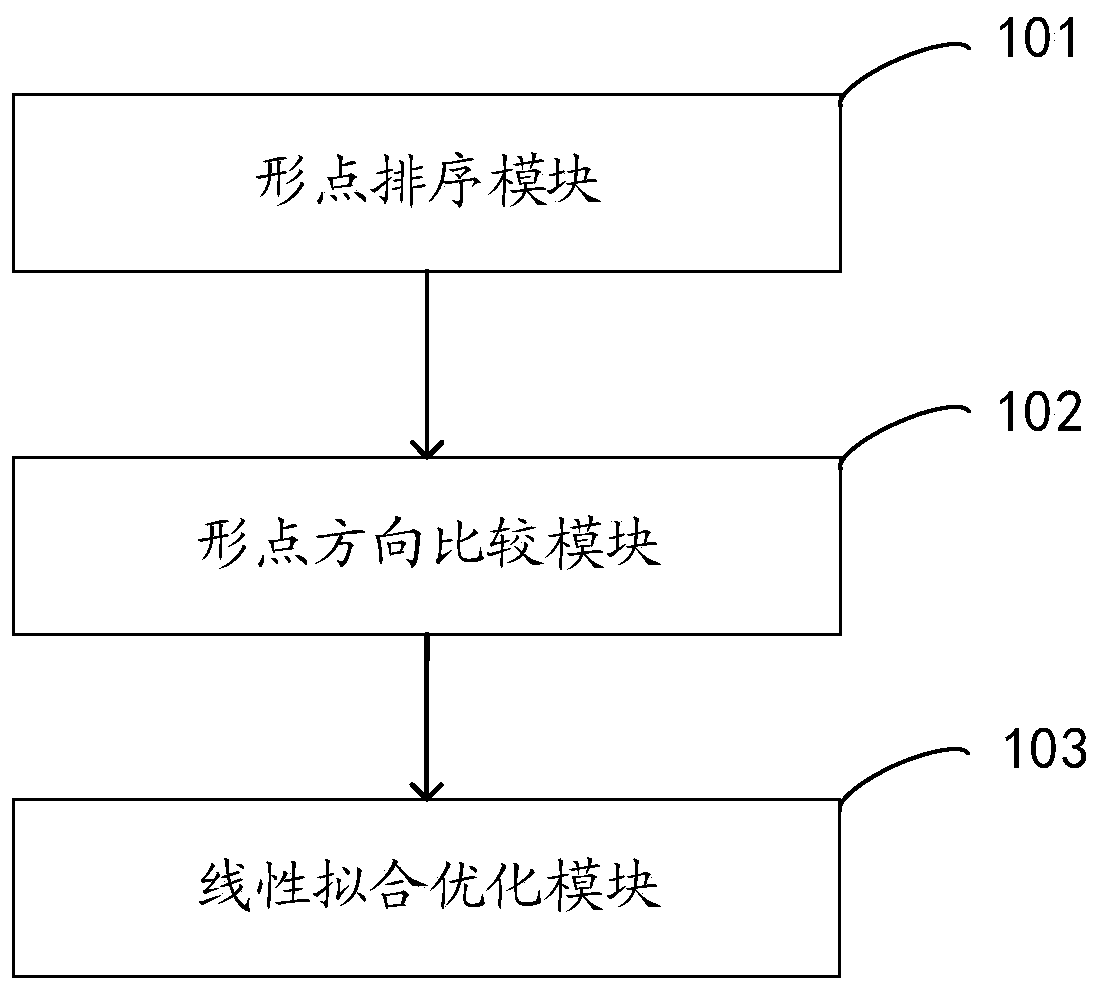

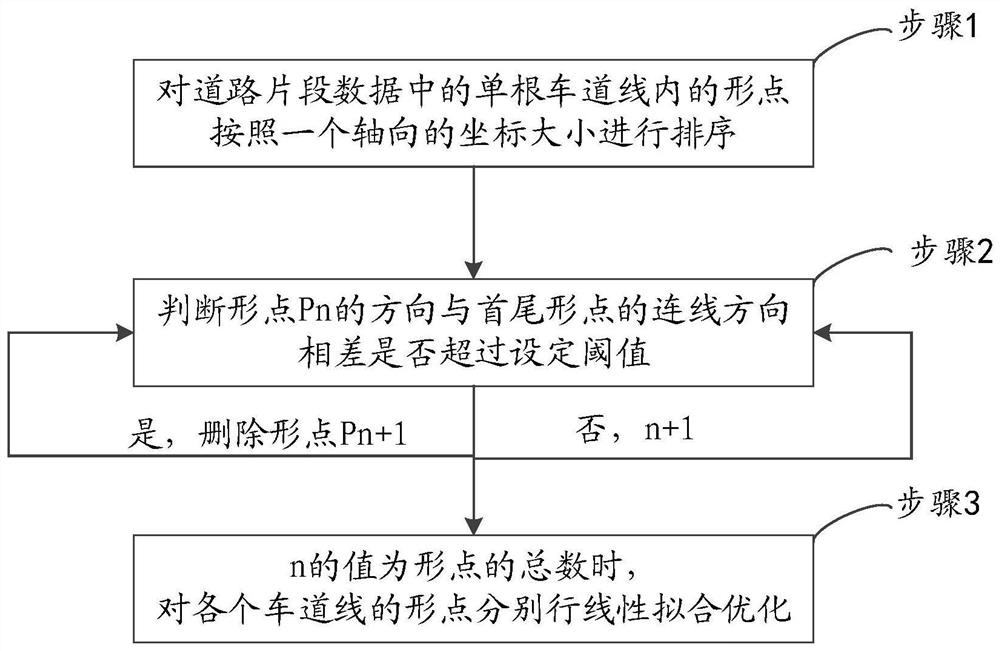

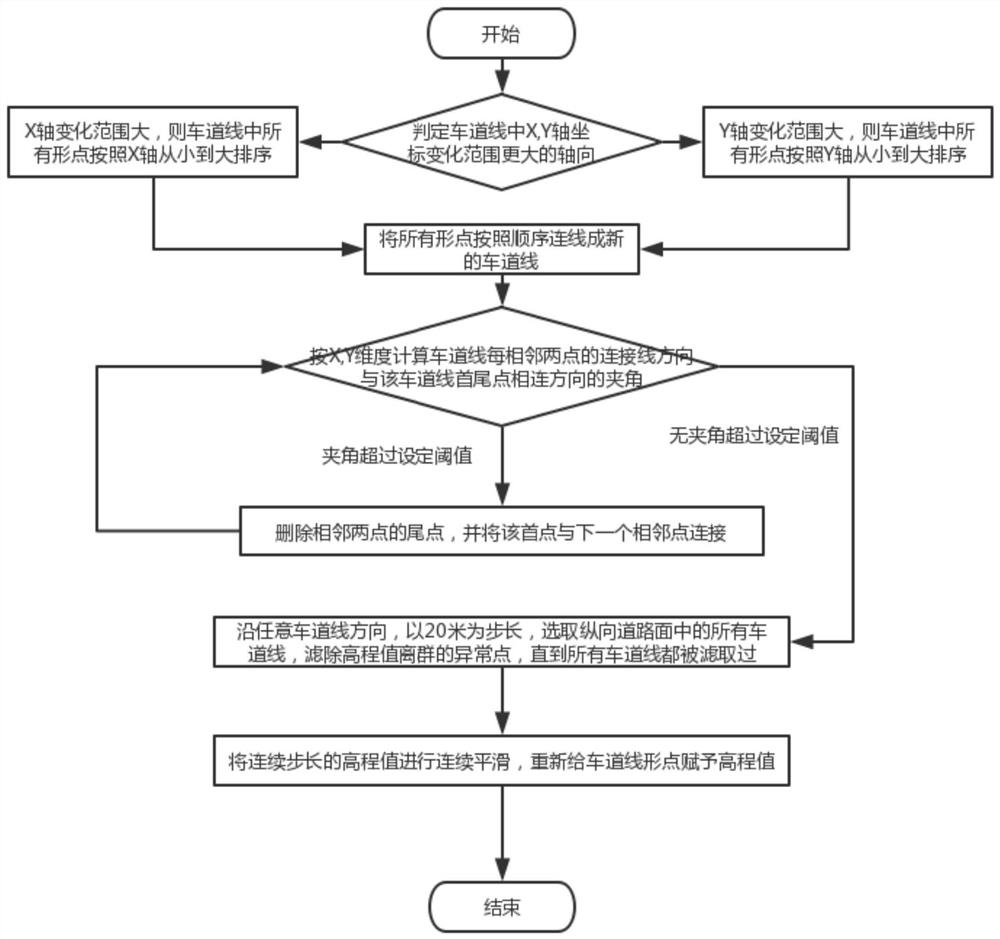

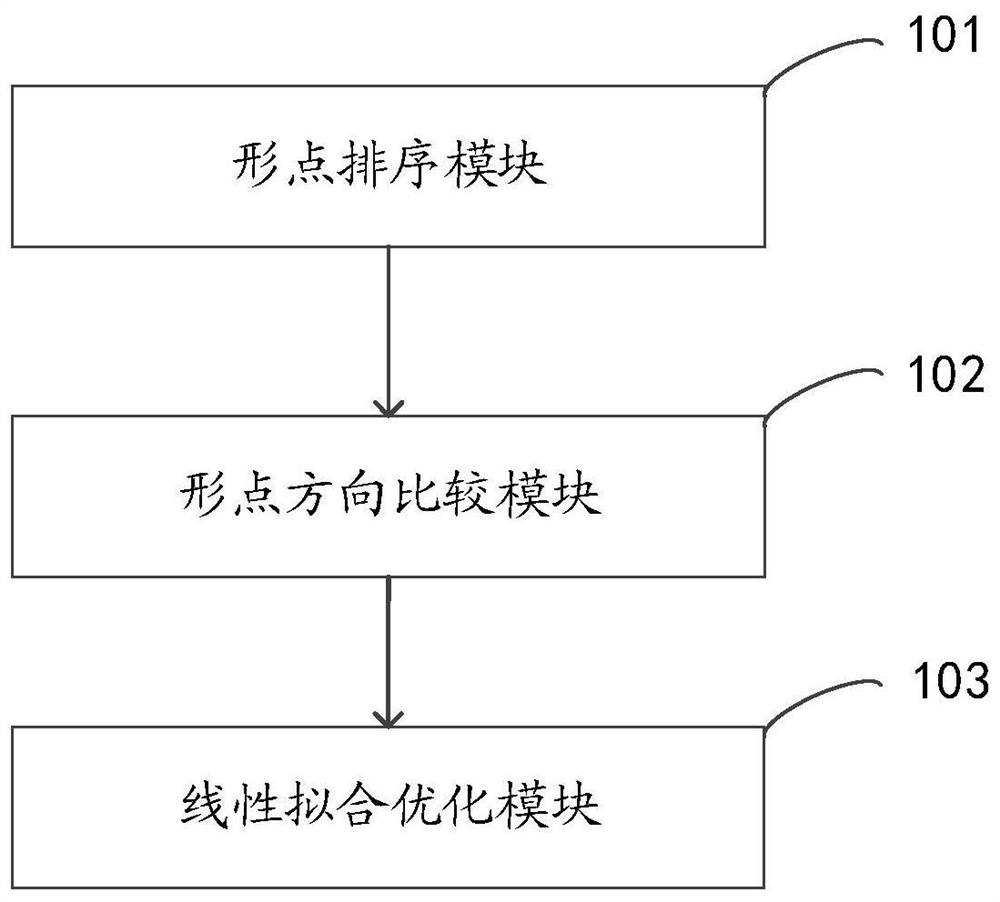

Preprocessing method and system for multi-road segment data of lane line crowdsourcing data

ActiveCN111141296AEfficient preprocessingMeet precision requirementsInstruments for road network navigationGeographical information databasesAlgorithmEngineering

The invention relates to a preprocessing method and system for multi-road segment data of lane line crowdsourcing data. The method comprises the steps that: 1, shape points in a single lane line in the road segment data are sorted according to coordinates in one axial direction; 2, whether the difference between the direction of the shape point pn and the connecting line direction of head and tailshape points exceeds a set threshold value or not is judged; if the difference between the direction of the shape point pn and the connecting line direction of head and tail shape points exceeds theset threshold value, the shape point pn+1 is deleted, otherwise, 1 is added to n, the direction of the shape point pn is the connecting line direction of the shape point pn and the shape point pn+1; and 3, the step 2 is circularly executed until the value of n is the total number of the shape points, and linear fitting optimization is performed on the shape points of each lane line. According to the method, all the shape points in each lane line are sorted according to the collinear relations between the points; abnormal outliers are filtered out; lane line data collected by crowdsourcing collection vehicles are effectively preprocessed; the effect and efficiency of subsequent optimization processing are improved; and therefore, high-precision lane line map data meeting a precision requirement are obtained.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

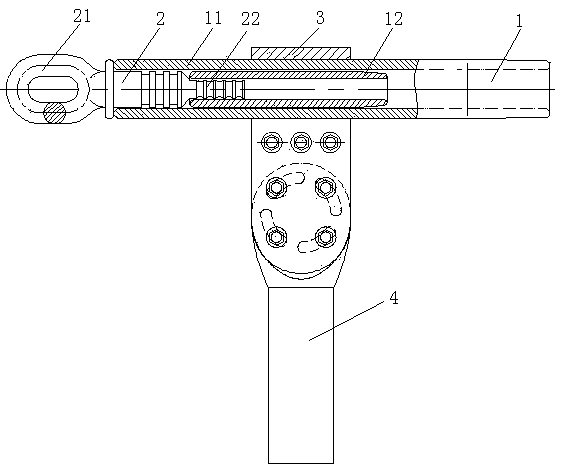

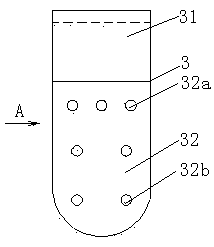

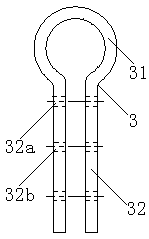

Adjustable strain clamp

PendingCN108075422ASimple structureReduce feverAdjusting/maintaining mechanical tensionClamp connectionMechanical engineering

The invention relates to an adjustable strain clamp which is composed of a clamp body, a steel anchor, a flow guide clamping plate and a flow guide clamp. Due to the fact that the flow guide clampingplate is installed on an aluminum pipe in a sleeving mode, can rotate around the aluminum pipe and are fixed after the declination angle of the aluminum pipe and the flow guide clamping plate is adjusted according to the design requirement, a dedicated angle positioning tool does not need to be adopted when the aluminum pipe is connected with a wire in a pressed mode; due to the fact that waist-shaped arc holes are formed in a connecting disc of the flow guide clamp, the angle that the flow guide clamp is relative to the flow guide clamping plate can be adjusted; due to the fact that the flowguide clamp is clamped by two flow guide clamp connection clamping plates when the flow guide clamping plate is connected with the flow guide clamp, the contact resistance is effectively reduced, andheat of the flow guide clamping plate is reduced; and due to the fact that a structure form of a shaft shoulder is arranged between a pull ring and an anchor rod of the steel anchor, the steel anchorcan be conveniently positioned in the aluminum pipe, and the phenomenon that rainwater enters the aluminum pipe from the end of the aluminum pipe is effectively prevented.

Owner:JIANGSU TIANNAN ELECTRIC POWER EQUIP

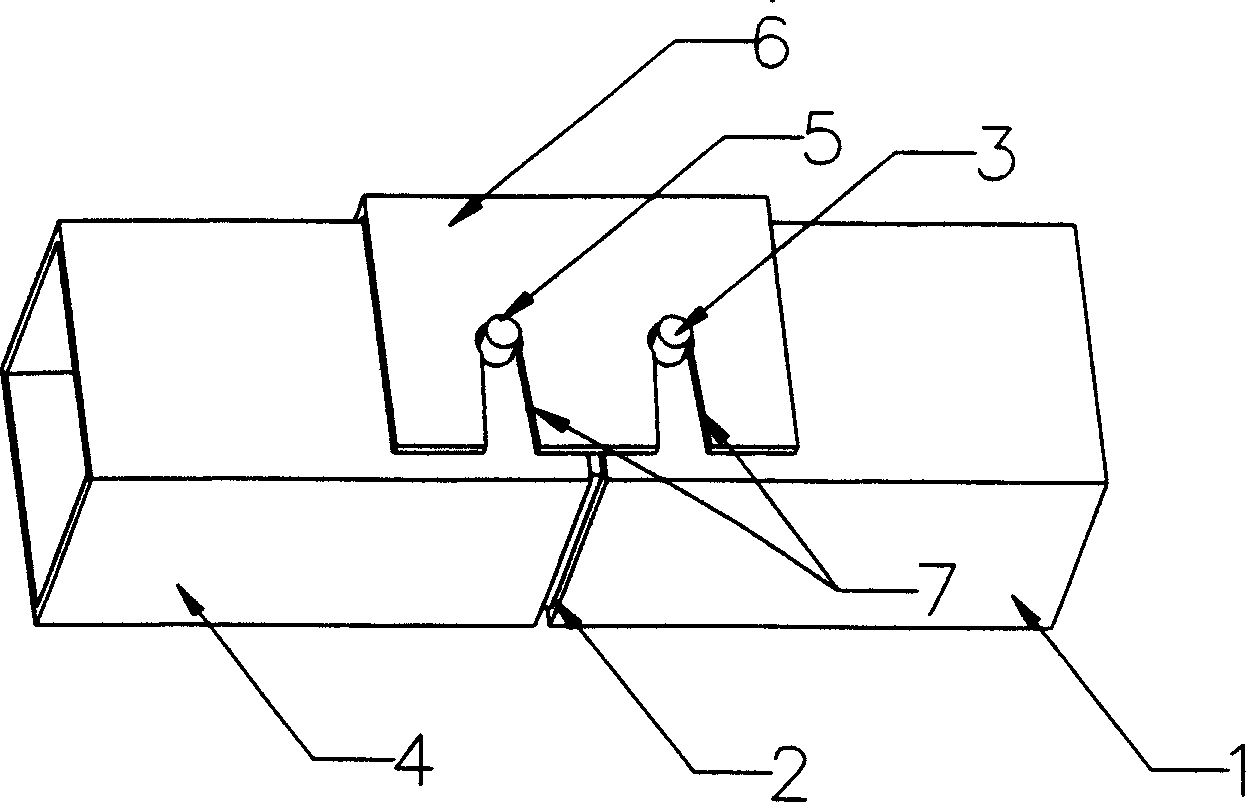

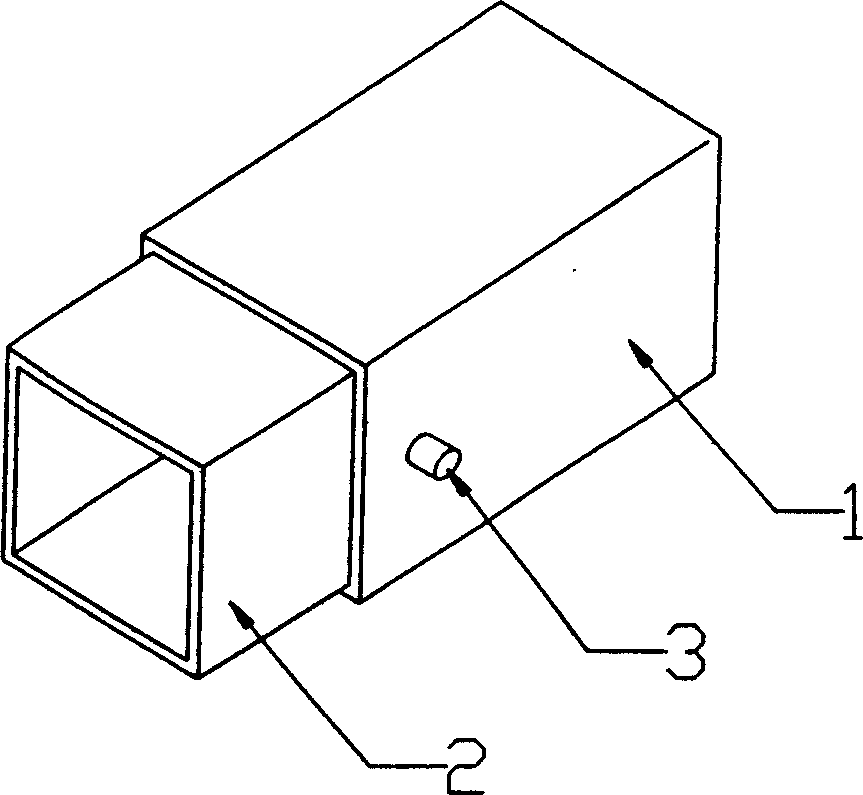

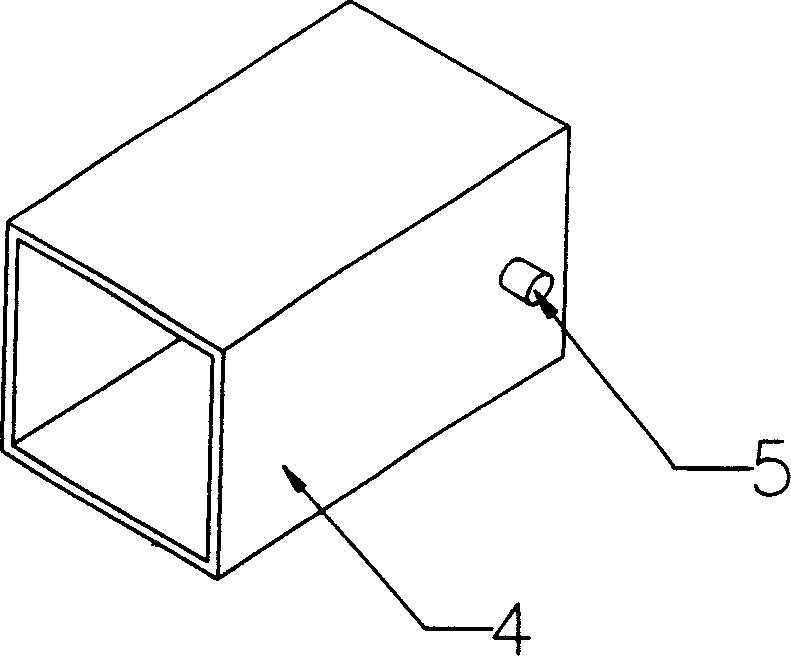

Detachable joint nodes of steel structure

InactiveCN1462829ASimple structureEasy to processBuilding constructionsPull forceAgricultural engineering

A detachable joint node for steel structure is composed of primary unit, secondary unit and cover plate. The main pipe of primary unit is connected with the main pipe of secondary unit via internal sleeve pipe. Said both main pipes has two fixed pins on each of two opposite surfaces. Said cover plate has two wing plates, on which there are two pin slots for matching with said two pins after the cover plate is installed. Its advantages are high strength, fast assembling, and cyclic use.

Owner:SHANGHAI JIAO TONG UNIV

Continuous beam curtain board construction technology

InactiveCN105625636AStraight linesLinear smoothGirdersJoistsArchitectural engineeringContinuous beam

A continuous beam curtain board construction technology comprises the following steps: arranging and fixing a template bottom template; binding steel bars, and arranging an embedded part; arranging a side die; arranging a foam plate according to a foam plate installation instruction; flattening and straightening the foam plate, and reinforcing and firming the foam plate; pouring concrete; carrying out demolding curing on concrete; and storing: transporting a curtain board to a field according to installation schedule requirements before installing construction, and temporarily storing the transported curtain board for installation. The construction technology has the advantages of simple operation, cheap material and cost reduction. A continuous beam can be effectively smoothly connected with curtain boards at two sides of the continuous beam, so integral linear straightness is guaranteed. The height of a curtain board bearing platform of the continuous beam curtain board is increased in advance, so linear straightness of the continuous beam curtain board and the simply supported beam curtain boards at two sides in the installation process is guaranteed, thereby resource waste and construction period prolongation caused by unable normal use of curtain boards produced as designed on the continuous beam are avoided.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

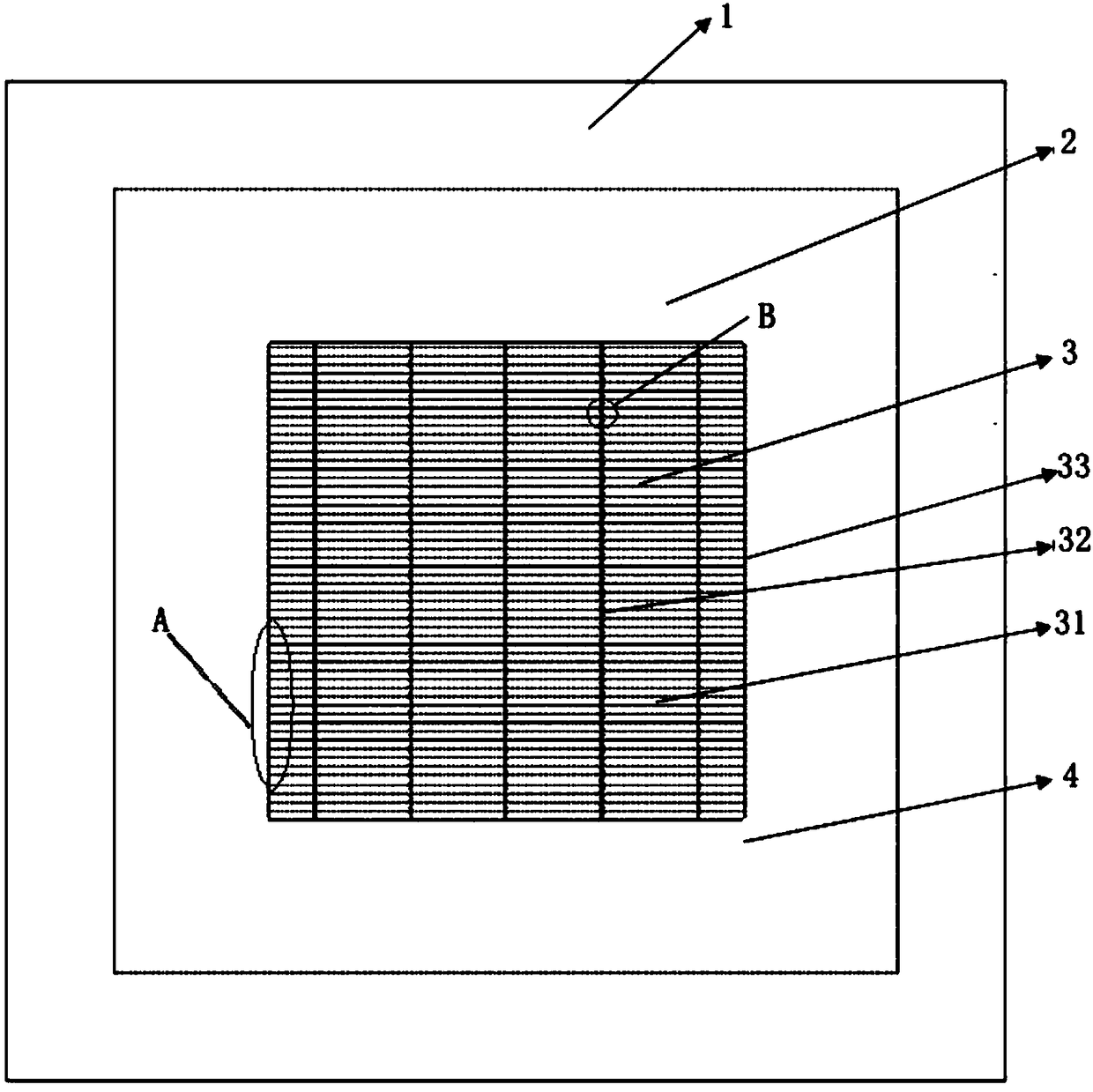

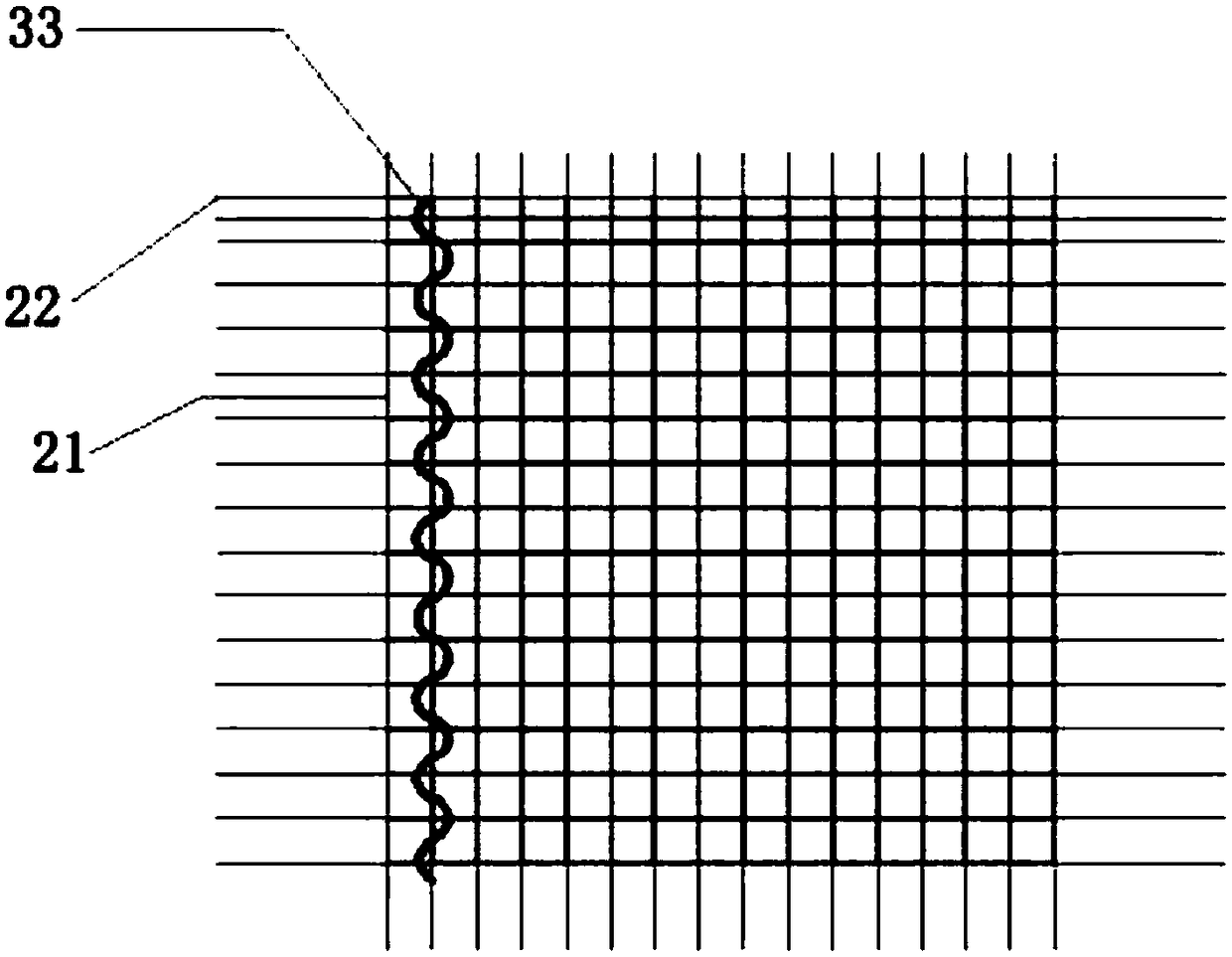

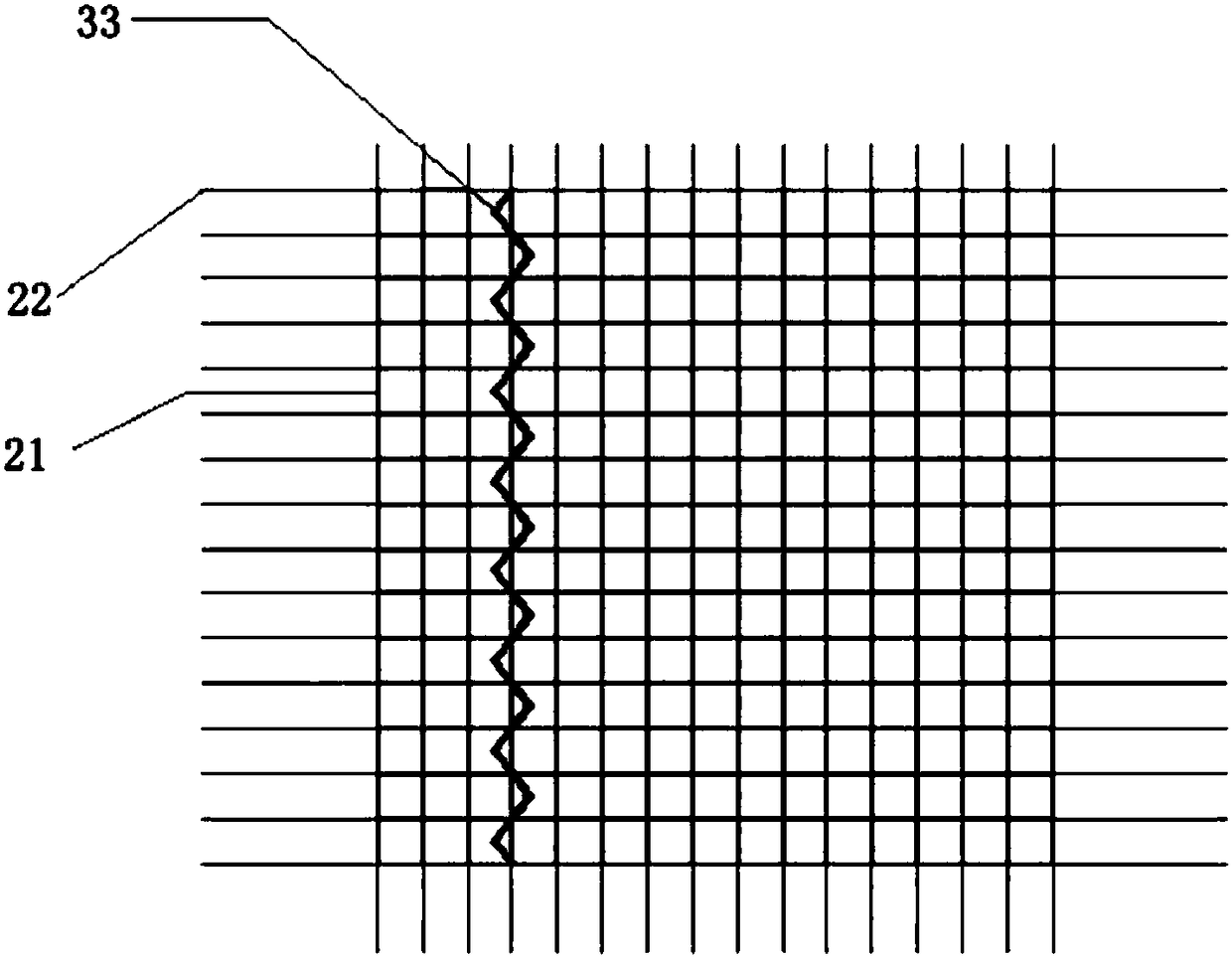

Tiny pattern net-joint-free printing screen plate for solar cell positive electrode

InactiveCN109421365AIncrease ink penetrationIncreased ink permeabilityScreen printersScreen printingWave shapeBorder line

The invention discloses a tiny pattern net-joint-free printing screen plate for a solar cell positive electrode. The printing screen plate comprises a screen frame and a mesh fixed into the screen frame in a tension connecting manner. Each longitudinal line and each latitude line in the mesh are parallel or perpendicular to the screen frame correspondingly. The mesh is provided with a printing area and a non-printing area. Patterns in the printing area comprise auxiliary grid line holes, main grid line holes and border line holes. The auxiliary grid line holes are located between every two adjacent latitude lines. Each main grid line hole communicates with multiple auxiliary grid line holes. The main grid line holes and the auxiliary grid line holes are arranged perpendicular to each other. Each main grid line hole is provided with multiple tiny patterns which electric conducting silver paste cannot penetrate through. Periphery border line holes are formed around the main grid line holes and the auxiliary grid line holes. The periphery border line holes are in wave shapes or sawtooth shapes. The printing screen plate solves the problems that net joints formed by the longitudinal lines and the latitude lines on screen cloth in the prior art severely influence printing paste, line breaking of printing is caused, and due to shielding of the longitudinal lines and the latitude lines, printing skip of a border and printing skip of a main grid are caused.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

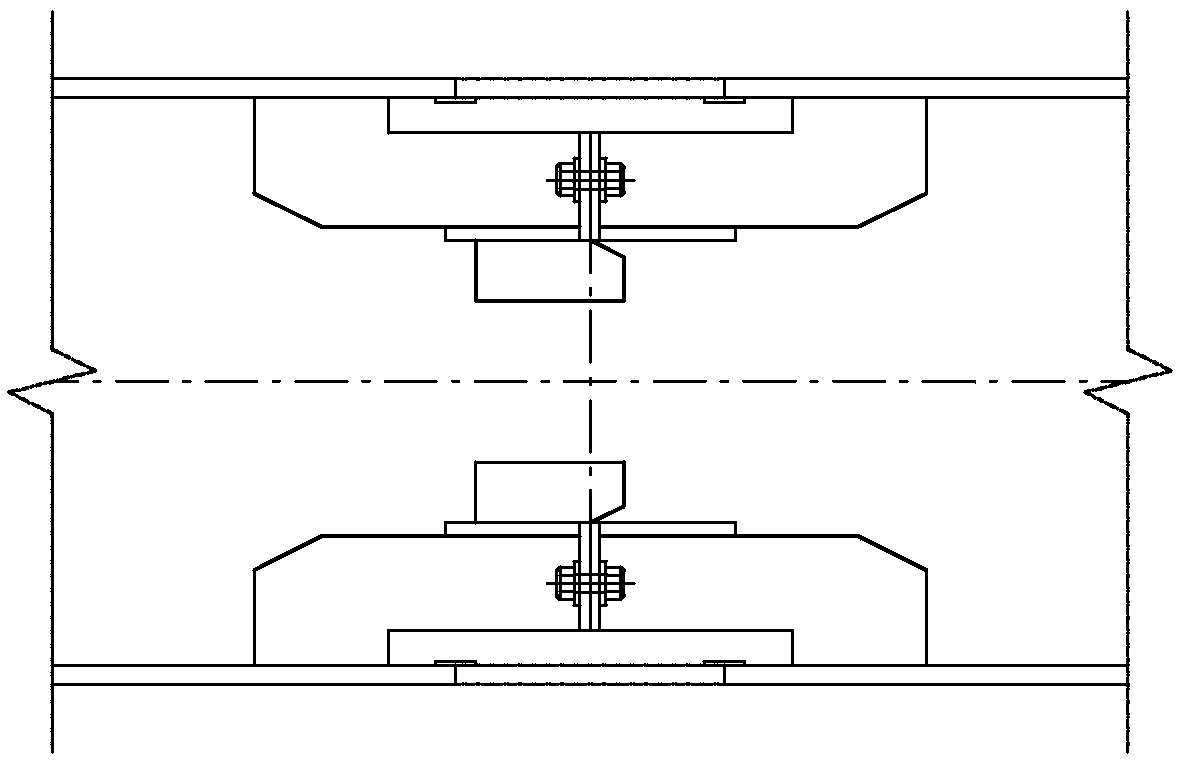

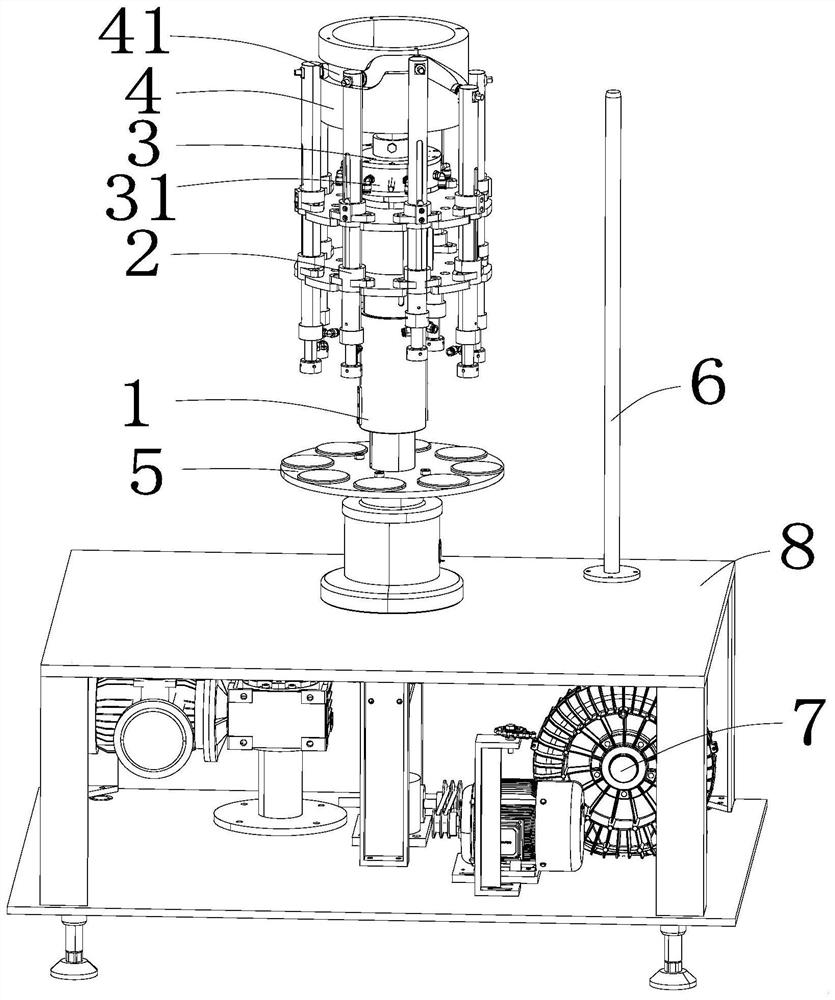

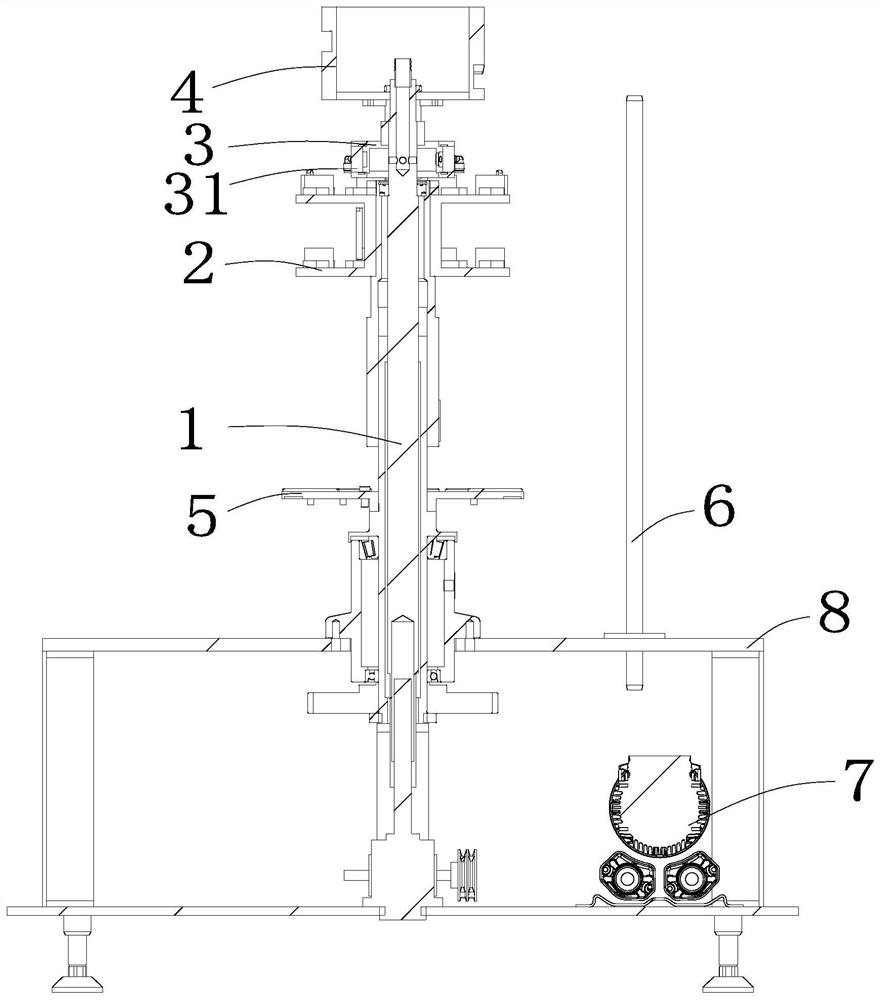

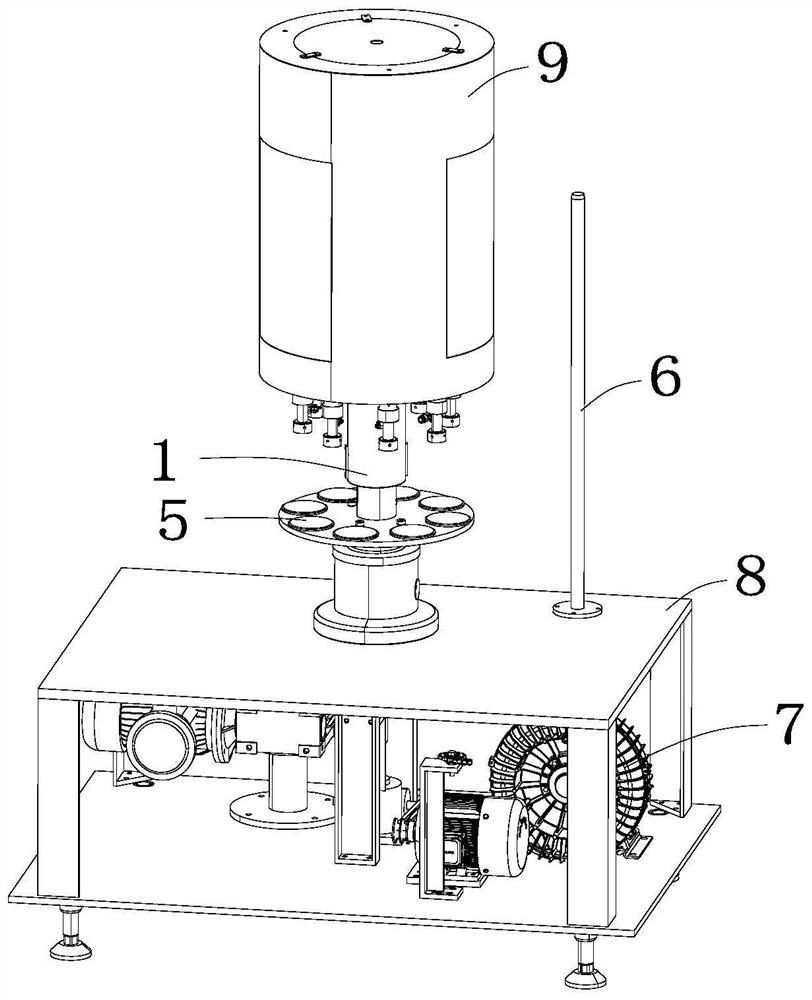

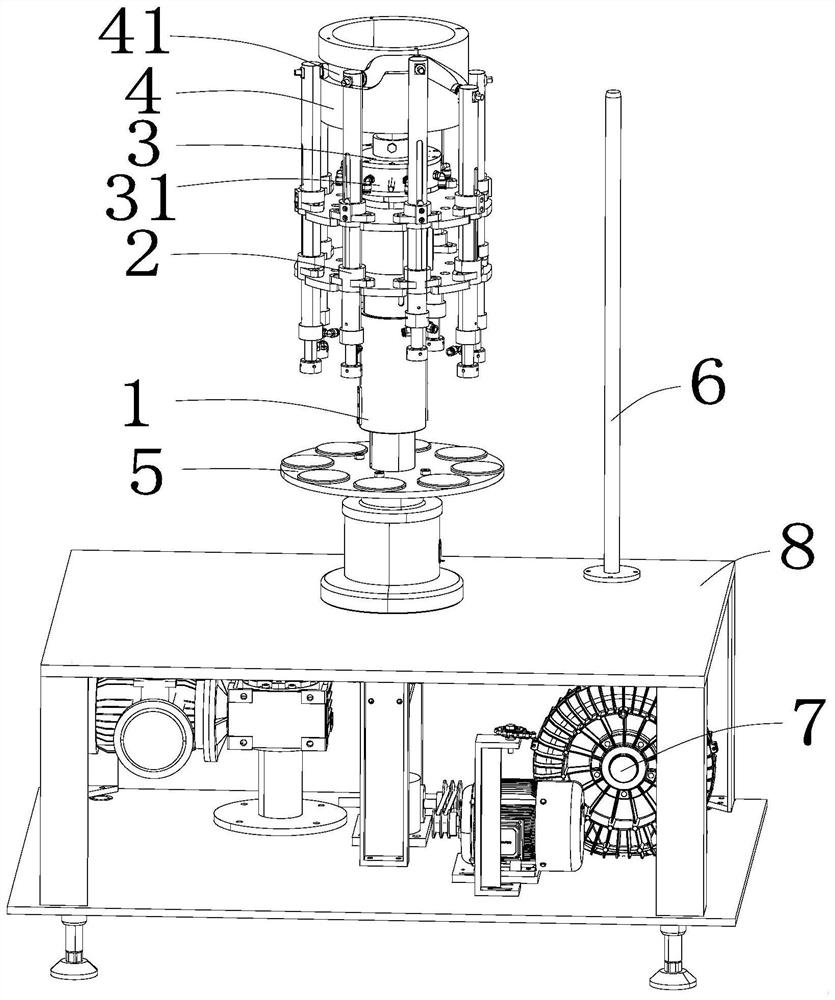

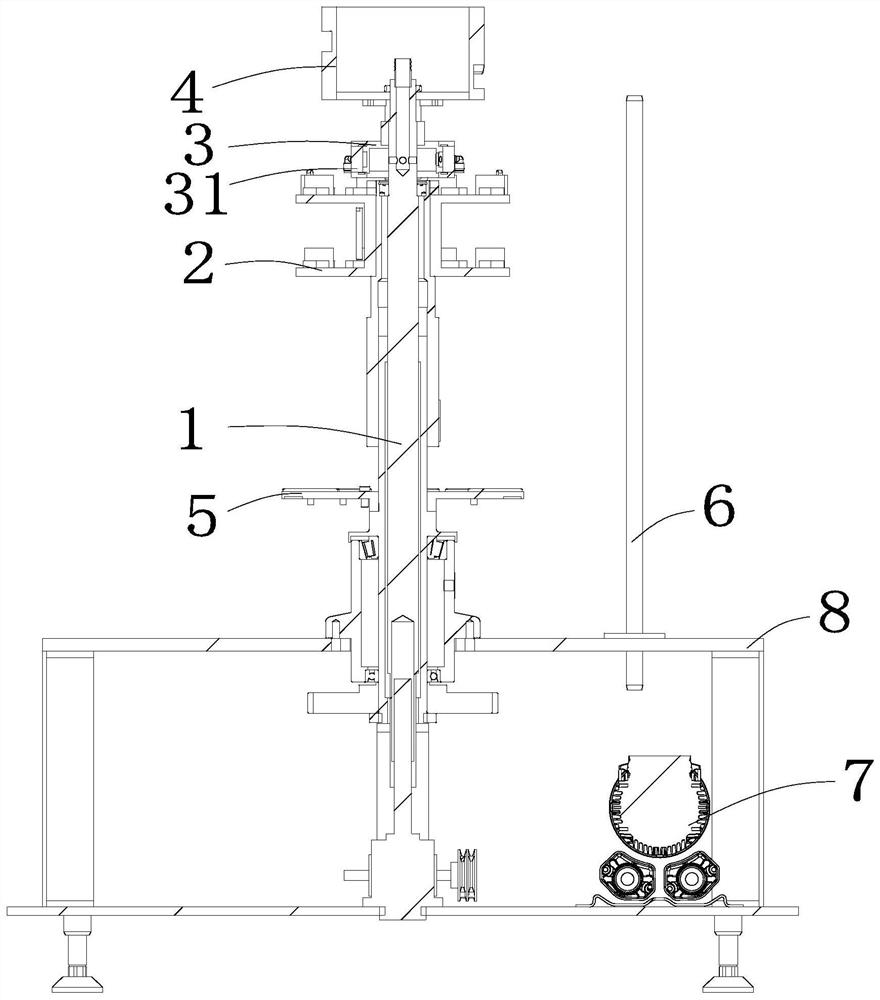

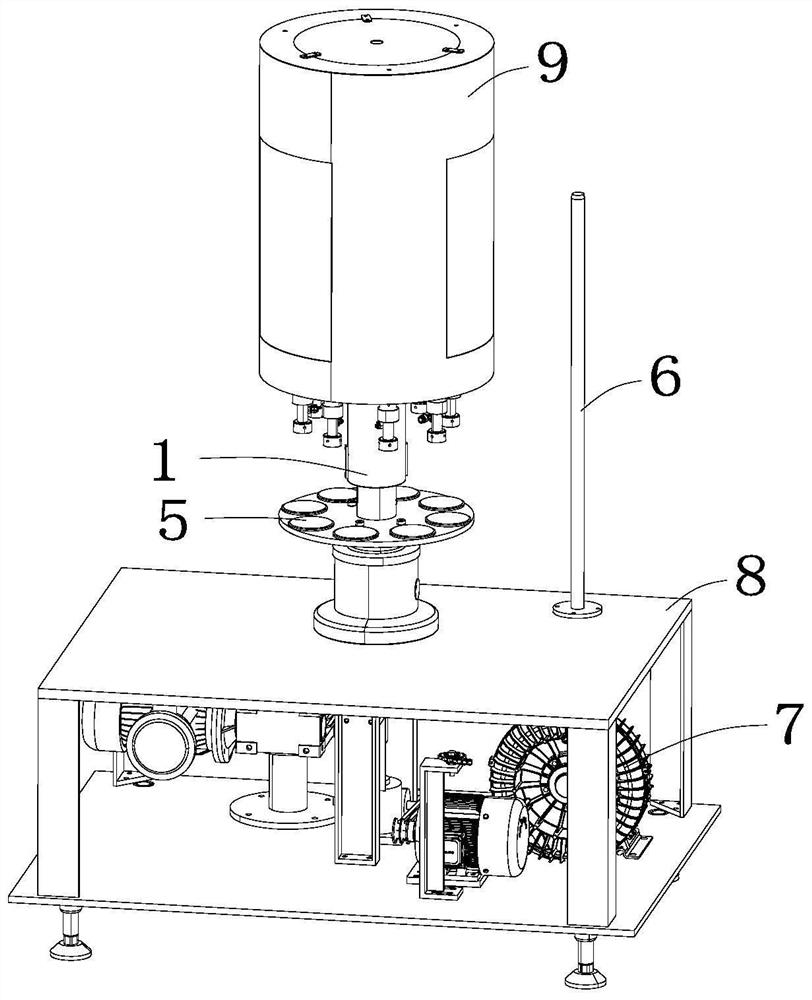

Capping mechanism of full-automatic capping machine

The invention discloses a capping mechanism of a full-automatic capping machine. The capping mechanism comprises a main shaft, wherein the main shaft is sequentially provided with a cam, a vacuum control device, a lifting portion and a cap sucking portion from top to bottom; a cam groove is formed in the side wall of the cam, the top of the lifting portion rotates along the cam groove in the cam, a capping head is arranged at the bottom of the lifting portion, and the lifting portion rotates along the cam groove and the vacuum control device is used for realizing cap sucking and pressing of the capping head on the cap sucking portion; the vacuum control device comprises a vacuum receiving disc, a vacuum rotating disc and a vacuum device; an annular gap is reserved between the vacuum receiving disc and the vacuum rotating disc, and the annular gap is divided into a ventilation area and an air-free area through a partition rib; and when the lifting portion is used for sucking and pressing caps, a corresponding second air joint on the vacuum rotating disc is rotated to the ventilation area, and when the lifting portion completes capping, the corresponding second air joint on the vacuum receiving disc is rotated to the air-free area. The capping mechanism is high in automation degree and high in safety coefficient, and the labor cost is saved.

Owner:JIANGSU TOM PACKAGING MACHINERY

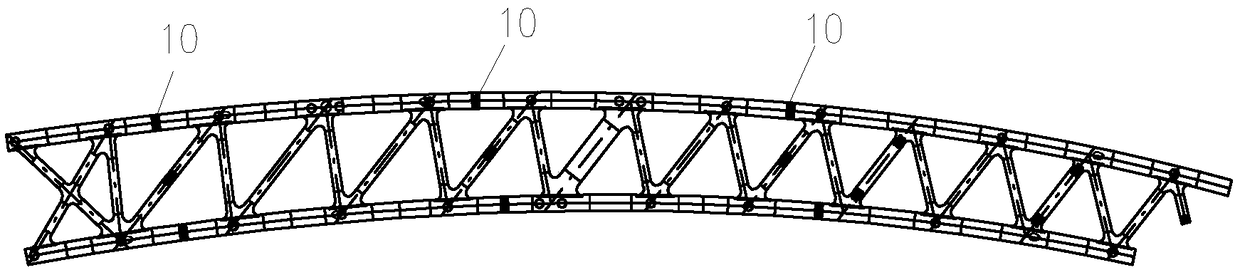

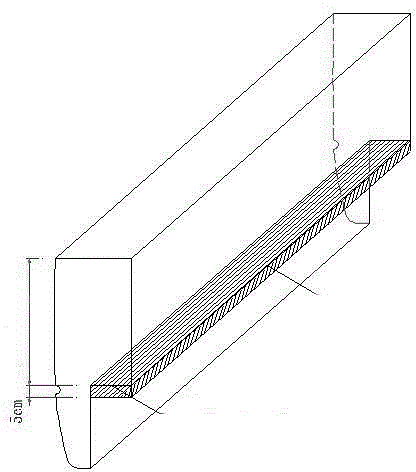

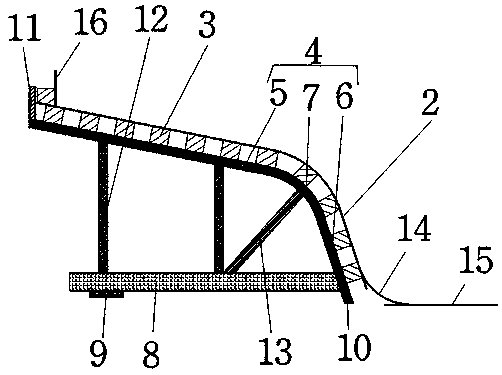

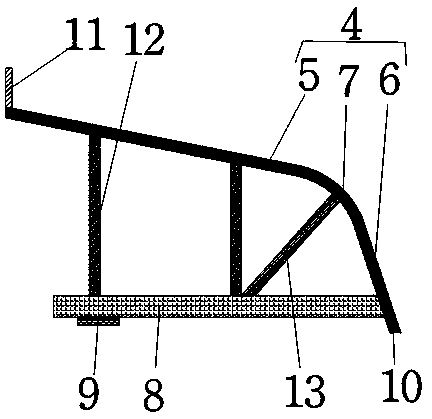

Arc support combined template used for cast-in-place box beam and erecting method thereof

InactiveCN110158479ALight structureEasy and safe to set upBridge erection/assemblyEngineeringMechanical devices

The invention belongs to the technical field of bridge building engineering construction, and particularly discloses an arc support combined template used for a cast-in-place box beam and an erectingmethod thereof. The arc support combined template comprises multiple arc supports, the arc supports are evenly arranged in the direction of a bridge, and multiple pieces of square timber located on anarc body of the arc support are included and are evenly laid from the lower end to the upper end of the arc body; through the square timber, the arc supports are connected into a whole, the laying supporting face is provided for a side template of the cast-in-place box beam, the cross section of the arc body is in a square or oval shape, the arc body is in face contact with the square timber, theside template of the cast-in-place box beam is formed through sequential connection of multiple bamboo plywood, and the bamboo plywood is fixed to the upper surface of the square timber through nails. Due to use of the arc support combined template, the appearance of the cast-in-place box beam is attractive, the line type is smooth, in the construction, use of mechanical devices like a crane is little, and construction cost is low.

Owner:陕西路桥集团有限公司

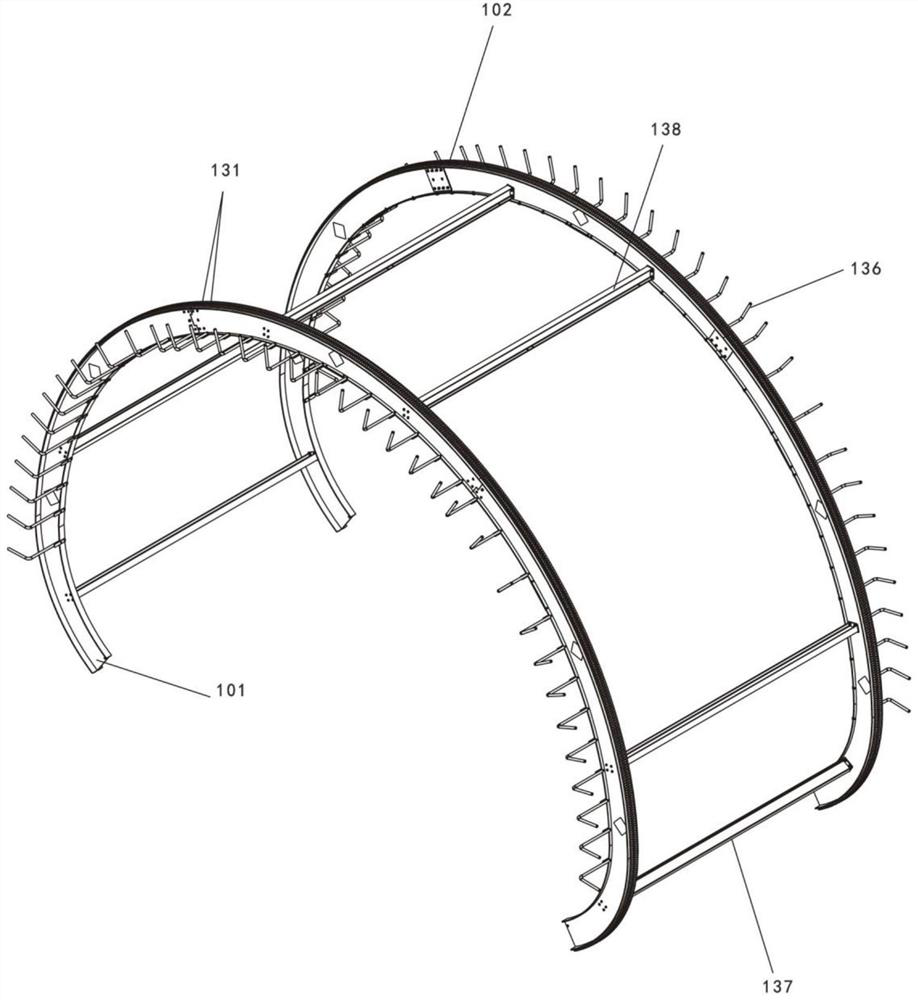

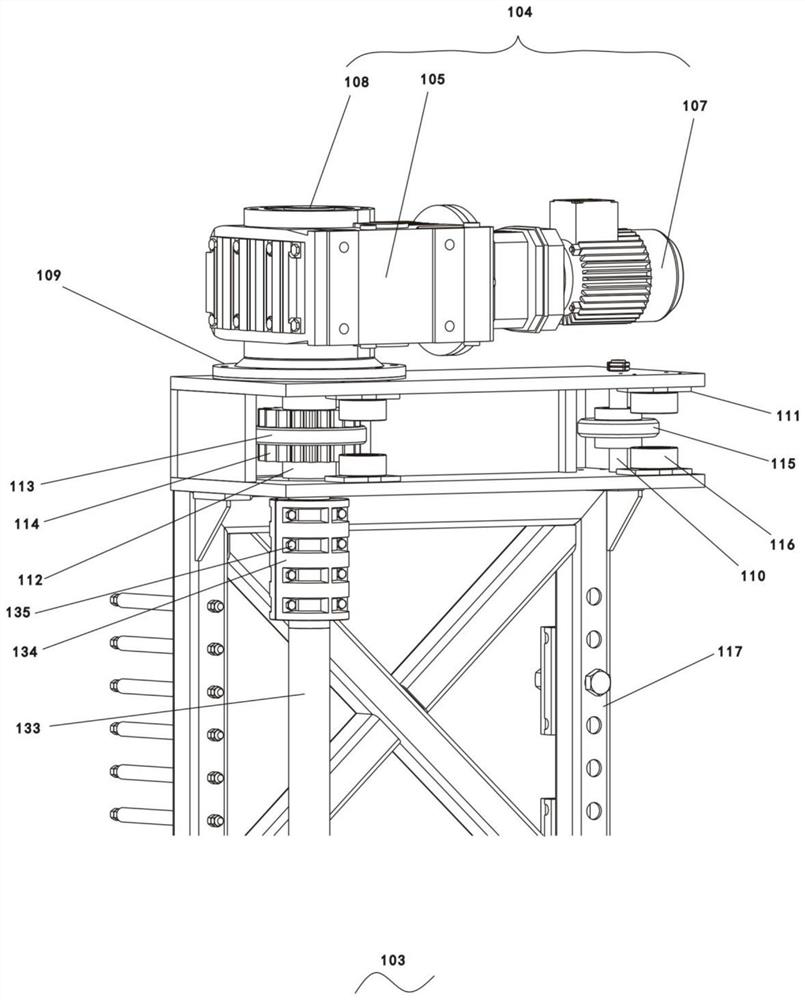

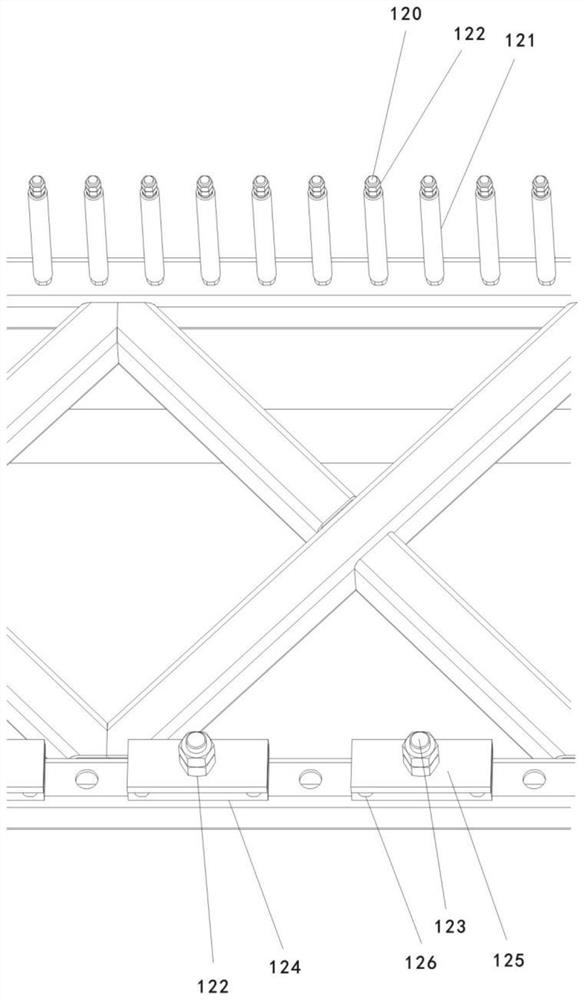

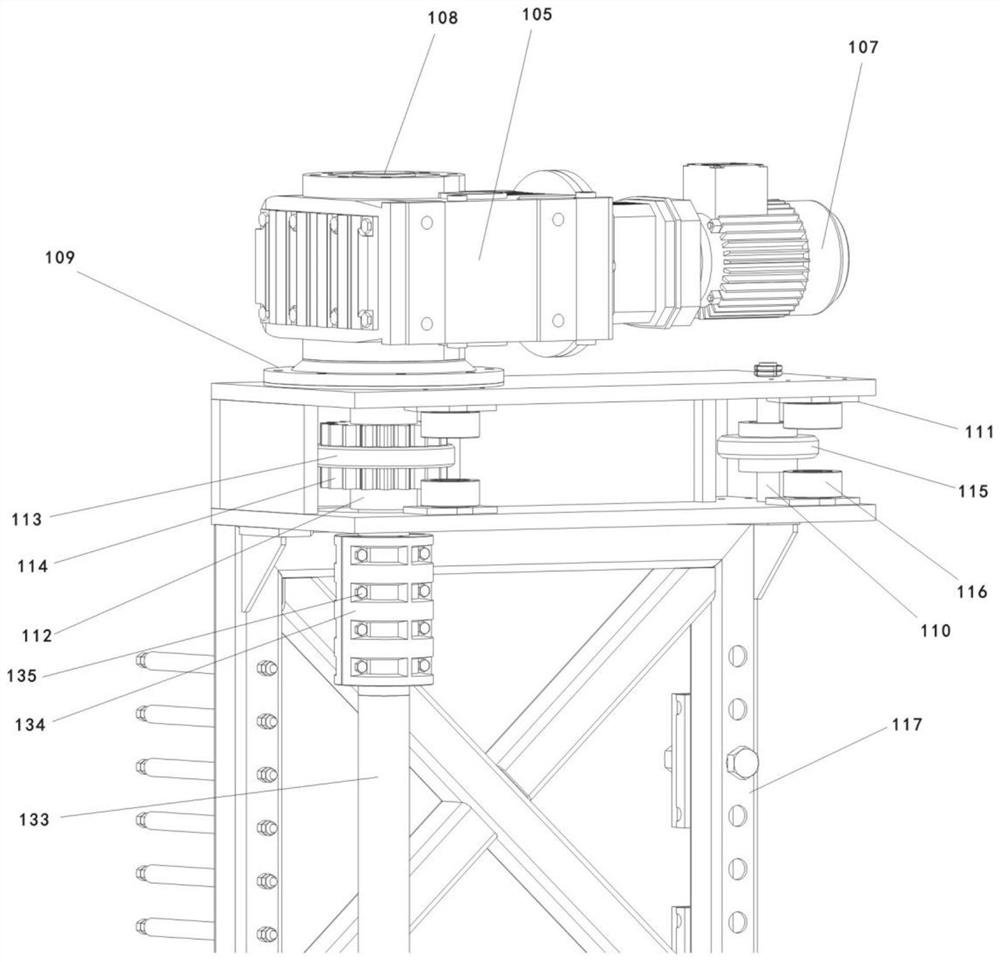

Reinforcing steel climbing frame for tunnel waterproof and drainage board paving trolley

PendingCN111980730AQuality assuranceFast installationUnderground chambersTunnel liningDrive shaftArchitectural engineering

The invention relates to the technical field of tunnel waterproof and drainage board paving, in particular to a reinforcing steel climbing frame for a tunnel waterproof and drainage board paving trolley. The reinforcing steel climbing frame for the tunnel waterproof and drainage board paving trolley comprises two sets of support rings, two sets of gear rings, two reinforcing steel climbing frame bodies and two sets of first drive motor groups, wherein the first drive motor groups are arranged on both sides of the reinforcing steel climbing frame bodies, the first drive motor groups comprise first hollow shafts and first motors, the first hollow shafts are arranged inside the first hollow shafts, first flanges are arranged on the first hollow shafts, the first flanges are connected to the reinforcing steel climbing frame bodies, the reinforcing steel climbing frame bodies are erected on the support rings, the gear rings are arranged between the support rings and the reinforcing steel climbing frame bodies, and first guide roller shafts, four second guide roller shafts and first drive shafts are arranged inside the reinforcing steel climbing frame bodies.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Tunnel waterproof-drainage board paving-hanging trolley

PendingCN111980728AQuality assuranceFast installationUnderground chambersTunnel liningArchitectural engineeringRebar

The invention relates to the technical field of tunnel waterproof-drainage board paving-hanging, in particular to a tunnel waterproof-drainage board paving-hanging trolley. The tunnel waterproof-drainage board paving-hanging trolley includes a steel bar climbing frame, a walking assembly, a body frame, a telescopic assembly, a nail gun part, and an outer stair platform assembly. The body frame isarranged on the walking assembly, and the steel bar climbing frame, the telescopic assembly, a coil material paving-hanging device and the outer stair platform assembly are arranged on the body frame.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Method and system for preprocessing multi-road segment data of lane line crowdsourcing data

ActiveCN111141296BEfficient preprocessingMeet precision requirementsInstruments for road network navigationGeographical information databasesAlgorithmSimulation

The present invention relates to a method and system for preprocessing multi-road segment data of lane line crowdsourcing data. The method includes: step 1, according to the size of an axial coordinate of the shape points in a single lane line in the road segment data Sort; step 2, judge shape point p n Whether the difference between the direction of the point and the connection direction of the head and tail points exceeds the set threshold; yes, delete the point p n+1 , no, add 1 to n; among them, the shape point p n The direction of the shape point p n and shape point p n+1 The connection direction of the line; step 3, execute step 2 in a loop until the value of n is the total number of shape points, and perform linear fitting optimization on the shape points of each lane line respectively. Sorting the shape points in each lane line according to the collinear relationship between points, filtering out abnormal outliers, effectively preprocessing the lane line data collected by crowdsourcing collection vehicles, and improving the efficiency of subsequent optimization processing Effect and efficiency, in order to obtain high-precision lane line map data that meets the accuracy requirements.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

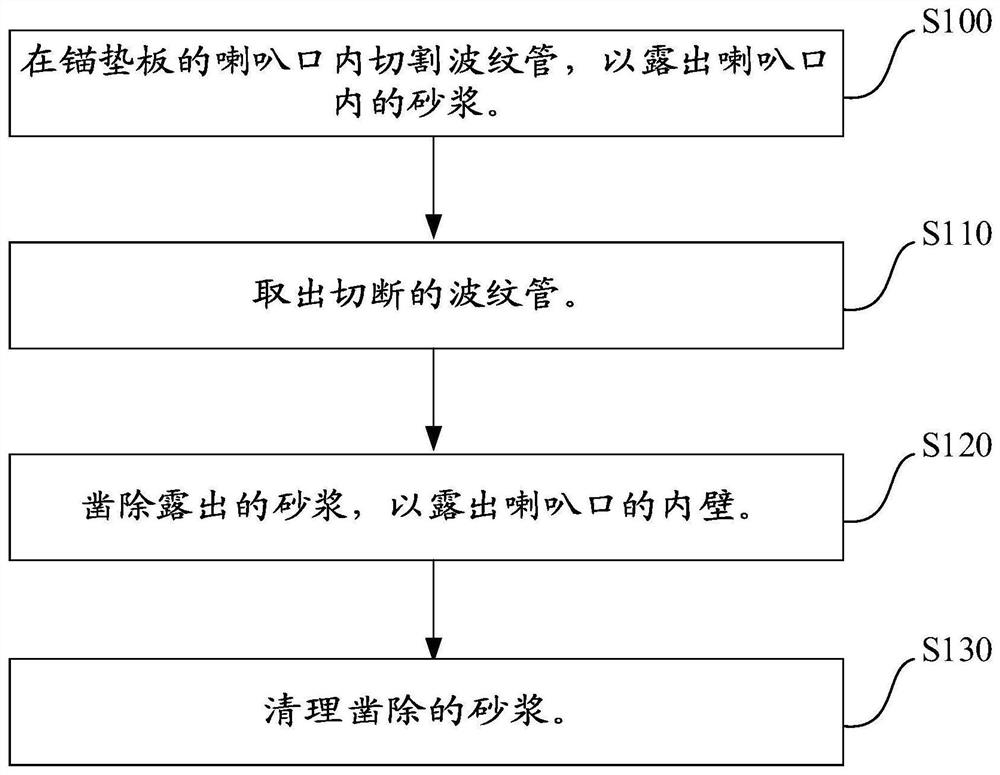

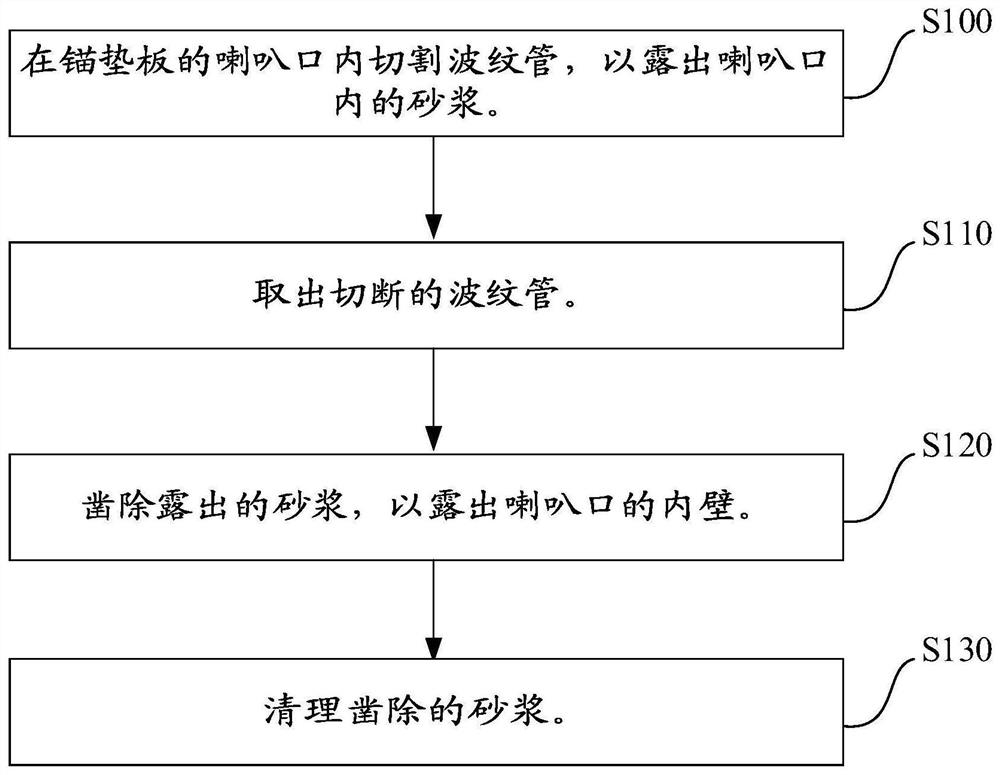

Anchor bearing plate horn mouth cleaning method

ActiveCN112207091ALinear smoothNormal tensionCleaning processes and apparatusPre stressWire breakage

The invention provides an anchor bearing plate horn mouth cleaning method, belongs to the technical field of prestress construction, and is used for cleaning mortar in a horn mouth of a post-tensionedprestressing anchor bearing plate. A corrugated pipe extending to the horn mouth is arranged in the anchor bearing plate, and the mortar is deposited and solidified between the anchor bearing plate and the corrugated pipe. The method comprises the steps that the corrugated pipe is cut in the horn mouth of the anchor bearing plate so as to expose the mortar in the horn mouth; taking out the cut corrugated pipe; chiseling off the exposed mortar to expose the inner wall of the horn mouth; and cleaning away the chiseled mortar. A steel strand is ensured to linearly and smoothly penetrate into ananchorage device from a pre-stressed duct through the horn mouth without any dead bend jamming, so that subsequent normal tensioning and normal anchoring are ensured, and the problems of wire breakage, wire slipping, clamping piece staggering and the like caused by the fact that the steel strand is pressed into a dead bend are solved.

Owner:NO 2 ENG CO LTD OF CHINA RAILWAY CONSTR 11 BUREAU GRP +1

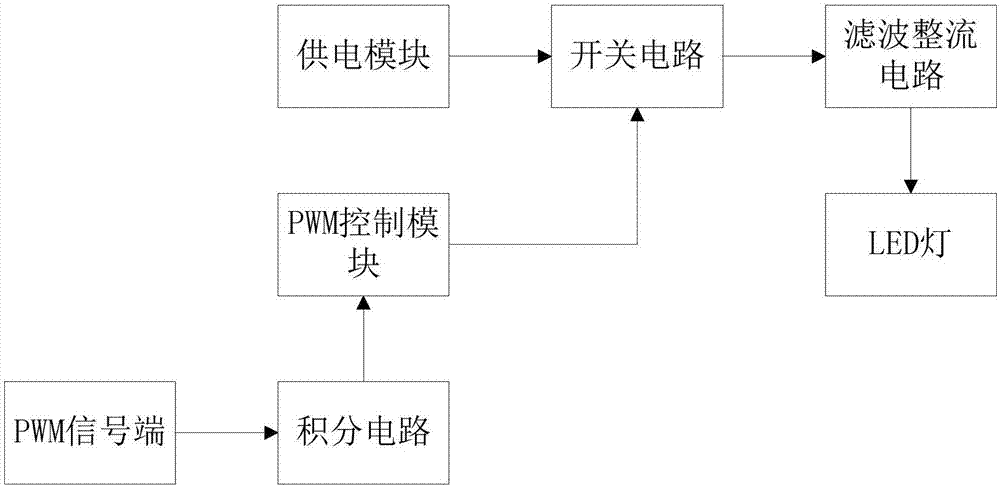

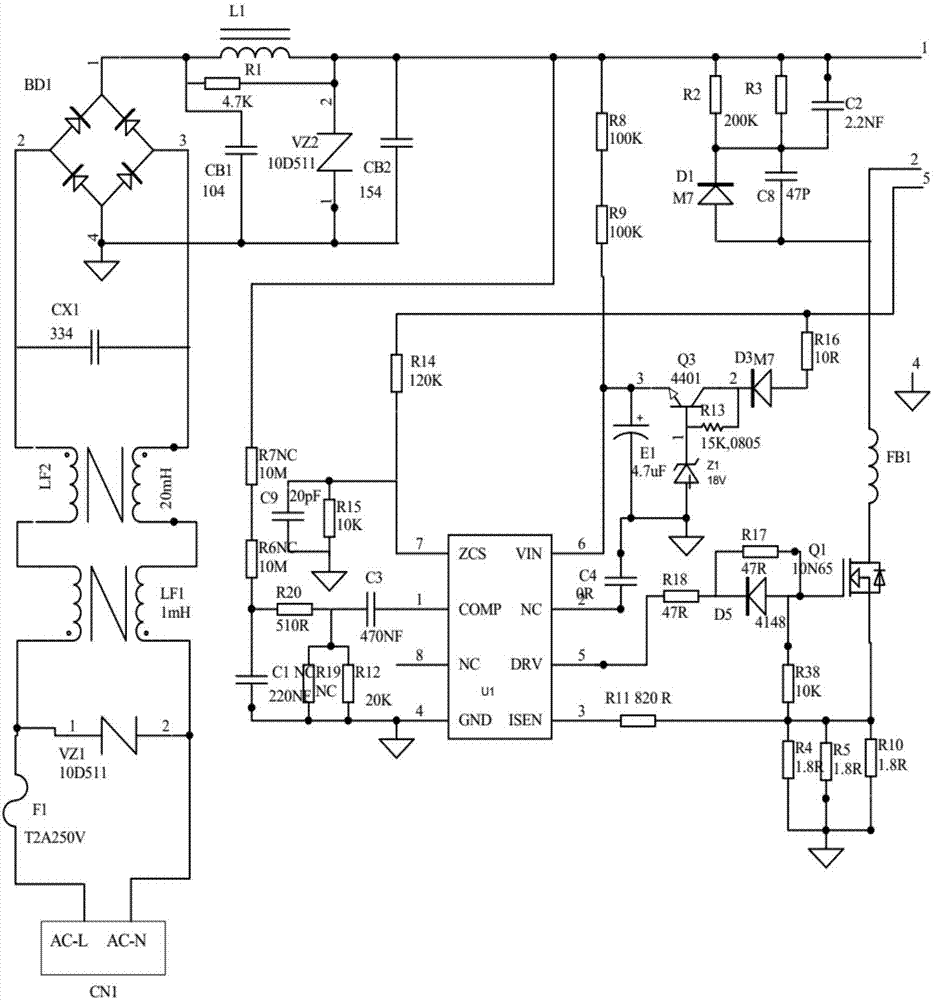

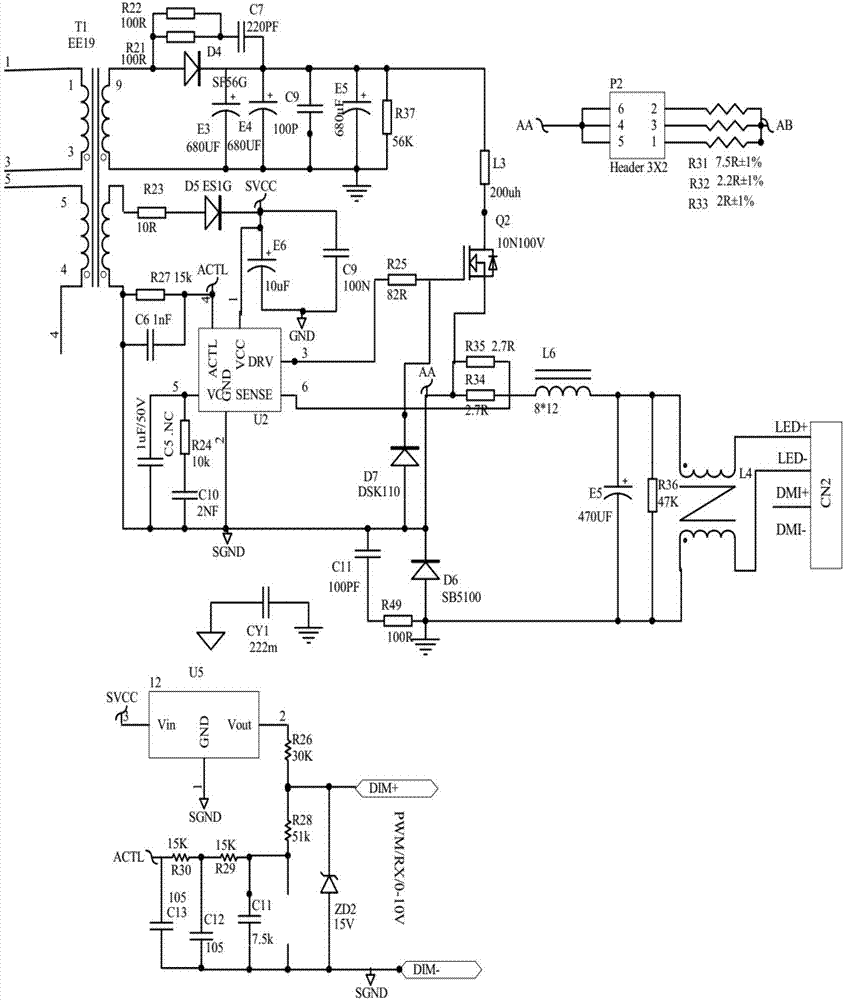

Strobe-free LED dimming circuit

PendingCN107454717ALinear smoothDelicate dimming signalElectrical apparatusElectroluminescent light sourcesComputer moduleEngineering

The invention discloses a strobe-free LED dimming circuit which comprises a power supply module, a PWM control module, a switch circuit, an LED lamp, an integrating circuit and a PWM signal terminal, wherein the output end of the power supply module is connected with the input end of the PWM control module and the input end of the switch circuit; the PWM signal terminal is connected to the input end of the PWM control module through the integrating circuit and inputs a PWM signal into the PWM control module; the output end of the PWM control module is connected to the input end of the switch circuit and controls the on-off state of the switch circuit; and the output end of the switch circuit is connected with the LED lamp. In virtue of the integrating circuit, the signal input from the PWM signal terminal to the PWM control module is linearly smooth so that a dimming signal is exquisite. When the dimming reaches 0 to 7%, a product does not flash or work improperly.

Owner:UP SHINE LIGHTING CO

Continuous beam segment prefabricating and assembling method

InactiveCN112609577ASignificantly superior effectReduce distractionsBridge erection/assemblyPre stressContinuous beam

The invention discloses a continuous beam segment prefabricating and assembling method. The method comprises the steps: 1, arranging a cast-in-place continuous segment at the pier top of a main pier; 2, carrying out re dividing by combining a continuous beam prestress full-length bundle anchor cable tensioning anchorage pier design; 3, dividing the prefabricated simply supported beam sections according to the prestress; 4, performing processing according to the shape and the length of the pier top continuous beam; 5, assembling the prefabricated segment hoisting equipment on the cast-in-place continuous segment; 6, performing hoisting section by section according to section arrangement; 7, hoisting the sections; and 8, measuring the strength of the concrete, penetrating and pulling an anchor cable, performing tensioning, grouting and anchoring, and completing system transformation. According to the continuous beam segment prefabricating and assembling method, traditional continuous beam cantilever pouring construction is adjusted to ground construction from high altitude, segment prefabricating of a beam body is conducted on a prefabricating field, then the beam body is transported to the field segment by segment and hoisted to a preset position in a cantilever progressive mode, and then prestress is applied to sequentially connect all segments into a whole; and finally, the mid-span wet joint is cast in place in a suspended formwork mode to complete beam body construction.

Owner:SINOHYDRO ENG BUREAU 4

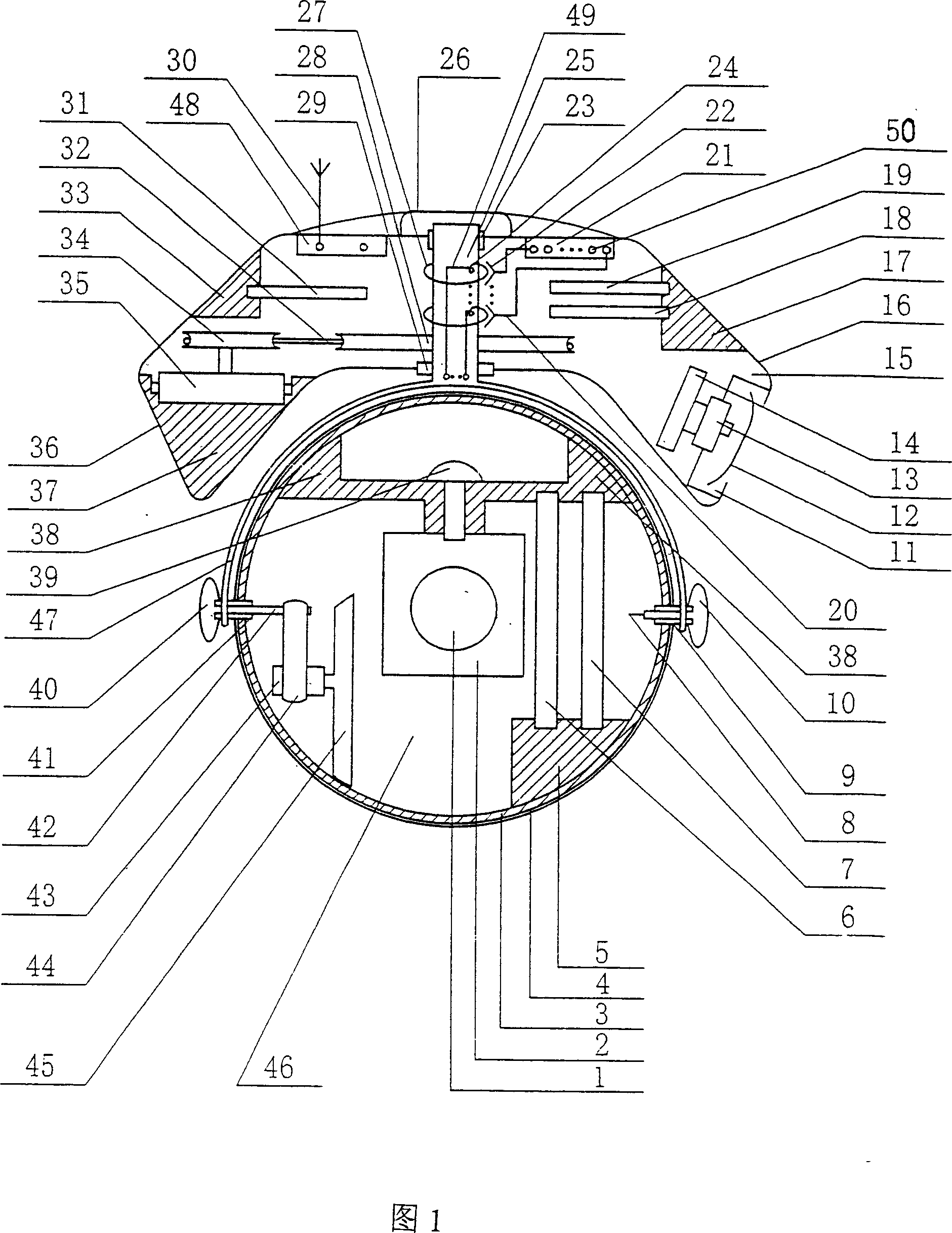

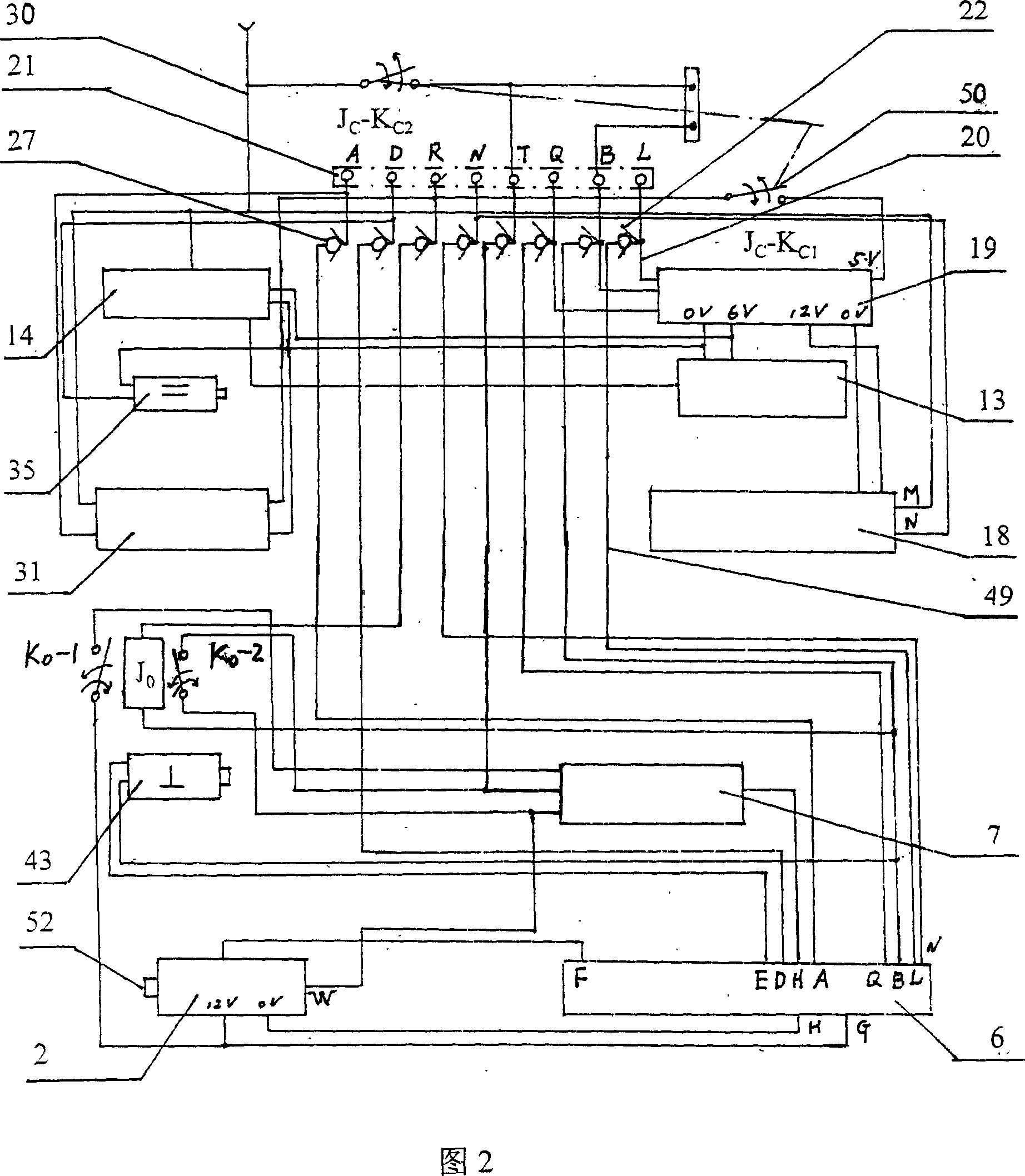

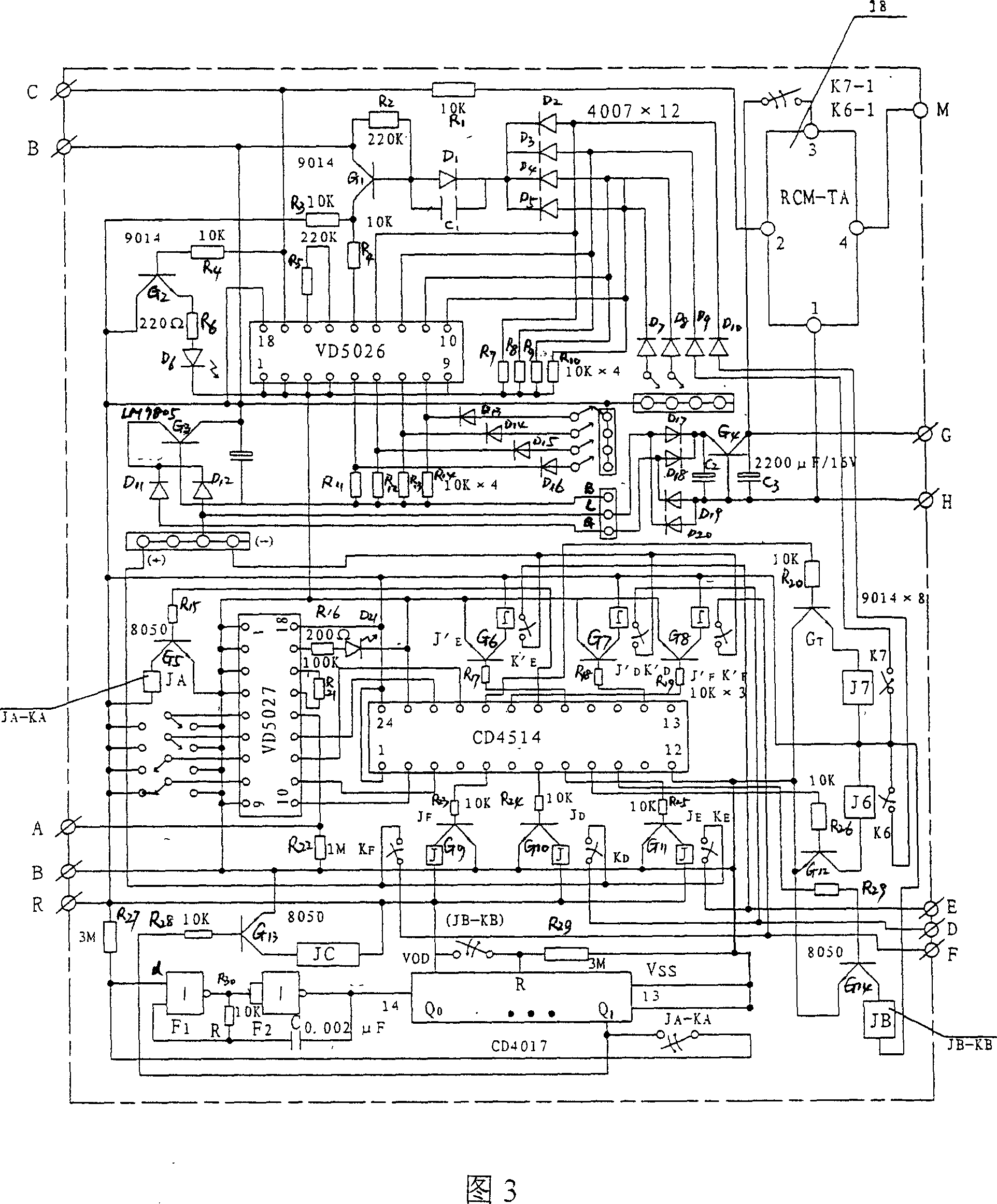

Biconditional transmission monitoring alarm and telemechanical control industrial television camera with integrative steel structure

InactiveCN100347604CIncrease demandSimple structureTelevision system detailsColor television detailsElectricityEngineering

This invention relate to an industry television cameral, which in detail is an industry television ball cameral integrated with visual picture and infrared alarming and remote moving control. It is characterized by the following: the cameral core is located in the perpendicular bisector of the main ball middle ring and together with its pitching rotation structure is located inside the main ball; there are located with the plug rolling connection by the middle ring right axis cover and left axis cover and right middle axis and left middle axis at the crossing point where the main ball middle ring both sides crosses along their diameter direction, wherein, its upper part is an electricity output brush formed by the conductive ring column in the center of the level box and conductive inner ring and outer ring; and its down part are the middle ring left axis hung outside the main ball and the conductive ring bridge rack of the semi-round arc.

Owner:孟令彪

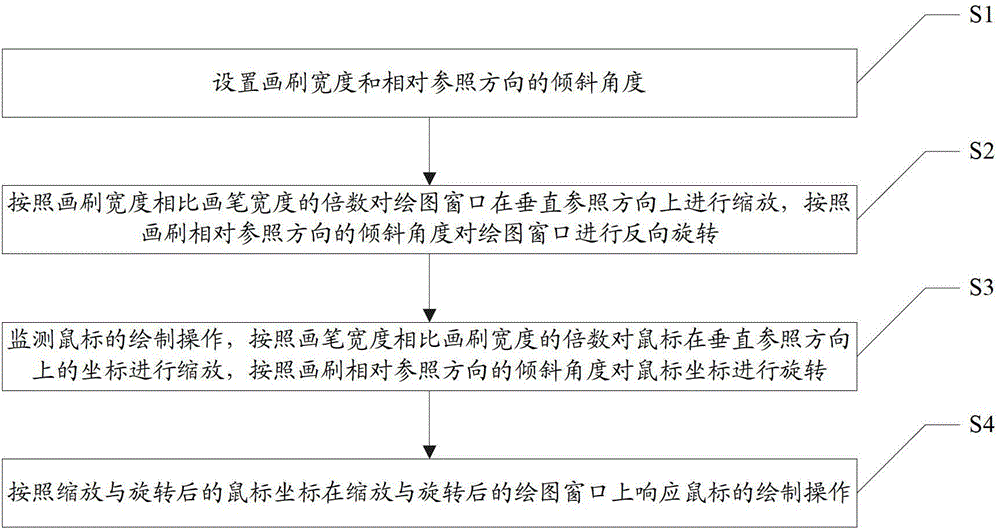

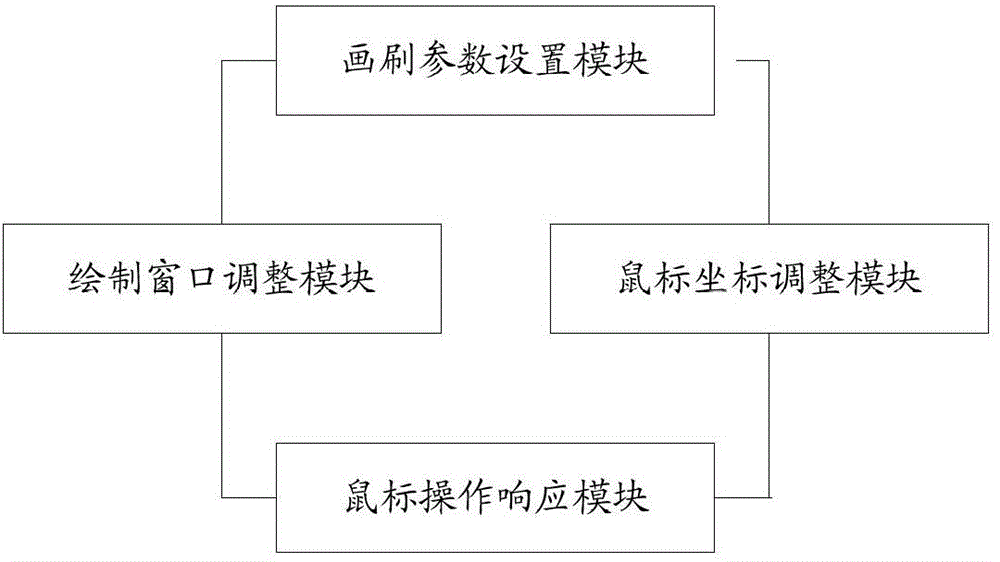

Paint brush realizing method and device

InactiveCN102651139BPreserve anti-aliasing effectSimple processModifying/creating image using manual inputEngineeringLinearity

The invention discloses a paint brush realizing method and a paint brush realizing device. The method comprises the following steps of adjusting a painting window according to preset paint brush parameters by starting from changing the angle of the painting window; operating the paint brush to obtain the paint brush effect and realizing the paint brush function. According to the method and device provided by the invention, only the adjustment of the painting window and the response of painting operation of a mouse are referred to, the process is simple, the amount of calculation is small, the application range is wide; and moreover, the anti-aliased effect of the paint brush is reserved and the linearity is smooth.

Owner:GUANGDONG VTRON TECH CO LTD

Electrical signal acquisition and transmission device for flat working electrode

ActiveCN105954340BIncrease contactImprove compatibilityMaterial electrochemical variablesInterface layerEngineering

The invention belongs to the technical field of electrochemical detection, and aims to provide an electrical signal acquisition and transmission device for a flat plate type working electrode. The electrical signal acquisition and transmission device is simple in structure, easy to operate and high in sensitivity, improves the detection effect, and comprises a base, an interface layer, a transmission layer and a top layer; a data transmission interface slot is formed in the left side of the interface layer; three electrode joint positioning holes are formed in the right side of the interface layer; the transmission layer comprises a printed circuit board; three electrode joint welding holes are respectively formed in the printed circuit board; a data transmission interface element is fixed on the printed circuit board; the top ends of three electrode joints are respectively welded at three welding holes; the lower ends of the three electrode joints respectively penetrate three electrode joint positioning holes in the interface layer; the top ends of the three electrode joints are respectively connected with the data transmission interface element through signal transmission lines; the top layer, the transmission layer, the interface layer and the base are sequentially mounted together from top to bottom; the upper end and the lower end of a spring are respectively mounted in an upper spring fixing slot and a lower spring fixing slot.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

A capping mechanism of a fully automatic capping machine

The invention discloses a capping mechanism of an automatic capping machine, which comprises a main shaft. The main shaft is provided with a cam, a vacuum control device, a lifting part and a cap suction part in sequence from top to bottom; The top of the part rotates along the cam groove on the cam, and the bottom is provided with a capping head, and the capping head can suck and press the cap on the cap suction part through the rotation of the lifting part along the cam groove and the vacuum control device; the vacuum control device includes Vacuum connection plate, vacuum turntable, vacuum device; an annular gap is left between the vacuum connection plate and the vacuum turntable, and the annular gap is divided into a ventilation area and an airless area by a partition rib; The corresponding second gas joint is transferred to the ventilation area, and when the lifting part completes the capping, the corresponding second gas joint on the vacuum connecting plate is transferred to the airless area. The capping mechanism in the present invention has a high degree of automation, a high safety factor, and saves labor costs.

Owner:JIANGSU TOM PACKAGING MACHINERY

A method for on-site horizontal assembly of steel pipe arches

ActiveCN109505266BHigh degree of mechanizationSmall footprintBridge erection/assemblyBridge materialsStress concentrationWeld seam

The invention discloses an on-site horizontal splicing method of a steel tube arch, which adopts horizontal splicing in the form of '3+1' to meet the requirements of the alignment and can be processedand manufactured normally. The method adopts a mode of drawing a ground sample and then hanging a vertical line to lead the wire to be centered and aligned, is convenient and practical, and ensures horizontal splicing precision and linear smoothness. An inner flange is adopted to connect the two arch rib sections, the connection precision is high, the adjusting speed is high when a steel beam iserected in the later period, and the safety of the inner flange is high. The arrangement of a pre-arch degree is considered during horizontal splicing, so that the problem that the linear change caused by the pre-arch degree in the erection process cannot accurately align an inner flange bolt is avoided, and unnecessary trouble is caused. The on-site horizontal splicing method of the steel tube arch adopts the mode of steel component processing and on-site assembly separation, and is convenient for management and error prevention by batch entry and batch acceptance. The middle part is welded first, and then the two sides are welded to prevent stress concentration. After the arch rib is welded, welding the inner flange and the arch rib which are connected by bolts in advance; the deformation caused by the shrinkage of a welding seam cannot be prevented so that the inner flange cannot be accurately aligned.

Owner:中铁一局集团厦门建设工程有限公司 +1

Stentless urban bridge anti-collision guardrail construction method and cradle vehicle and gun carrier thereof

ActiveCN102877418BLinear smoothStraight linesBridge structural detailsBridge erection/assemblyRough surfaceArchitectural engineering

The invention discloses a stentless urban bride anti-collision guardrail construction method, which is characterized in that a self-driven gun carrier back transportation template and a self-driven cradle vehicle are used for hoisting a anti-collision guardrail template, and an inner side template is used for hoisting an outer side template, so that the stentless construction is realized; the outer side template is hung and reinforced by a triangular support on the inner side template, the lower part of the outer side template is fixedly connected with an inner template through a counter-strain bolt, the straightness of the template is adjusted by utilizing a supporting rib and a basket bolt, the concrete is poured after the template is well adjusted, and a template cover is dismounted after the concrete strength meets the requirement so as to perform the moistening maintenance. Due to the adoption of the stentless urban bridge anti-collision guardrail construction method, the technical difficulties of the traditional support method that a support is previously arranged and the influence on the road traffic and the construction is large can be solved, not only can the working period be guaranteed, but also the normal construction and the traffic of the pavement road can be guaranteed, and the construction cost is also reduced; and the quality defects such as difficulty for installing and reinforcing the anti-collision rail steel template, easiness in template deviation and leakage, uncompactness for pouring the concrete, easiness for resulting in honeycomb, rough surface, bubbles, unattractive outline and the like can be solved.

Owner:JINAN URBAN CONSTR GRP

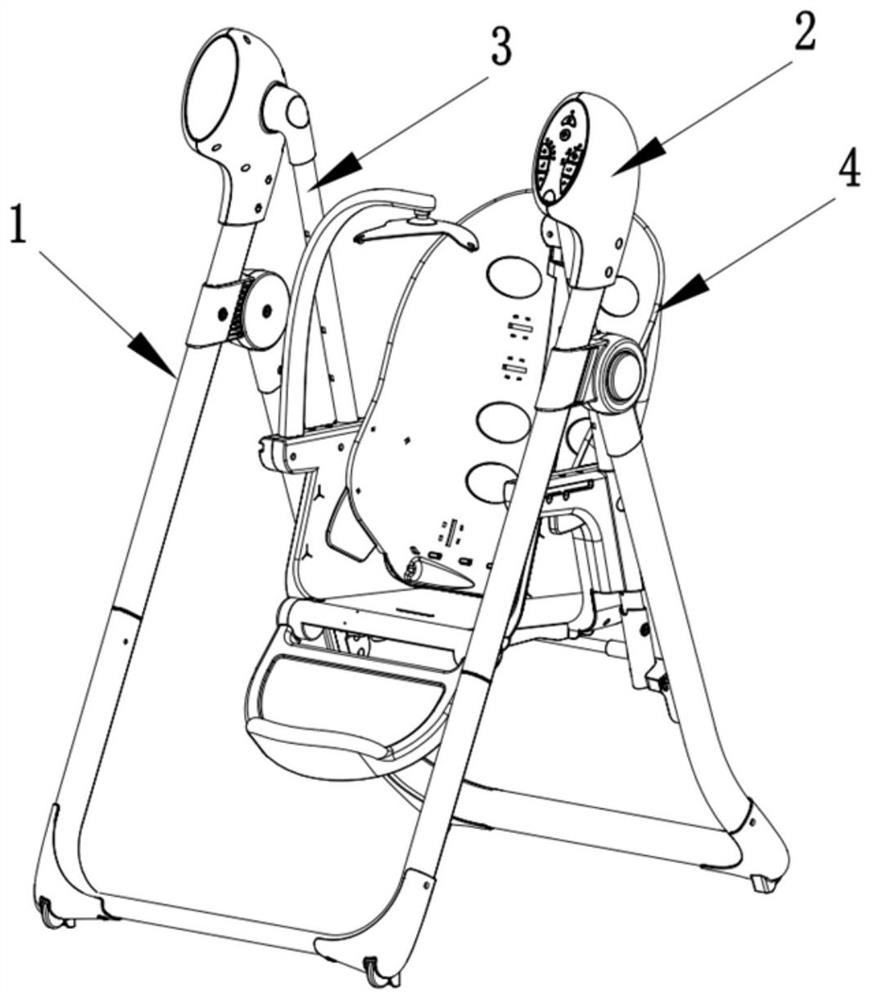

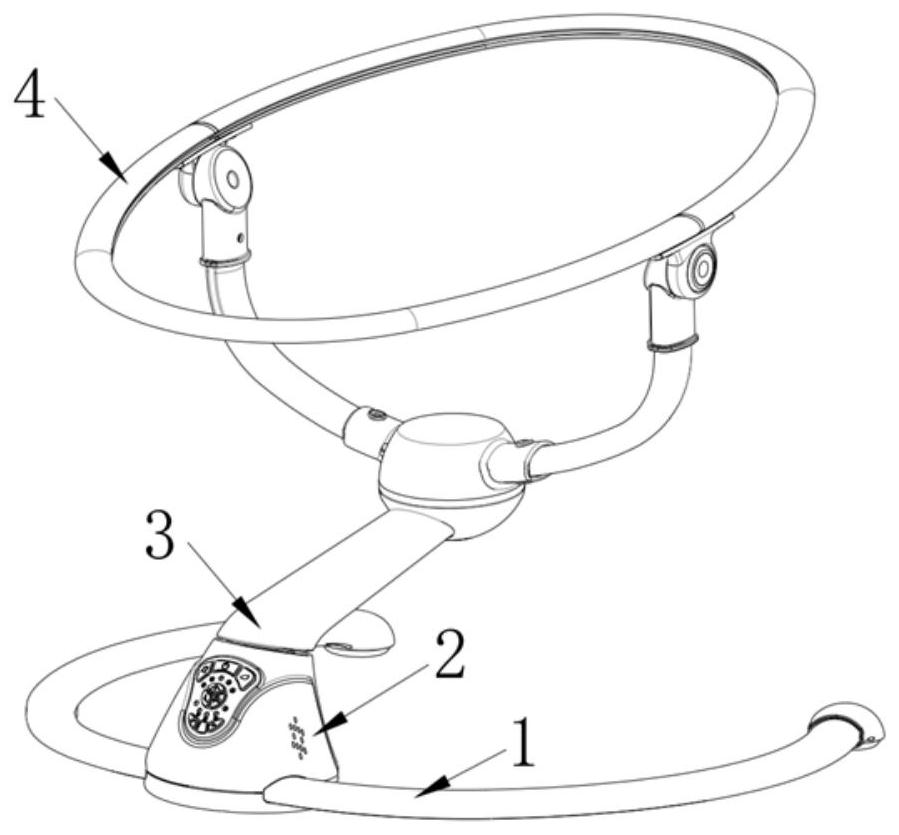

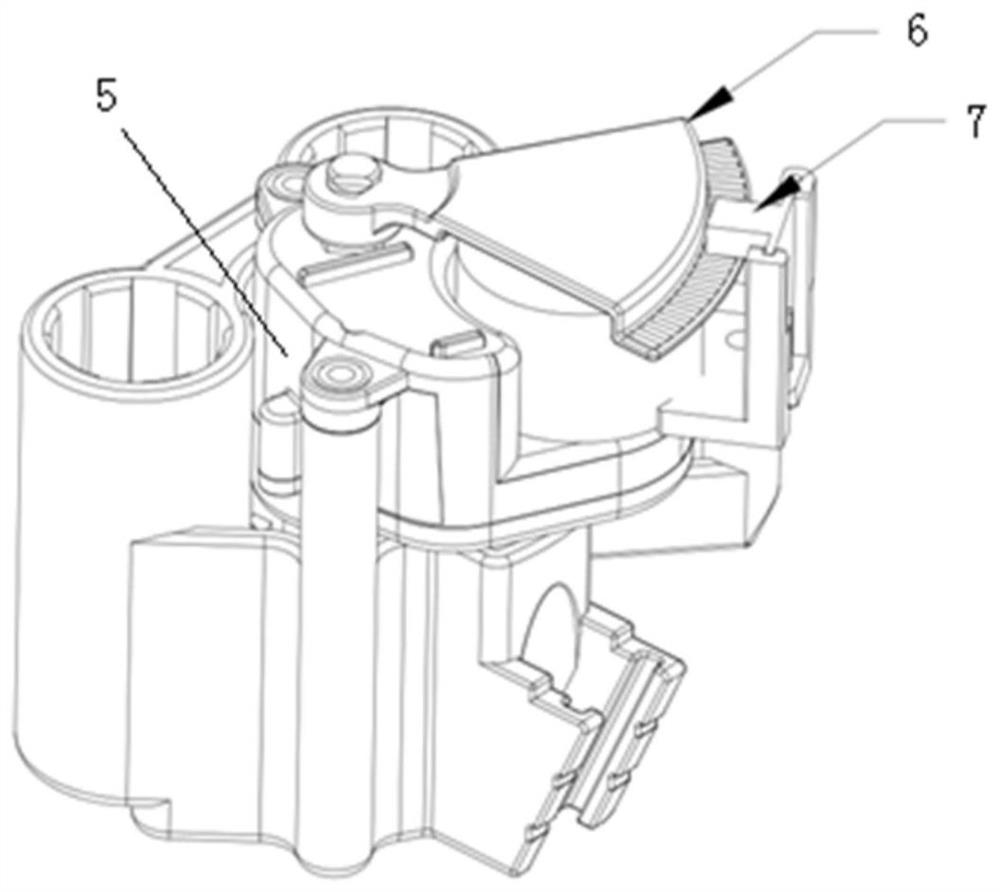

Shaking control method and device

The invention discloses a shaking control method, which comprises double photoelectric sensors and a grating, and comprises the following steps of: detecting the time when a grating interrupting or opening part passes through the photoelectric sensors; in each shaking period, comparing the shortest time value with a time value corresponding to a preset shaking amplitude, and when the shortest time value is not equal to the preset time value, generating a control signal for adjusting the output power of the motor so as to enable the shaking amplitude to reach the preset shaking amplitude; detecting a current shaking direction; and judging whether the current shaking direction is changed or not, and when the current shaking direction is changed, generating a control signal for adjusting the output power of the motor to perform homodromous supplementary stress application. The swing speed of a swing is controlled by calculating the time value of the blocking or opening part of the grating passing through the photoelectric sensors, the control precision is improved, and the problem of insufficient precision is effectively solved. Forward and reverse same-direction supplementary force application is correspondingly carried out according to the shaking direction, and shaking power can be corrected in advance.

Owner:KUNSHAN LUCKY CHILD PROD CO LTD

Device and method for calling qt drawing based on jni multi-thread in android system

ActiveCN107818588BImprove experienceImprove drawing speedDrawing from basic elementsProcessor architectures/configurationSoftware engineeringDisplay device

The invention discloses a device and method for an Android system to call Qt drawing classes based on JNI multithreading, including: running the Android system, clearing the system memory, performing canvas initialization, activating the so dynamic library to prepare for calling Qt drawing classes, if the canvas If the initialization fails, the activation of the so dynamic library is carried out again; after the so dynamic library is successfully activated, the image data sampling thread and the SurfaceView drawing thread are started simultaneously under the environment of the first language; and the operation of executing the image data sampling thread is passed The drawing action MotionEvent event generates coordinate points, uses the Rect command to draw a rectangular frame according to the generated coordinate points, and loads the point coordinates float (x, y) to the so dynamic library, and the Qt drawing class according to the point coordinates float (x, y) Draw and execute the SurfaceView drawing thread at the same time, use the Android system's own SurfaceView to draw, and display the surface drawn by SurfaceView on the display. As a result, the drawing speed is significantly improved, and cross-platform calls are realized at the same time.

Owner:SHENZHEN HONGHE INNOVATION INFORMATION TECH CO LTD

A cleaning method for bell mouth of anchor backing plate

The invention provides a method for cleaning the bell mouth of an anchor backing plate, which belongs to the technical field of prestressed construction and is used for cleaning the mortar in the bell mouth of a post-tensioned prestressed anchor backing plate. A corrugated pipe with a bell mouth, the mortar is deposited and solidified between the anchor backing plate and the bellows, the method includes: cutting the bellows in the bell mouth of the anchor backing plate to expose the bell the mortar in the bell mouth; take out the cut bellows; chisel the exposed mortar to expose the inner wall of the bell mouth; clean the chiseled mortar. Guarantee the smooth linearity of the steel strand from the prestressed channel through the bell mouth into the anchorage, and no dead bend jamming will occur, so as to ensure the subsequent normal tension and normal anchoring, and solve the problem caused by the steel strand being pressed into a dead bend Broken wires, slipped wires, wrong clips and other problems.

Owner:NO 2 ENG CO LTD OF CHINA RAILWAY CONSTR 11 BUREAU GRP +1

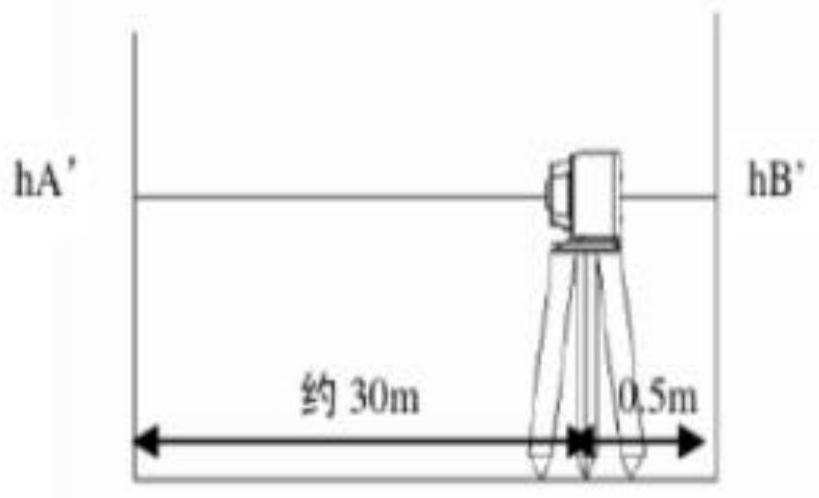

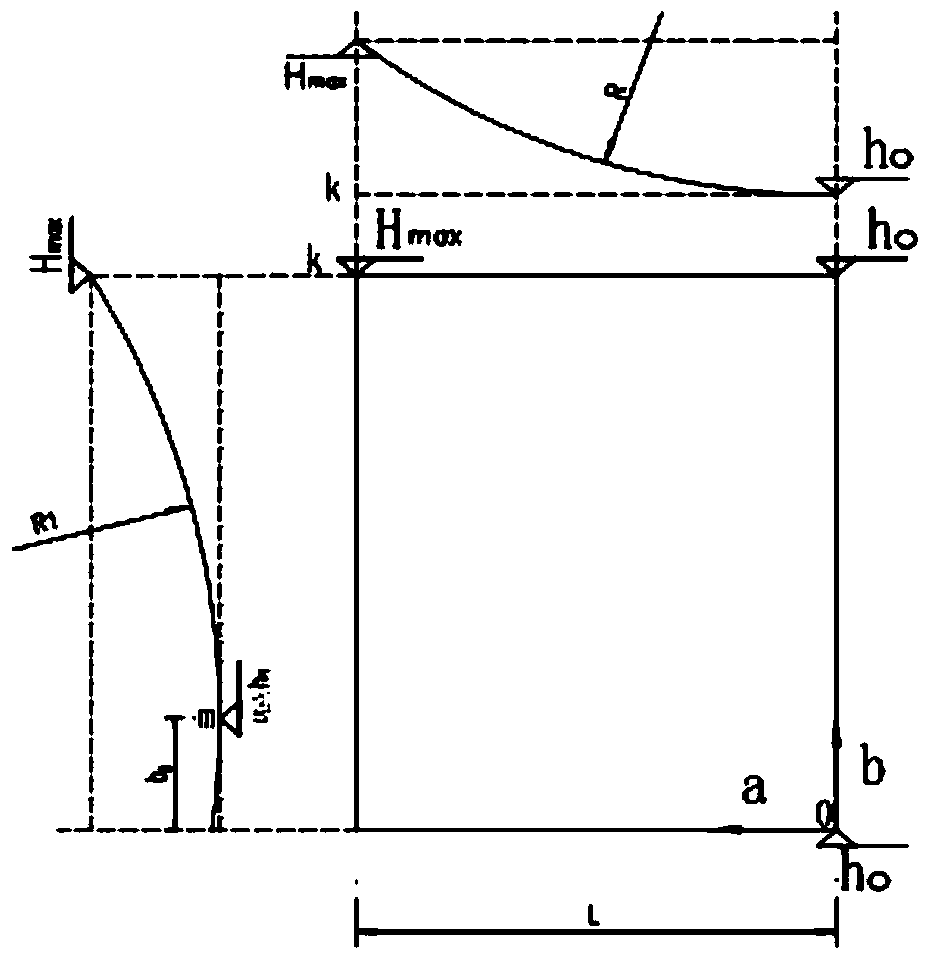

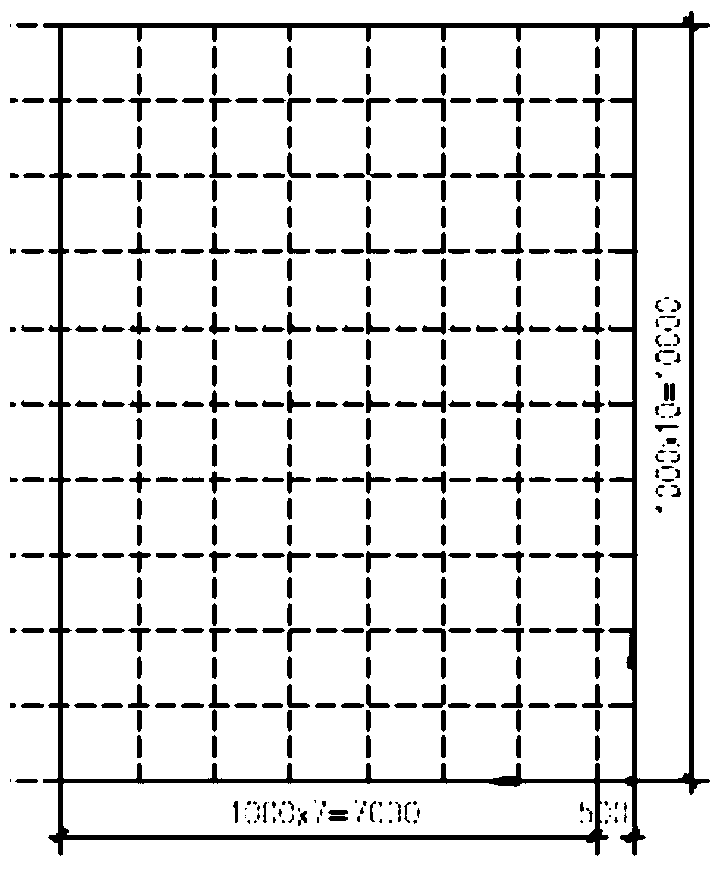

Method for measuring and controlling elevation location of curved concrete bridge deck nodes

ActiveCN104636545BLinear smoothAccurate elevation positioningSpecial data processing applicationsBridge deckSurveyor

The invention relates to the field of curved-surface concrete bridge deck construction buildings, in particular to a curved-surface concrete bridge deck joint measurement and control elevation positioning method. According to the method, on the aspect of measurement and positioning, projection segmenting is conducted on the curved surface of a concrete bridge deck in reference to a finite element segmentation method, and through a coordinate plane transformation calculation formula, the spatial elevation of any point on the curved surface can be precisely worked out. Based on the axis, the horizontal projection of the curved surface is divided into a plurality of grids of small specifications, the elevation of the grid joints of the grid is worked out, then surveying and positioning are conducted, and finally the joints are connected to form a smooth spatial curved surface. By the adoption of the method, operation is simple, elevation positioning is very precise, the surveying difficulty and labor intensity can be greatly lowered, the construction progress is accelerated, good conditions are provided for formwork erection, the formwork erection positioning is made to be accurate, and thus the construction quality of the curved-surface concrete bridge deck is guaranteed.

Owner:CHINA NUCLEAR IND HUATAI CONSTR

Construction method for bridge steel box basket arch

ActiveCN100478522CStrong typhoon resistanceEnsure construction safetyBridge erection/assemblyTotal stationEngineering

The steel box and basket arch bridge constructing process with 500-ton crane boat and full framing includes the following steps: determining the structural shape, rise-to-span ratio, arch rib toe-in angle and arch rib section form; installing the steel box girder support and midspan steel box girder; hoisting side arch and sidespan steel box girder and finally hoisting arch center. During the process, a total station meter and water level gages are adopted for overall process measurement, and jacks in longitudinal, transverse and vertical directions are utilized to locate the arch ribs and the steel box girder precisely, so as to ensure correct structural form and construction safety. At the same time, ANSYS program for calculating the installation profile and sensors for structure and stress control are also utilized. The constructing process is simple and easy to control, and the steel box and basket arch bridge has high typhoon resistance and high efficiency.

Owner:THE 5TH ENG MBEC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com