Adjustable strain clamp

A tension clamp, adjustable technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problem of reducing the service life of tension clamp and jumper, difficult to ensure the uniformity of jumper production process, and drainage of tension clamp. The problem of splint deformation and other problems can avoid the phenomenon of tip discharge, the structure is simple, and the cost of raw materials can be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

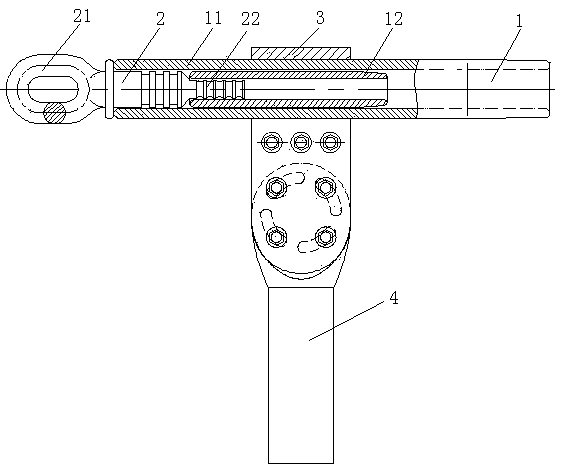

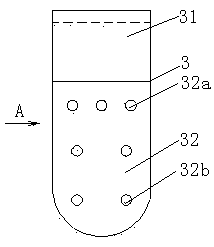

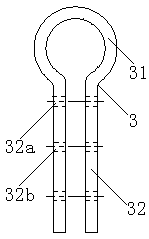

[0018] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , an adjustable strain-resistant clamp of the present invention, which is composed of a clamp body 1, a steel anchor 2, a drainage splint 3, and a drainage clamp 4. The steel anchor 2 is inserted in the clamp body 1; the drainage splint 3 and The clamp body 1 is connected; one end of the drainage clamp 4 is connected to the drainage splint 3, and the other end is crimped with the jumper; the drainage splint 3 is in the form of a clamp and is set on the aluminum tube 11; The angle between the vertical position of the drainage splint and the drainage clamp is 0°, and the angle adjustment range of the drainage clamp relative to the drainage splint is -5°~45°; Set in the aluminum tube 11; the aluminum tube 11 and the crimping tube 12 are aluminum alloy hollow tubes; the inner diameter of the aluminum tube 11 is the same as the outer diameter of the wire; the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com