Detachable joint nodes of steel structure

A steel structure and node technology, applied in the direction of building structure, construction, etc., can solve the problems of limited ability to transmit tensile force, ineffective transmission of tensile force, unfavorable recycling and other problems, achieve smooth linear shape, and is conducive to installation and disassembly operations and processing. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

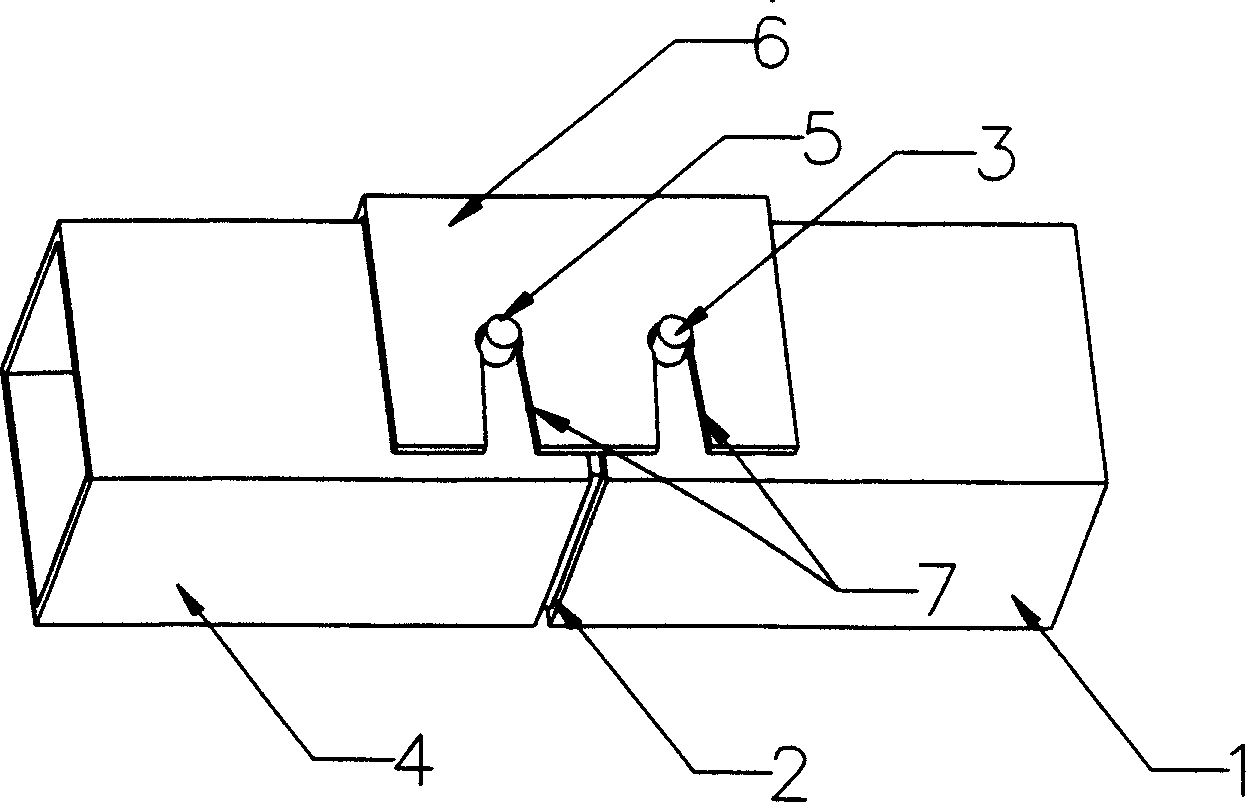

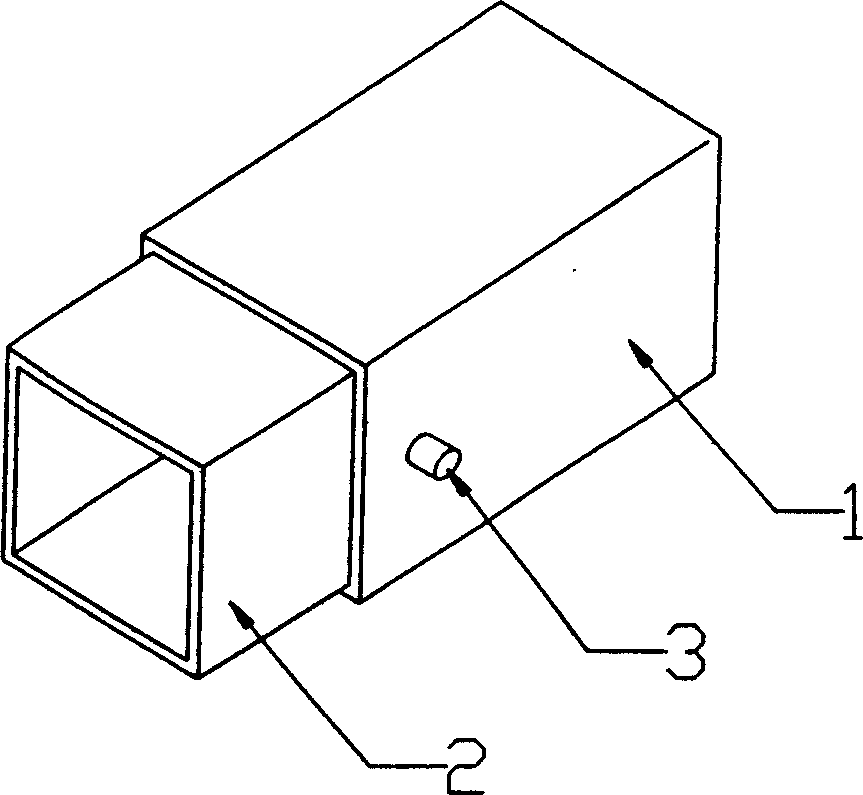

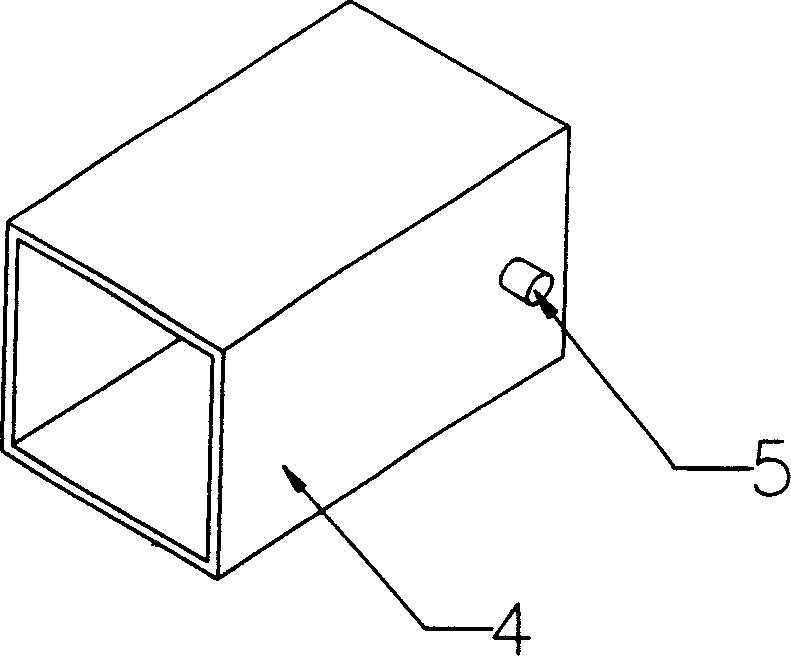

[0022] The overall structure of the detachable steel structure plug joint node adopted in the present invention is as follows: figure 1 shown. The node is composed of three parts: main unit, sub unit and cover plate. The main pipe 1 of the main unit is connected with the main pipe 4 of the auxiliary unit through the inner sleeve 2. Two pins 3 are respectively fixed on the two sides opposite to the main pipe 1 of the main unit, and two pins 3 are respectively fixed on the two opposite sides of the main pipe 4 of the auxiliary unit. The pin 5 and the grooved cover plate 6 are set on the main and auxiliary units. Two pin grooves 7 are respectively opened on the two wings of the grooved cover plate 6. The distances are equal, so that the pin 3 on the main unit and the pin 5 on the secondary unit are inserted into the pin g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com