Stentless urban bridge anti-collision guardrail construction method and cradle vehicle and gun carrier thereof

A technology of anti-collision guardrails and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., which can solve the problems of template handling, installation, reinforcement difficulties, high-altitude construction difficulty, and long construction period for erecting supports. Good social and economic benefits, reduced construction costs, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The method of the present invention is described in detail below with reference to the accompanying drawings.

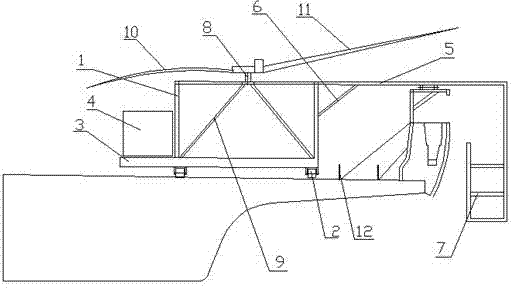

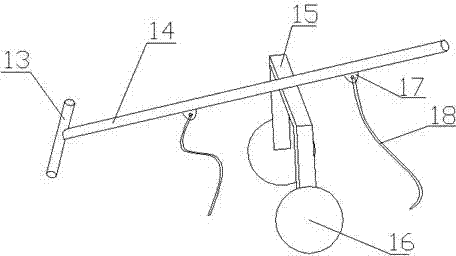

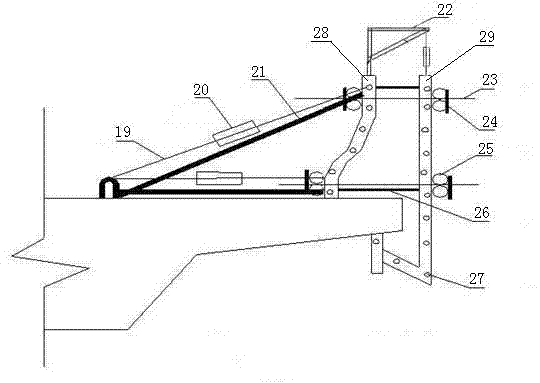

[0016] As shown in the accompanying drawings, on the construction line of the anti-collision guardrail of urban bridges without supports, the self-propelled cannon car is used to reverse the formwork, the self-propelled hanging basket car is used to lift the anti-collision guardrail formwork, and the inner formwork 28 is used to suspend the outer formwork 29, so that there is no Bracket construction. The outer formwork 29 is suspended and reinforced by the upper triangular support 22 of the inner formwork 28, and the lower part is connected and fixed with the inner formwork 28 through the pull bolts 26. The straightness of the formwork is adjusted by using the support bars 21 and the basket bolts 20. After the concrete strength meets the requirements, the formwork is removed and covered with moisture and health preservation. The specific construction steps ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com