Arc support combined template used for cast-in-place box beam and erecting method thereof

A technology of arc-shaped brackets and combined templates, which is applied in bridge construction, bridge erection/assembly of bridges, etc. It can solve the problems of high cost, heavy transportation tasks, and low efficiency, and achieve high utilization rate, convenient and safe dismantling, and light structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

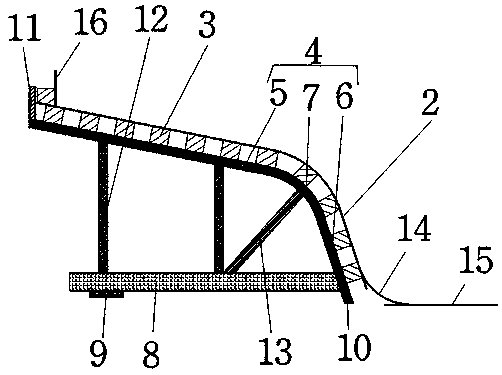

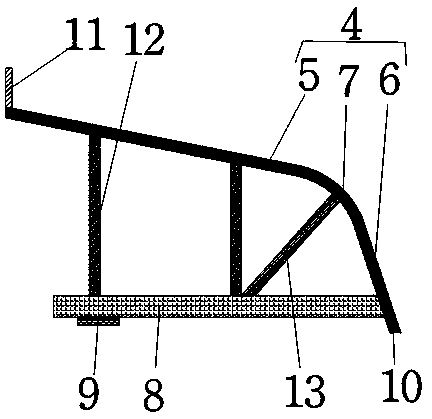

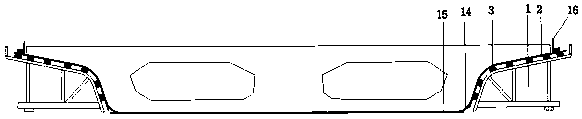

[0043] Please refer to figure 1As shown, an arc-shaped bracket combination formwork for cast-in-place box girders, in this embodiment, the arc-shaped bracket combination formwork includes several arc-shaped brackets 1, multiple square timbers 3, and cast-in-place box girder side formwork 2 composition. Several arc-shaped brackets 1 are evenly arranged along the direction of the bridge, and a plurality of square timbers 3 are detachably fixed on the upper part of the arc-shaped body 4 of the arc-shaped bracket 1 through fixing parts (steel wires, plastic ropes, hemp ropes, etc.). A plurality of square logs 3 are evenly laid along the lower end to the upper end of the arc-shaped body 4 . The square wood 3 is used to connect several arc-shaped supports 1 into a whole, and the square wood 3 provides a laying support surface for the cast-in-place box girder side formwork 2 .

[0044] After fixing the arc-shaped support 1 and the square timber 3 along the direction of the bridge, ...

Embodiment 2

[0052] Wherein, as a further improvement to Embodiment 1, in order to make the arc-shaped bracket combined formwork suitable for the construction of various structures of cast-in-place box girders, it is convenient to adjust the radian of the arc-shaped bracket combined formwork. The arc-shaped support 1 also includes an adjustment part 10, which is formed by extending downward from the free end of the web formwork support part 6, and the adjustment pad 9 and the adjustment part 10 are used to adjust the angle of the side formwork 2 of the cast-in-place box girder. Further, when the arc-shaped support 1 is set, according to the setting angle of the cast-in-place box girder side formwork 2 (web formwork and wing formwork), it is adjusted through the adjustment part 10 and different adjustment pads 9 are set at the free end of the bottom plate 8, Make the arc-shaped support 1 conform to the inclination angle of the side formwork 2 (web formwork and wing formwork) of the cast-in-p...

Embodiment 3

[0055] In Embodiment 1 and Embodiment 2, a 1.2m-high cast-in-place box girder is taken as an example to describe the arc-shaped bracket combined formwork in detail.

[0056] Among them, the arc-shaped body 4 of the arc-shaped bracket 1 is made of a square steel pipe with a diameter of φ4.8 and an anti-corrosion and anti-rust treatment. The length of the wing template support part 5 is 135 cm; the length of the arc bending part 7 is 42 cm. , and the arc bending part 7 is formed by bending 30° by a bending machine; the length of the abdominal template support part 6 is 52cm. The bottom plate 8 of the arc support 1 is formed by channel steel or I-beam, and the length of the bottom plate 8 is 150cm. In order to strengthen the strength of the channel steel or I-beam, reinforcing ribs are also provided on the channel steel or I-beam. The protective leg 11 of arc support 1 is upwardly welded on the upper end of arc body 4 by φ 3.0 steel pipe.

[0057] Both the vertical support body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com