A capping mechanism of a fully automatic capping machine

A capping machine, fully automatic technology, applied in the direction of packaging, etc., can solve the problems of reducing automation efficiency, capping machine is not stable enough, can not normally suck caps, etc., to achieve the effect of improving automation efficiency, saving labor costs, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

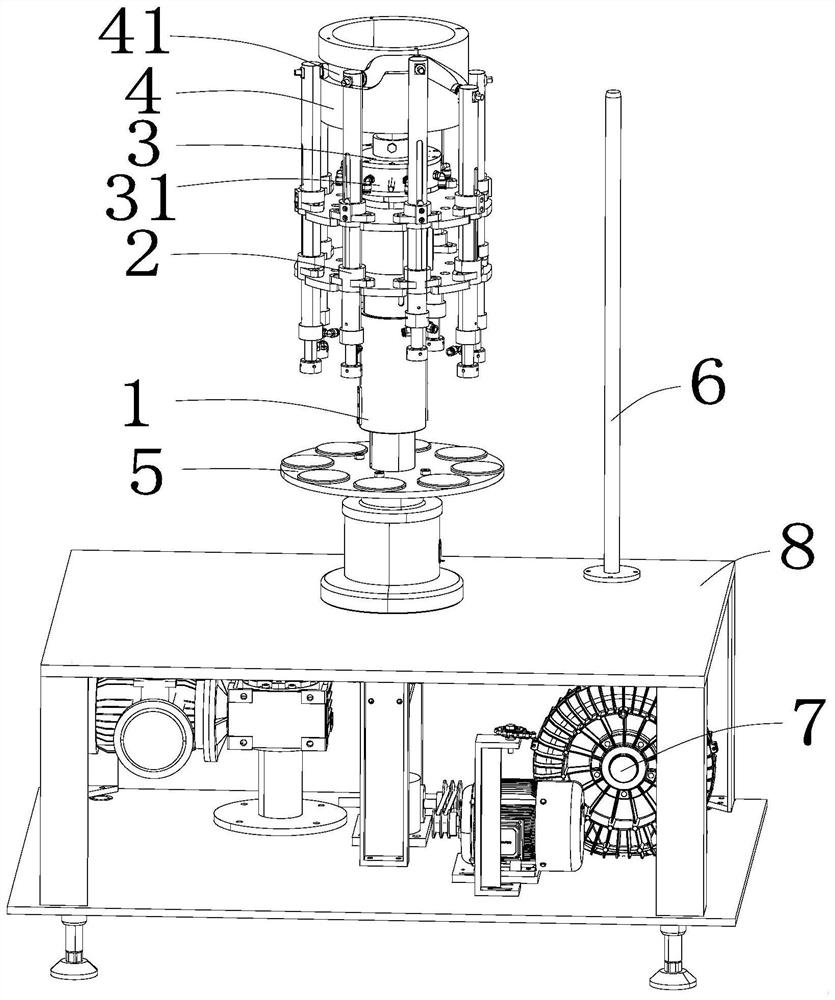

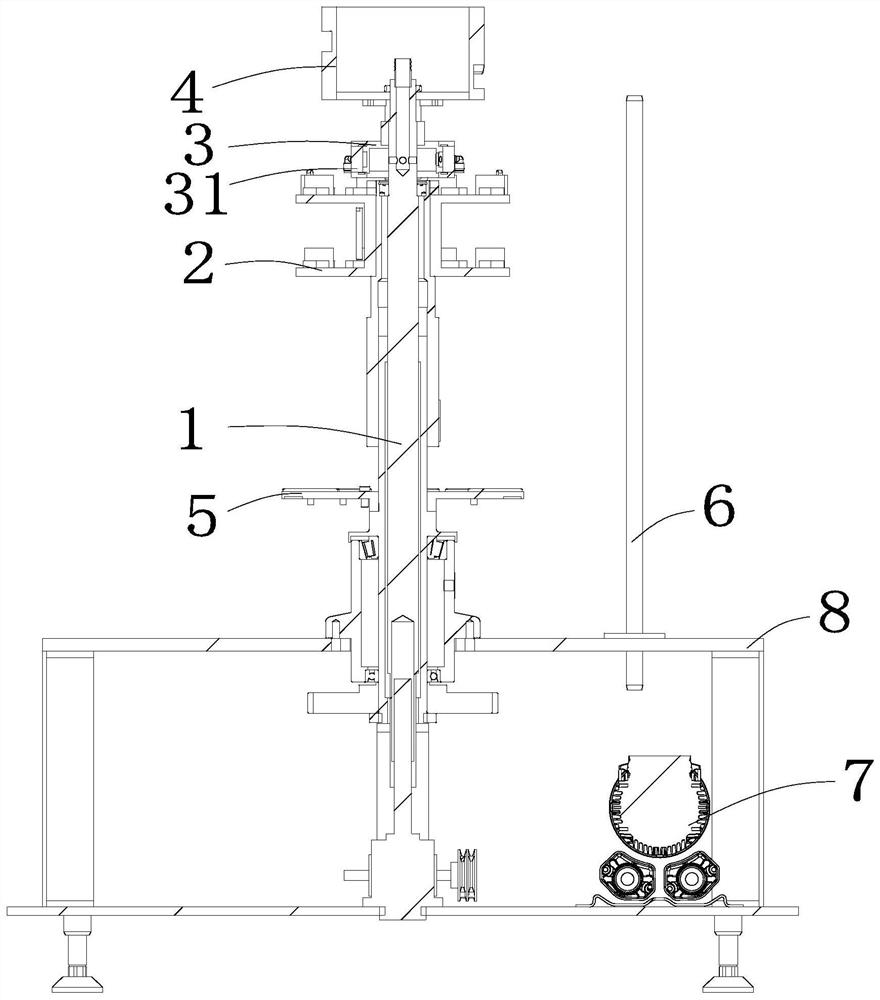

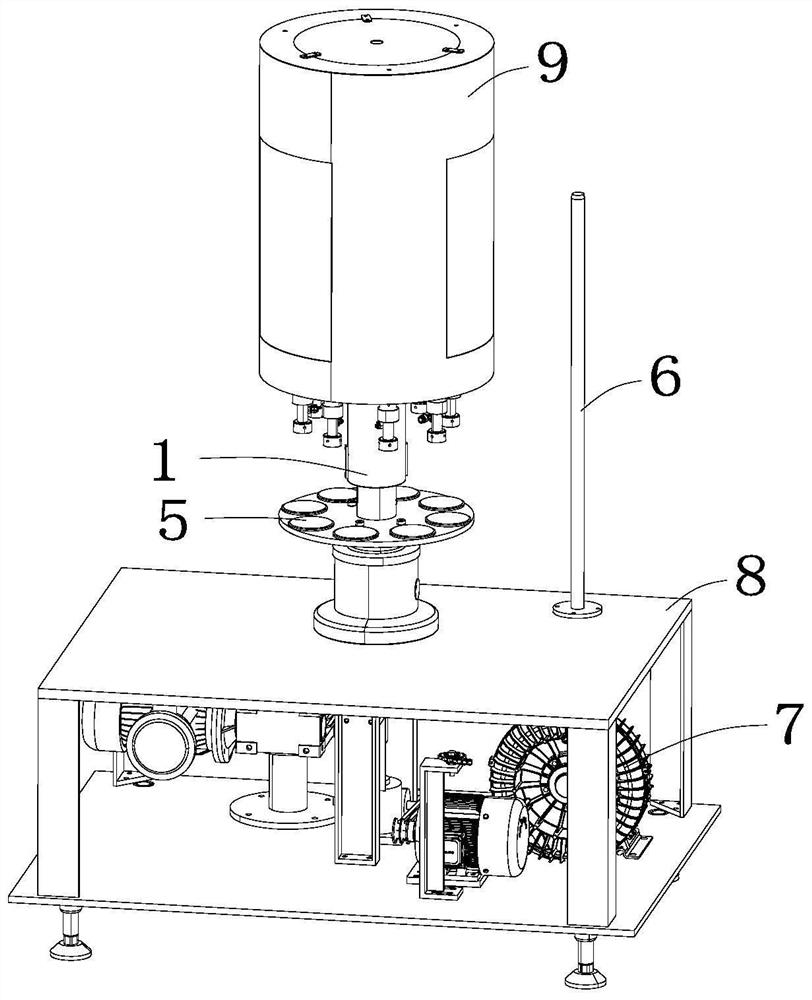

[0035] Example: a capping mechanism of an automatic capping machine, as attached figure 1 and 2 As shown, the capping mechanism in this embodiment includes a main shaft 1, and the main shaft 1 is provided with a cam 4, a vacuum control device, a lifting part 2 and a suction cap part 5 in sequence from top to bottom; the main shaft 1 in this embodiment is provided in the installation On the rack 8, the mounting rack 8 includes a mounting surface at the top, a mounting cavity at the middle and a mounting leg at the bottom, wherein the cam 4, the vacuum control device, the lifting part 2 and the suction cover part 5 are all located above the mounting surface, The power unit that drives the rotation of the main shaft 1 is located in the installation cavity; image 3 As shown, the main shaft 1 in this embodiment is provided with a protective casing 9 outside, and the casing 9 covers and protects the cam 4, the vacuum control device, and the lifting part 2 on the main shaft 1 to im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com