Continuous beam curtain board construction technology

A kind of construction technology and shroud technology, which is applied in the direction of bridges, joists, girders, etc., can solve the problems that the overall linearity of the shrouds cannot be straight, the shrouds cannot be connected smoothly, and cannot be used normally, so as to achieve cheap materials and prolong construction Effects of construction period and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

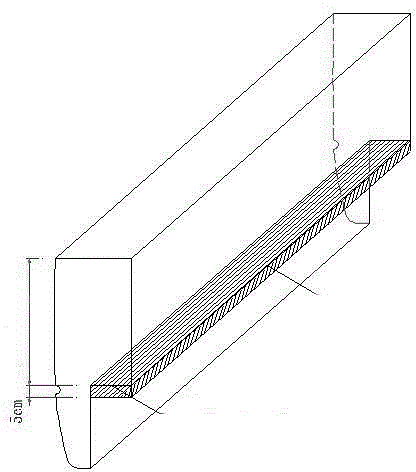

[0008] Construction process of continuous beam shutters, formwork bottom formwork installation and fixing; binding steel bars, installing embedded parts; installing side forms; foam board installation: install foam boards according to the "foam board installation diagram"; foam board installation must be flat and straight, Reinforcement; Concrete pouring; Concrete formwork removal and maintenance; Storage: Before installation and construction, the shutters are transported to the site according to the installation progress requirements and temporarily stored for installation and use.

[0009] After the construction of the continuous beam is completed, prefabricated shutters need to be installed. Before installation, measure the elevation of the beam surface and the elevation of the hanging line; install the shutter, use a truck crane or a miniature gantry crane to lift it, and install it according to the elevation of the hanging line; the gap between the shutter and the beam surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com