Continuous beam segment prefabricating and assembling method

A prefabricated assembly and segment technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increasing the safety risk of concrete continuous beams, difficult to control the quality of prefabricated beams, and large interference on the construction site. Effective quality control, less construction safety risks, and less construction site disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

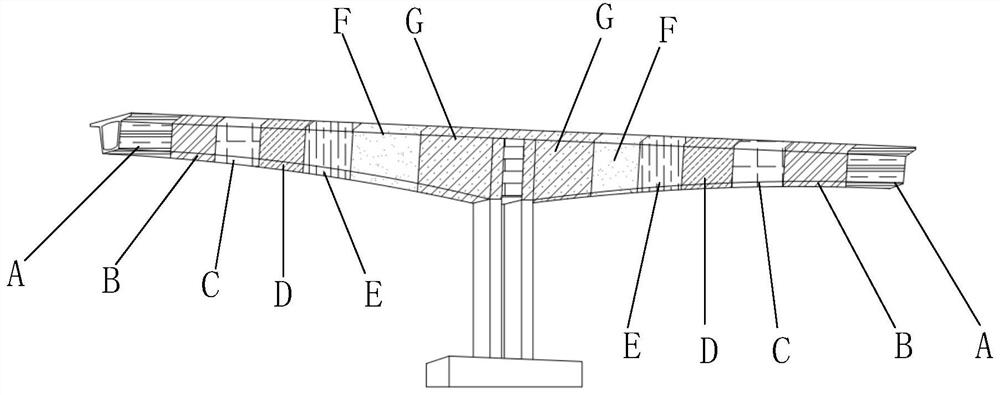

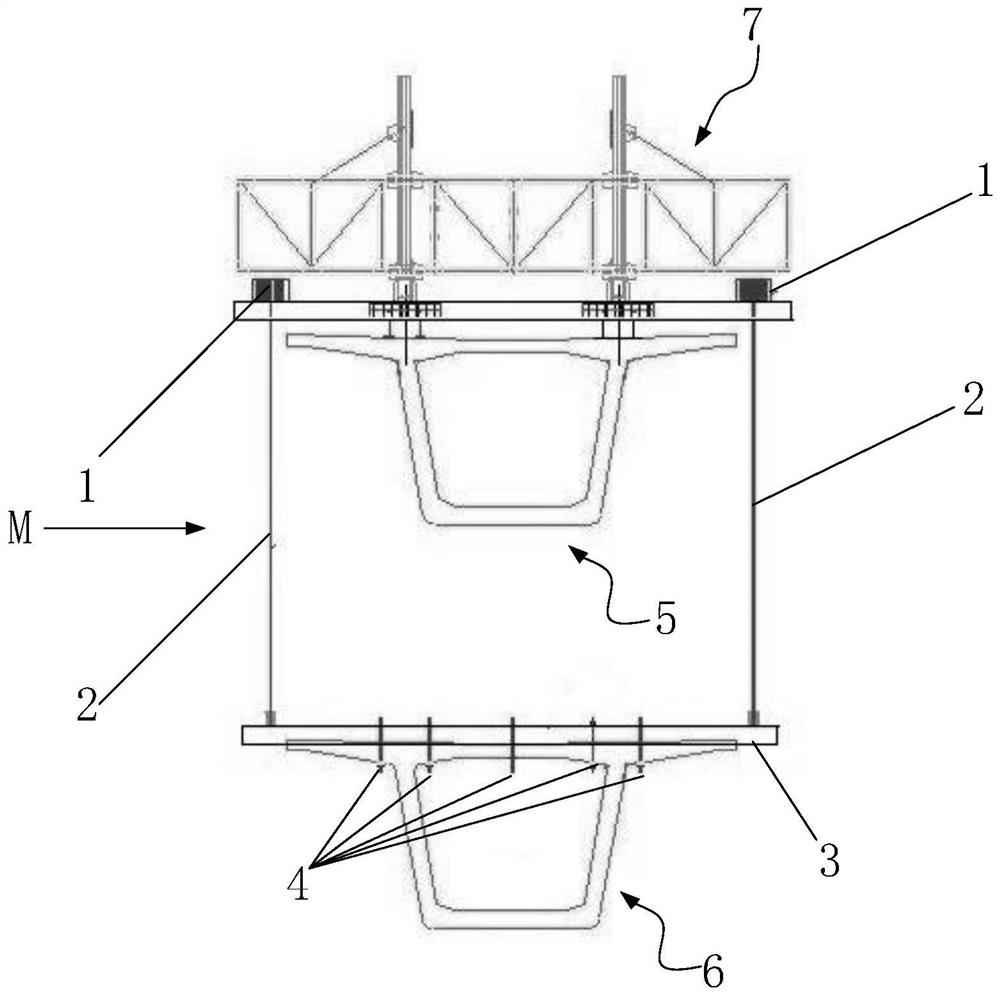

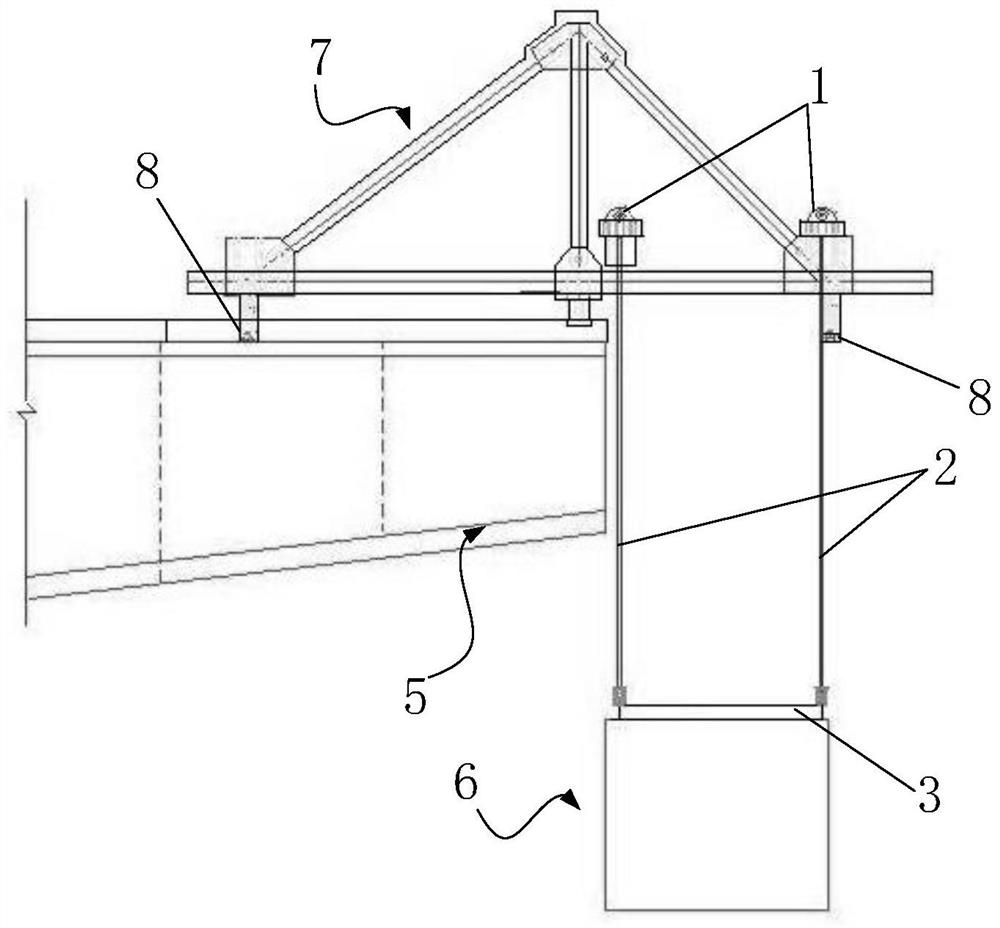

[0069] like Figure 1 to Figure 6 As shown, the continuous beam section prefabricated assembly method includes the following steps:

[0070] Step 1. Set the cast-in-place continuous section on the top of the main pier to meet the installation of segmental assembly and hoisting equipment. The length of the cast-in-place continuous section is based on the design shape of the continuous beam. Standard segment length on both sides;

[0071] Step 2, combined with the design of tensioned anchor pier with prestressed long beam anchor cables, re-divide the standard section of prestressed continuous beam so that the tensioned anchor pier is close to the end of the standard section;

[0072] Step 3: According to the division of prestressed prefabricated simply supported beam segments, pouring is carried out on the adjustable prefabricated ped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com