Patents

Literature

82results about How to "Effective connectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

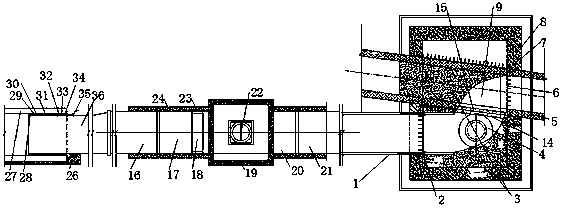

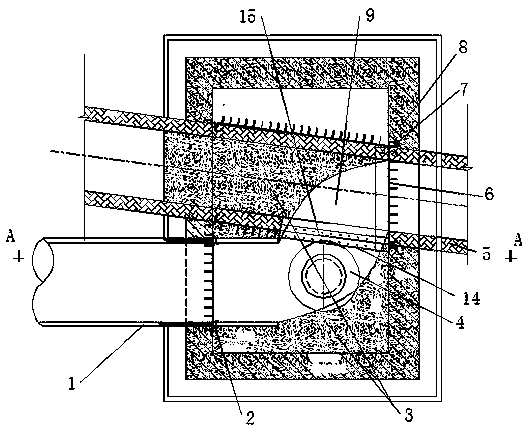

A method for underground coal gasification

InactiveCN102287177AEfficient developmentChange areaConstructionsFluid removalMultiple injectionChemical reaction

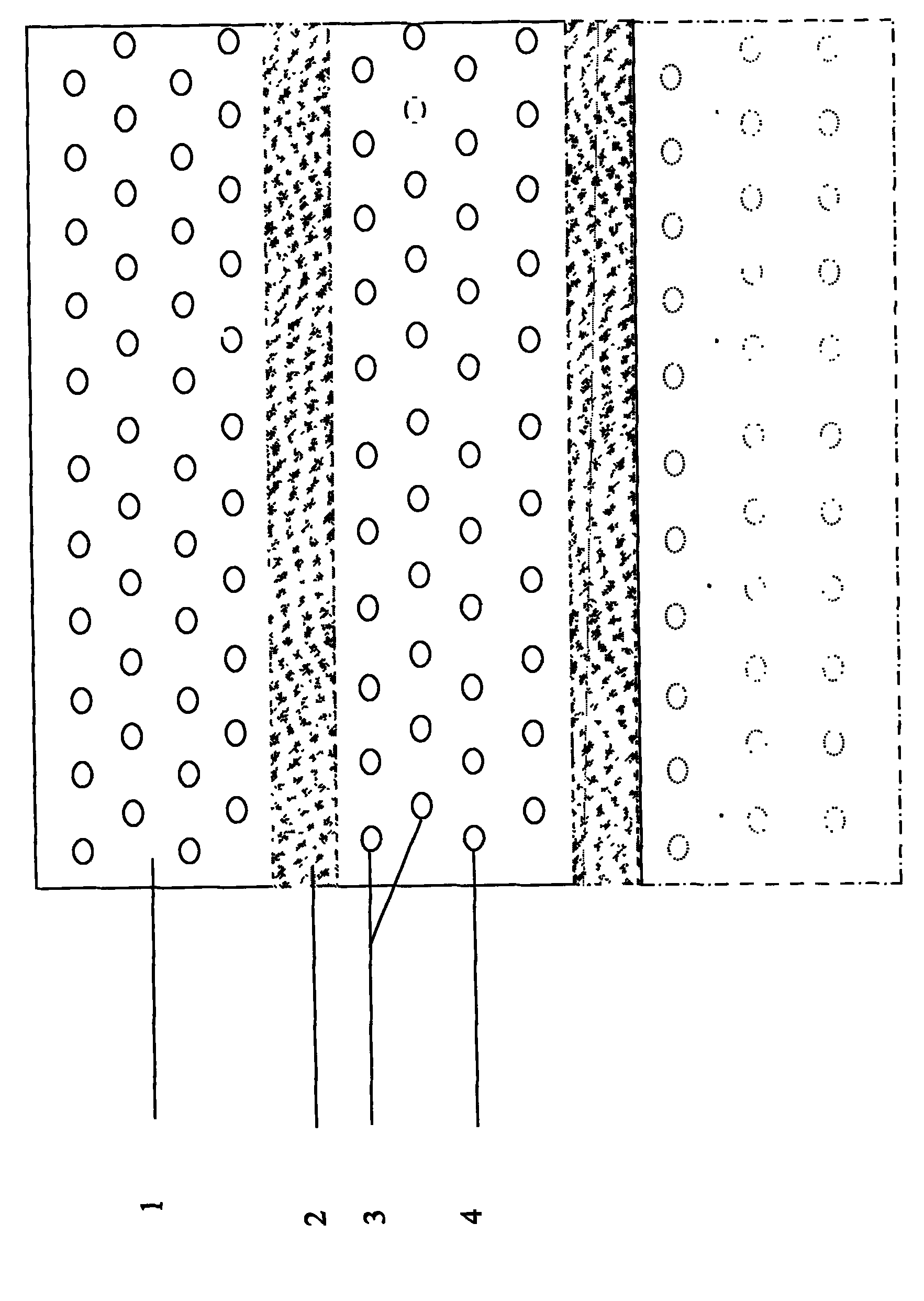

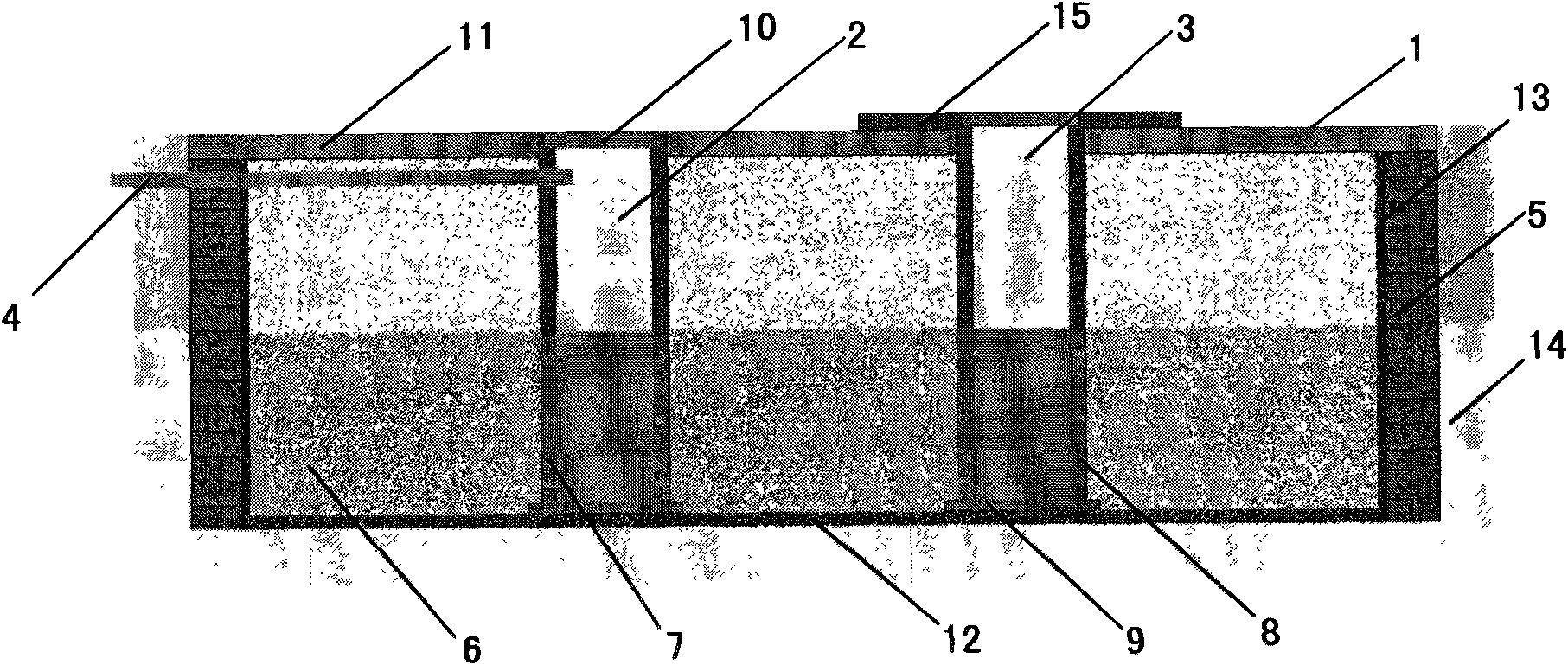

An underground coal gasification method. The method comprises disposing multiple injection wells (3) and gas collection wells (4) in a gasification operation zone; adding a catalyst and a propping agent into injection wells and gas collection wells by means of a fluid medium; fracturing and reforming the coal layer using a fracturing device to form large areas of fissures and cracks; forming gasification paths in the form of directional wells between the injection wells and gas collection wells; adding a gasification agent, a catalyst, and water through the injection wells to cause coal layer combustions and chemical reactions; collecting at the gas collection wells the gas produced by means of collection devices. The fissure paths between the wells formed by reforming large fractures, and the metal mineral particles used as a propping agent for the paths between wells effectively enable the maintenance of the effective communication in the injection well network for long durations; the metal mineral particles also function as a catalyst and an aggregating agent during gasification, thereby substantially enhancing the coal gasification volume.

Owner:秦勇 +2

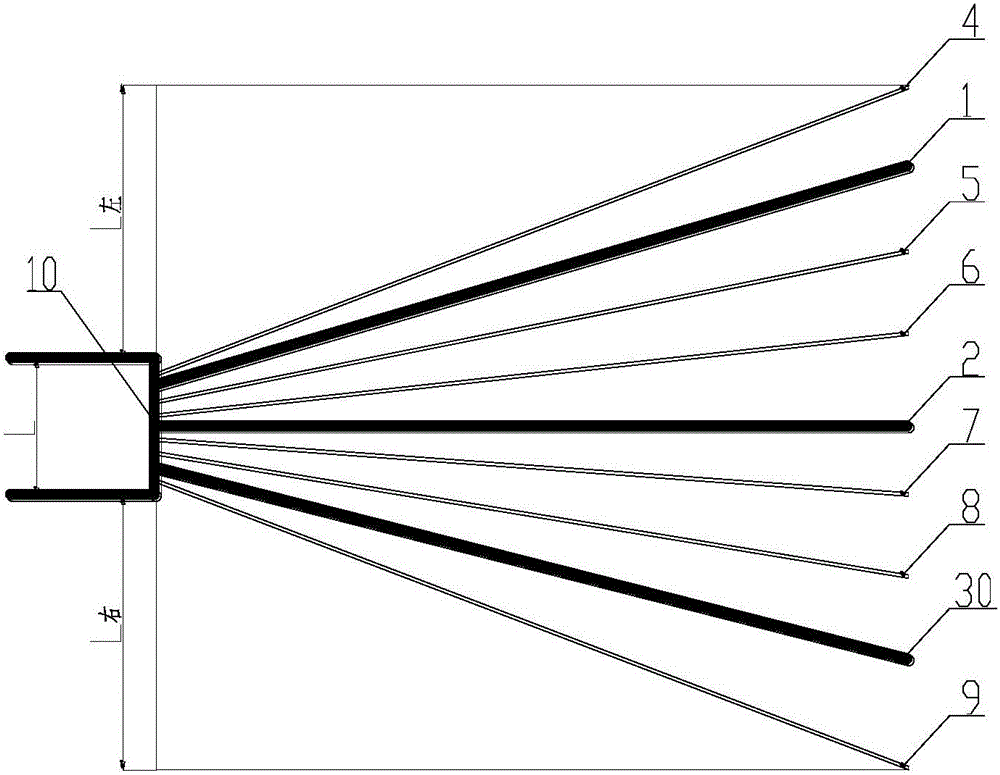

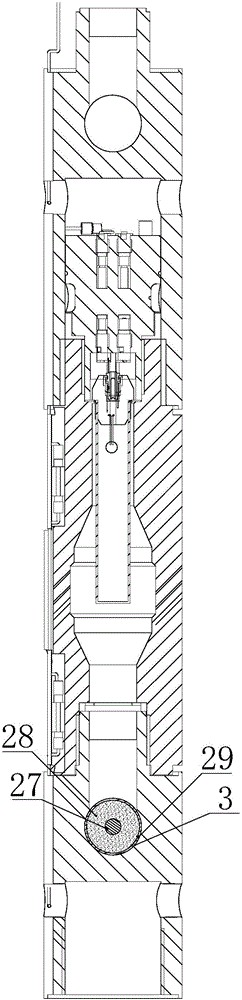

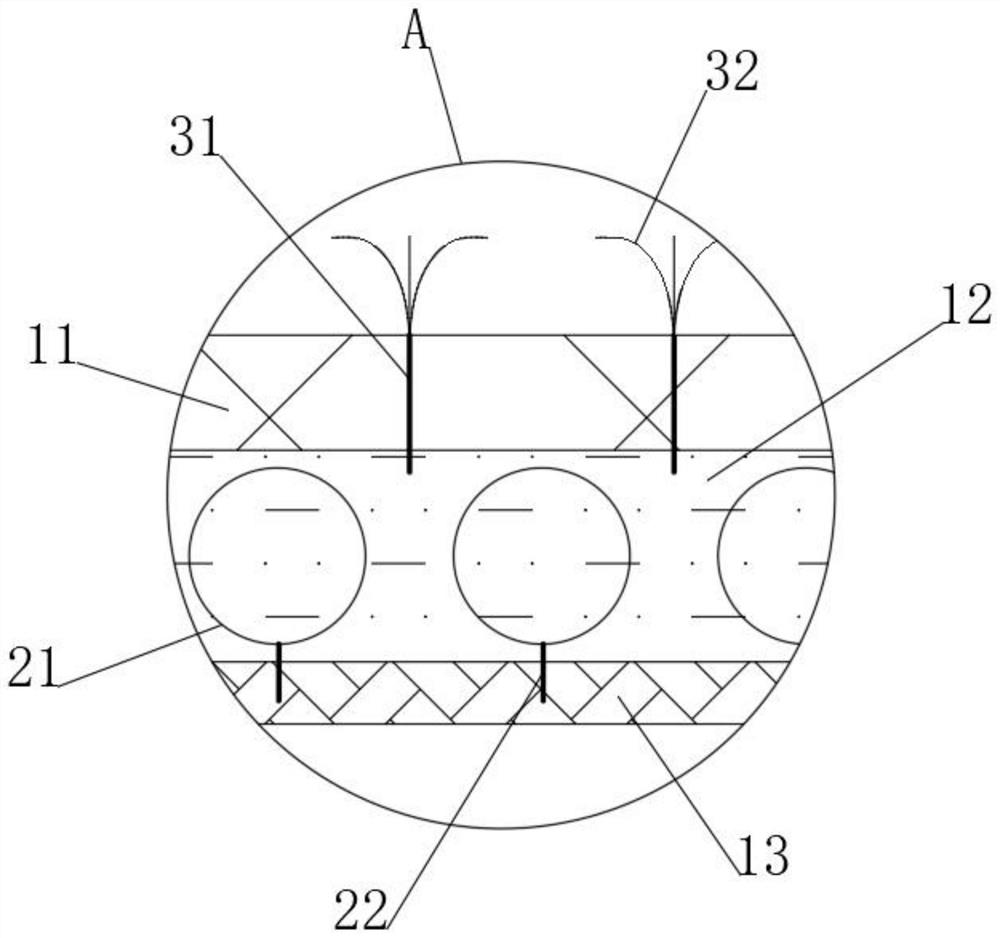

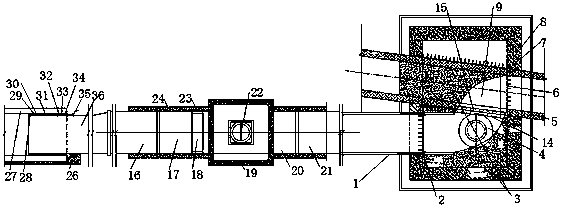

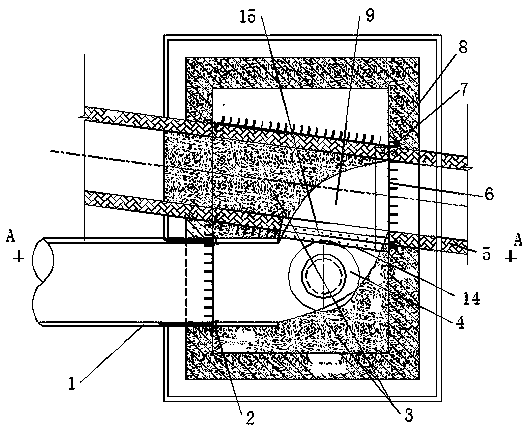

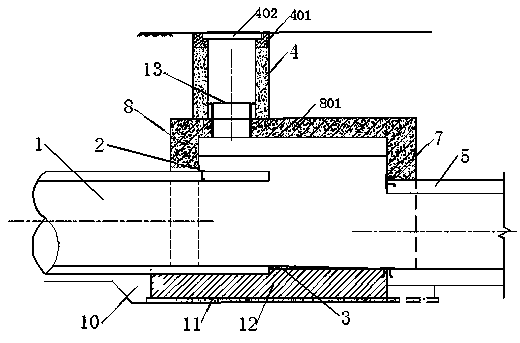

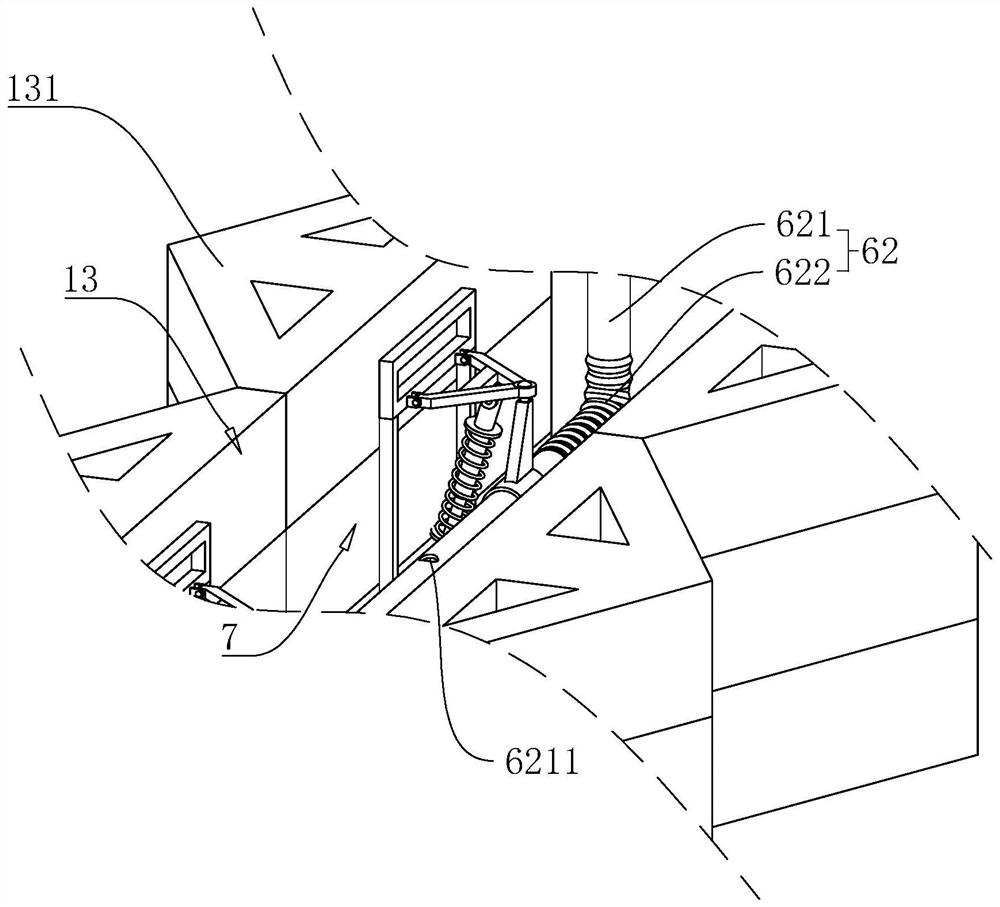

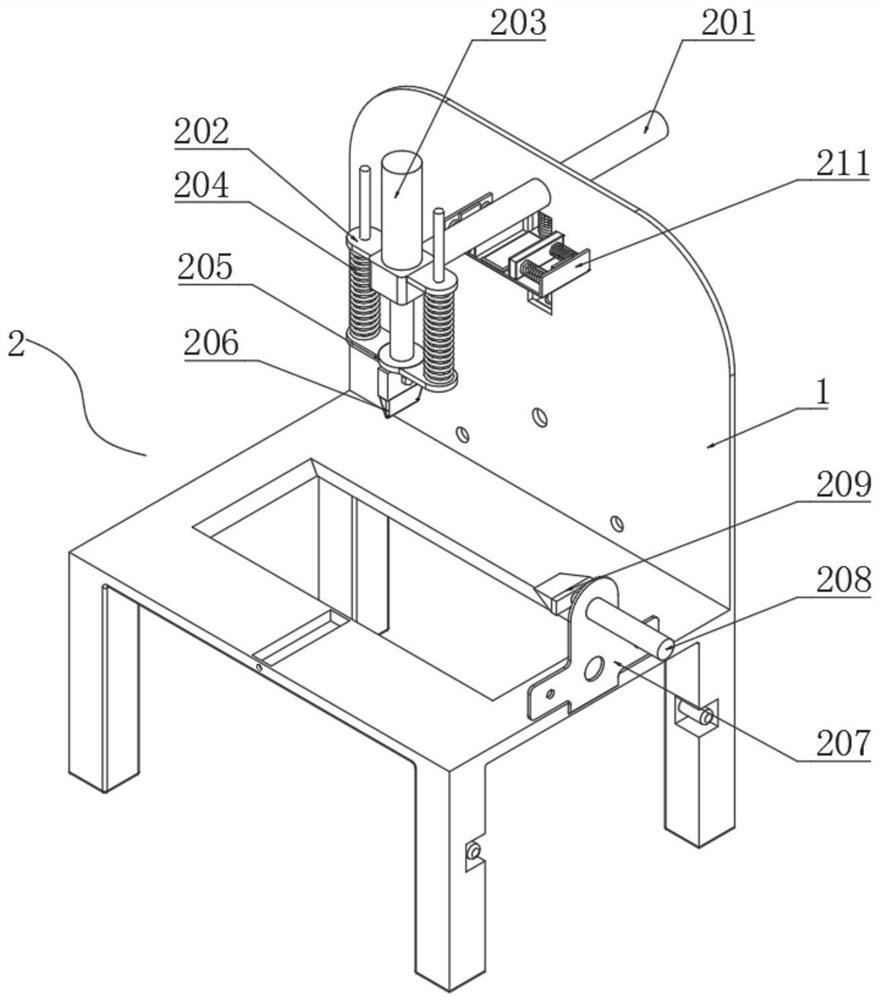

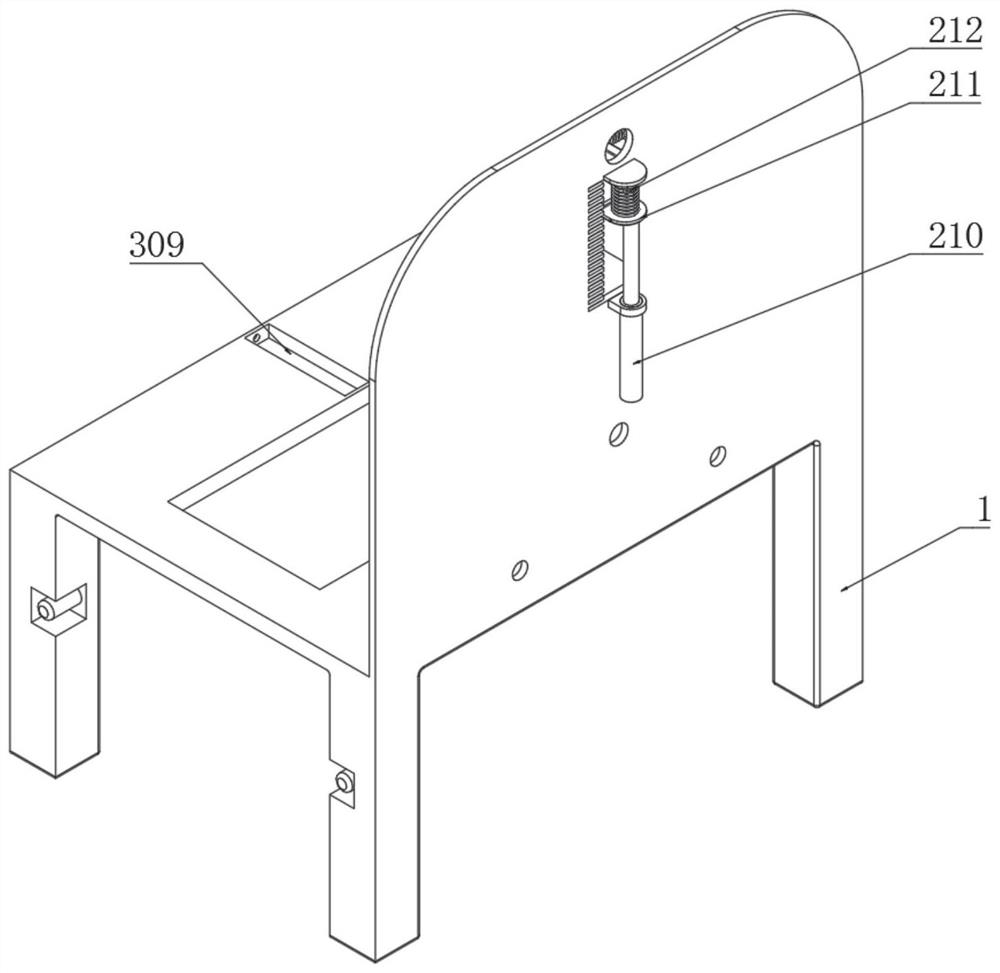

Carbon dioxide phase-change coal seam cracking guiding perforating device and outburst-preventing and scour-preventing method

InactiveCN105888624AEffective connectivityGood cracking effectFluid removalGas removalHigh energyEngineering

The invention relates to a carbon dioxide phase-change coal seam cracking guiding perforating device and an outburst-preventing and scour-preventing method. The carbon dioxide phase-change coal seam cracking guiding perforating device comprises a carbon dioxide phase-change coal seam cracking instrument and is characterized in that a perforating bullet is arranged in an explosion venting hole of the carbon dioxide phase-change coal seam cracking instrument and the explosion venting hole is plugged by a plug. The invention also provides the outburst-preventing and scour-preventing method. The device combined with the outburst-preventing and scour-preventing method provided by the invention is used for guiding the high energy gas through a perforating bullet track, so that the cracking effect is better; the orientation arrangement is adopted, so that the permeability is added to the perforating bullet track; the blast hole and the control hole are arranged, so that the cracks surrounding the blast hole and the control hole are more effectively communicated with each other; the cracking area is increased due to the fan-shaped arrangement.

Owner:CCTEG SHENYANG RES INST +1

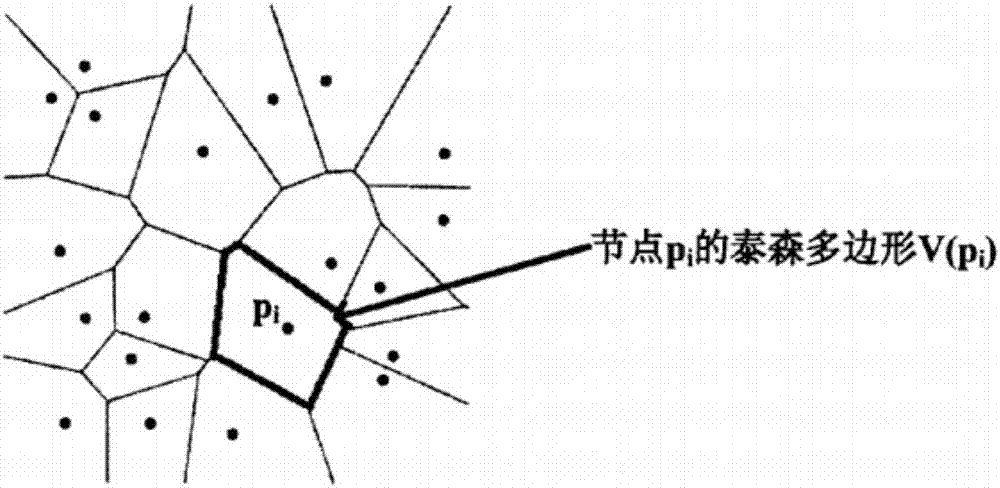

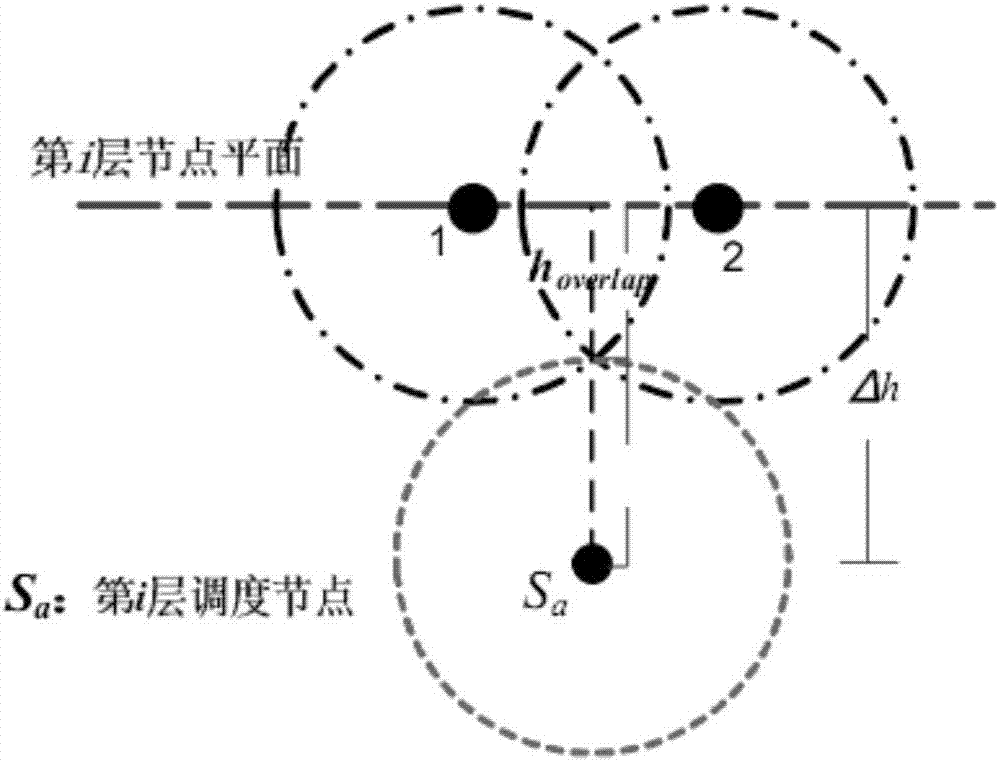

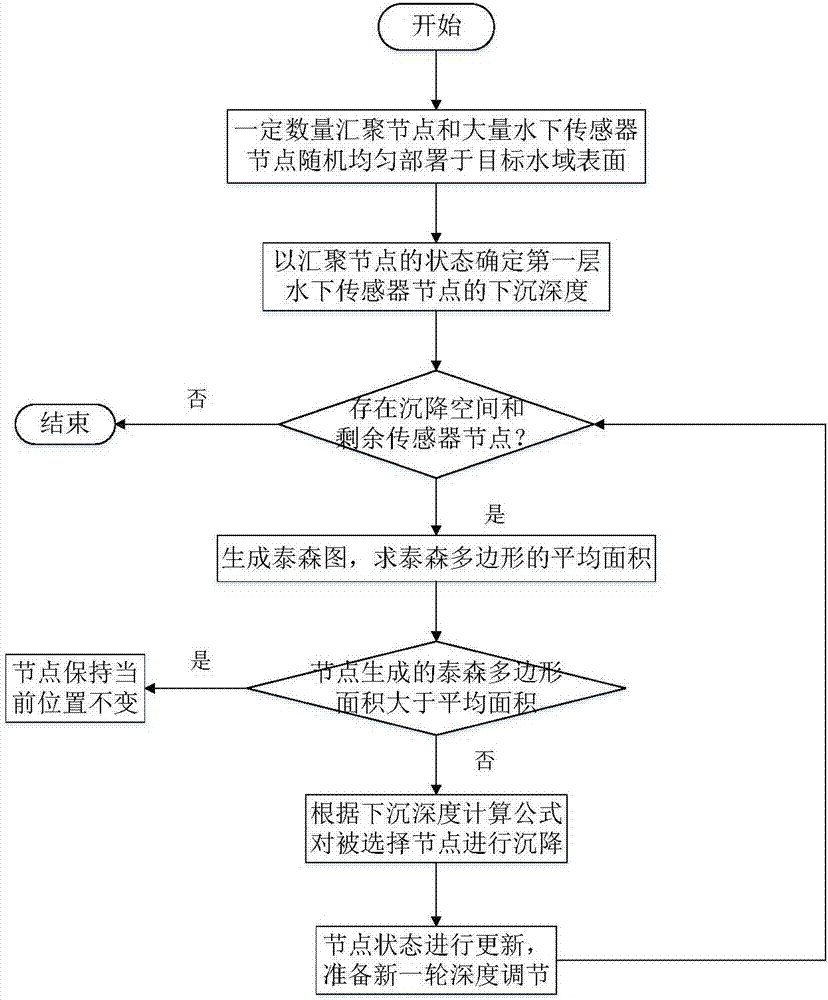

Effective sensor node deployment method based on layering

InactiveCN107277825AImprove performanceProlong survival timeNetwork topologiesTransmissionNode clusteringNODAL

The invention relates to an effective sensor node deployment method based on layering. The method comprises the following steps: deploying a part of nodes among the nodes scattered on the surface of a target water area on the water level to serve as aggregation nodes, locating the nodes on the 0 layer, and causing the other nodes to sink for a certain distance relative to the aggregation nodes; generating voronoi diagrams and calculating an average area of the voronois by the sunk nodes, keeping the depths of the nodes greater than the average area unchanged, and causing the nodes smaller than the average area to continue to sink; judging whether a sinking space exists during the sinking, and if the sinking space is greater than a node sensing radius r and is smaller than an interlayer spacing obtained by calculation, changing the sinking distance into r; if the sinking space is smaller than the node sensing radius r, indicating the termination of the node skinning process; performing discontinuous sleep by the nodes that cannot sink on the last layer and serve as redundant nodes; and performing node clustering.

Owner:TIANJIN UNIV

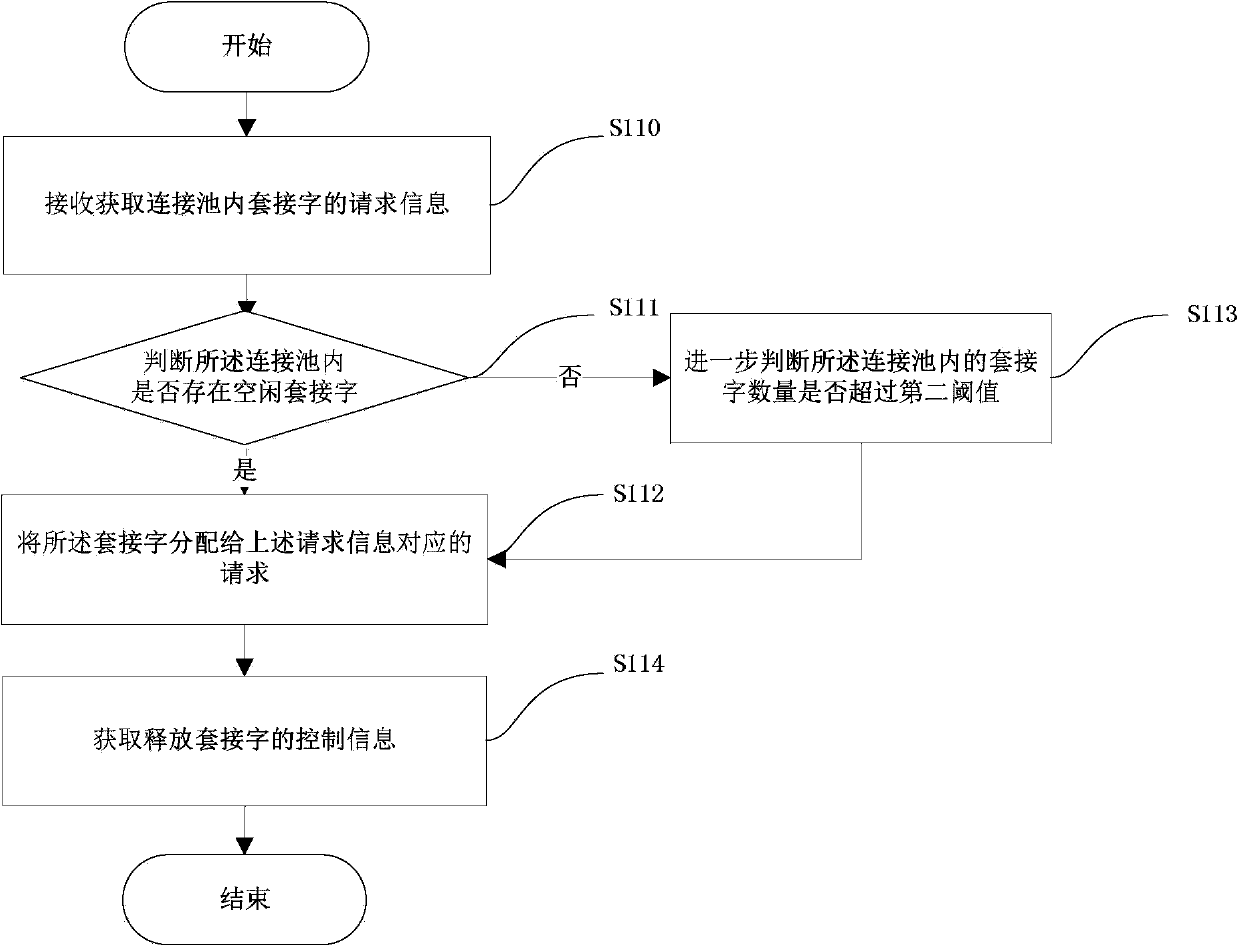

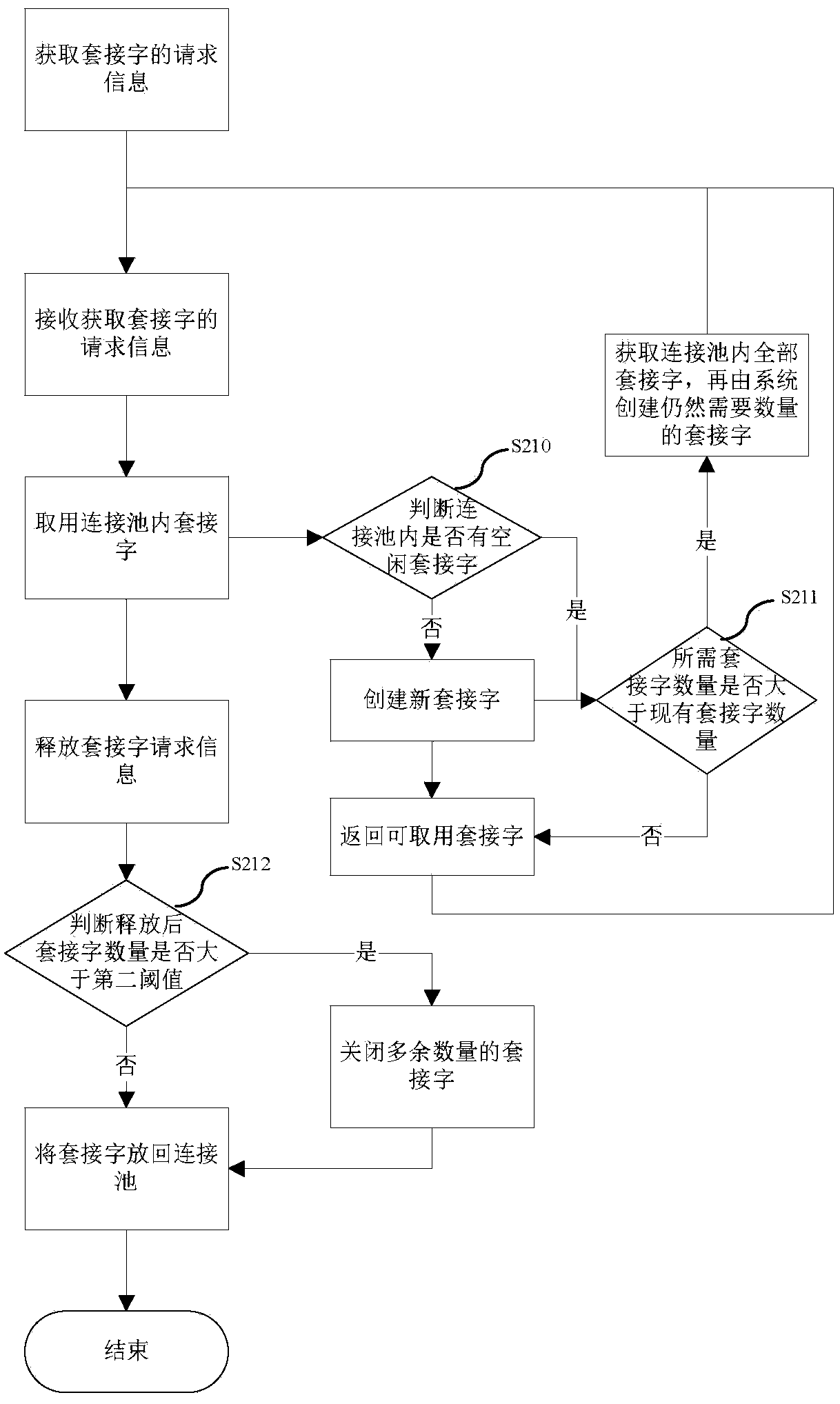

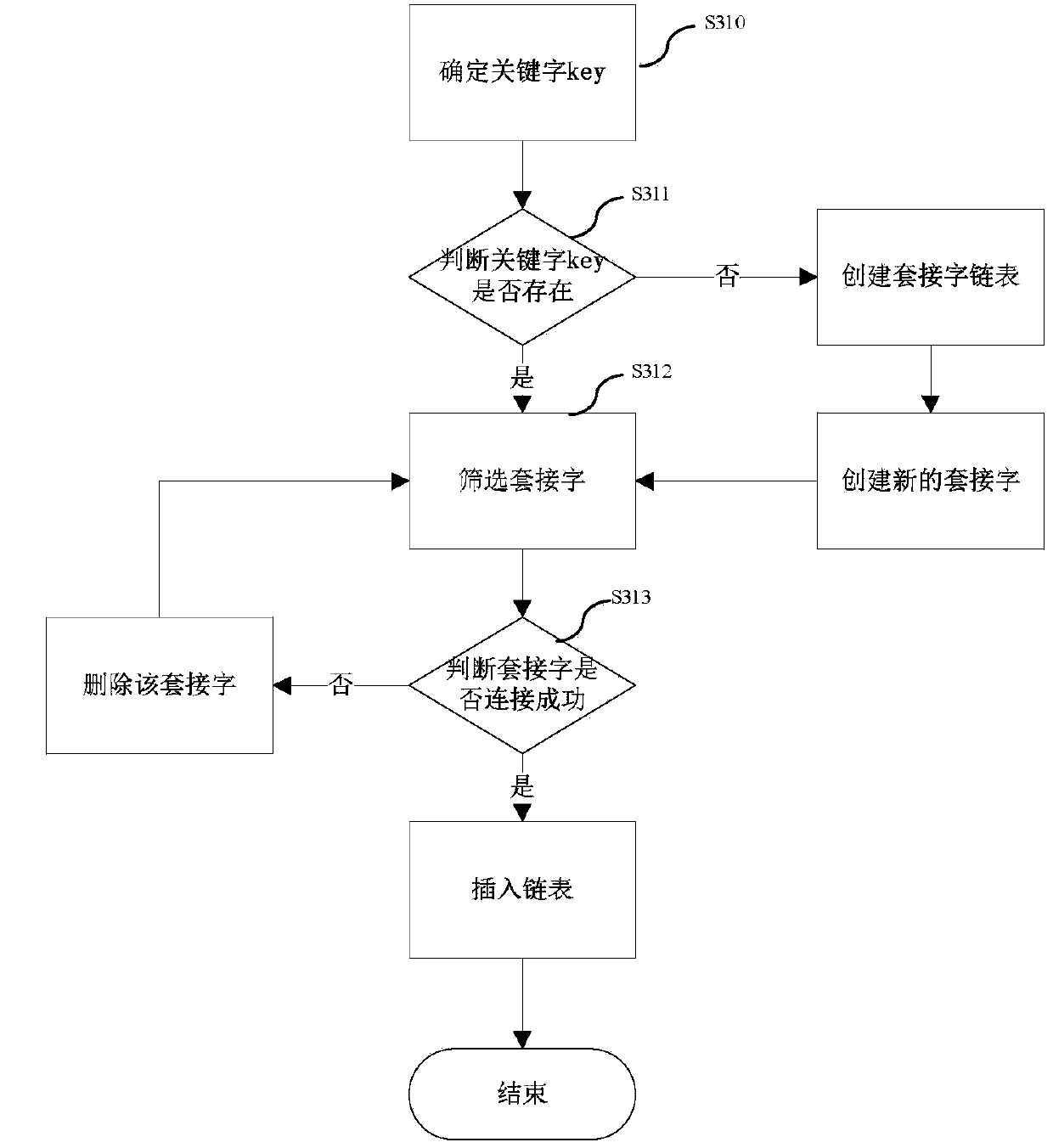

Control method for socket connection pool

InactiveCN103441999AEffective connectivityEfficient releaseTransmissionConnection poolOperating system

The invention discloses a control method for a socket connection pool. The method comprises the following steps: (1) receiving and obtaining request information of sockets in the connecting pool, (2) judging whether the free sockets exist in the connection pool or not, and (3) allocating the sockets to a request corresponding to the request information if the free sockets exist. According to the method, frequency establishing of socket descriptors is avoided, so that the sockets are saved for a system. Meanwhile, by the adoption of the socket connection pool, the process time of connection establishment after the socket descriptors are established each time is saved, and therefore performance is improved.

Owner:ALLYES NETWORK SCI & TECH SHANGHAI

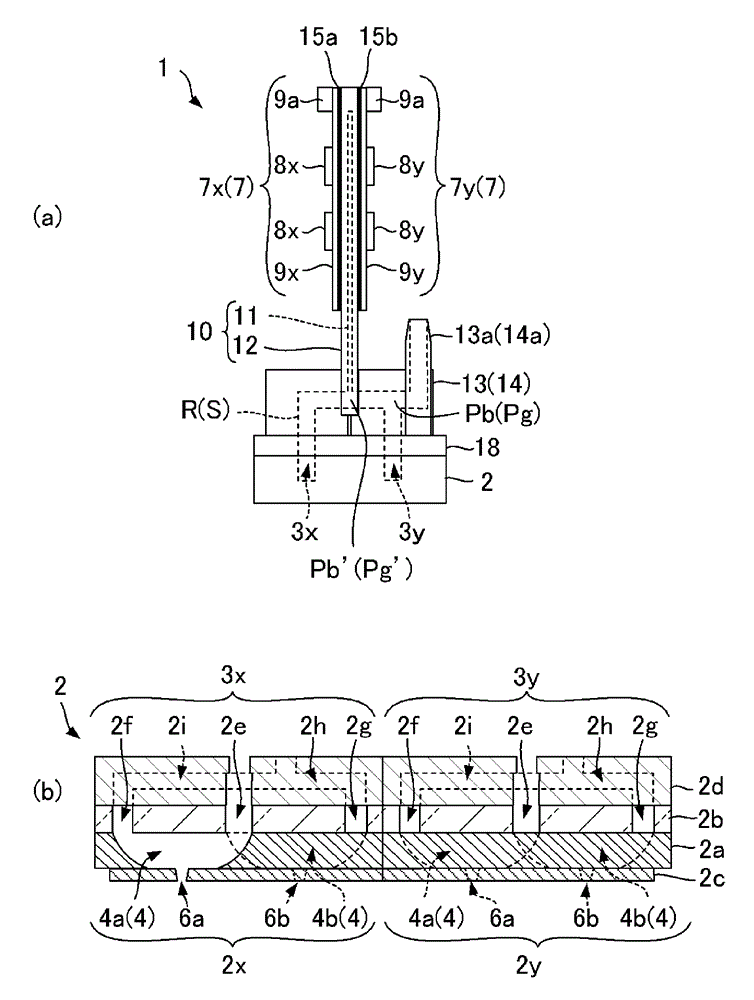

Liquid jet head and liquid jet apparatus

A liquid jet head includes: a head portion including a supply flow path configured to allow liquid supplied from the outside to flow therethrough, a pressure chamber communicating with the supply flow path, a driver element configured to drive the pressure chamber, and a nozzle communicating with the pressure chamber, the head portion being configured to eject liquid droplets through the nozzle; a circuit portion configured to supply a drive waveform to the driver element; and a cooling portion including a cooling flow path configured to allow the liquid to flow therethrough, the cooling portion being coupled and fixed to the circuit portion, wherein the liquid flows through the supply flow path and through the cooling flow path in parallel.

Owner:SII PRINTEK

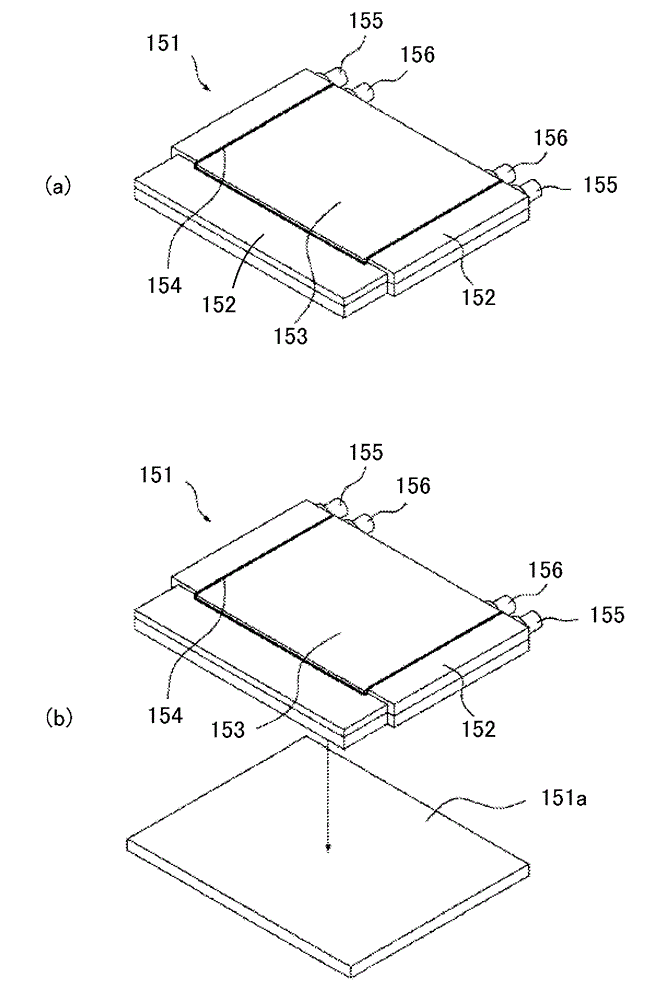

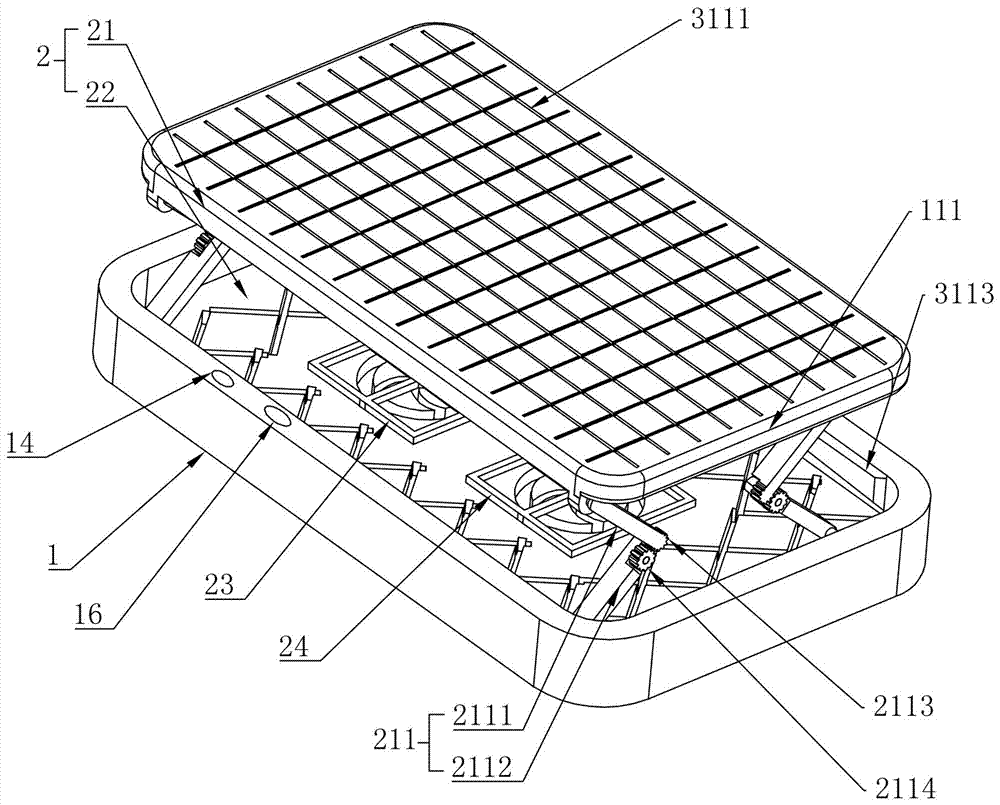

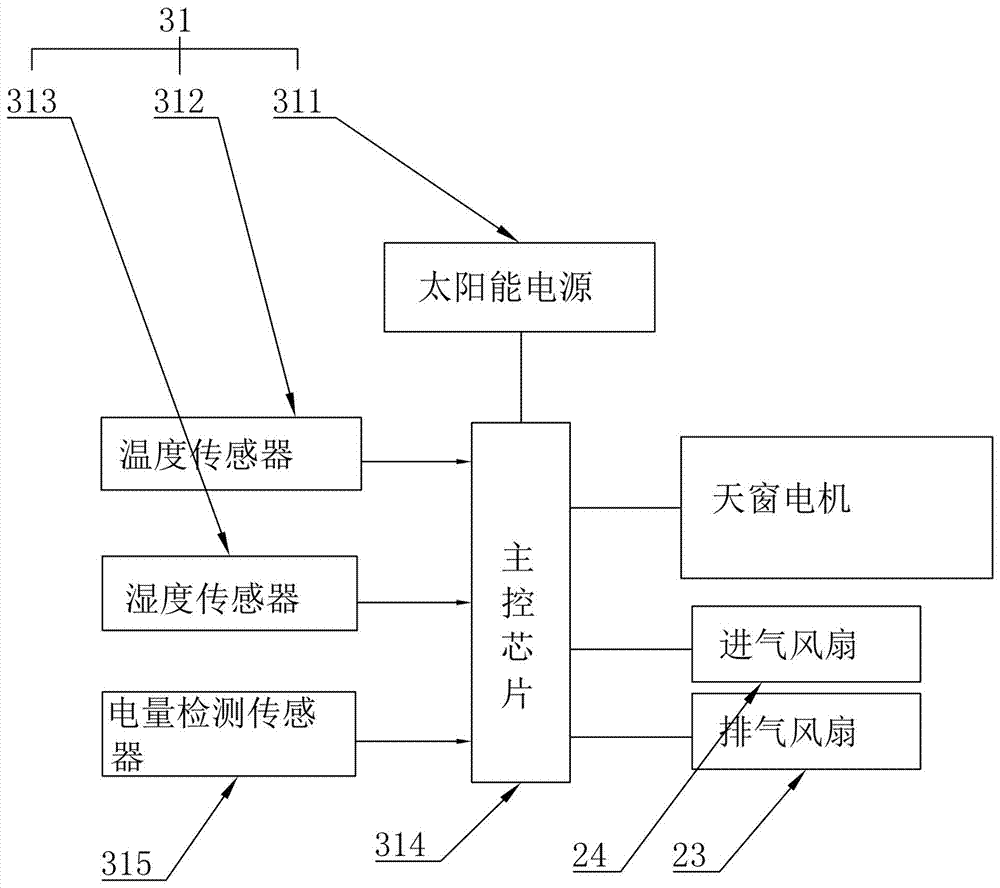

Sun-blocking and automatic temperature controlling automobile window

ActiveCN107351660AAvoid the problem of getting into the carPrevent agingAir-treating devicesVehicle heating/cooling devicesTemperature controlEngineering

The invention discloses a sun-blocking and automatic temperature controlling automobile window. The sun-blocking and automatic temperature controlling automobile window comprises a windowsill which is arranged on an outer roof of an automobile, and a window plate which is arranged on the windowsill and used for opening or closing the windowsill, wherein the window plate comprises an upper window plate and a lower window plate which are arranged in the windowsill in a manner of overlapping from top to bottom; the lower window plate is of a burglar mesh structure, and an exhaust fan and an air intake fan are arranged on the lower window plate; a controller is arranged on the upper window plate and comprises a solar power supply, a temperature sensor, a humidity sensor, an electric power detection sensor and a main control chip. According to the sun-blocking and automatic temperature controlling automobile window, the temperature sensor and the humidity sensor are arranged, so that the inner temperature and the external humidity of the automobile can be effectively detected, and the effect of opening a skylight in case of high temperature and closing the skylight in case of raining can be achieved; in addition, the upper window plate and the lower window plate are arranged, and thus the effect of preventing foreign matters from entering the automobile after the skylight is opened can be effectively achieved.

Owner:温州益泰光电有限公司

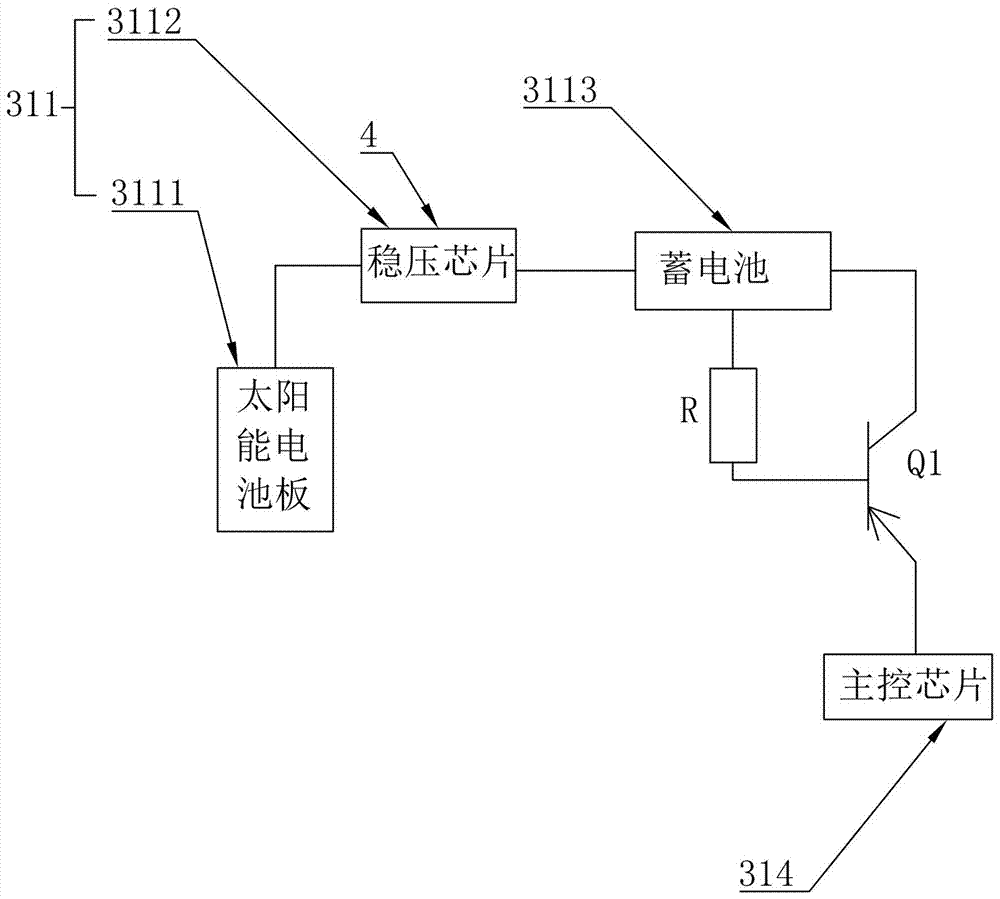

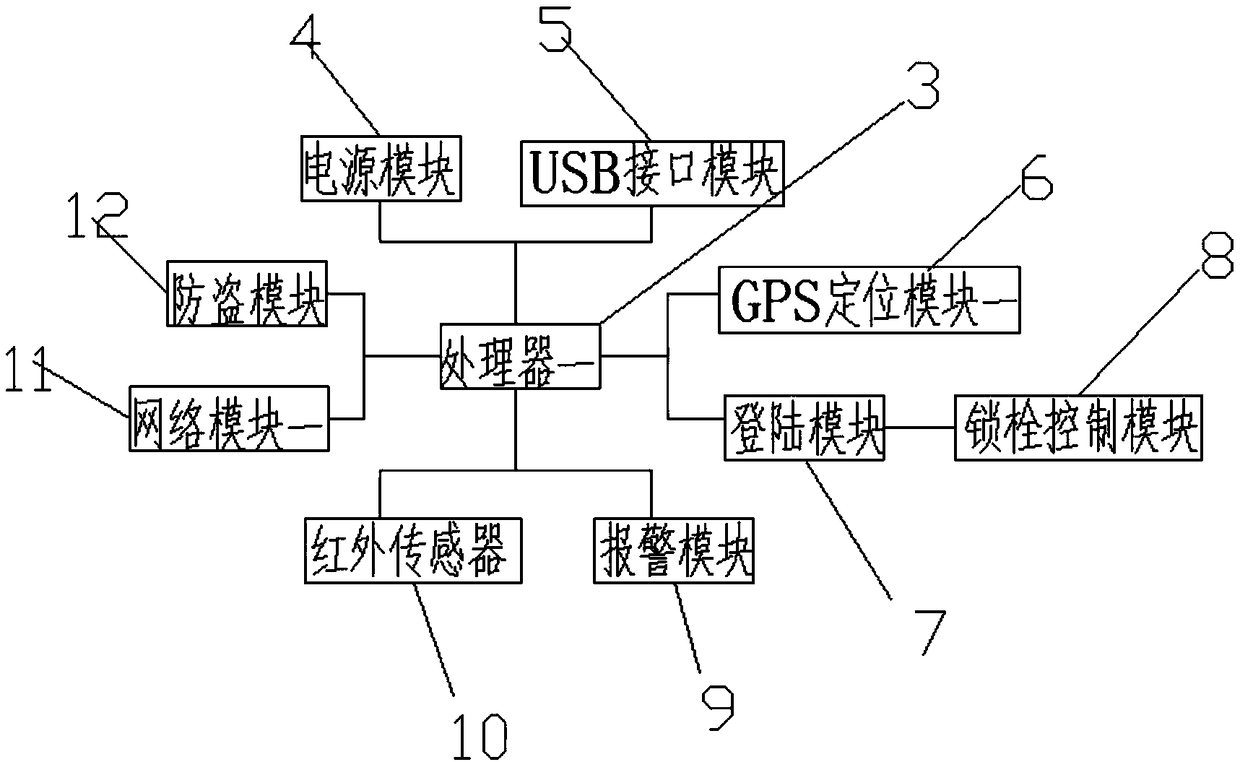

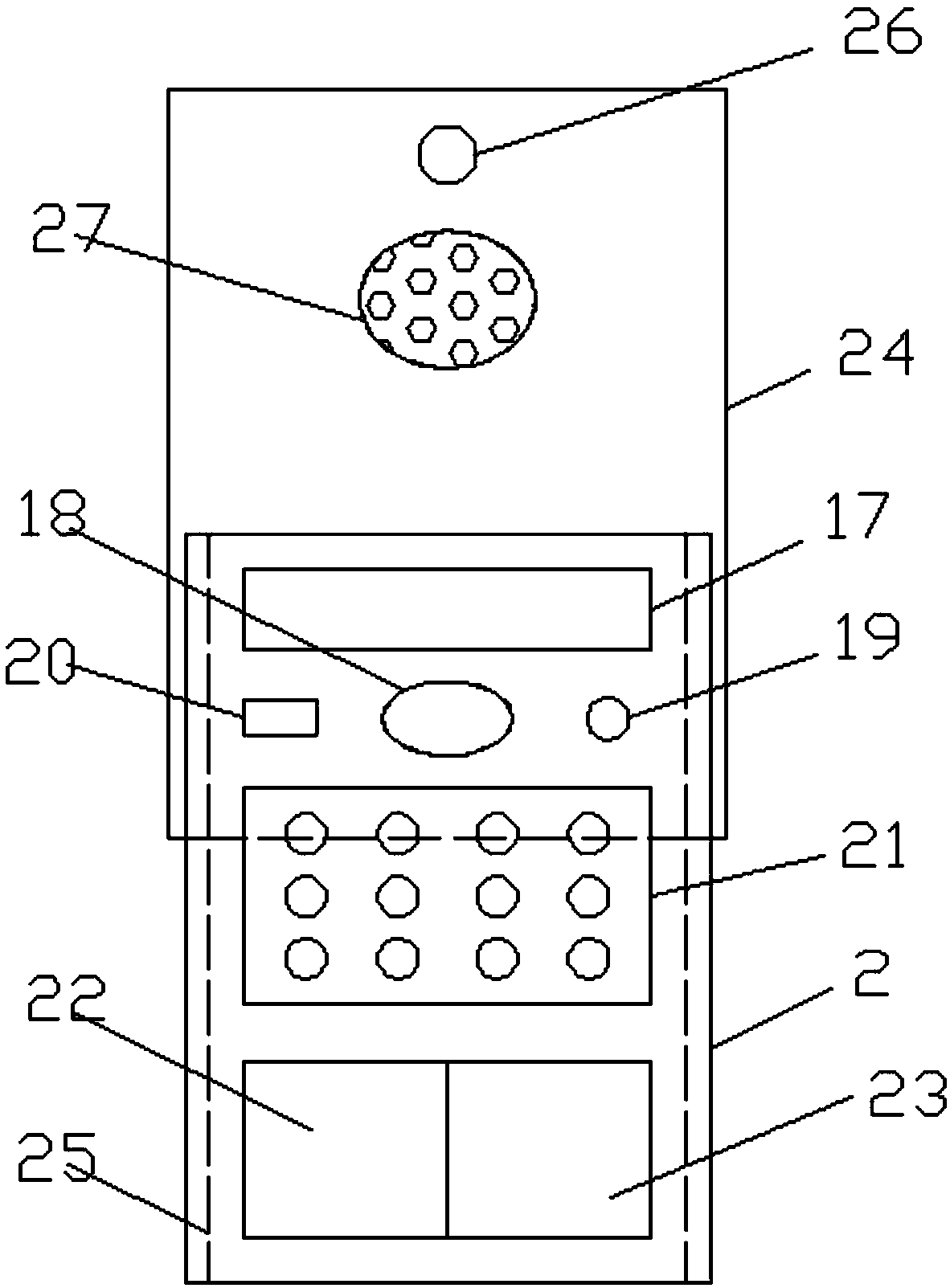

Non-embedded type remote monitoring intelligent door lock

ActiveCN108868344AGuarantee property securityEasy to manageElectric permutation locksIndividual entry/exit registersControl systemComputer terminal

The invention discloses a non-embedded type remote monitoring intelligent door lock. The non-embedded type remote monitoring intelligent door lock comprises an intelligent door lock, a mobile terminaland a control center. The control center is connected with the intelligent door lock and the mobile terminal. The intelligent door lock comprises a lock body and a control panel. A control system isarranged in the lock body, and comprises a first processor, a power module, a USB interface module, a first GPS positioning module, a login module, a lock plunger control module, an alarm module, an infrared sensor, a first network module and an anti-theft module. The non-embedded type remote monitoring intelligent door lock has the beneficial effects that the design is reasonable, use is convenient, compared with an existing intelligent door lock, the effect of simultaneously positioning and managing the mobile terminal and the intelligent door lock can be achieved, the safety effect can alsobe achieved, and therefore the property safety of residents is effectively guaranteed while convenience is brought to use by people.

Owner:全民认证科技(杭州)有限公司

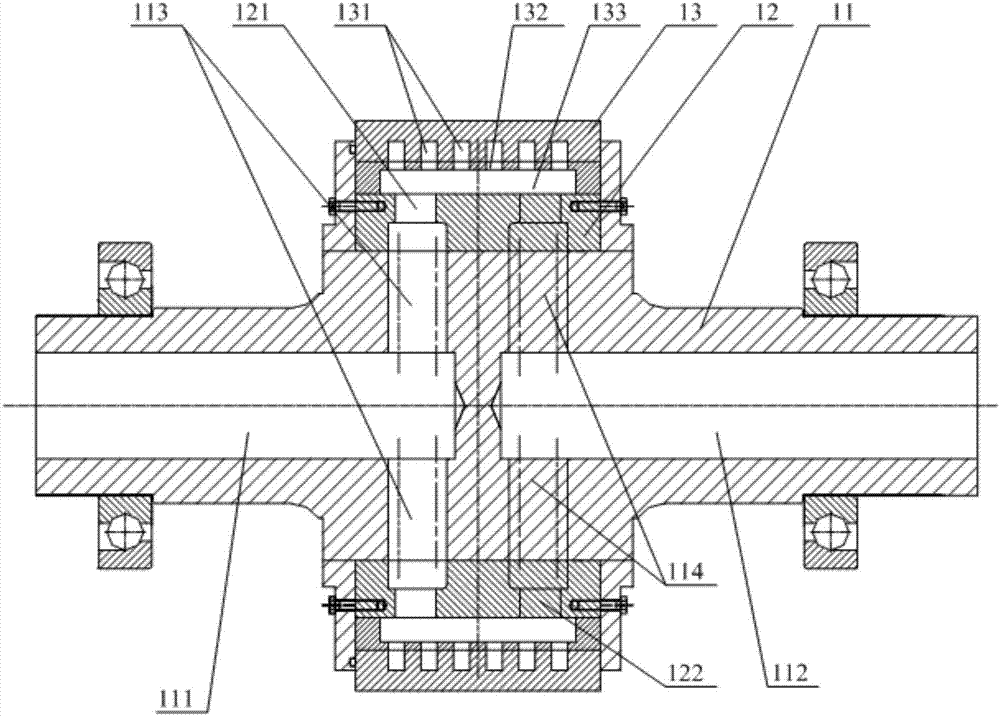

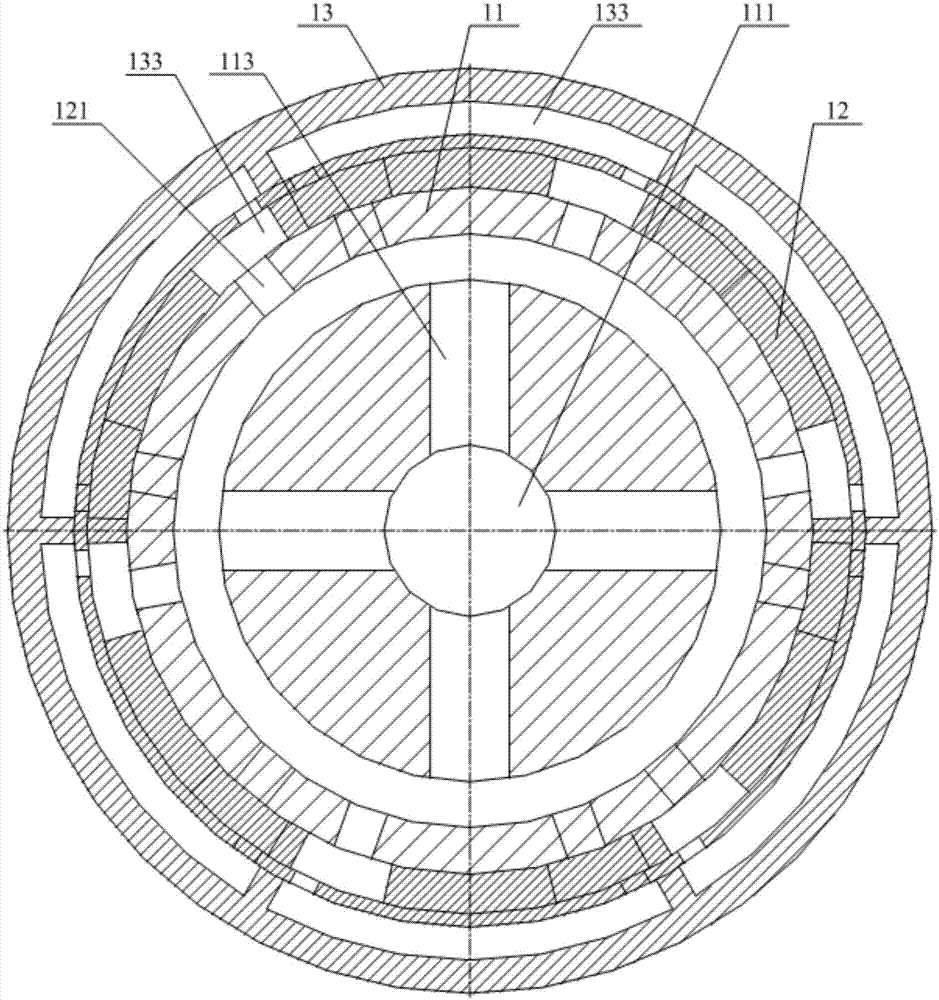

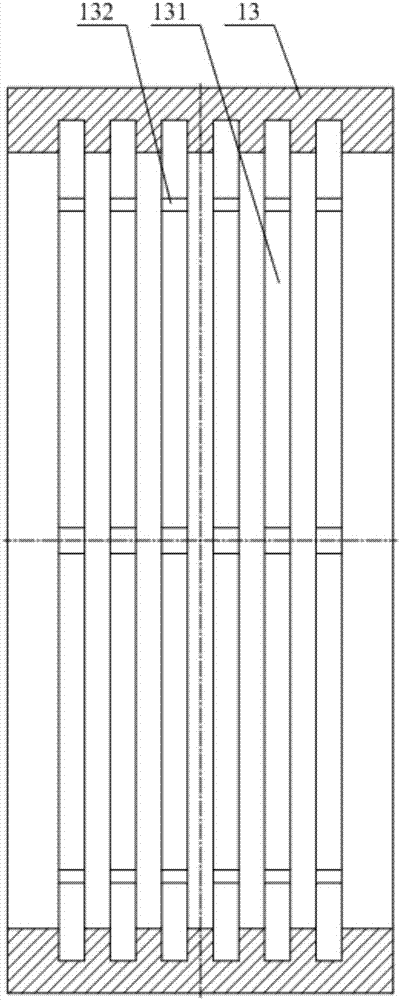

Cooling roller

InactiveCN107052288AGuaranteed performanceUniform and efficient cooling and cooling treatmentWater flowEngineering

The invention discloses a cooling roller. The cooling roller comprises a main shaft. The periphery of the main shaft is sleeved with a supporting piece. The periphery of the supporting piece is sleeved with a copper sleeve. A water inlet pipe which extends in the axial direction of the main shaft is arranged in the middle of the one end of the main shaft, and a drain pipe which extends in the axial direction of the main shaft is arranged in the middle of the other end of the main shaft. A plurality of annular cooling grooves which extend in the circumferential direction of the copper sleeve and are sequentially distributed in the axial direction of the copper sleeve are formed in the inner wall of the copper sleeve. A first water inlet branch penetrates through the side wall of the water inlet pipe. A first drain branch penetrates through the side wall of the drain pipe. A second water inlet branch and a second drain branch penetrate through the supporting piece. The water inlet pipe, the first water inlet branch, the second water inlet branch and the annular cooling groove sequentially communicate in the water flow direction. The annular cooling grooves, the second drain branch, the first drain branch and the drain pipe sequentially communicate in the water flow direction. The cooling process of the cooling roller is uniform and efficient.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Iron notch pretreatment method used during blowing in of blast furnace

InactiveCN103757167AImprove efficiencyQuick startBlast furnace componentsBlast furnace detailsSlagHot blast

The invention discloses an iron notch pretreatment method used during blowing in of a blast furnace. The iron notch pretreatment method comprises the following steps: preboring an iron notch, flatly putting an oxygen pipe while enabling the oxygen pipe to directly face the iron notch, feeding oxygen, enabling the oxygen pipe to burn inwards and melt cold iron slag in an iron notch channel, when the inward movement distance of the oxygen pipe is approximate to the normal thickness of a furnace wall, upwards bending the oxygen pipe, meanwhile swinging the oxygen pipe, and enabling the oxygen pipe to spirally advance so as to burn upwards and melt cold iron slag in the furnace; meanwhile, feeding oxygen, enabling the oxygen pipe to burn from air ports at the two sides of the iron notch to the direction of the iron notch so as to melt cold iron slag in the iron notch channel and an air port channel, after hot iron slag outflows, continuing feeding oxygen so as to heat iron slag for draining, and after the iron notch channel and the air port channel is burned through, plugging and thus completing iron notch pretreatment. According to the iron notch pretreatment method, the iron notch channel and the air port channel are quickly and effectively communicated with each other by doing various preparatory work well such as butt welding and lengthening the oxygen pipe in advance and swinging the oxygen pipe during burning the iron notch, the rapid blowing in and the designed capacity achievement are realized, and good economic benefits are achieved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

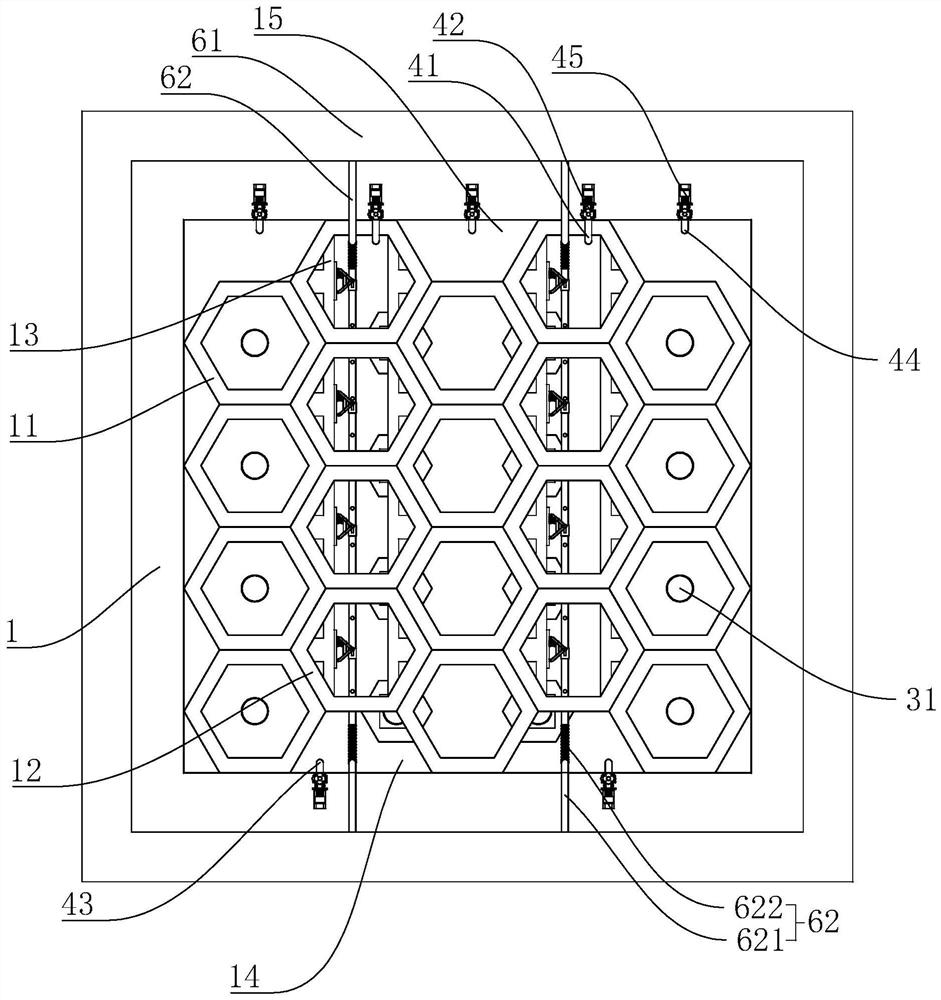

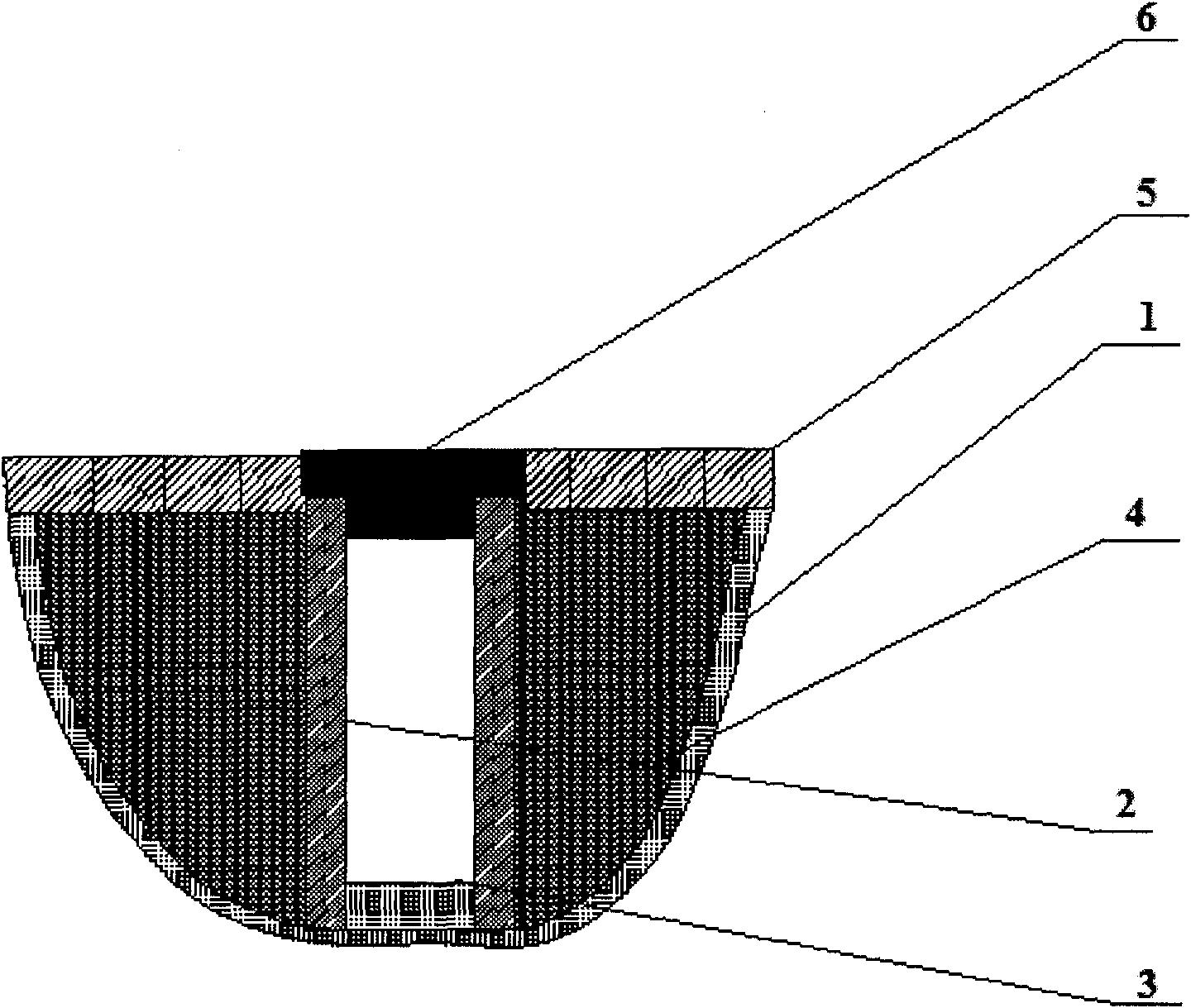

Water purification and storage system

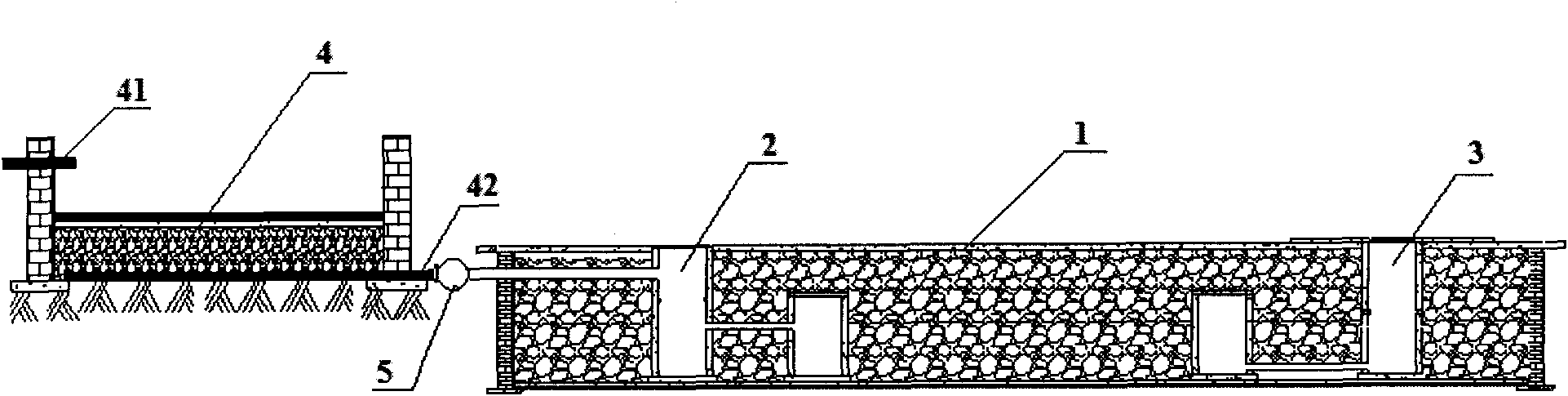

ActiveCN102212998AAchieve purificationAvoid lostGeneral water supply conservationLoose filtering material filtersFiltrationWater filter

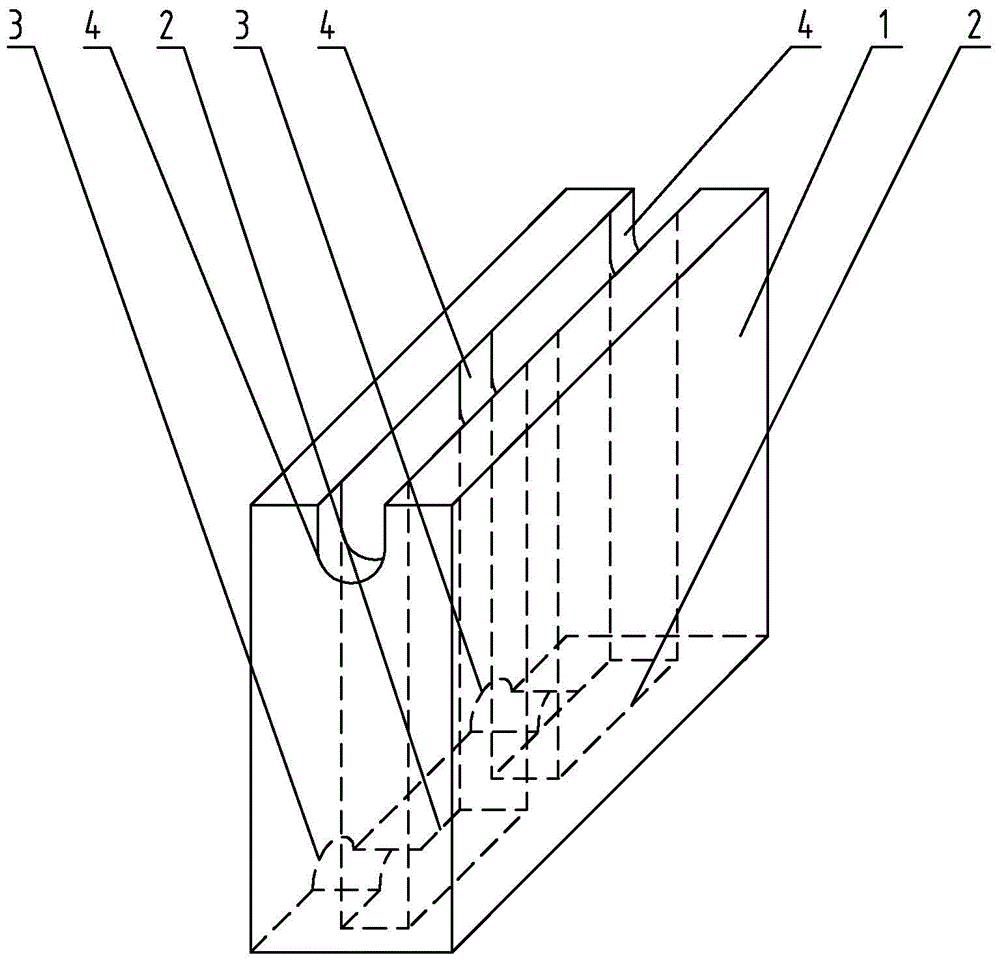

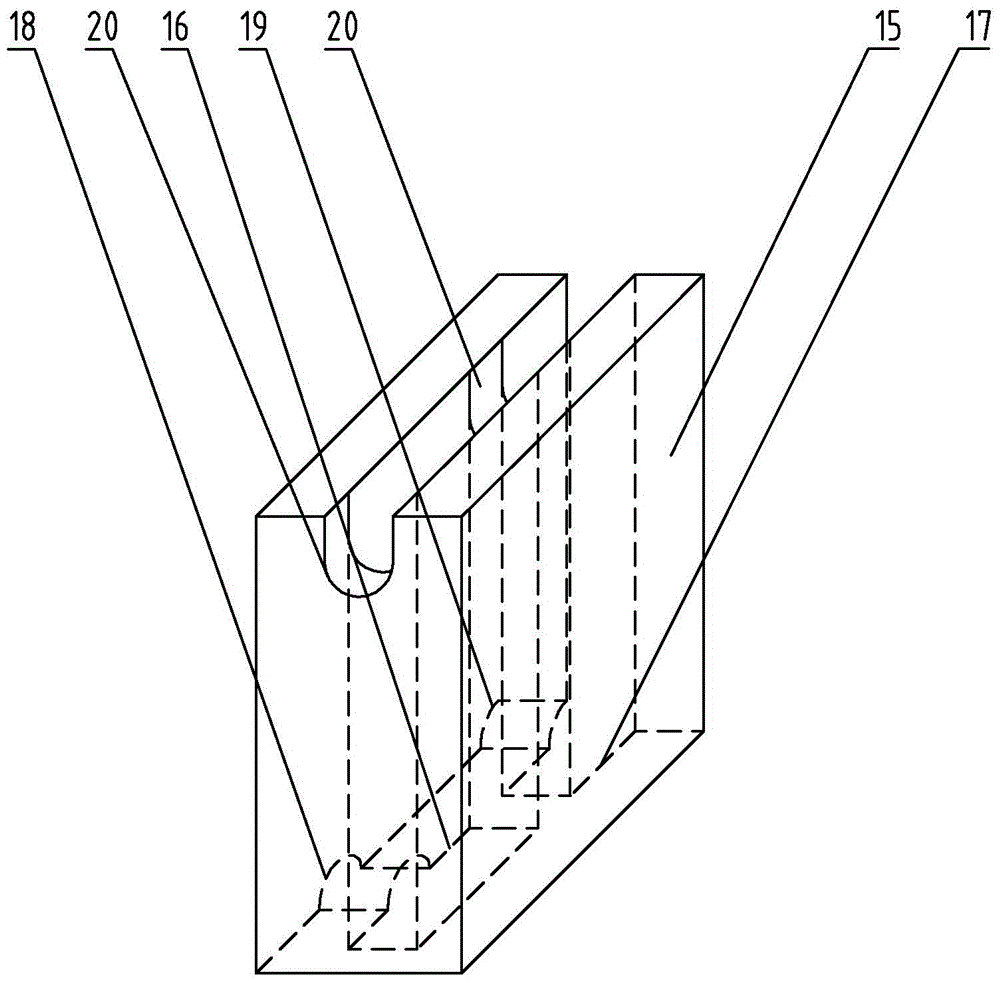

The invention provides a water purification and storage system. The system comprises a water storage container (1), at least one water inlet well (2), at least one water outlet well (3) and a water filter channel (4). In the water purification and storage system, the primary filtration of various natural water sources such as river water, rain water, lake water, snow water and the like can be realized through the water filter channel, the water sources subjected to primary filtration through the water filter channel are led into the water inlet wells, complete purification of the water sources is realized by a water purification material filled in the water storage container, the purified water sources can be taken out of the water outlet wells, so the problem of limitation on water collection sources is solved, multi-channel water collection is realized, the loss of the water sources in the water storage container caused by spontaneous evaporation can be avoided, effective communication between the water sources and land air is realized, the water sources in the water storage container can be prevented from penetrating towards underground, and the water sources can be kept refresh for a long time without deterioration.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Self-heating bulge type facial mask

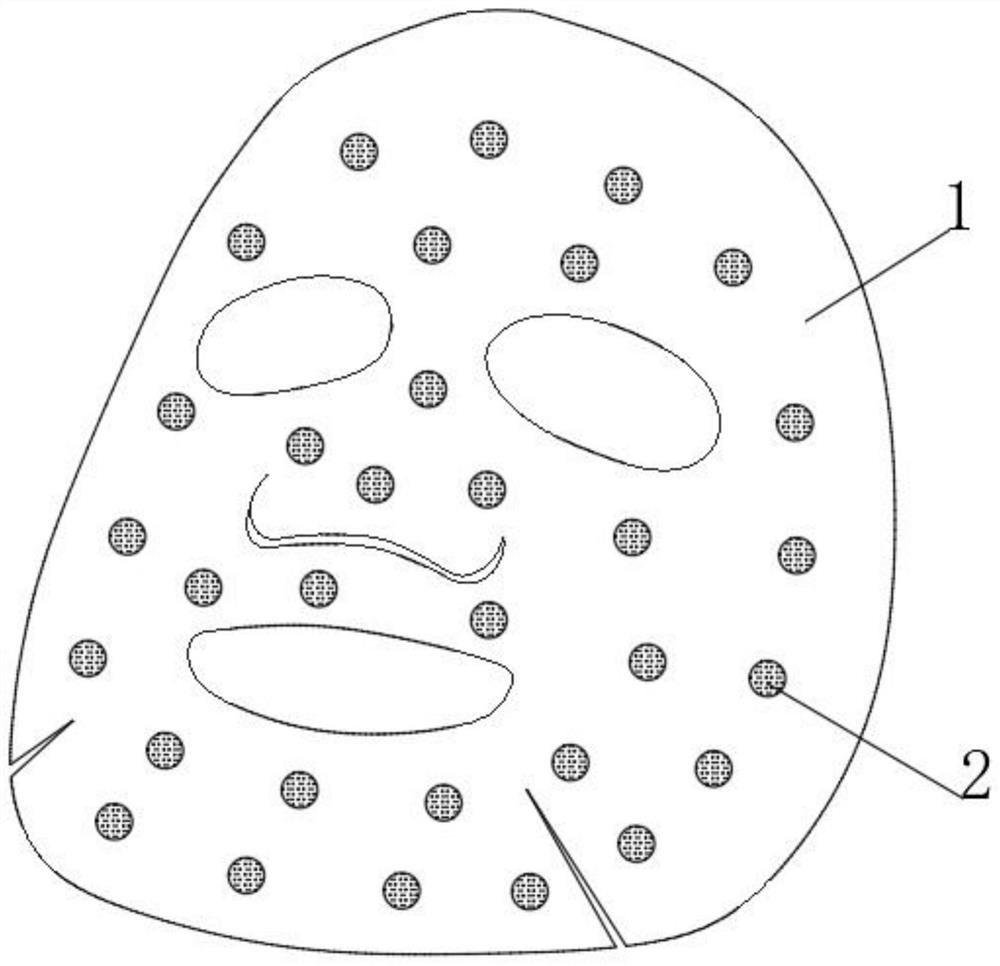

InactiveCN112336637AImprove absorption rateAvoid high heatCosmetic preparationsToilet preparationsPhysicsFacial skin

The invention discloses a self-heating bulge type facial mask, and belongs to the field of facial masks. According to the self-heating bulge type facial mask, in a cold environment in winter, after the facial mask is applied for a period of time, a user can press the face, self-heating liquid in the facial mask overflows and is in contact with self-heating wires to generate heat, and air in self-heating bags is heated to expand; on one hand, the expanded self-heating bags extrude essence in internal self-heating liquid supplementing balls to accelerate overflowing of the essence, so that the content of the essence on facial mask paper can be effectively supplemented, compared with the operation of manually supplementing the essence to the facial mask paper of the face in the prior art, theoperation adopted in the self-heating bulge type facial mask is simpler and more convenient, and the waste amount of the essence can be effectively reduced; and on the other hand, the temperature ofthe facial mask is increased to a certain extent due to heat generated by the self-heating wires, so that pores in facial skin in contact with the facial mask are in a certain relaxing and opening state, the absorption speed of the facial skin to the essence is increased, and the use effect of the facial mask is further improved.

Owner:尹慧

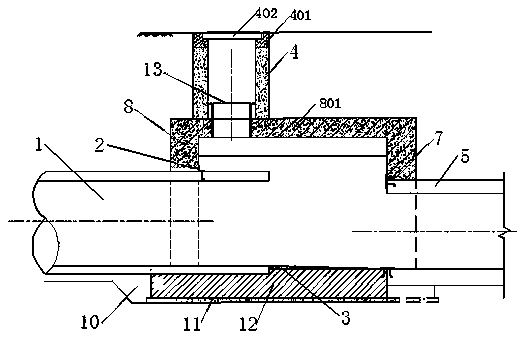

Construction method for connecting new and old sewage pipes during sewage pipe shifting transformation

The invention discloses a construction method for connecting new and old sewage pipes during sewage pipe shifting transformation. The construction method includes carrying out construction for connecting side surface PCCP (prestressed concrete cylinder pipes) with original three-pollution communicating pipes and connecting PCCP with three-pollution communicating pipes of square canals and carryingout construction for connecting the adjacent PCCP with inspection wells. Section construction can be simultaneously carried out or can be carried out step by step. The construction method has the advantages that non-intersection zones, the inspection wells and package wells are constructed in integral foundation pits at first according to actual plane intersection conditions of the new and old three-pollution communicating pipes, then cutover construction processes for the new and old three-pollution communicating pipes are further carried out, the construction method includes simple and convenient construction processes and is suitable for popularization and application, and the obtained new and old sewage pipes are stable in connection structure.

Owner:HANGZHOU MUNICIPAL CONSTR GRP CO LTD

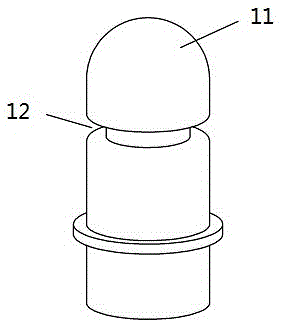

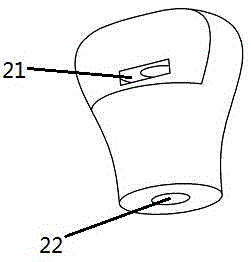

Controllable annular spring and detachable pot cover lifting handle with the same

InactiveCN105852652AEffective connectivityEffective detachmentCooking-vessel lids/coversEngineeringMechanical engineering

A controllable annular spring and a detachable pot lid handle applied thereto, including a male buckle and a female buckle, the male buckle is cylindrical as a whole, one end adopts an arc design, and is provided with a groove; the female buckle is provided with a cylindrical male buckle The hole is provided with a controllable ring spring, which is characterized in that the controllable ring spring is in the shape of an ellipse as a whole, or a semicircle and a half ellipse, or a ring shape with force points at both ends, or one end is fixed and the other end is supported. Force ring. This structure makes the ring spring controllable by improving the buckle mode of the snap button, which is more convenient for people's life. When applied to the detachable pot cover, it is simpler than the existing design and easy to implement.

Owner:盛明星

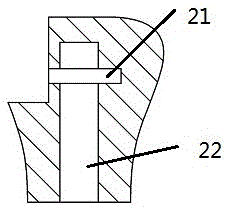

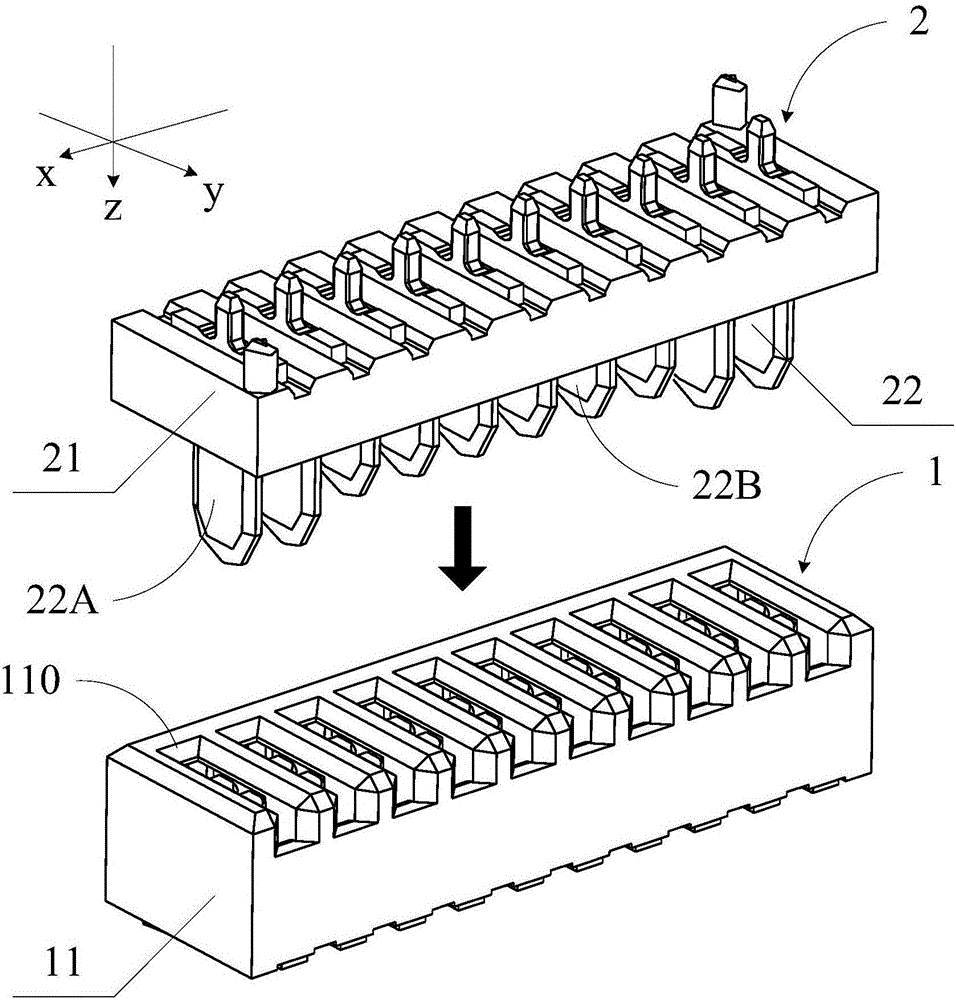

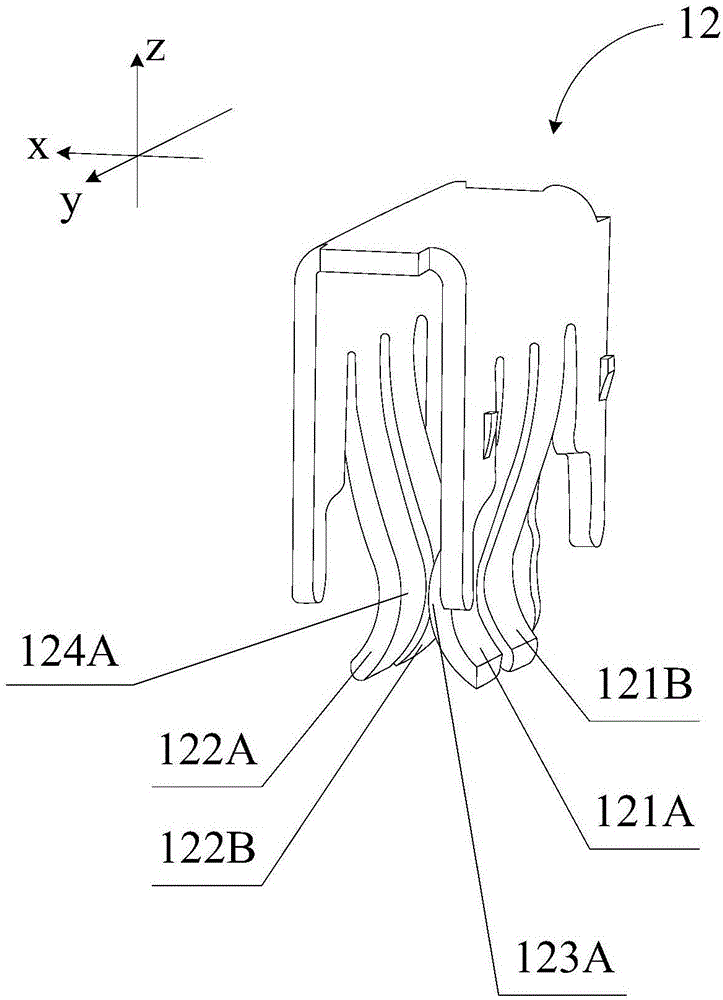

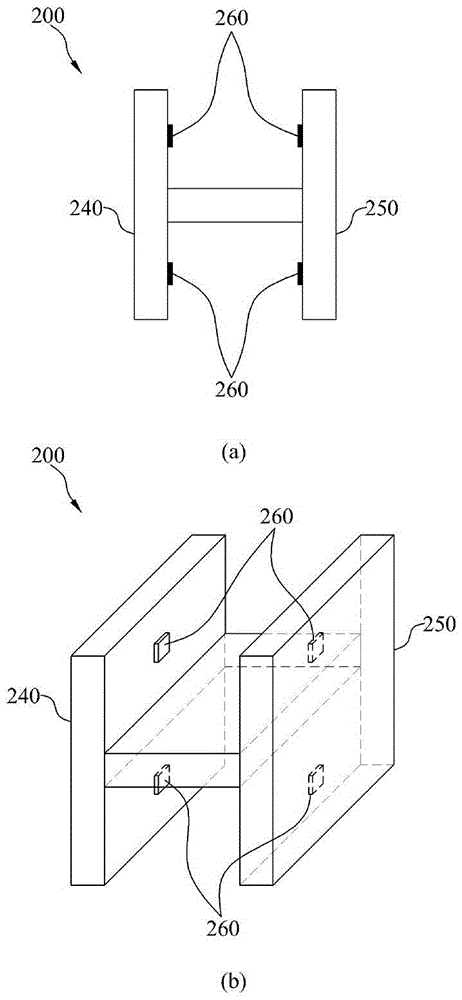

Unmanned aerial vehicle, anti-vibration connector, and male seat and female seat thereof

InactiveCN106129677APhysical stabilityFirmly connectedCoupling contact membersTwo-part coupling devicesMechanical engineeringHigh frequency vibration

The disclosure relates to an unmanned aerial vehicle, an anti-vibration connector, and a male seat and a female seat thereof. The female seat of the anti-vibration connector comprises a female seat shell body provided with a number of accommodating chambers, and a number of clamping structures that are correspondingly fixed in the accommodating chambers in a one-to-one manner so as to respectively clamp a number of male plug heads on the male seat of the connector that correspond to the clamping structures in a one-to-one manner, wherein each clamping structure comprises at least one group of oppositely arranged elastic sheets and at least one independent elastic sheet, and each group of the oppositely arranged elastic sheets are oppositely positioned along a first horizontal direction; on one elastic sheet in each group of the oppositely arranged elastic sheets, at least one contact point, facing toward the other elastic sheet, is formed; at least one contact point, facing toward an inner part of a gap between the oppositely arranged elastic sheets along a second horizontal direction, is formed on each independent elastic sheet; the second horizontal direction is perpendicular to the first horizontal direction. Via a technical solution of the disclosure, stable connection of the connector can be realized; the anti-vibration connector, and the male seat and the female seat thereof are suitable for high frequency vibration environment such as unmanned aerial vehicles and the like.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

Alternation construction connection structure of new and old sewage connecting pipes

PendingCN108086443ASimple structureFirmly connectedSewerage structuresSewer pipelinesEngineeringSewage

The invention discloses an alternation construction connection structure of new and old sewage connecting pipes, which comprises several PCCP pipes, an original sewage connecting pipe, a square channel three-dirt connecting pipe; the adjacent PCCP pipes are connected, the PCCP pipes are connected with the square channel three-dirt connecting pipe, and inserted to the square channel three-dirt connecting pipe from the side face; manholes are arranged at the joint of the PCCP pipes and the joint of the PCCP pipes and the square channel three-dirt connecting pipe from the side face. Through applying a transition connecting pipe to connect the PCCP pipes and the square channel three-dirt connecting pipe, the side face opening of the original sewage connecting pipe is connected with the PCCP pipe, and further provided with a coating square well; for the structure is a low-pressure pipe, manholes are required to arrange; adjacent PCCP pipes arranged with the manholes are connected by three sections of steel pipes and reinforced by the steel sleeve ring while further sealed and reinforced by the coating square well. The alternation construction connection structure is simple in structure,stable in connection, good in sealing property, and safe in use; the service life of the sewage pipe is greatly improved, thus the pipe can adapt to different using environments.

Owner:HANGZHOU MUNICIPAL CONSTR GRP CO LTD

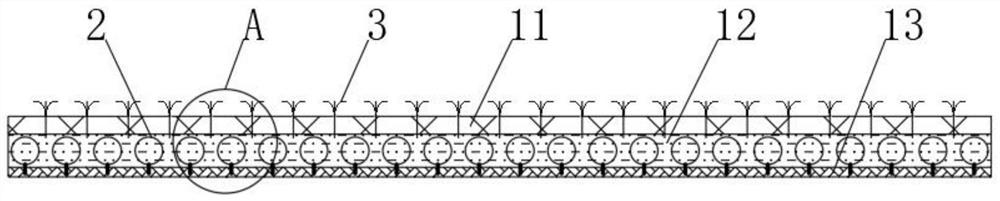

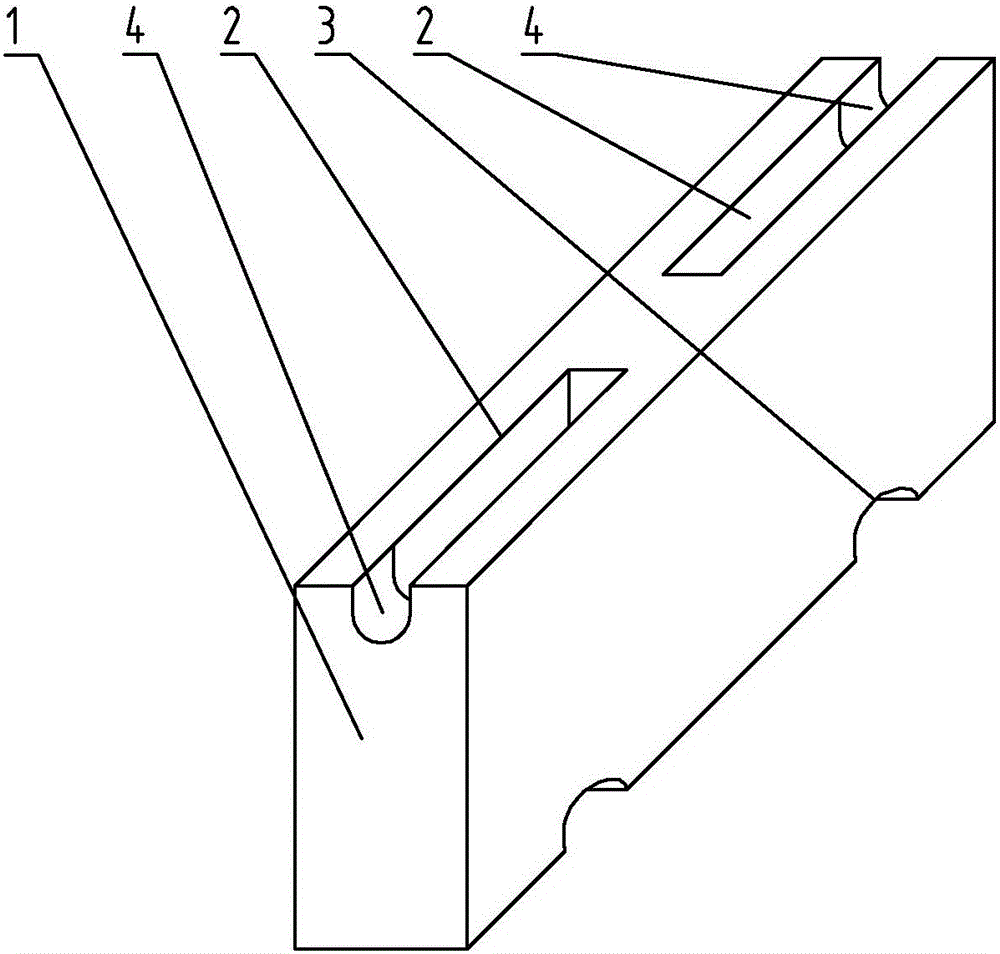

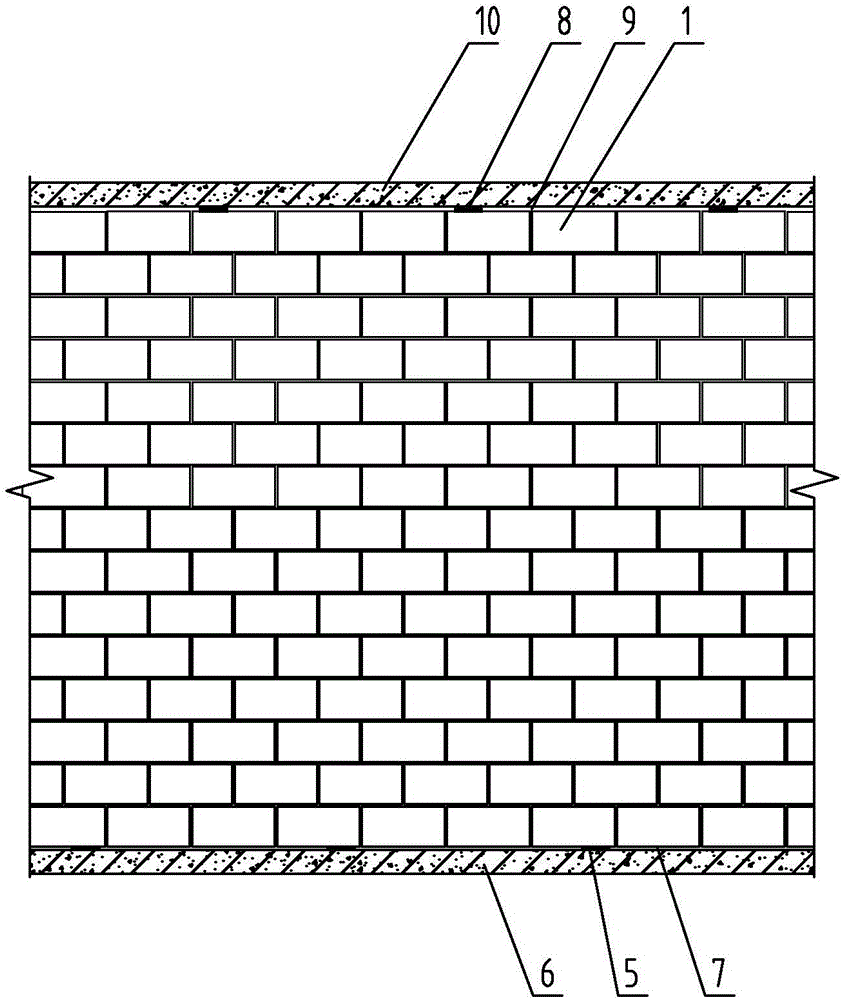

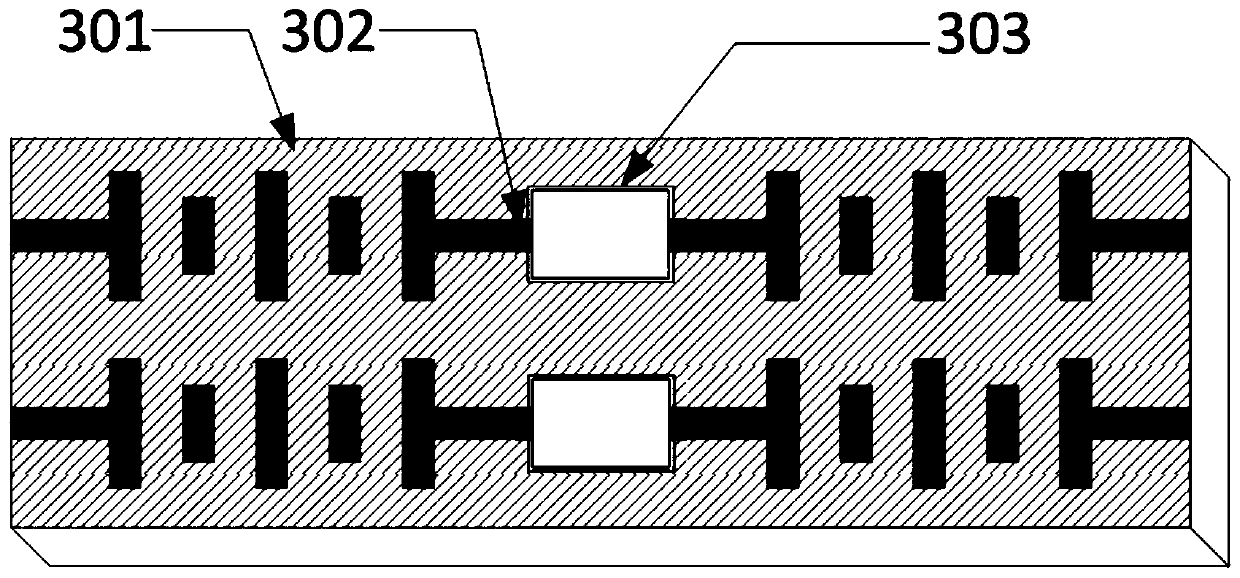

Method for constructing block-integrating air-layer-free air permeable type sandwich wall

InactiveCN105839810AReduce construction difficultyGuarantee the quality of the projectLighting and heating apparatusWallsThermal insulationStructural stability

The invention relates to a masonry method of an air-layer-breathing-free sandwich wall in agglomerate mode, which relates to a wall masonry method. The invention aims to solve the problem that the rainwater and moisture in the thermal insulation layer of the existing sandwich wall are difficult to discharge, which causes the wall to grow hairy and moldy, deteriorate, reduce the structural stability and thermal insulation performance of the wall, and affect the use of residents. Masonry method: build the inner leaf wall; lay the insulation layer; set the air intake through hole; build the outer leaf wall by masonry; set the air outlet through hole; set the tie bars; set the decorative surface. The invention is used for the masonry of air-layer-free breathing sandwich walls.

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

Thin film circuit with large-area side wall metal pattern and preparation method thereof

ActiveCN111243964AAvoid glue retentionAvoid completenessSemiconductor/solid-state device detailsSolid-state devicesSputteringHemt circuits

The invention discloses a thin film circuit with a large-area side wall metal pattern and a preparation method thereof, and belongs to the technical field of thin film circuits. The method comprises the steps of manufacturing a cavity shape mark, manufacturing a front metallized pattern, carrying out two-layer protection on the front surface of a substrate, opening a cavity, carrying out metal sputtering and electroplating thickening from the back surface to the top, removing photoresist, cutting and the like. According to the prepared thin film circuit, the side wall metal layer and the backmetal layer of the thin film circuit are formed at the same time, so that the connecting part of the two metal layers is of a complete, continuous and smooth transition structure. The method is simple, convenient and easy to implement, the prepared thin film circuit is more excellent in structure and effect, can be used as a key technology for achieving a miniaturized, high-reliability and high-frequency microwave / millimeter wave circuit, and has important significance in related technical fields.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Circulating ventilation system of silica sand water storage and purification tank

InactiveCN112811625AIncrease the areaIncrease dissolved oxygen contentWater aerationTreatment involving filtrationWater storageSludge

The invention relates to a circulating ventilation system of a silica sand water storage and purification tank, belongs to the technical field of environmental engineering, and provides the following technical scheme for solving the problem that purification treatment of sewage is not facilitated, the circulating ventilation system of the silica sand water storage and purification tank is technically characterized by comprising a tank body, impermeable layers are laid on the bottom wall and the side wall of the tank body, and a water storage well and a water purification well are arranged in the tank body; the water storage well and the water purification well are both defined by silica sand water filtering walls, the water purification well is communicated with a water inlet pipe, and the water storage well is communicated with a water outlet pipe. A desilting channel is further arranged in the tank body, the desilting channel is communicated with the water purification well, and the desilting channel is provided with a sludge discharge pipe; an air inlet pipe is arranged in the tank body, the two ends of the air inlet pipe extend out of the tank body, an air channel capable of supplying air to the air inlet pipe is arranged outside the tank body, and a plurality of air outlet holes are formed in the air inlet pipe located in the tank body. The circulating ventilation system has the advantages of increasing the content of dissolved oxygen in sewage and improving the sewage filtering effect.

Owner:北京金河水务建设集团有限公司

Condenser and refrigeration device

InactiveCN104329834AMeet cooling needsImprove cooling effectEvaporators/condensersRefrigeration devicesRefrigerationRefrigerant

The invention provides a condenser and a refrigeration device. The condenser comprises N collecting pipes and M sets of flat pipes, wherein each set of flat pipes are arranged between the adjacent collecting pipes in a parallel form; the flat pipes are mounted on the collecting pipes; the two ends of the flat pipes are respectively communicated with the adjacent collecting pipes; N is an integer more than or equal to 3; M is an integer more than or equal to 2. Through the technical scheme provided by the invention, on the one hand, the heat exchange area is increased, the heat exchange effect is enhanced, and the radiating property of the condenser is further improved; on the other hand, materials are effectively saved, and the pressure drop of a compressor and the on-way resistance of refrigerant are reduced, so that the overall power consumption is reduced and the charging quantity of the refrigerant is reduced.

Owner:HEFEI HUALING CO LTD

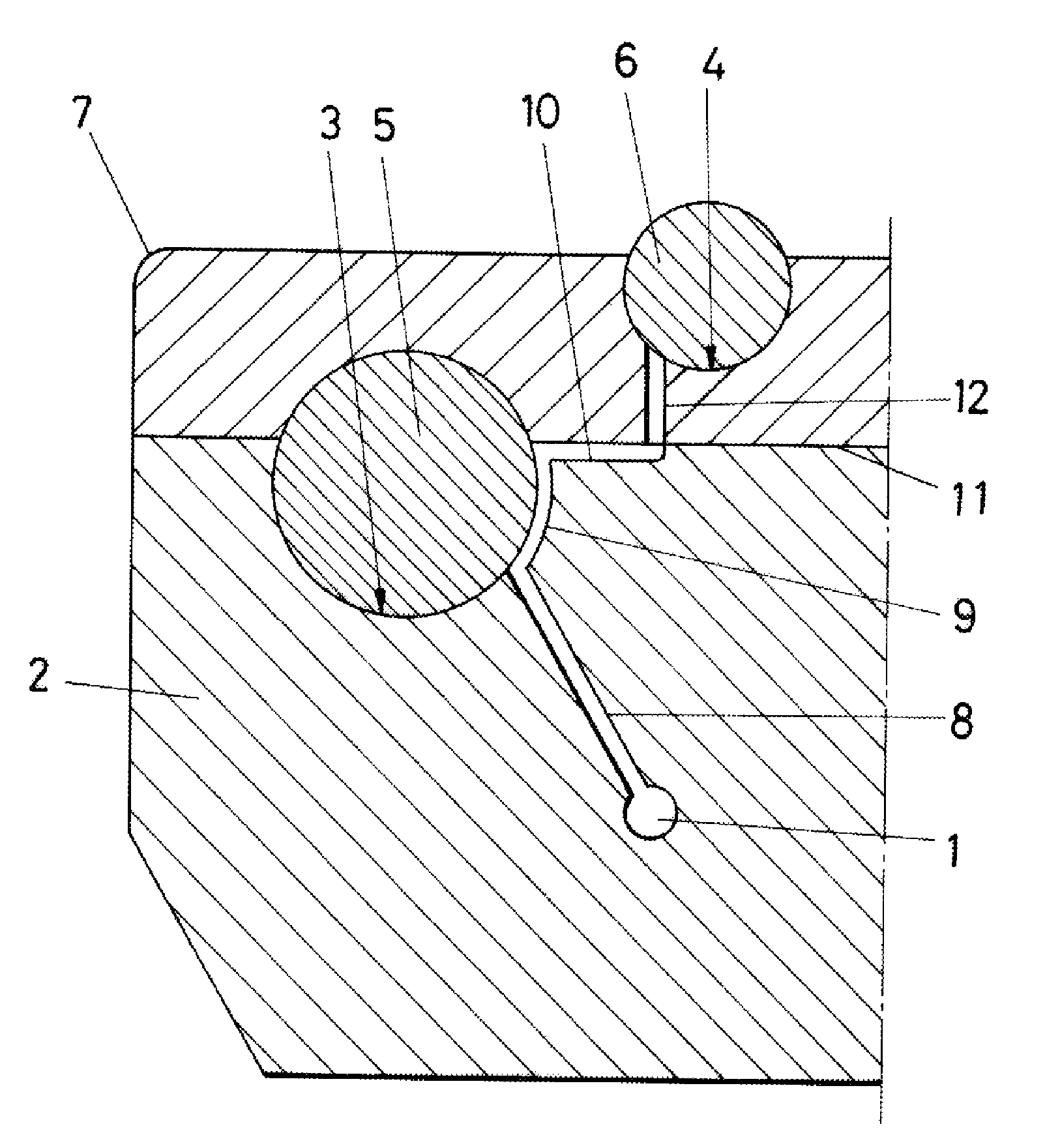

Improvements to the lubrication of the seats of a camshaft and a rocker-arm shaft in an internal combustion engine

InactiveCN103026013AImprove the lubrication effectEffective connectivityLubrication of auxillariesMachines/enginesLine tubingExternal combustion engine

The invention relates to improvements that essentially comprise a novel arrangement of the lubricant lines that start at a deep transverse bore made in the cylinder head of the engine, characterised in that the lubricating oil line follows a path that reaches, via a first front line, each seat of the camshaft, with a second rear line starting at said seat and connecting to each seat of the rocker-arm shaft.

Owner:AMADEO MARTI CARBONELL

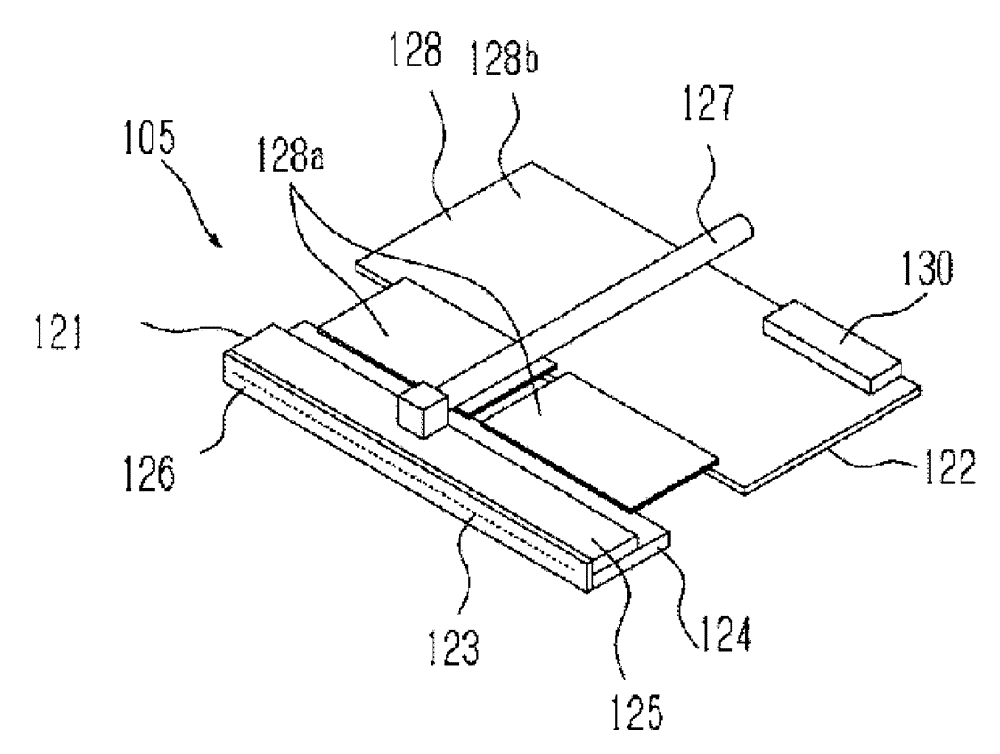

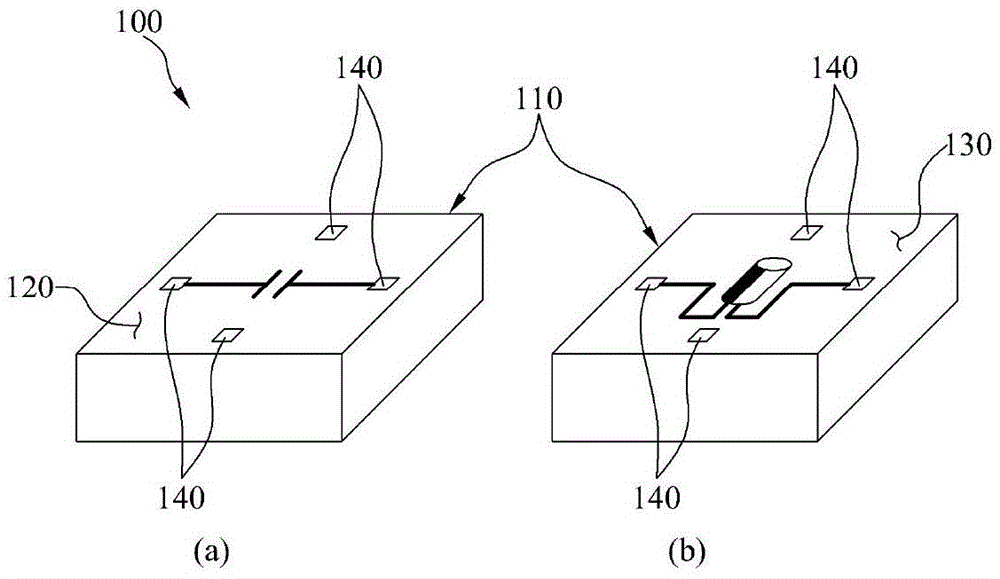

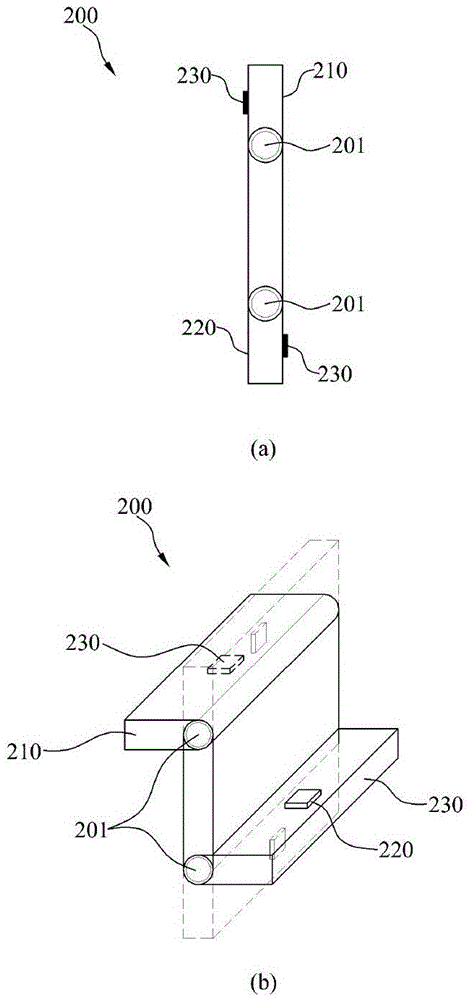

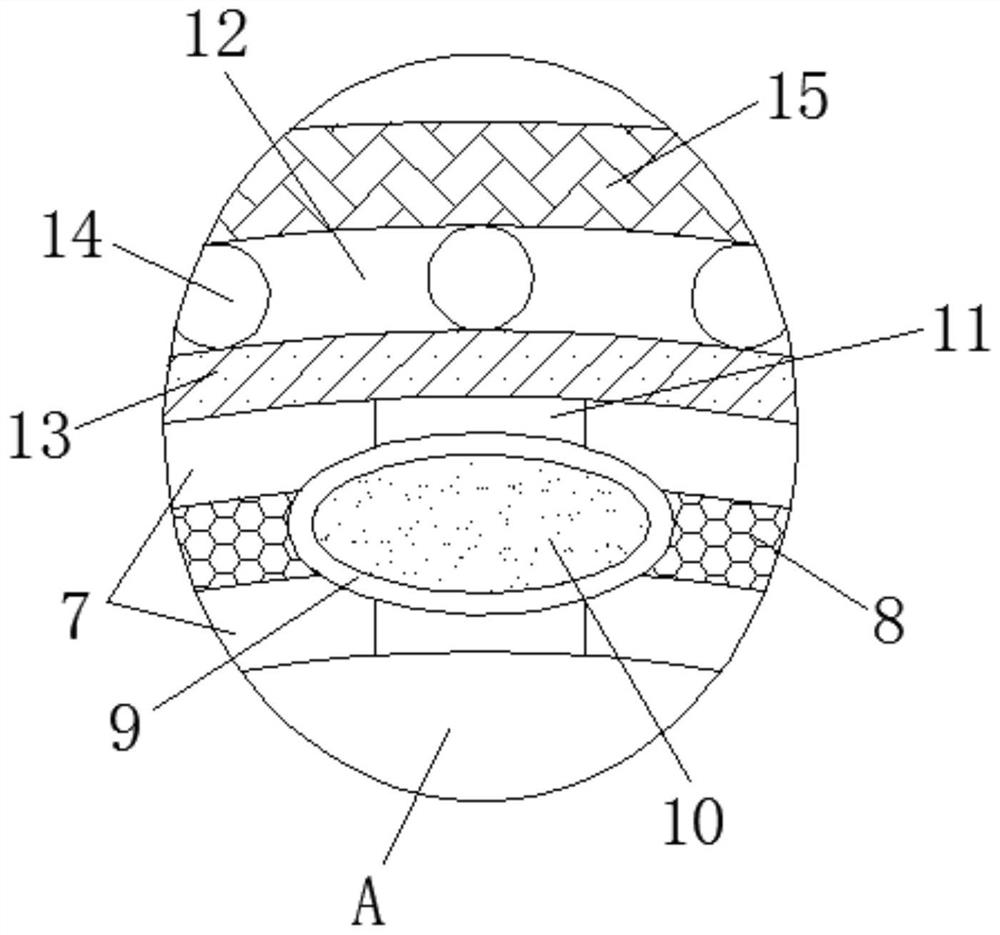

Improved construction kit of modular circuit elements

InactiveCN105659307ASimple associativitySimple separabilityCircuit arrangements on support structuresEducational modelsModularityElectrical connection

According to an improved construction kit of modular circuit elements provided by the present invention, the individual circuit elements for forming an electronic circuit are formed in the shape of a module, and the circuit elements are configured to be connected to a square or rectangular circuit element block module by an I-shaped or H-shaped circuit element coupling module for an electrical connection such that the electrical connection of the electronic circuit for testing a circuit and a coupled state between the modules can be stably maintained.

Owner:康民洙

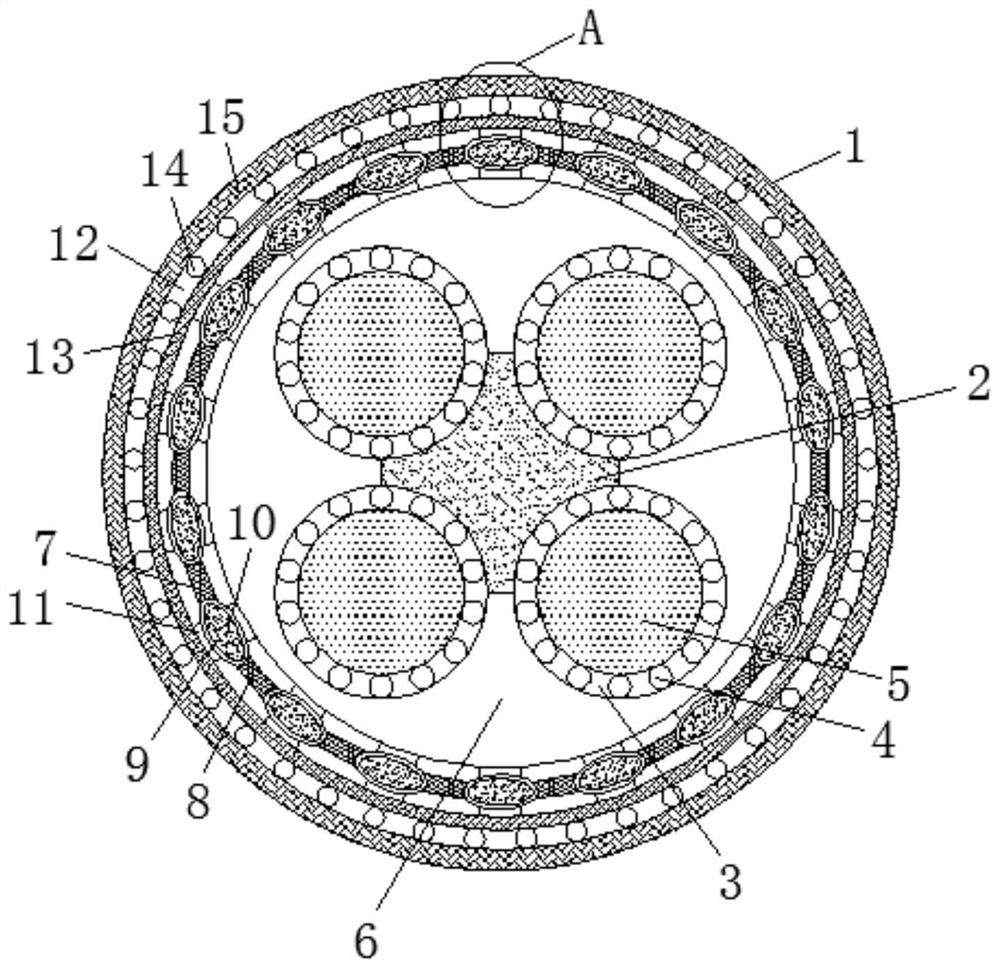

Cold-proof photovoltaic cable

ActiveCN112700918AActive connectionImprove insulation effectInsulated cablesInsulated conductorsEngineeringHeat conservation

The invention relates to the technical field of photovoltaic cables, and discloses a cold-proof photovoltaic cable which comprises a cable body, wherein a center body is arranged in the cable body, an insulating cavity is formed in the side edge of the center body, a cable core is arranged on the inner side of the insulating cavity, a through hole connecting layer is arranged on the outer wall of the insulating cavity, a heat preservation cavity is formed in the outer wall of the through hole connecting layer, by arranging the heat preservation cavity, a good heat preservation cavity layer effect on four sets of cable cores arranged in the body is achieved while mechanisms in the body are arranged, through the communication layer arranged in the heat preservation cavity, the effective communication effect in a heat preservation layer of the body is achieved, and the arrangement effect on a plurality of accommodating cavities in the body is achieved; and by arranging the plurality of accommodating cavities, the filling effect on the heat absorption material body in the photovoltaic cable is facilitated, the heat preservation and storage effects are effectively achieved through the body material, the body photovoltaic cable can be conveniently placed in a cold environment, and the effective heat preservation and cold prevention effects in the heat preservation cavity are achieved.

Owner:欧耐特线缆集团有限公司

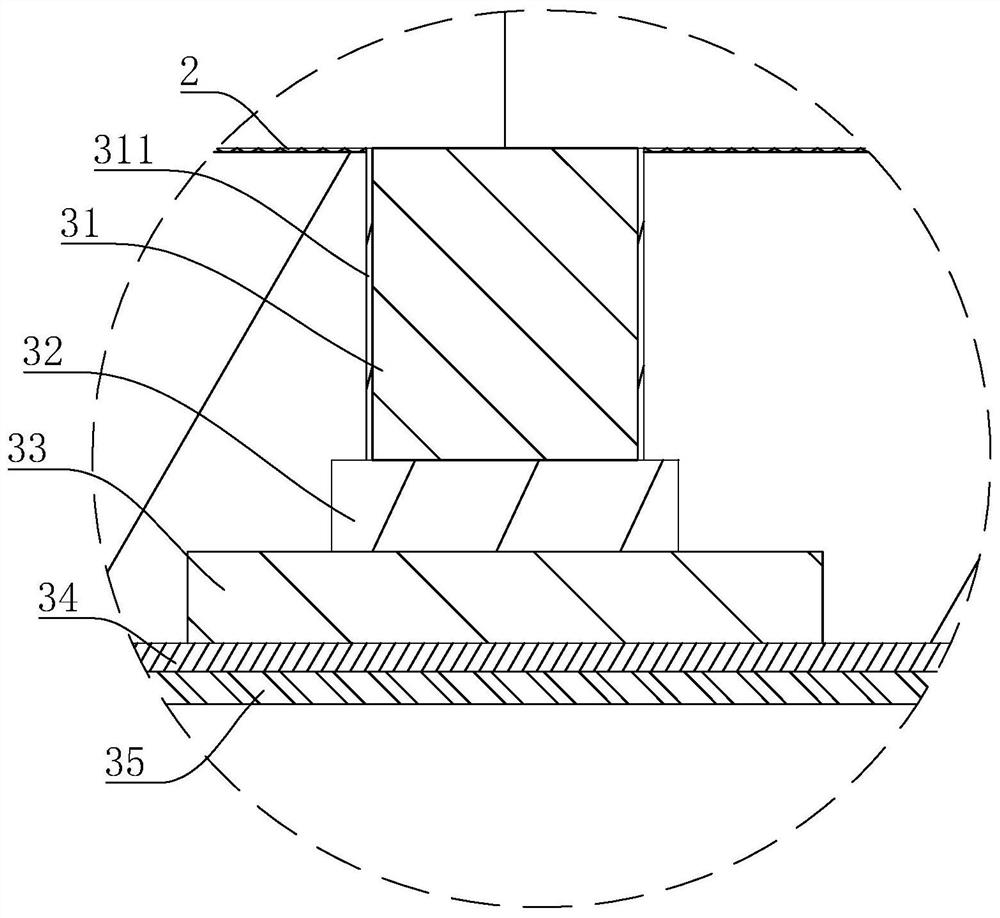

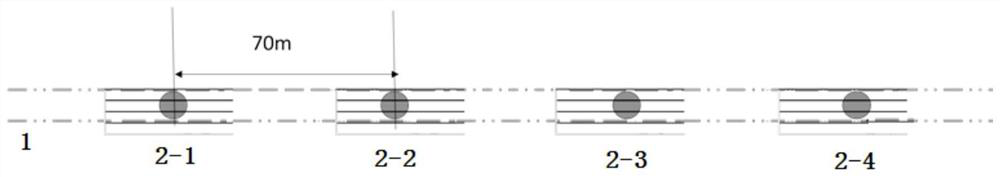

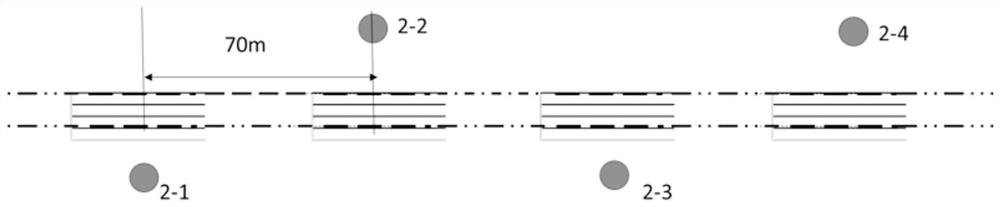

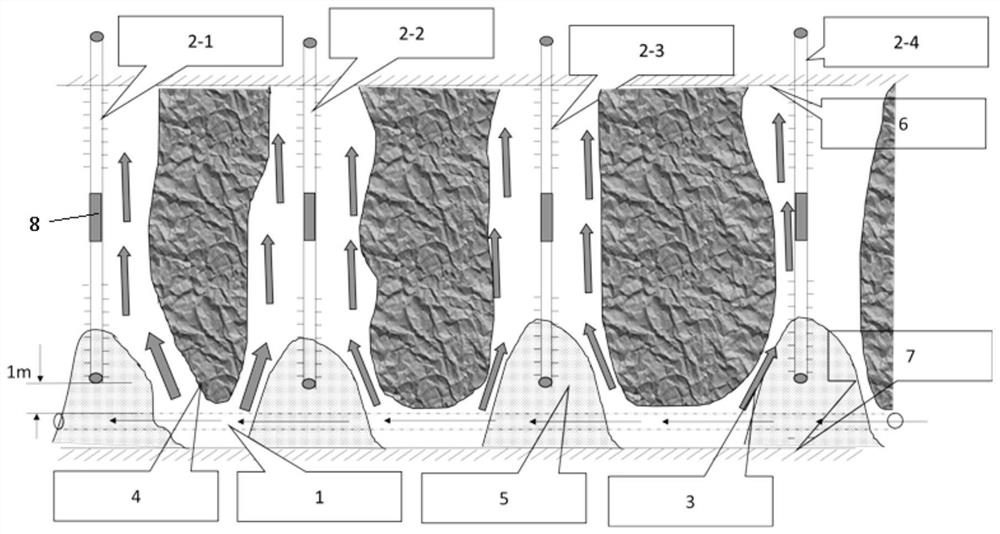

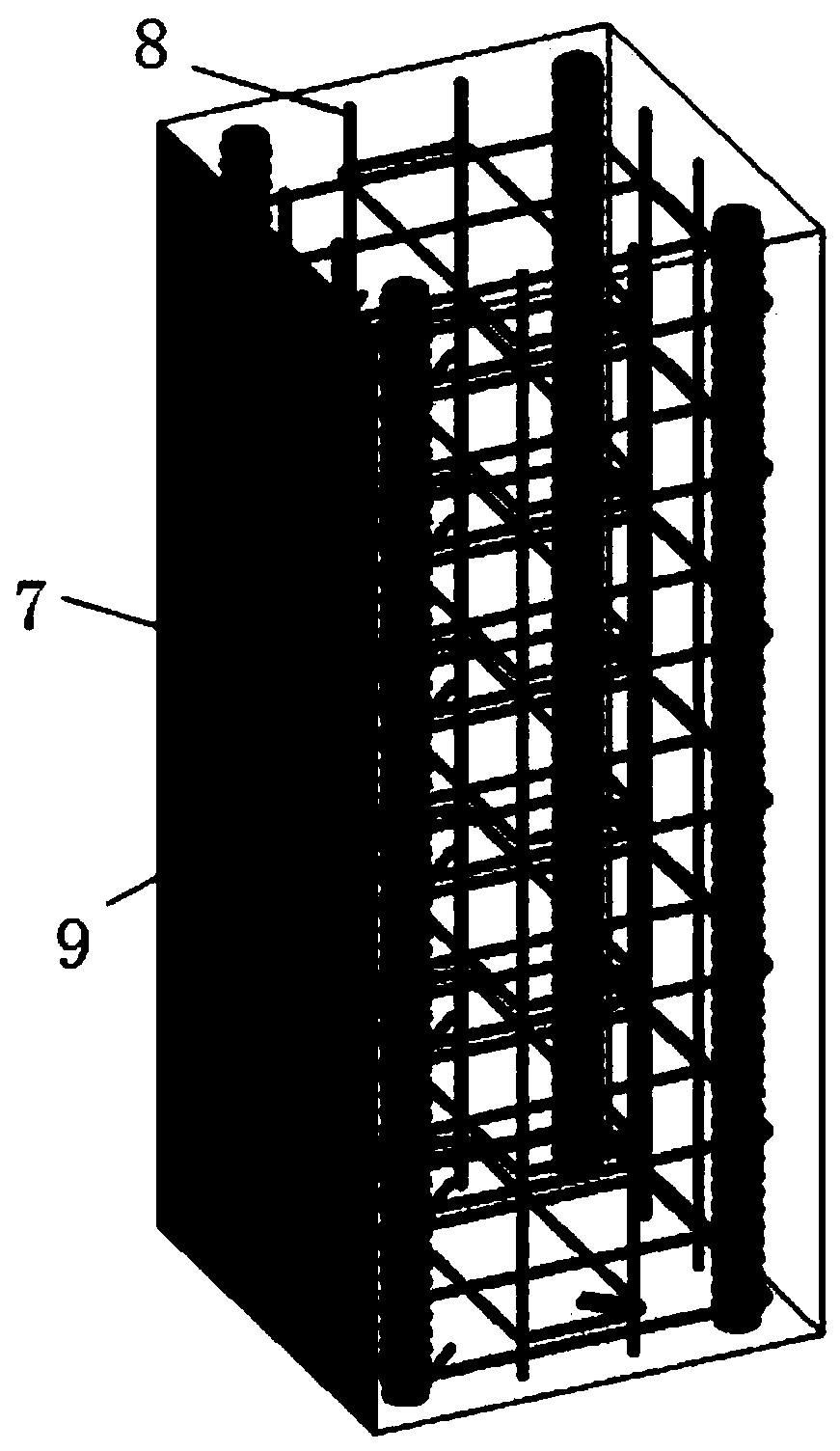

Ultra thick seam underground gasification method

ActiveCN111963137AIncreased creep volumeImproved creep propertiesConstructionsFluid removalThermodynamicsHorizontal wells

The invention discloses an ultra thick seam underground gasification method. By adopting a way of combining vertical wells with horizontal wells, a way of gas injection by the vertical wells and production by the horizontal wells is adopted first and then the way of gas injection by the vertical wells and production by the horizontal wells is converted into a way of gas injection by the horizontalwells and production by the vertical wells after a cavity of a certain scale is formed. The seam is developed longitudinally by means of overlapping action of gas effectively, and a burning front edge is kept nearby the horizontal wells. The method is an effective method of gasifying a deep seam, the thickness of which is greater than above 30 m, so that the complexity of operation is reduced effectively, the production efficiency of the seam is improved and the employing effect and the gasification effect of the deep seam are improved.

Owner:PETROCHINA CO LTD

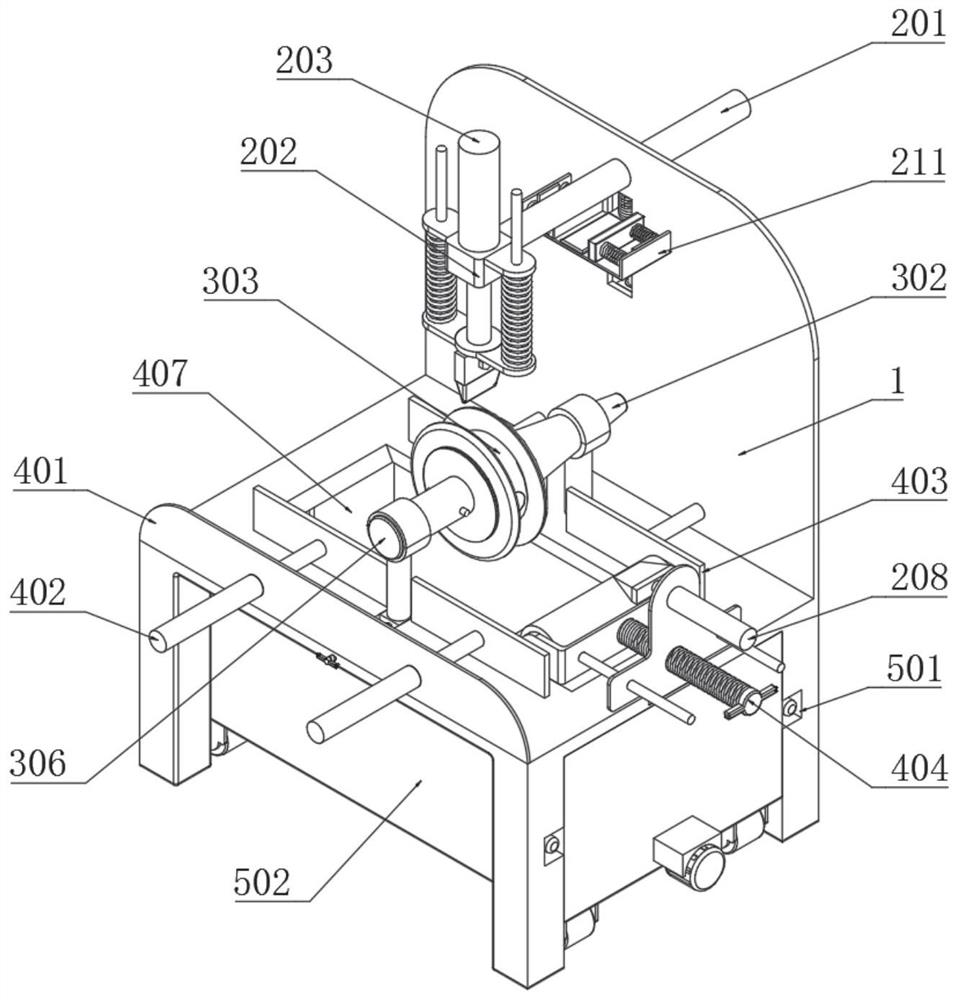

Portable machining tool for machining

ActiveCN113414591AAvoid residual effectsHeight adjustableOther manufacturing equipments/toolsMaintainance and safety accessoriesHydraulic cylinderMachine parts

The invention discloses a portable machining tool for machining. A cutting hydraulic cylinder penetrates through one end of a fixed supporting frame, a downward pressing electric push rod penetrates through the middle of a downward pressing frame, a cutting knife is connected to the inner side of a fixed connecting plate in an embedded manner through a screw, a correction knife is fixedly connected to one end of a pushing electric push rod, and cleaning cotton is placed at the inner side of a fixed protection box; and a contact detector is mounted in the top end of a limiting sliding plate, the cutting hydraulic cylinder and the downward pressing electric push rod drive the downward pressing frame and the fixed connecting plate to move, so that the cutting knife can quickly and stably move to the side end of a machined part to cut the machined part, and in the cutting process, the cutting hydraulic cylinder and the downward pressing electric push rod drive the cutting knife to reset, a rising electric push rod drives a limiting sliding plate to ascend, so that the contact detector is directly attached to the bottom end of the cutting knife, the pressing height can be rapidly adjusted in the cutting process, and the cutting size error is prevented.

Owner:程旭

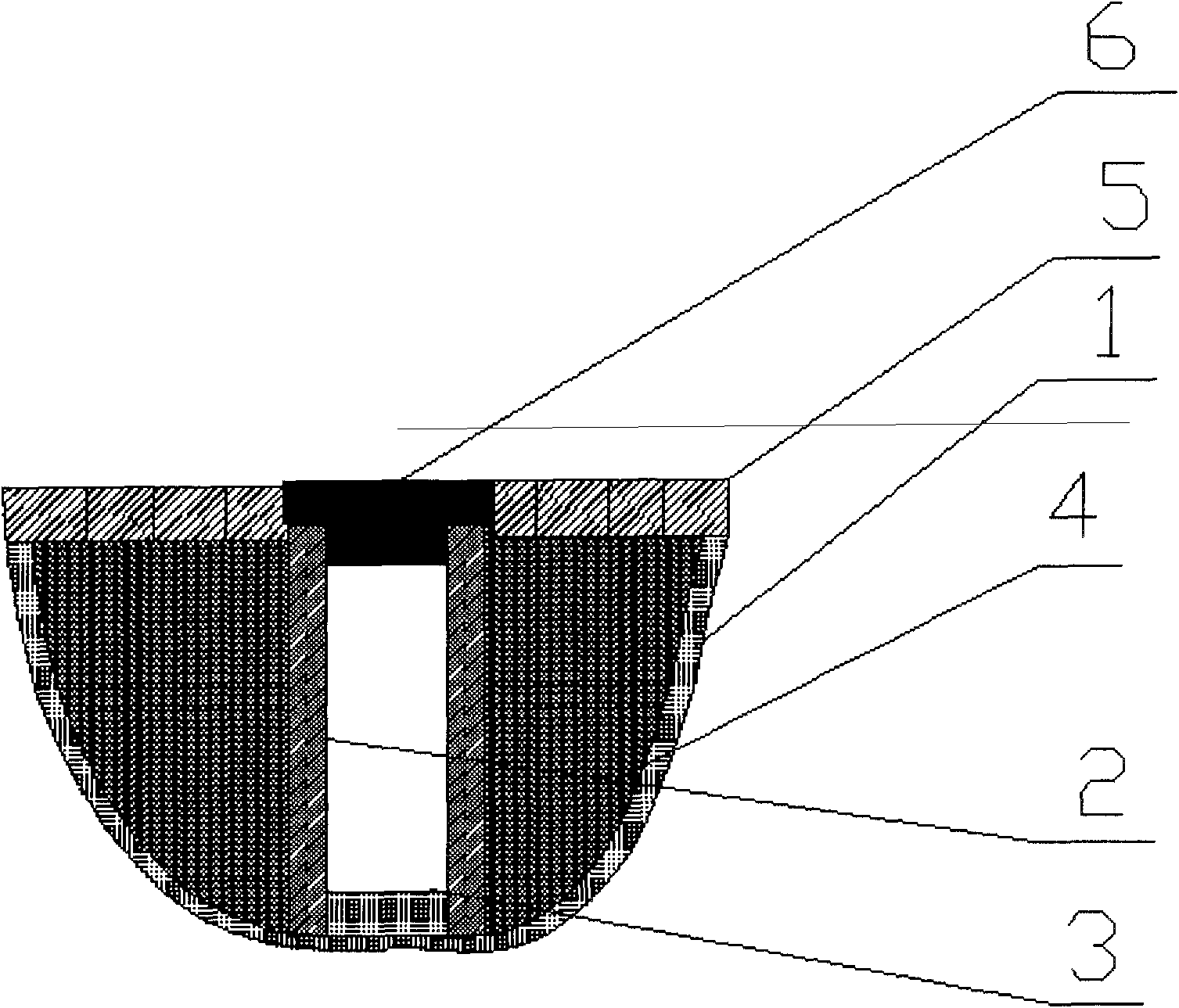

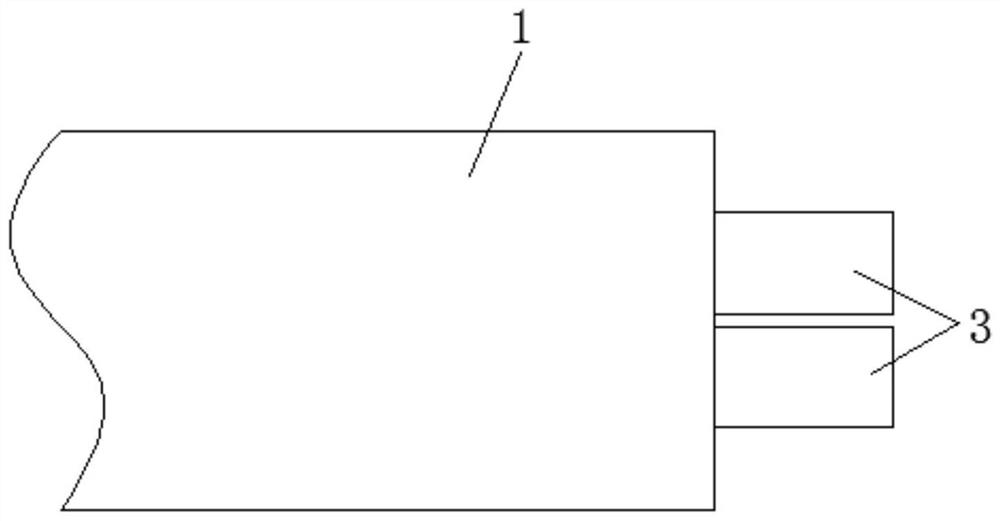

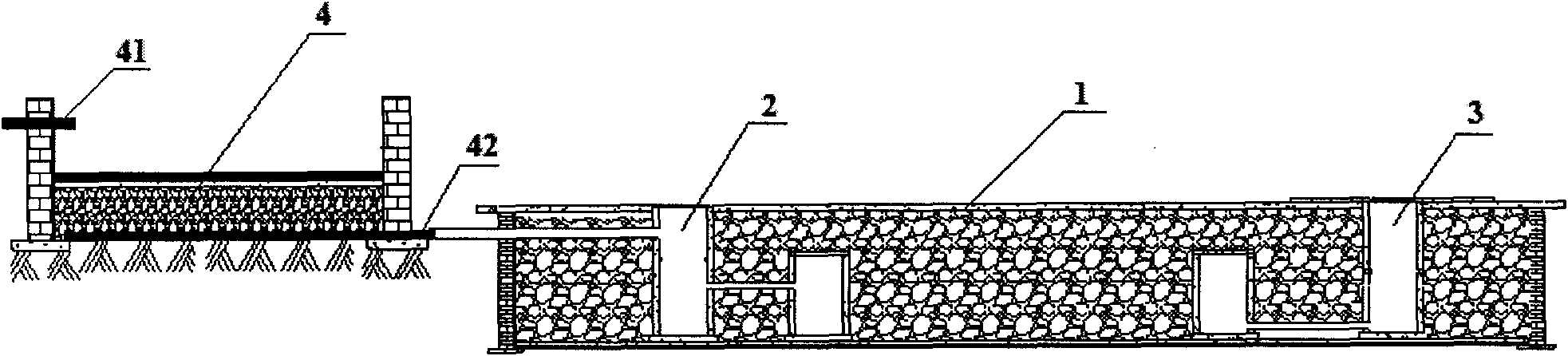

Clear water storage system

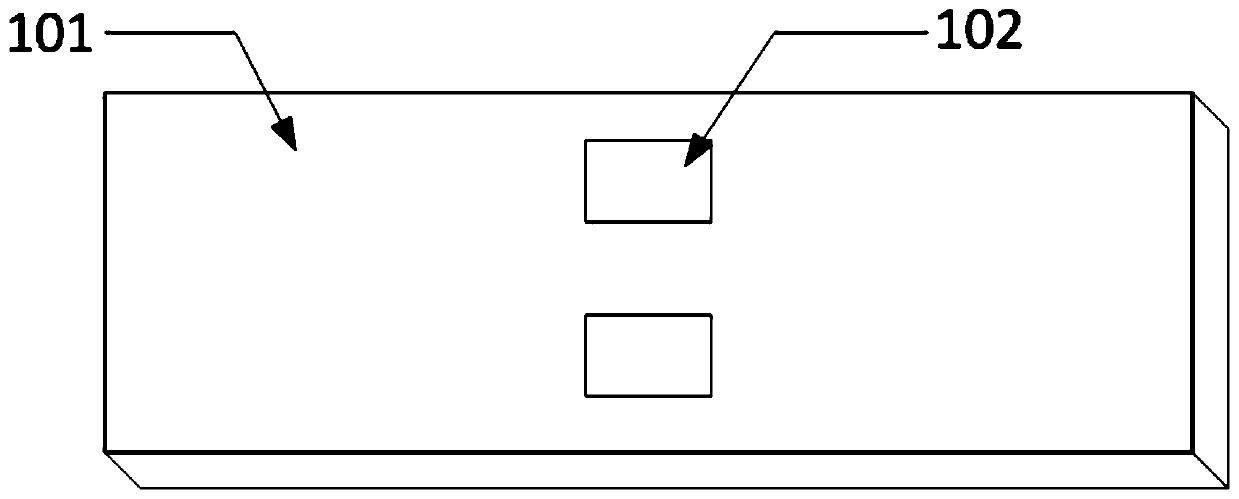

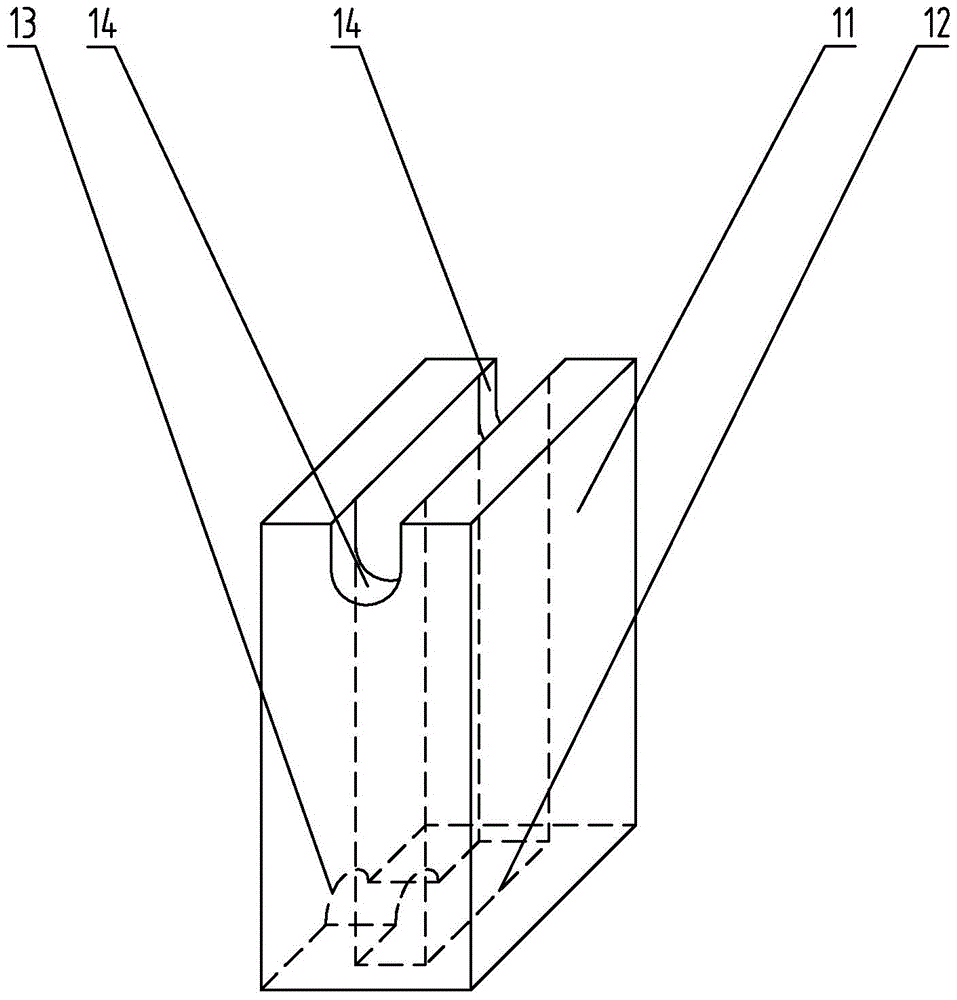

InactiveCN102213001AAvoid lostGuaranteed freshnessMultistage water/sewage treatmentWater supply tanksWater storageWater quality

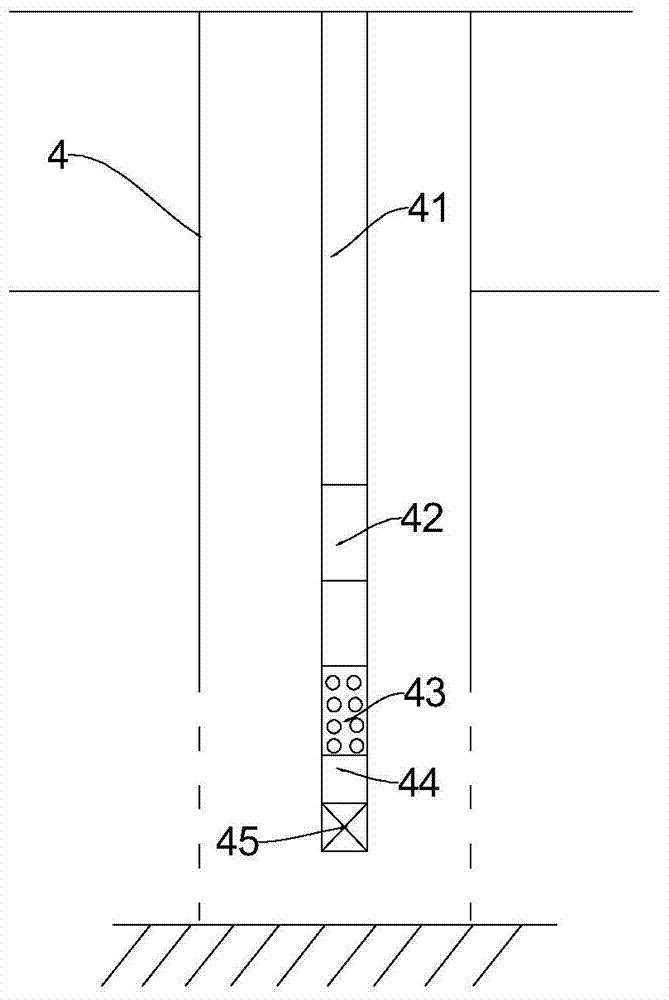

The invention relates to a clear water storage system. The system comprises a water storage container (1), at least one water inlet well (2), at least one water outlet well (3) and a filter pool (4); the top part of the water storage container (1) is closed by a seal layer, a water purification material is filled in the water storage container; the water inlet well (2) is positioned inside the water storage container (1) and comprises a first opening; the water outlet well (3) is positioned inside the water storage container (1), comprises a second opening, and is communicated with the outer part the water storage container (1) through the second opening; the filter pool (4) comprises a water inlet pipeline (41) and a water outlet pipeline (42); the water outlet pipeline (42) is communicated with at least one of the water inlet wells (2) through the first opening; and the water inlet well (2) and the water outlet well are embedded into the water purification material. The clear water storage system provided by the invention can be used for reducing natural loss of stored water and keeping water quality for a long time.

Owner:合肥仁创新材料科技有限公司

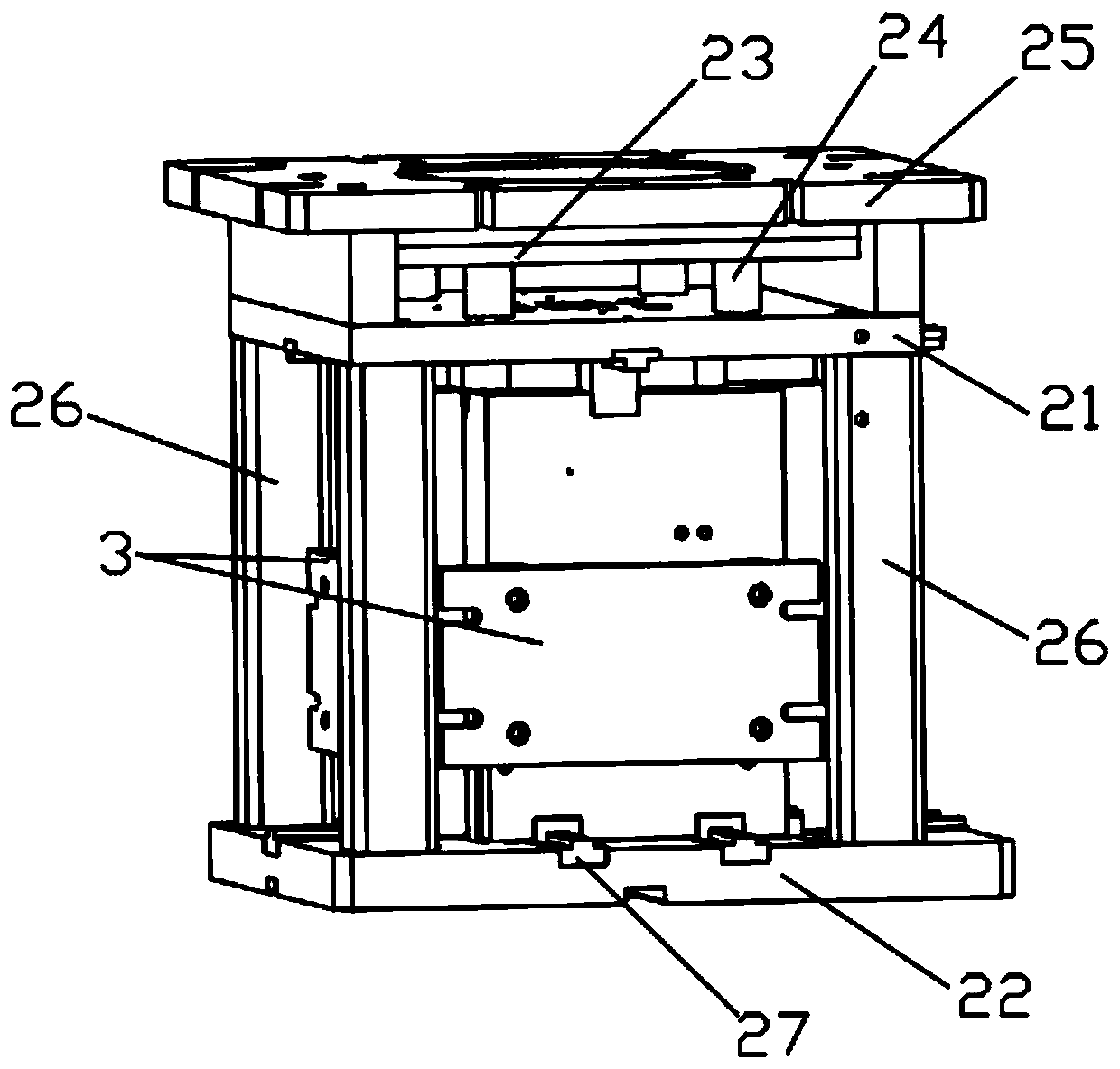

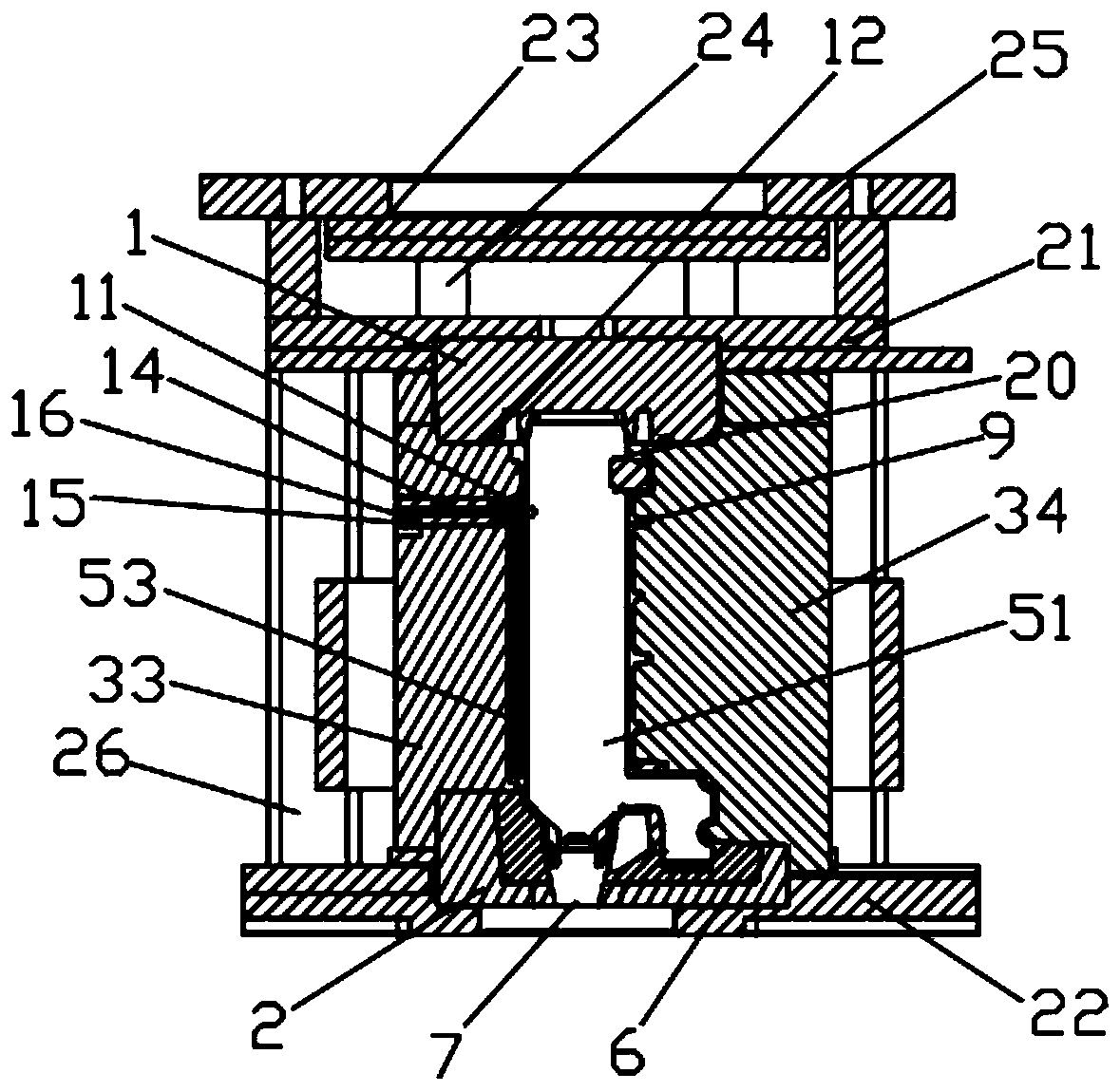

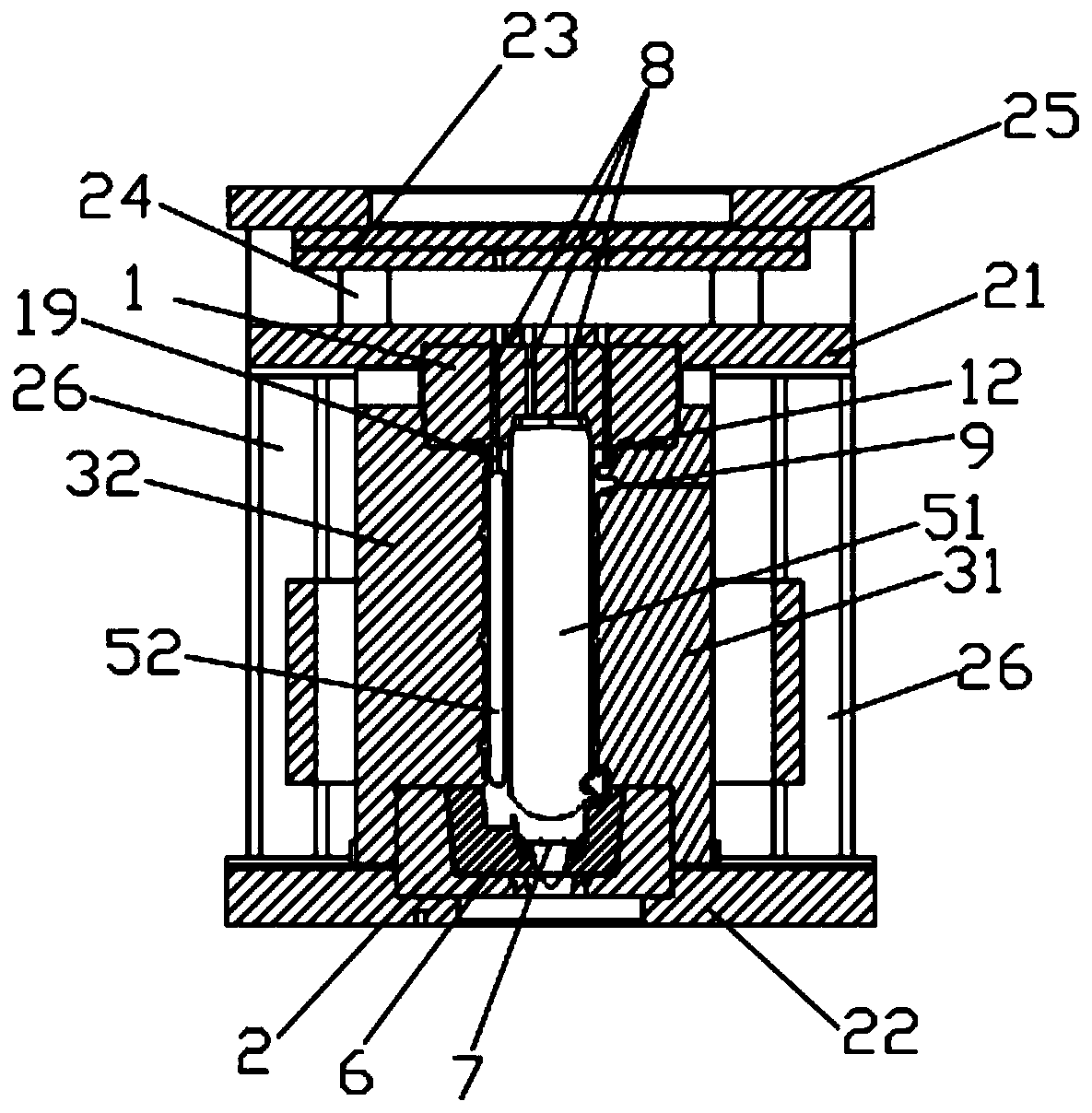

A low-pressure casting mold for a vehicle box

The invention discloses a low-pressure casting mold for a box body for a vehicle, and relates to the technical field of aluminum alloy casting. The defects that because the exhaust of the mold is notuniform, the casting partial gas hole, misrun or unclear outline and the like are easily formed are overcome. The low-pressure casting mold comprises an upper mold, a lower mold and a side mold assembly, and further comprises a casting cavity of a sand core assembly, the sand core assembly is fixed on the lower mold through a positioning base, the positioning base is provided with a diversion holecommunicating with the casting cavity, and an exhaust passage is arranged on the upper mold; the sand core assembly communicates with each other, and a main sand core is hollowed out; and an overflowsystem communicating with the casting cavity is arranged on the upper mold. By the technical scheme, balanced exhaust gas in the casting process of the box body can be realized, the gas in the cavityof the casting is rapidly discharged out, and the defects that the casting gas hole, misrun or unclear outline and the like do not exist in the forming box body are overcome, the qualified rate of the products reaches more than 99.9%, and the qualified rate of the formed casting is effectively improved.

Owner:四川省犍为恒益铝业有限公司

Prefabricated concrete frame structure with rear-mounted longitudinal bars in prefabricated beam column built-in corrugated steel pipes and manufacturing method thereof

InactiveCN110468961AEasy to operateSimple and fast constructionBuilding constructionsRebarPrecast concrete

The invention provides a prefabricated concrete frame structure with rear-mounted longitudinal bars in prefabricated beam column built-in corrugated steel pipes and a manufacturing method thereof andrelates to the technical field of civil engineering construction, in particular to the prefabricated concrete frame structure with the rear-mounted longitudinal bars in the prefabricated beam column built-in corrugated steel pipes and the manufacturing method thereof. The prefabricated concrete frame structure is provided for solving the problems that beam column nodes of an existing prefabricatedconcrete frame structure are connected through the bolt connecting process, the process is too complex, the construction efficiency is low and the connecting effect is poor. The prefabricated concrete frame structure comprises prefabricated concrete columns and prefabricated concrete superposed beams. The prefabricated concrete columns are vertically connected by arranging finishing rolled deformed bars in corrugated steel pipes at the four column corners of the prefabricated concrete columns and pouring concrete. The upper and lower layers of the finishing rolled deformed bars can be connected through finishing rolled deformed bar connectors. The prefabricated concrete superposed beams are connected with prefabricated column steel bars through beam bottom steel bars anchored in the corrugated steel pipes and beam top steel bars bound on site. The prefabricated concrete frame structure with the rear-mounted longitudinal bars in the prefabricated beam column built-in corrugated steel pipes is applied to the technical field of prefabricated concrete structure construction.

Owner:HARBIN INST OF TECH

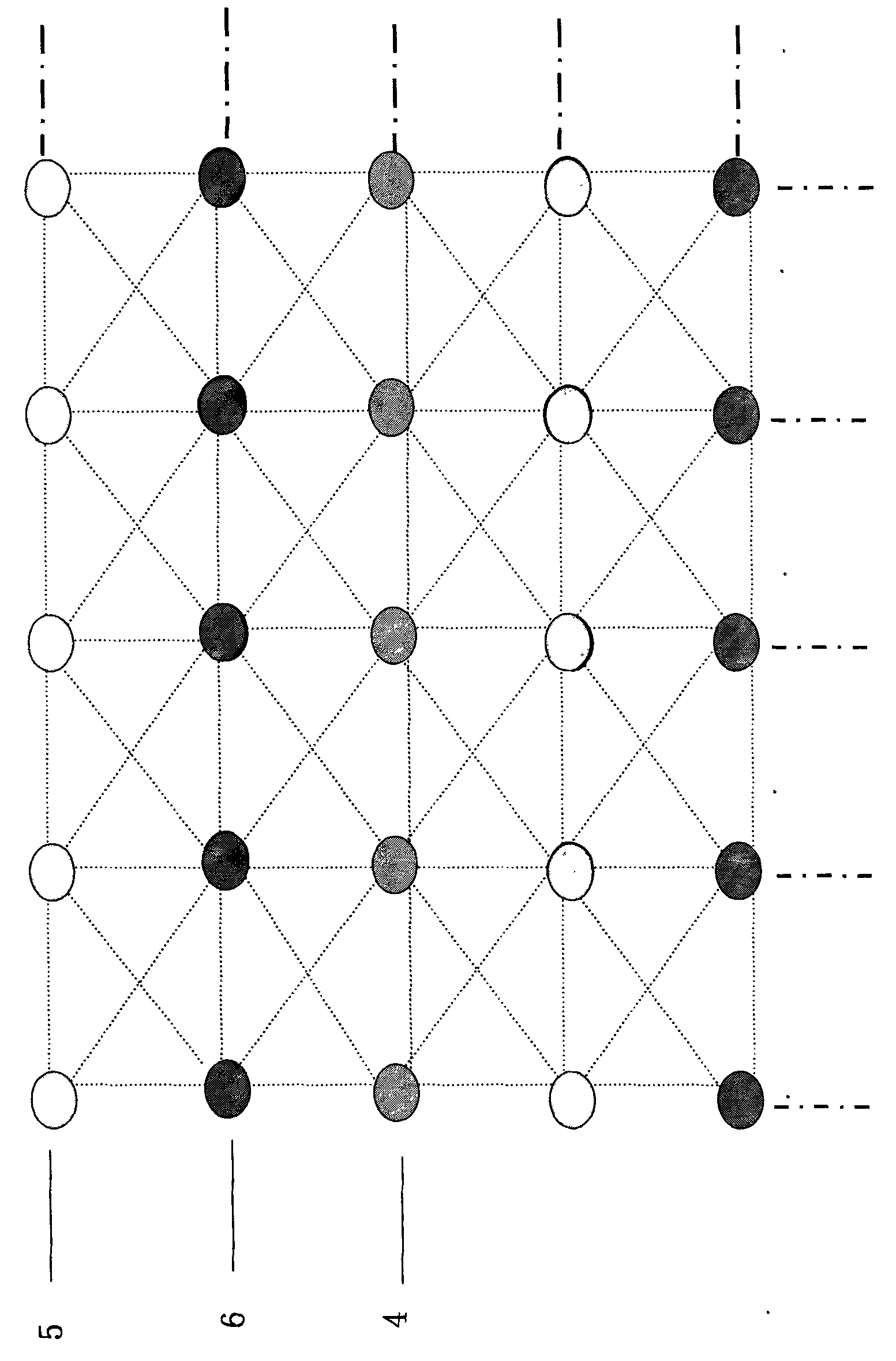

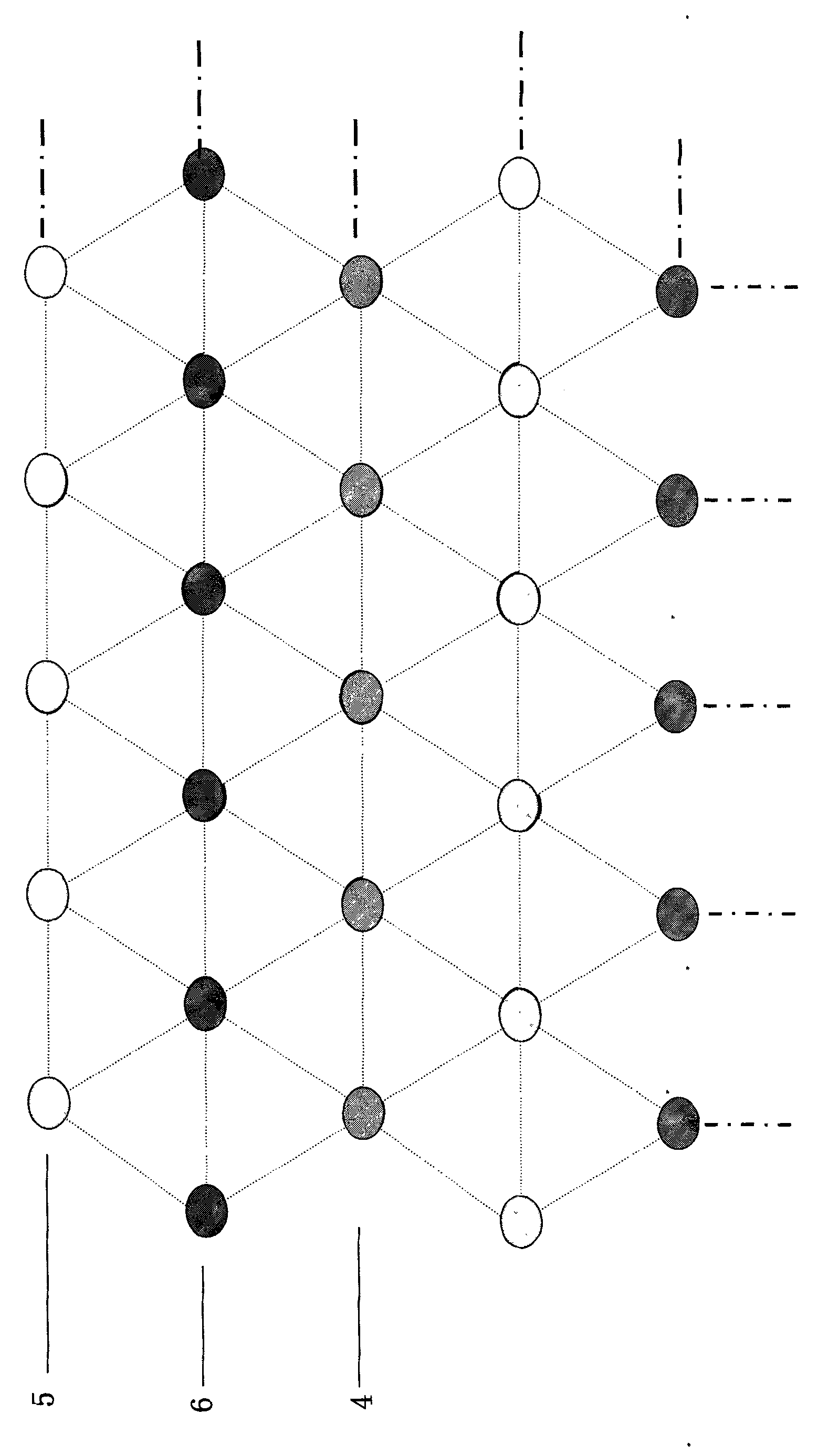

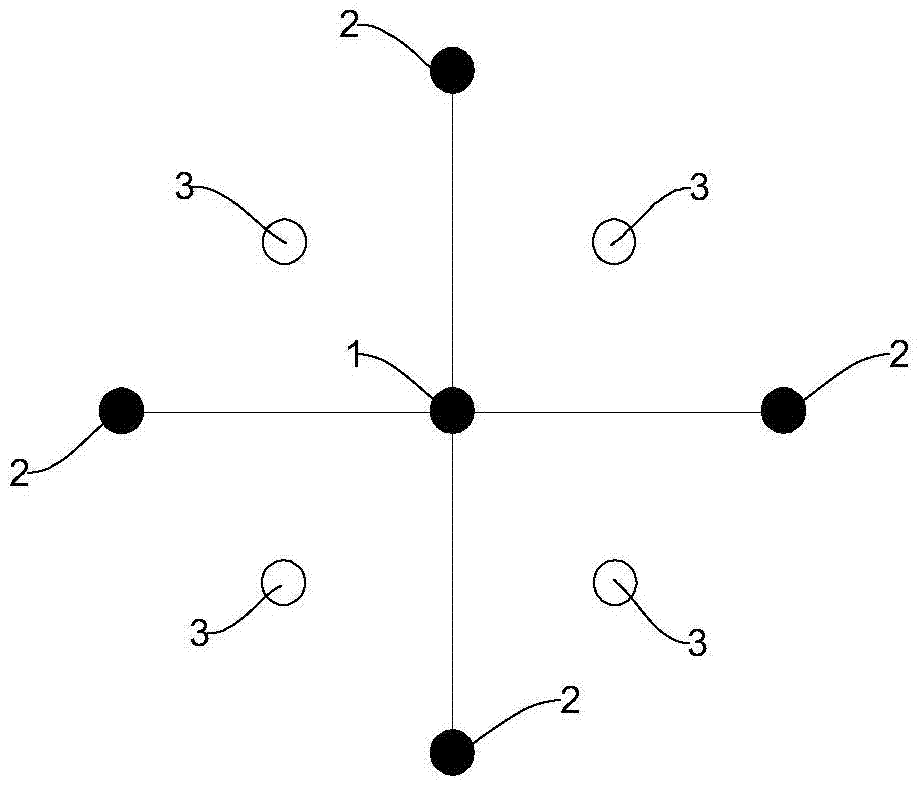

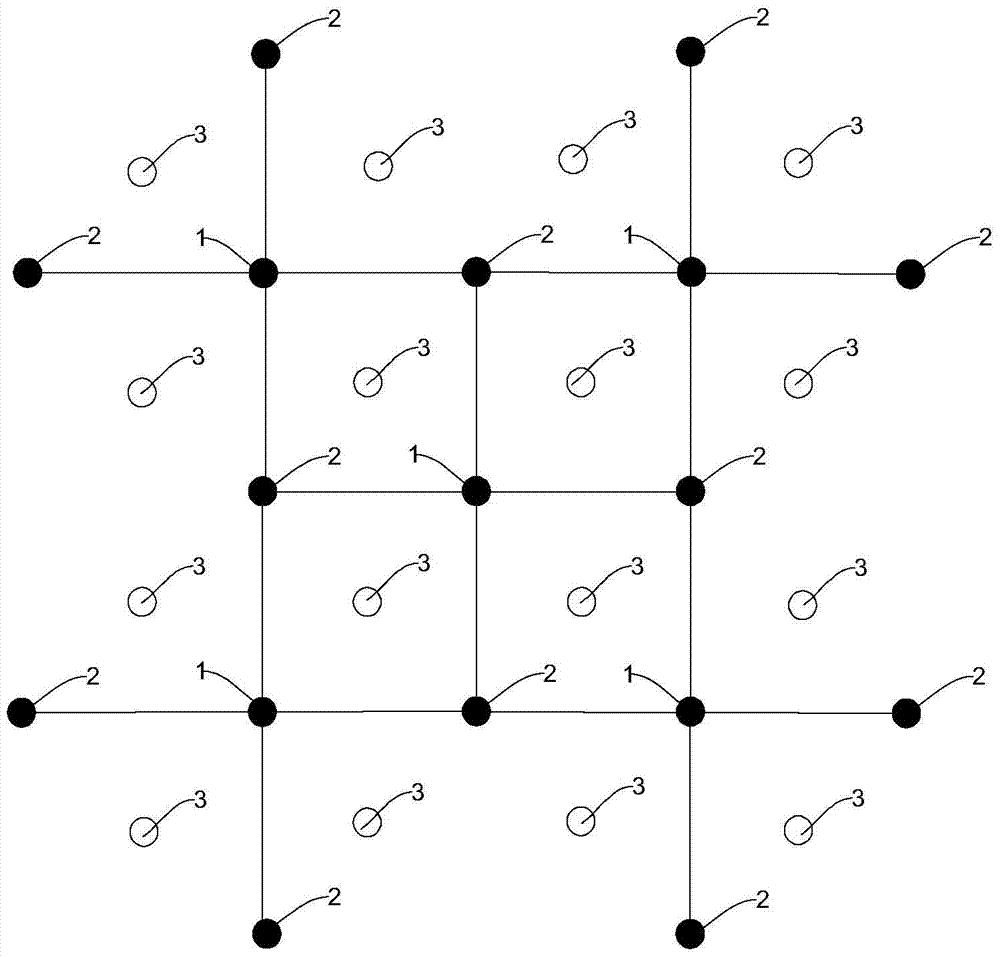

Oil treatment method

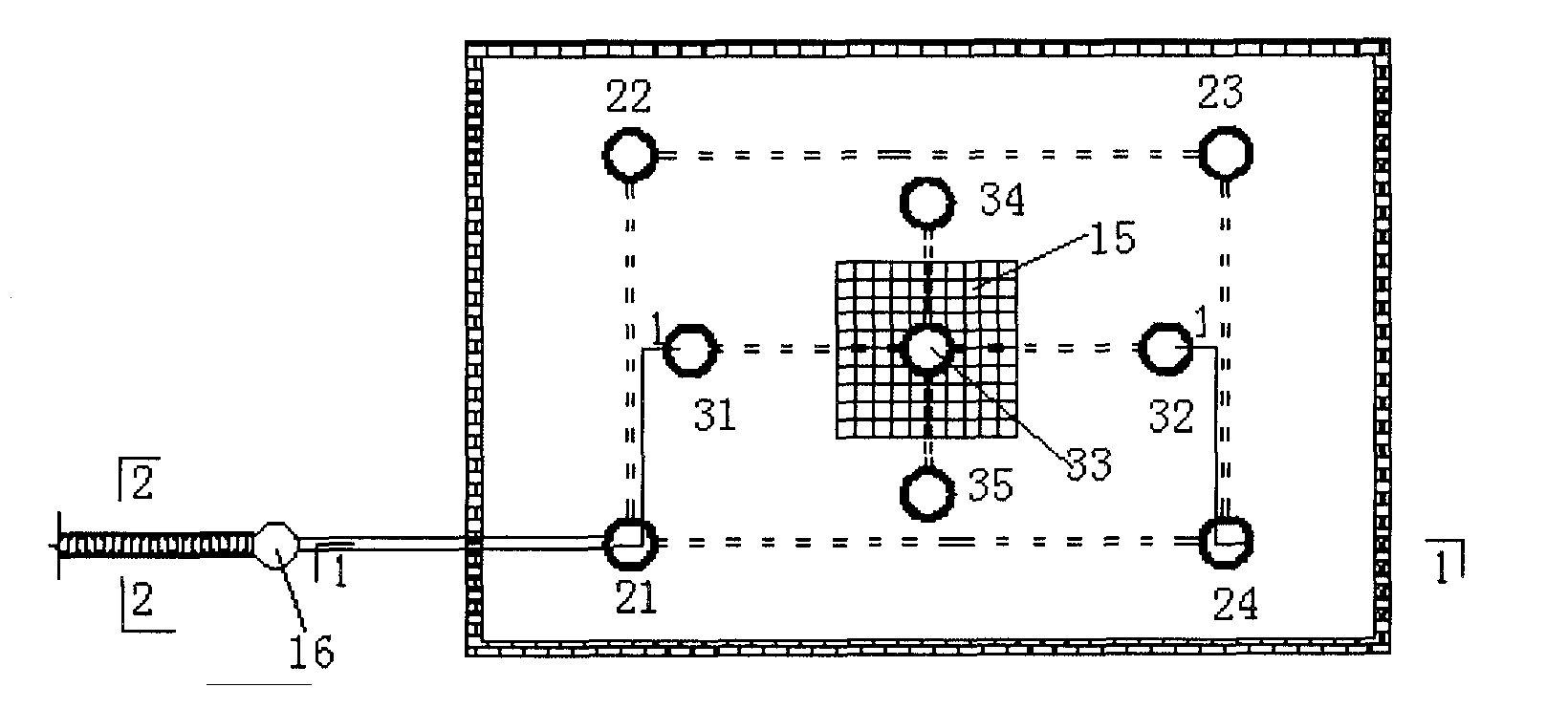

The invention discloses an oil recovery treatment method, comprising the following steps: arranging a first vertical well; arranging four second vertical wells surrounding the first vertical well, the four second vertical wells are respectively located at the vertices of a quadrilateral; arranging and four second vertical wells The vertical wells are alternately arranged as four third vertical wells around the first vertical well. Inject air into the first vertical well and the second vertical well, so that the heavy oil in the oil layer flows into the third vertical well, and the third vertical well lifts the heavy oil to the surface; at the same time, the third vertical well discharges tail gas; The tail gas discharge is stable, and air is injected into the third vertical well so that the heavy oil in the oil layer flows into the first vertical well and the second vertical well, and the first vertical well and the second vertical well lift the heavy oil to the surface; at the same time, the second vertical well The tail gas is discharged from the straight well and the second straight well. By adopting the oil recovery treatment method of the present invention, the gas injection well and the production well can be effectively connected, greatly improving the production efficiency of fire flooding oil recovery, and is safe and reliable.

Owner:PETROCHINA CO LTD

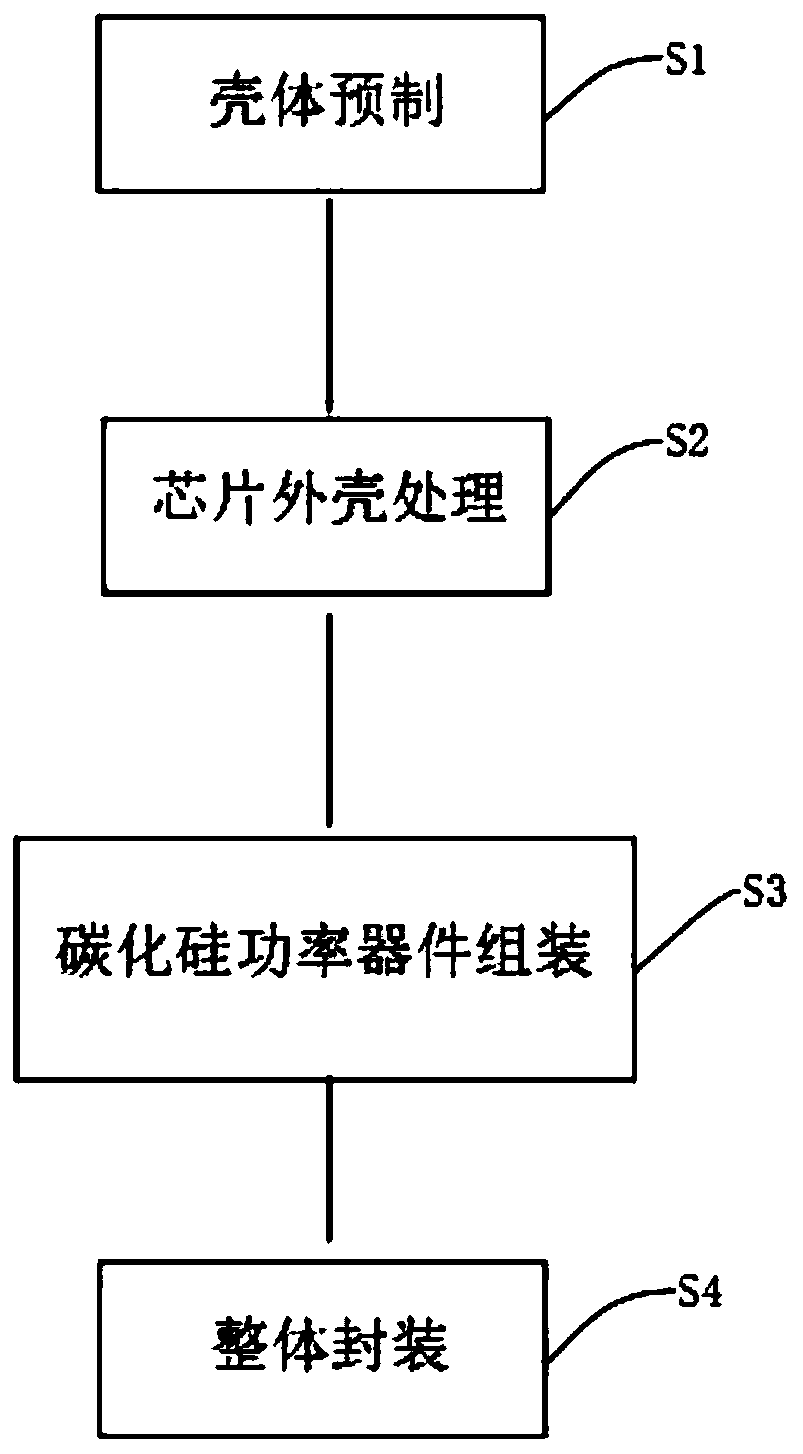

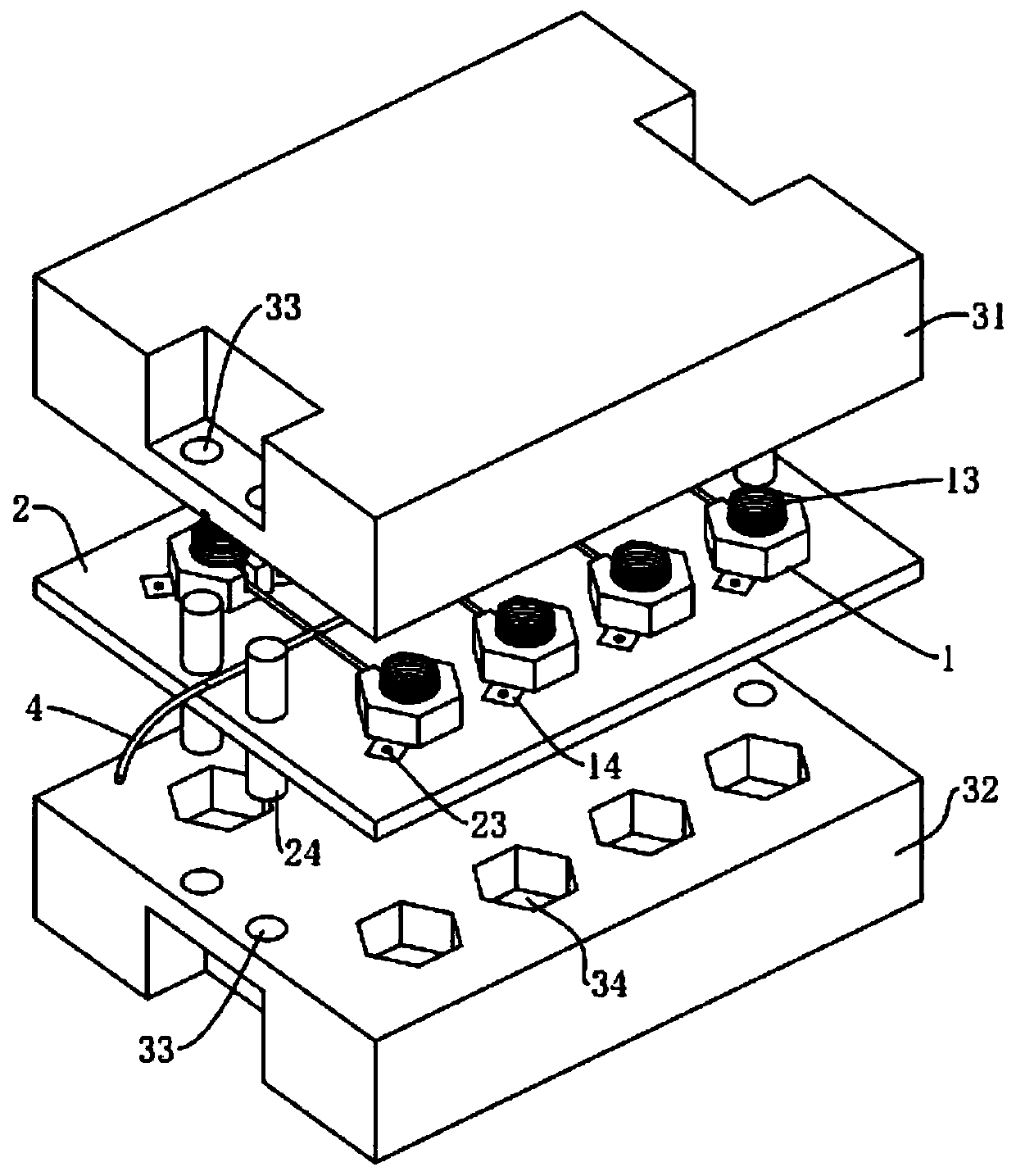

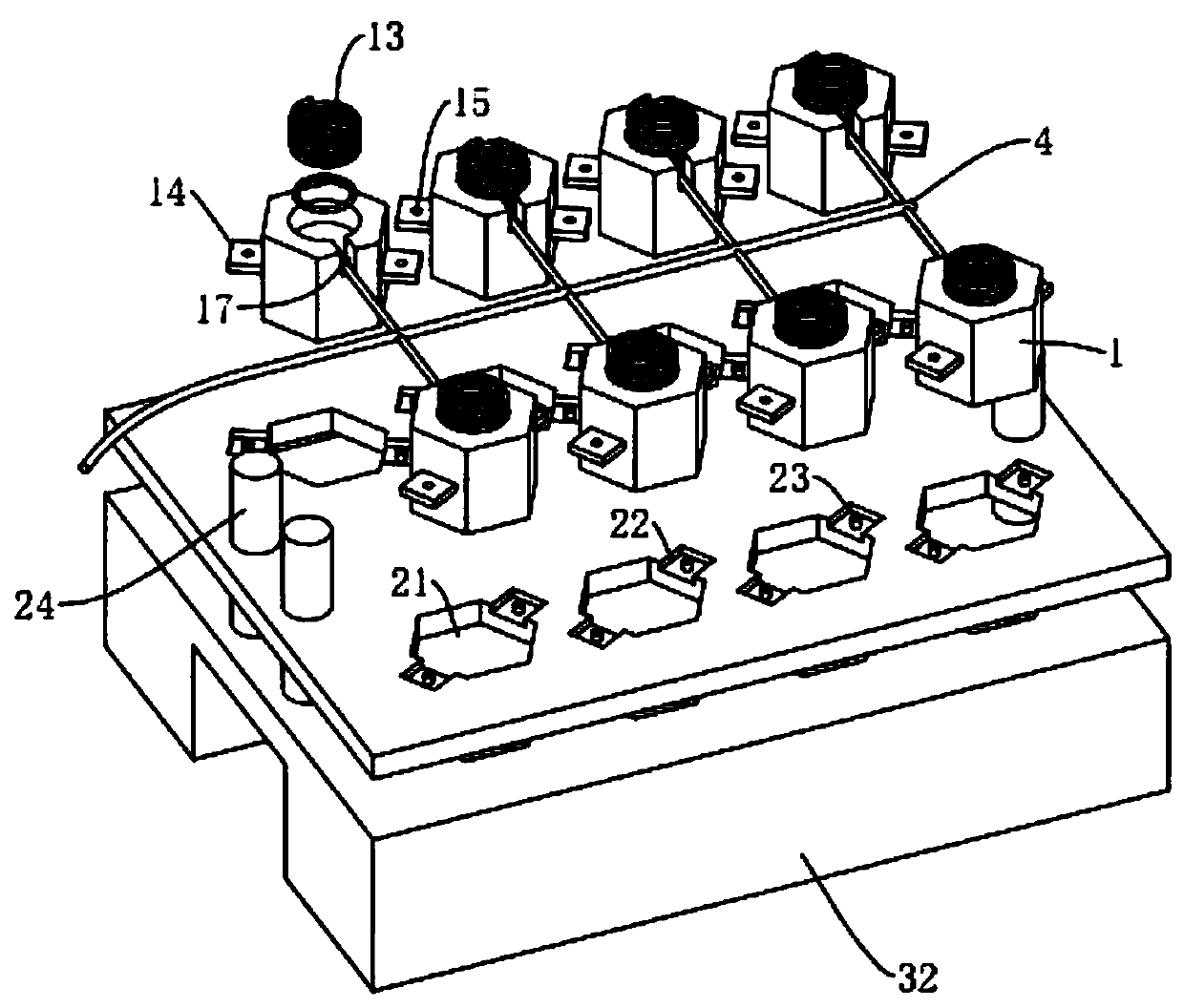

High-temperature packaging method for a wide-band-gap semiconductor silicon carbide power module

ActiveCN108682655AEffective connectivityEasy to wearSemiconductor/solid-state device detailsSolid-state devicesEpoxyComputer module

The invention discloses a high-temperature packaging method for a wide-band-gap semiconductor silicon carbide power module and relates to the technical field of silicon carbide power module packaging.The high-temperature packaging method comprises the follow steps: S1, modulating an epoxy resin material, placing the epoxy resin material into a mold for shaping, and obtaining a housing after demoulding; S2, opening holes in housings of silicon carbide power devices, and placing elastic members in the holes; S3, mounting the silicon carbide power devices one by one according to mounting positions reserved on an isolation liner plate; S4: making the upper housing and the lower housing draw close to the isolation liner plate, tightening bolts on studs after the housing is buckled, and then completing packaging, wherein the elastic members stay in a compressed state after packaging. According to the scheme of the invention, the silicon carbide power devices are positioned through the prefabricated housing and a buffer is obtained before external force is transmitted to the silicon carbide power devices, so the silicon carbide power devices in the packaged body are better protected.

Owner:江苏芯澄半导体有限公司

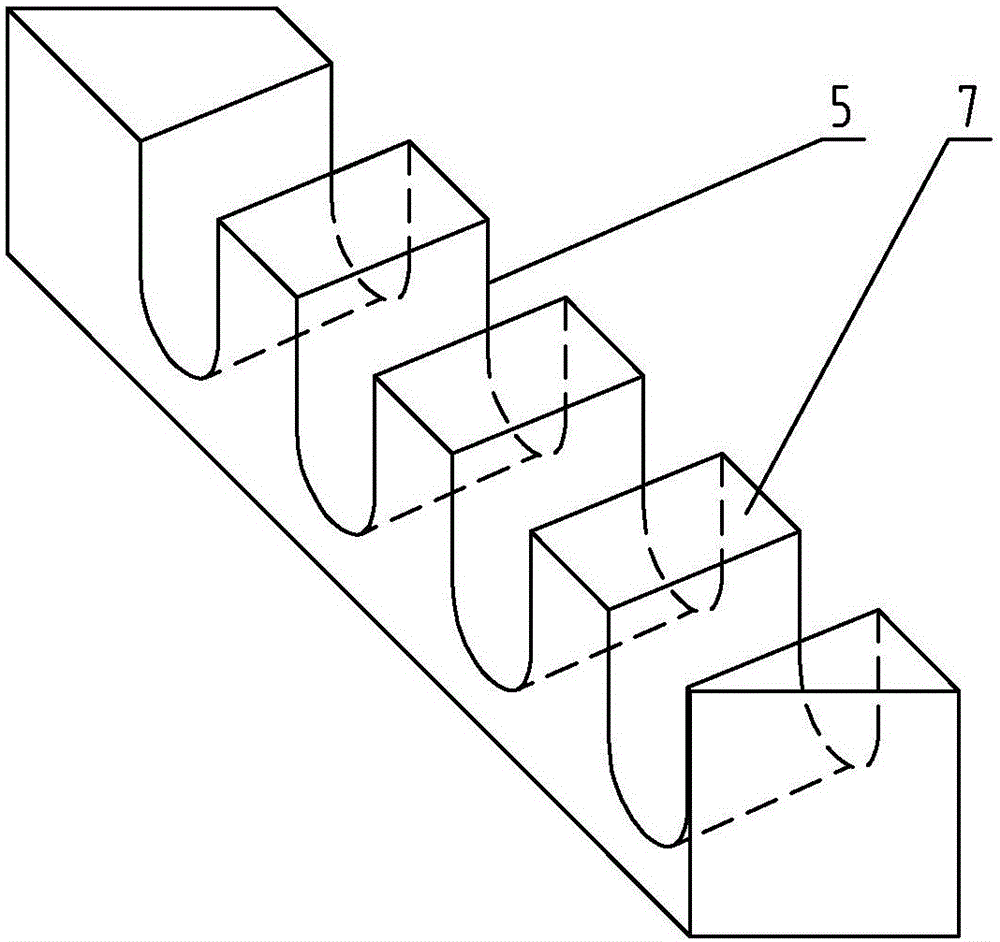

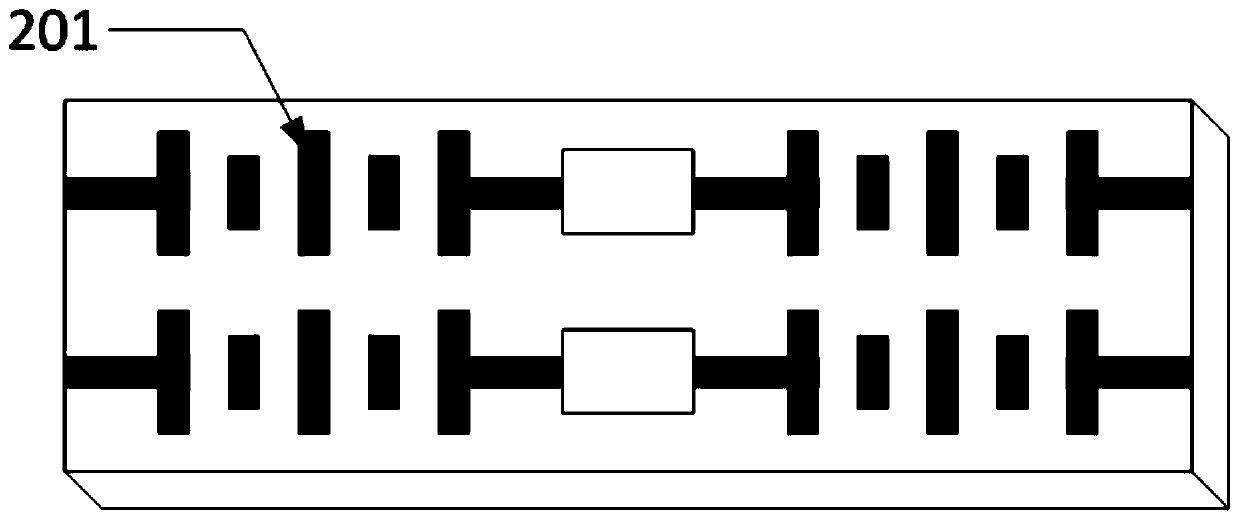

A method of building outer leaf walls using breathing sandwich wall blocks

ActiveCN104652686BEffective connectivityGuarantee the quality of the projectWallsStructural engineeringEngineering

The invention relates to a breathing-type sandwich wall building block and an outer wythes building method utilizing the same, and relating to a wall body building block and a building method thereof and solving the problems of wall body mildewing caused by that rain water and wet gas inside the heat-insulating layer of the traditional sandwich wall are difficult to discharge. The breathing-type sandwich wall building block comprises a building block body, two vertical through holes, two semi-circular grooves and a plurality of U-shaped grooves, wherein the two vertical through holes are symmetrically formed on the upper end surface of the building block body respectively; each vertical through hole is respectively formed along the height direction of the building block body, the semi-circular grooves are respectively formed between the front side wall of each vertical through hole and the front end surface of the building block body, the two semi-circular grooves are symmetrically formed on the lower end surface of the building block body respectively; and the plurality of U-shaped grooves are uniformly distributed on the upper end surface of the building block body.

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com