Method for constructing block-integrating air-layer-free air permeable type sandwich wall

An air layer, sandwich wall technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of reducing the structural stability and thermal insulation performance of the wall, affecting the use of households, and growing hair and mildew on the wall, so as to improve the overall performance, Reduce construction difficulty and enhance overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

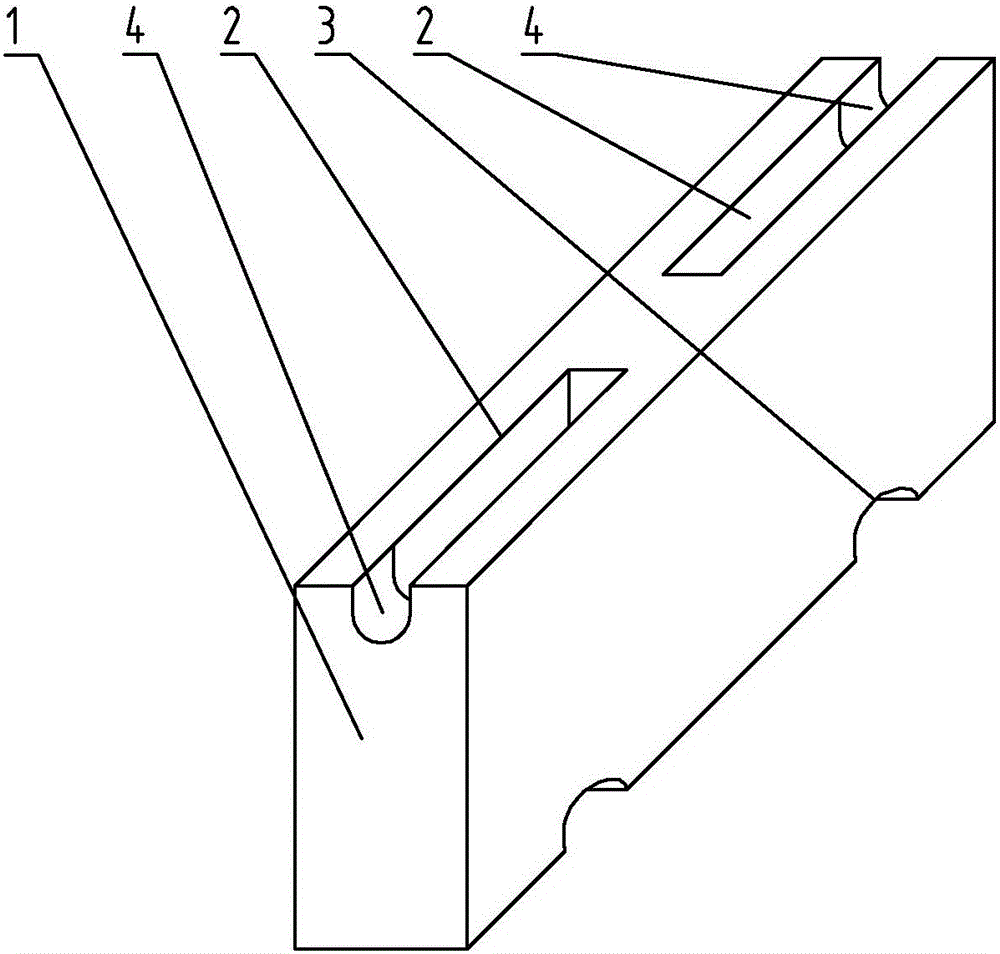

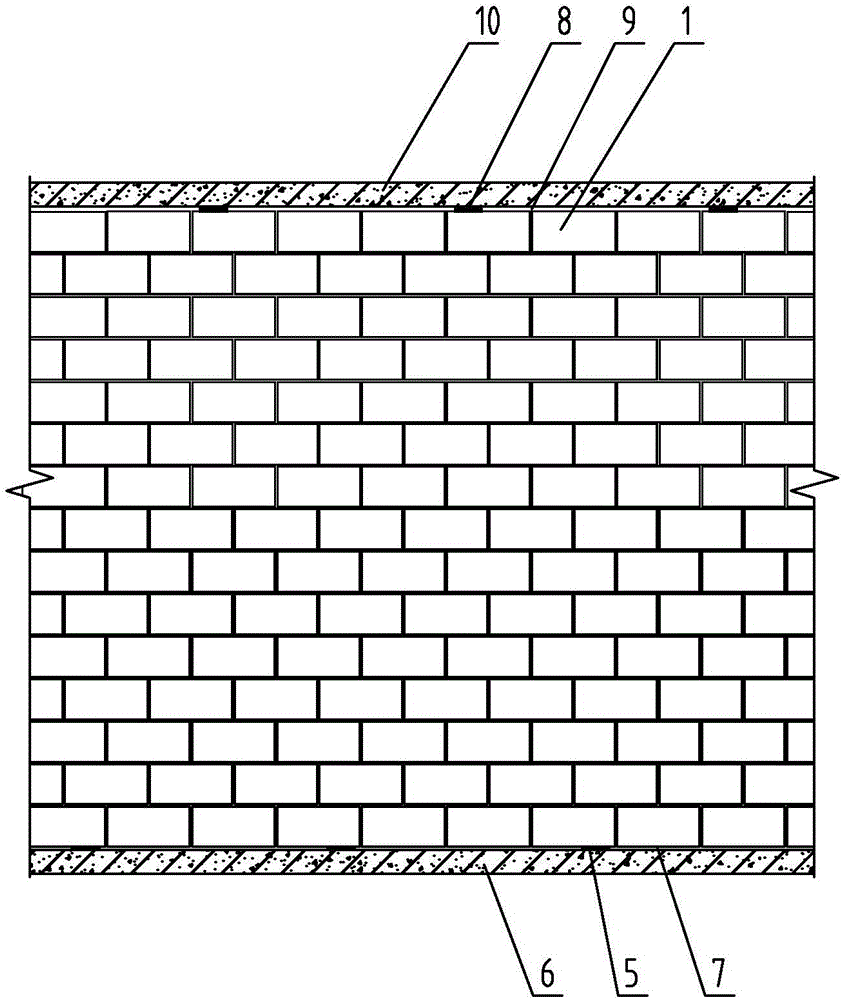

[0028] Specific implementation mode one: combine Figure 1 to Figure 7 To illustrate this embodiment, the method for building a block-mode air-layer-free breathing sandwich wall in this embodiment is characterized in that: the method includes the following steps:

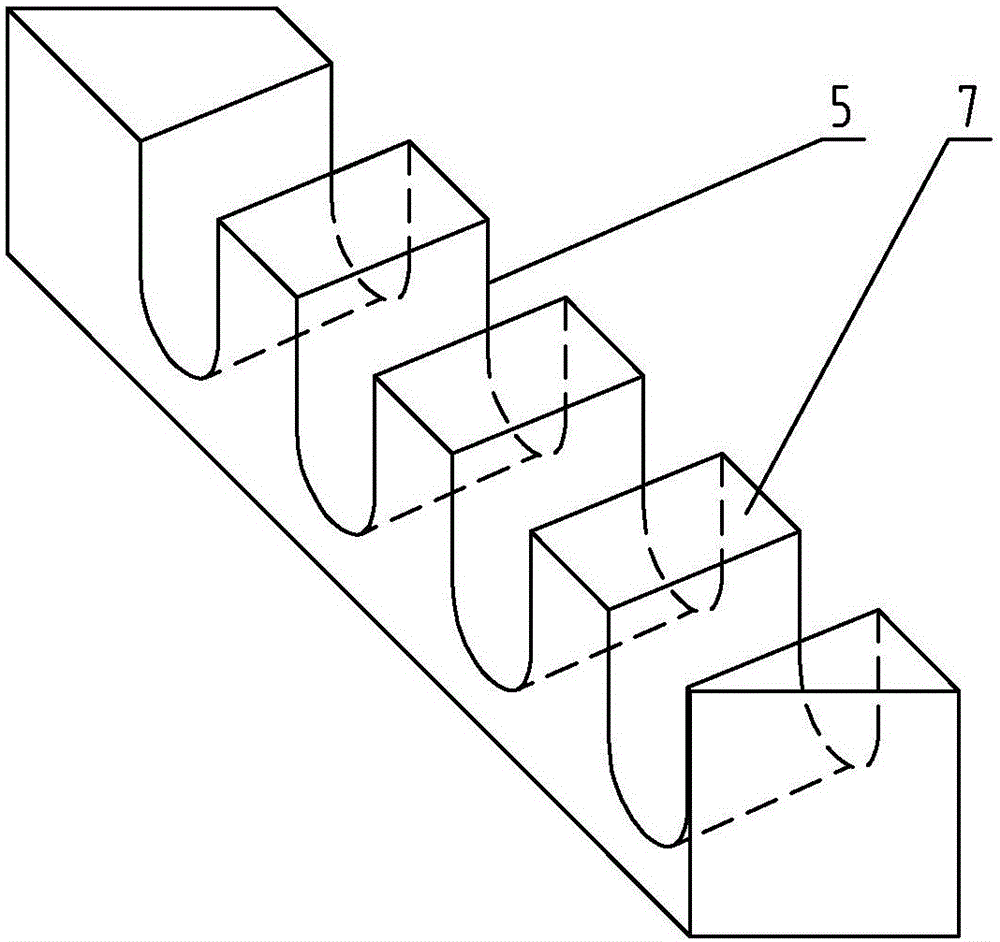

[0029] Step 1: Masonry inner leaf wall: first lay the bottom skin gray joint 7 on the upper end surface of the bottom lintel 6, and build the inner leaf wall on the inner side of the bottom skin gray joint 7;

[0030] Step 2: laying the insulation layer: laying a layer of insulation layer on the outer surface of the inner leaf wall;

[0031] Step 3: Set air intake through holes 5: set a group of air intake through holes 5 on the front face of the bottom skin gray seam 7, each air intake through hole 5 is U-shaped, and the upper end surface of each air intake through hole 5 They are respectively flush with the upper end faces of the bottom skin gray seams 7, and the horizontal distance between two adjacent air intak...

specific Embodiment approach 2

[0041] Specific implementation mode two: combination Figure 1 to Figure 7 To describe this embodiment, in the third step of this embodiment, each air intake through hole 5 is provided with a first filter. The undisclosed technical features in this embodiment are the same as those in the first embodiment. Such a design can effectively prevent sundries and insects from entering and blocking the air outlet through hole 8 .

specific Embodiment approach 3

[0042] Specific implementation mode three: combination Figure 1 to Figure 7 Describe this embodiment, the axis of each air intake through hole 5 along the length direction in the step three of this embodiment forms an acute angle with the front end face of the bottom skin gray seam 7, and the front and rear end faces of each air intake through hole 5 Staggered settings. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment. This design can effectively prevent rainwater from splashing into the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com