Prefabricated concrete frame structure with rear-mounted longitudinal bars in prefabricated beam column built-in corrugated steel pipes and manufacturing method thereof

A technology of prefabricated concrete and corrugated steel pipes, which is applied in the direction of building construction and construction, can solve the problems of poor connection effect, complicated bolt connection process, and low construction efficiency, and achieve simple and fast construction, strong operability, and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

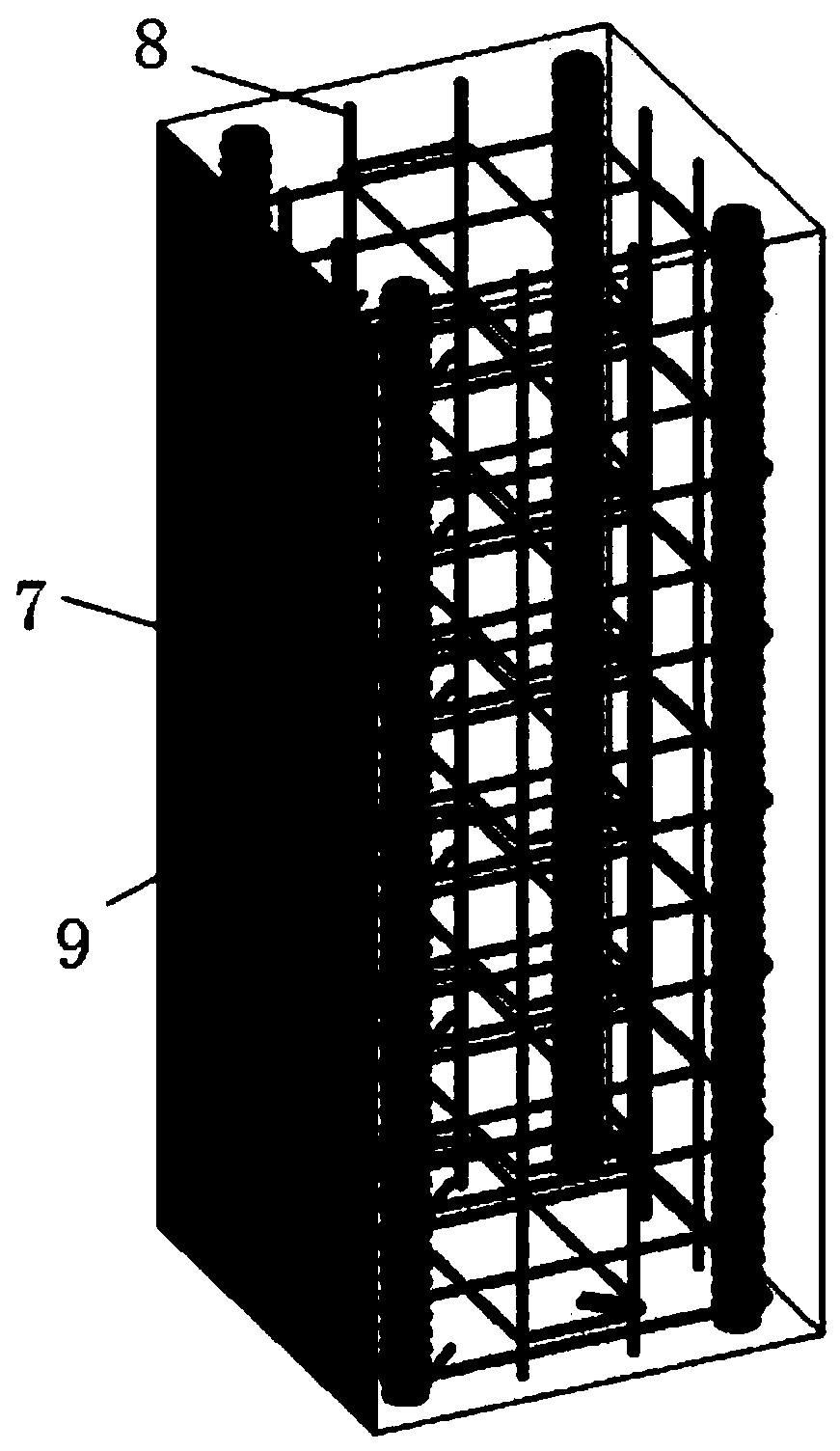

[0027] Specific Embodiment 1: In this embodiment, a prefabricated concrete frame structure with post-installed longitudinal reinforcement in corrugated steel pipes built in prefabricated beams and columns includes prefabricated concrete columns 2 and prefabricated concrete composite beams 10; the prefabricated concrete columns 2 and precast concrete Side-span side node connection, side-span mid-node connection and mid-span mid-node connection are performed between the composite beams 10;

[0028] A single prefabricated concrete column 2 is provided with corrugated steel pipes 7 at four corners and finish-rolled rebar 11; the finish-rolled rebar 11 is located in the center of the corrugated steel pipe 7, and the finish-rolled steel pipe 7 is realized by pouring micro-expansion fine stone self-compacting concrete into the corrugated steel pipe 7 Reliable connection of threaded steel 11 and corrugated steel pipe 7; stirrups 9 and small-diameter hot-rolled steel bars 8 are arranged...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that the strength of the micro-expanded fine stone self-compacting concrete is not lower than that of the precast concrete column 2 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: In this embodiment, a manufacturing method of a prefabricated beam-column built-in corrugated steel pipe with prefabricated concrete frame structure with post-installed longitudinal reinforcement is specifically carried out according to the following steps:

[0032] 1. Bind corrugated steel pipes 7, small-diameter hot-rolled steel bars 8 and stirrups 9 to form a steel bar skeleton according to the design requirements; formwork is placed on the pedestal and concrete is poured to obtain precast concrete columns 2;

[0033] 2. Bind the full-length corrugated steel pipe 1, U-shaped stirrup 3 and waist bar 4 into a steel skeleton, and electroslag weld the U-shaped stirrup 3, full-length corrugated steel pipe 1 and waist bar 4; the thickness of the protective layer of the steel bar on the beam side not less than 45mm; extrude the composite beam to form a through hole 6 along the beam length; after the concrete of the composite beam is hardened, rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com