Carbon dioxide phase-change coal seam cracking guiding perforating device and outburst-preventing and scour-preventing method

A technology of carbon dioxide and phase change, applied in safety devices, earthwork drilling, gas discharge, etc., can solve problems such as limited communication of fracturing channels, achieve increased fracturing area, good fracturing effect, and increased permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

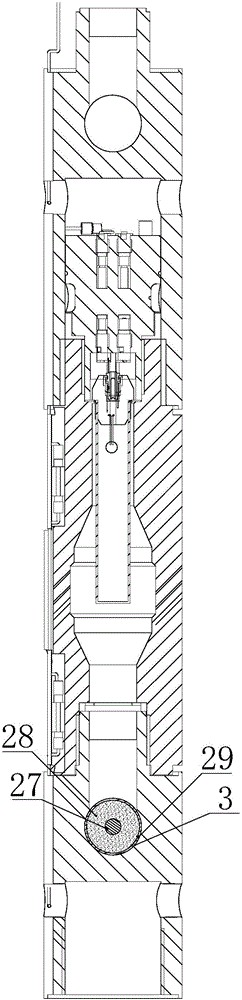

[0018] see figure 1 , a carbon dioxide phase change coal seam fracturing guide perforation device, including a carbon dioxide phase change coal seam cracker, characterized in that: a perforating charge 27 is placed in the explosion vent hole 3 of the carbon dioxide phase change coal seam cracker, and the explosion vent hole is plugged Head 29 blocked.

[0019] Wherein: the perforating charge 27 is placed in the explosion venting hole 3 and sealed with packaging material 28, and the plug 29 for the blast venting hole is made of plastic material.

[0020] Wherein: the packaging material 28 is yellow clay, and the perforating charge 27 is porous ceramsite.

Embodiment 2

[0022] see figure 1 , a carbon dioxide phase change coal seam fracturing guide perforation device, including a carbon dioxide phase change coal seam cracker, characterized in that: a perforating charge 27 is placed in the explosion vent hole 3 of the carbon dioxide phase change coal seam cracker, and the explosion vent hole is plugged Head 29 blocked.

[0023] Wherein: the perforating charge 27 is placed in the explosion venting hole 3 and sealed with packaging material 28, and the plug 29 for the blast venting hole is made of plastic material.

[0024] Wherein: the packaging material 28 is resin, and the perforating charge 27 is porous ceramsite.

Embodiment 3

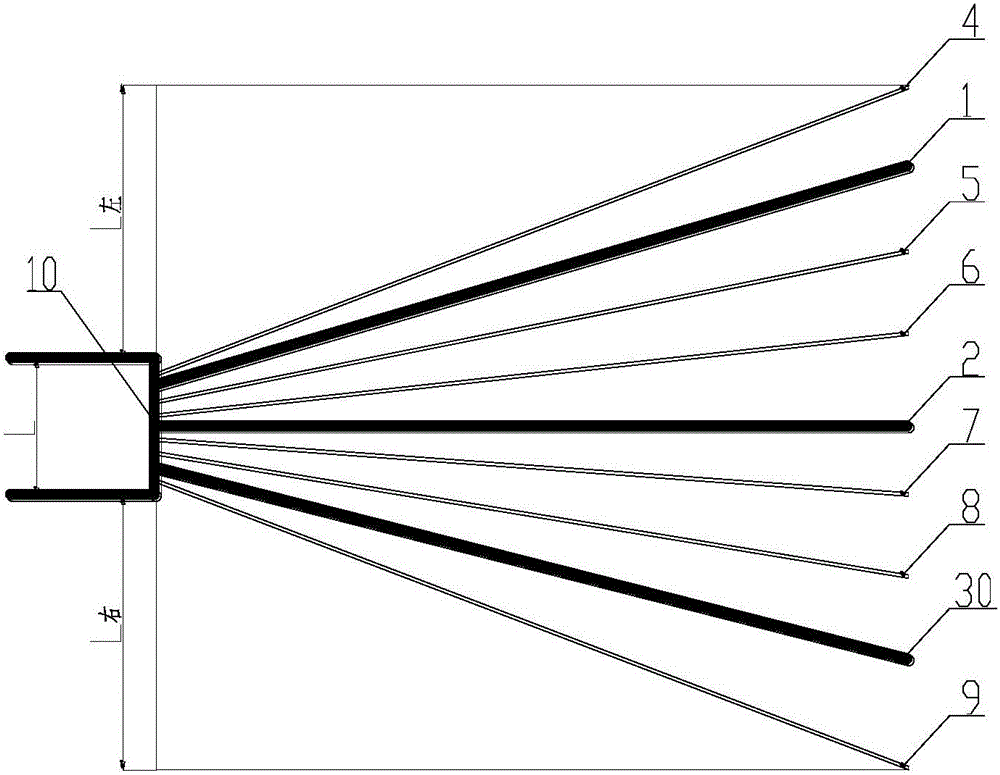

[0026] see figure 2 , a method of anti-outburst and anti-shock, including ① starting at the same height of 1 meter at the head of the excavation working face 10, drilling a group of fan-shaped drilling holes at an equidistant distance of 0.5 meters on the roof of the parallel coal seam, consisting of blast holes and control holes, each blast hole Both sides are control holes, the specific order is control hole one 4, blast hole one 1, control hole two 5, control hole three 6, blast hole two 2, control hole four 7, control hole five 8, blast hole three 30, control hole three Hole six 9, ② Put a carbon dioxide phase change coal seam fracturing guide perforation device into all blast holes, including blast hole one 1, blast hole two 2, blast hole three 30, and the carbon dioxide phase change coal seam in blast hole one 1 The two explosion venting holes 3 of the fracturing-guiding perforation device are respectively aligned with the control hole 1 4 and the control hole 2 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com