A method of building outer leaf walls using breathing sandwich wall blocks

A sandwich wall and block technology, applied to walls, buildings, building components, etc., can solve the problems of long hairs and mildew, difficult to discharge the wall, etc., to avoid condensation, reduce construction difficulty, and ensure the effect of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

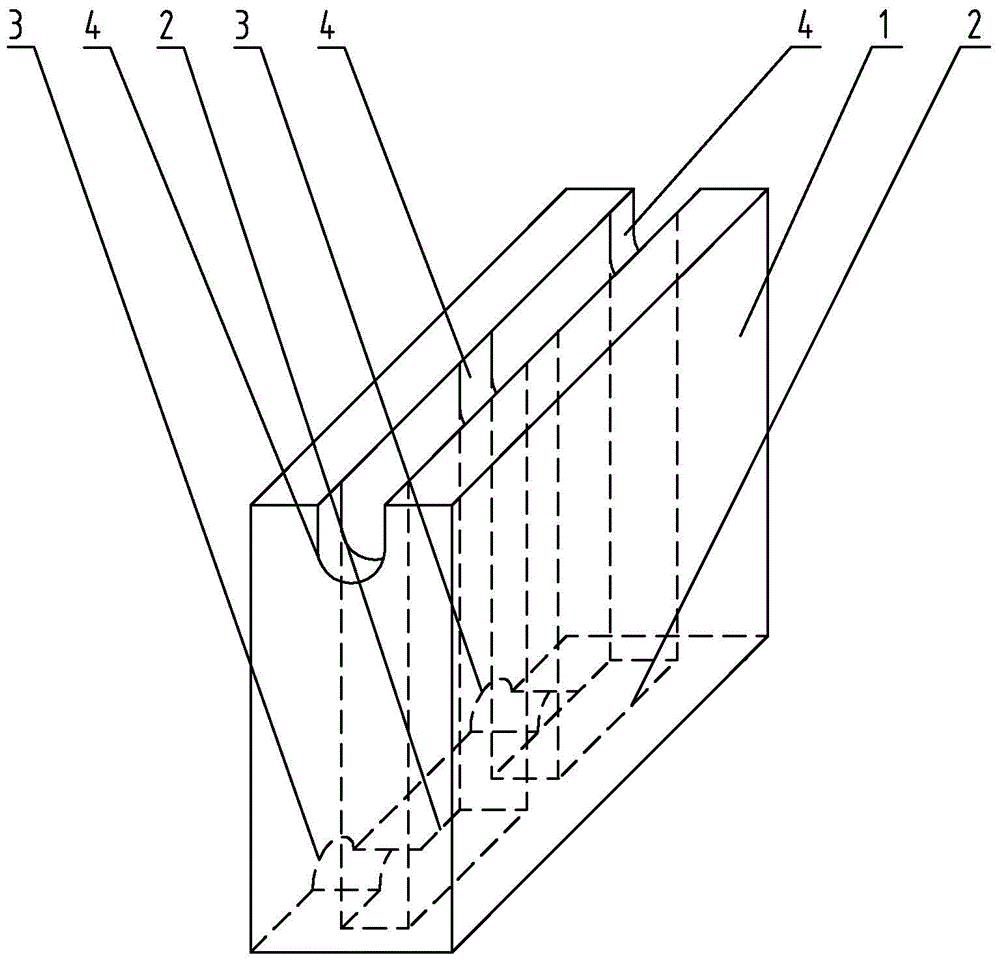

[0013] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, a breathing sandwich wall block described in this embodiment includes a block body 1, two vertical through holes 2, two semicircular grooves 3 and a plurality of U-shaped grooves 4, two vertical through holes Holes 2 are arranged symmetrically on the upper end surface of block body 1 respectively, and each vertical through hole 2 is respectively arranged along the height direction of block body 1, and the front side wall of each vertical through hole 2 is connected with the side wall of block body 1. A semi-circular groove 3 is respectively provided between the front end surfaces, two semi-circular grooves 3 are arranged symmetrically on the lower end surface of the block body 1 respectively, and a plurality of U-shaped grooves 4 are uniformly arranged on the upper end surface of the block body 1 .

[0014] In such a design, multiple U-shaped grooves 4 of the block body 1 are ...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 The present embodiment will be described. The number of the plurality of U-shaped grooves 4 in this embodiment is three. The undisclosed technical features in this embodiment are the same as those in the first embodiment. Such a design makes the mortar joint fully contact with the block body 1, thereby ensuring the strength of the entire outer leaf wall.

specific Embodiment approach 3

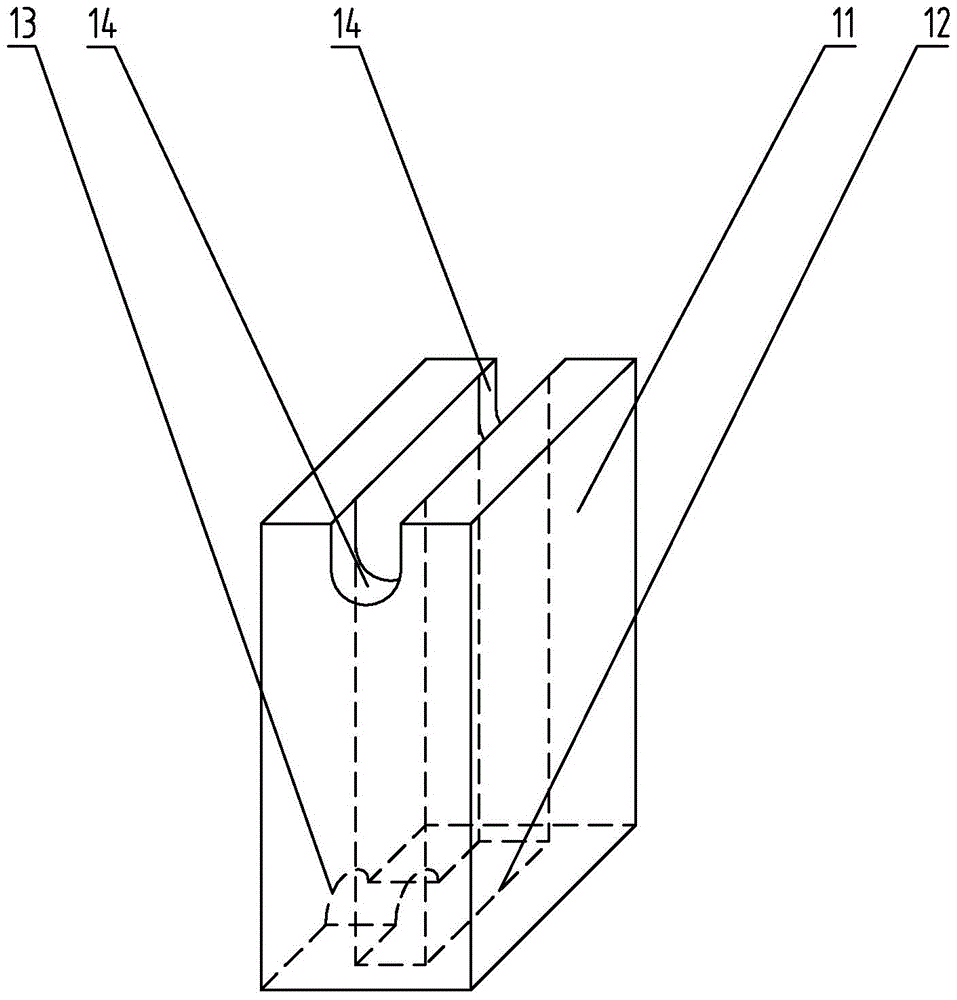

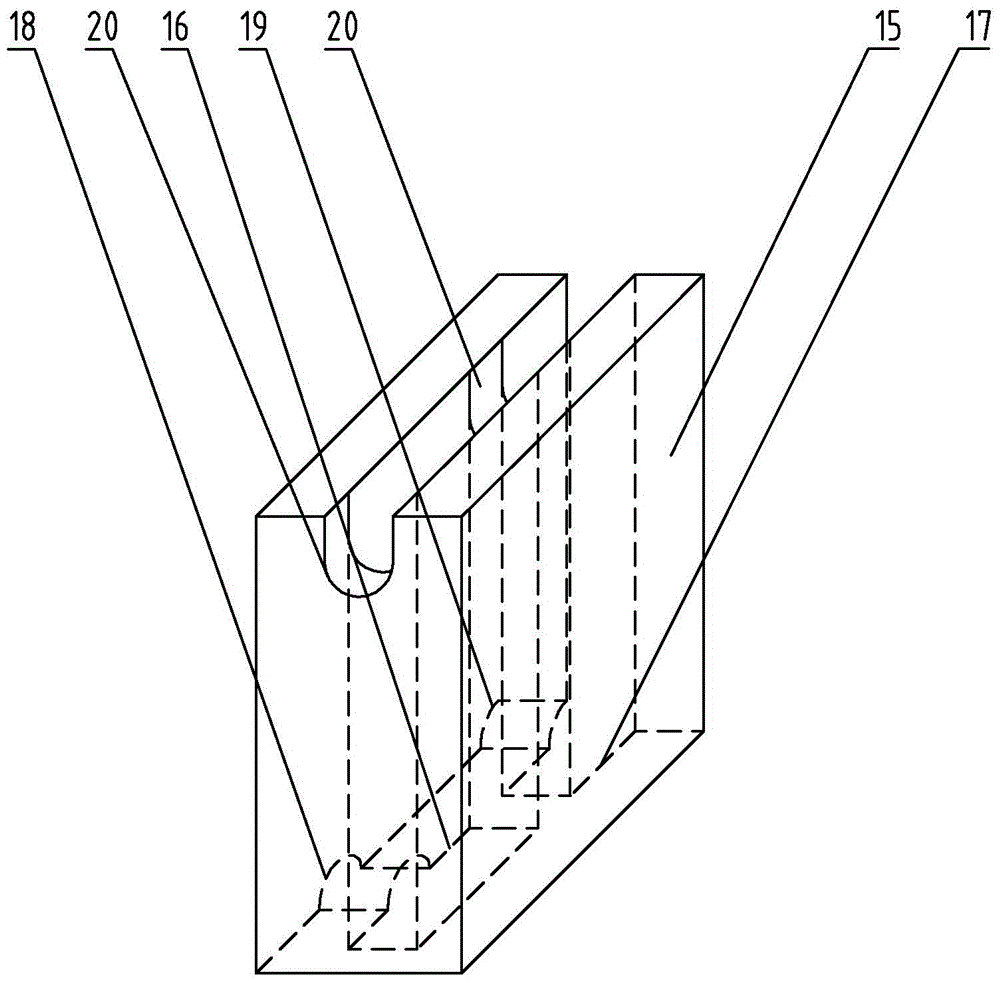

[0020] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the width of each vertical through hole 2 in this embodiment is not less than 3cm, the groove depth of each semicircular groove 3 is not less than 2.5cm, and the groove depth of each U-shaped groove 4 is not less than 5cm. The width of the first special-shaped block through hole 12 is not less than 3cm, the groove depth of the first special-shaped block semicircular groove 13 is not less than 2.5cm, the groove depth of each first special-shaped block U-shaped groove 14 is not less than 5cm, and the second special-shaped block through The width of the hole 16 is not less than 3cm, the width of the second special-shaped block through groove 17 is not less than 3cm, the groove depth of the second special-shaped block semicircular groove 18 is not less than 2.5cm, and the groove depth of the second special-shaped block quarter circular groove 19 Not less than 2.5cm, and the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com