High-temperature packaging method for a wide-band-gap semiconductor silicon carbide power module

A wide-bandgap semiconductor and power module technology, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as damage to silicon carbide power devices, achieve effective connectivity, improve compression limit, The effect of good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

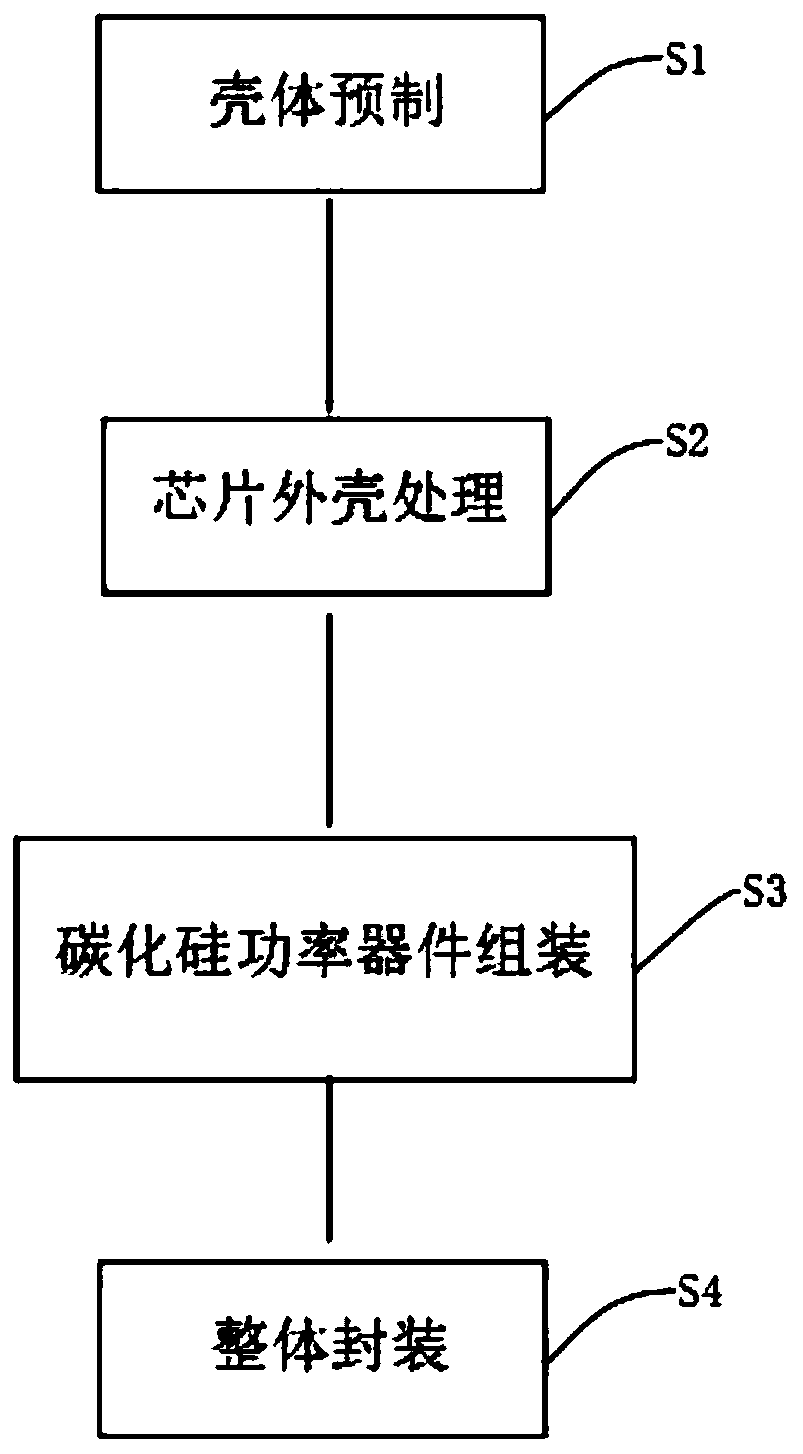

[0033] A high-temperature packaging method for a wide bandgap semiconductor silicon carbide power module, comprising:

[0034] S1: The casing 3 is prefabricated. After the epoxy resin material is prepared, it is put into a mold for finalizing the shape, and the casing 3 is obtained after demoulding. A slot 34 for placing the silicon carbide power device 1 is reserved on the opposite surface of the shell 3 to which the chip belongs, and dibutyl phthalate or dioctyl phthalate is added to the epoxy resin material, and the epoxy The ratio of resin to dibutyl phthalate is 1:0.05~1:0.03, and the ratio of epoxy resin to dioctyl phthalate is 1:0.05~1:0.02;

[0035] S2: Process the chip case 11, open a hole on the case of the silicon carbide power device 1, place an elastic member 13 in the hole, and extend the hole to the inside of the silicon carbide power device 1 to the terminal of the built-in chip to become a wiring hole 16, the wiring hole 16 The side wall is provided with a wi...

Embodiment 2

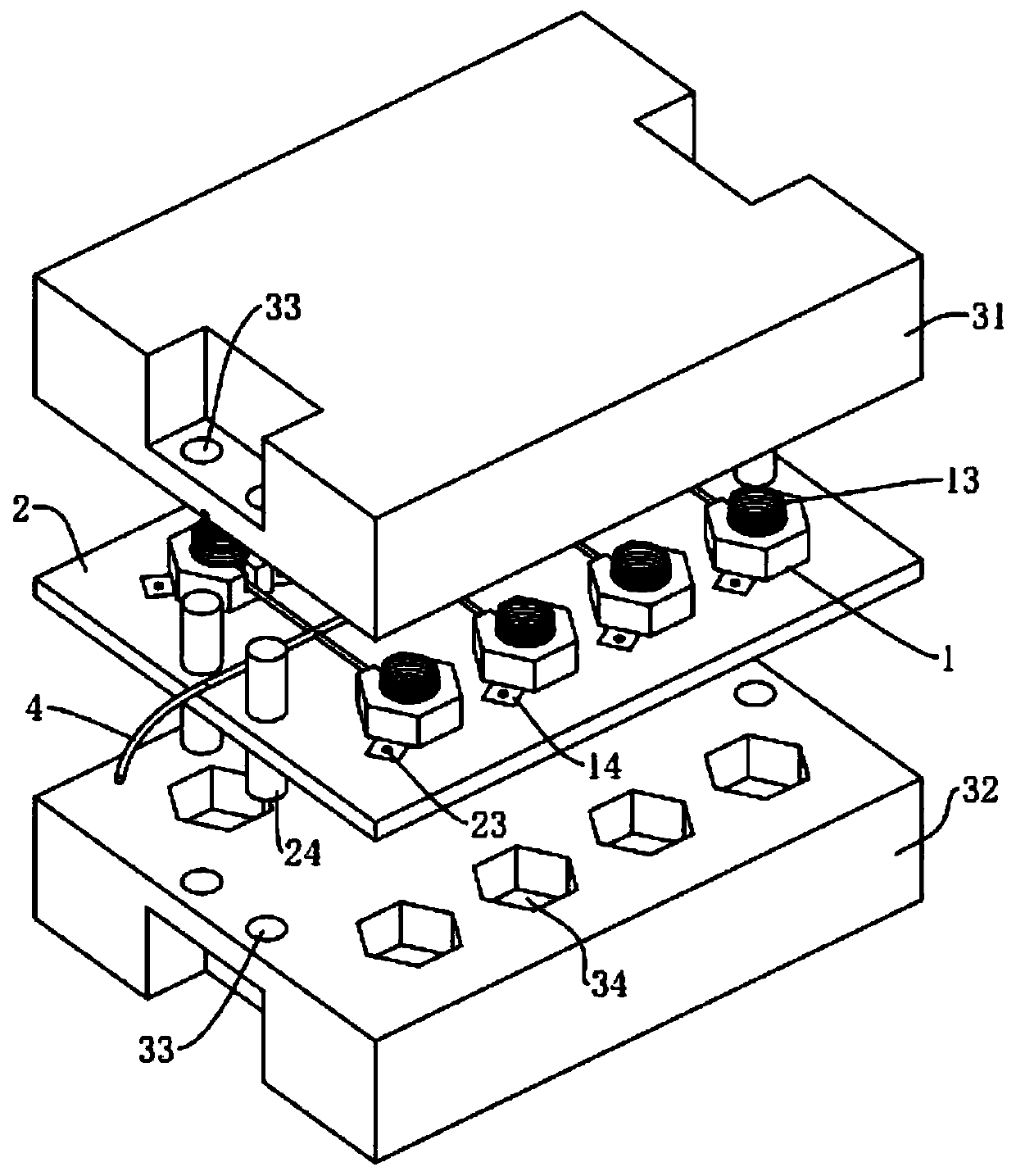

[0039] This embodiment provides a high-temperature packaging structure of a wide-bandgap semiconductor silicon carbide power module using the method of Embodiment 1, as shown in the figure.

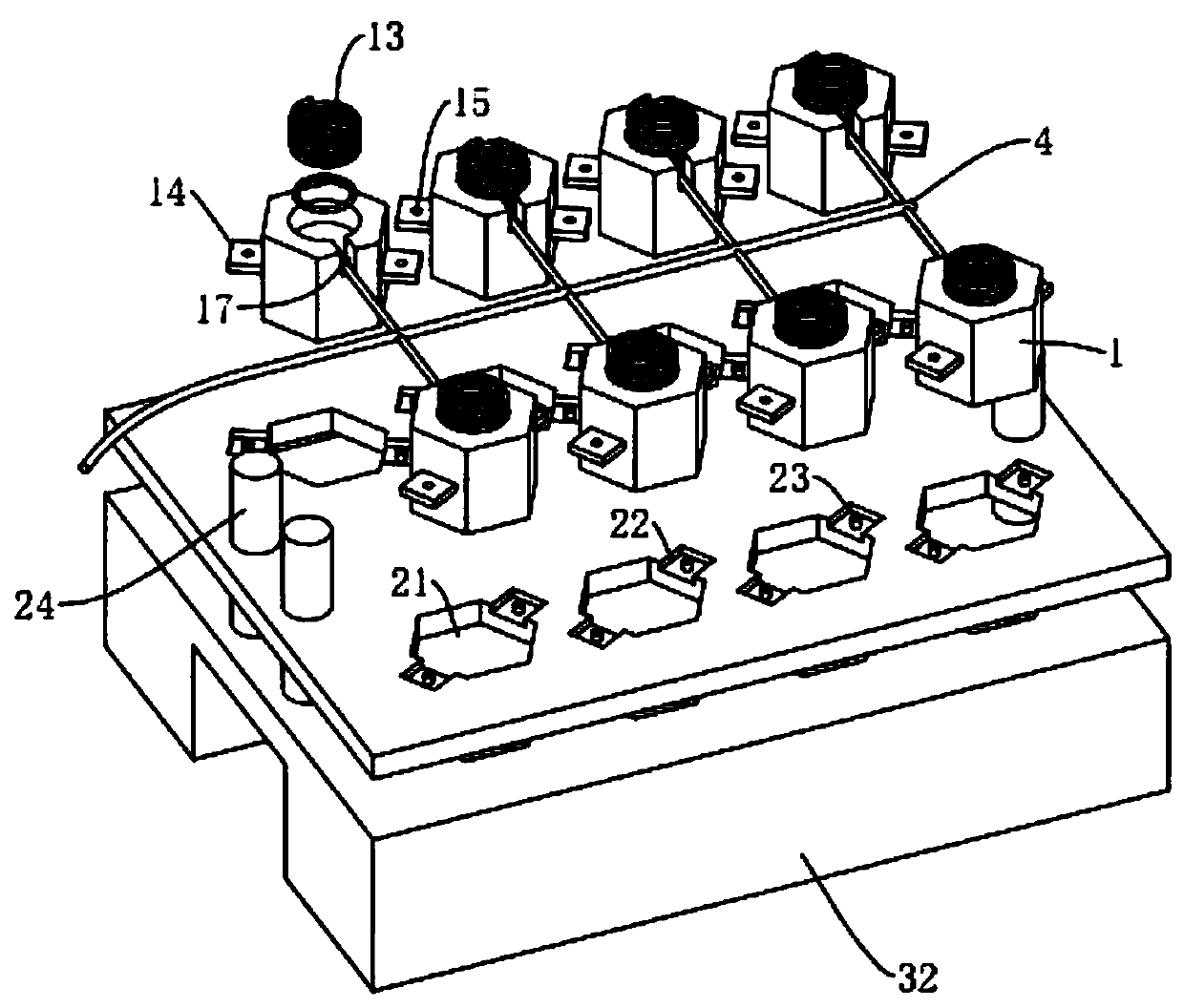

[0040] The high-temperature packaging method of a wide bandgap semiconductor silicon carbide power module includes a silicon carbide power device 1 and a wiring group 4 connecting each silicon carbide power device 1, and also includes an isolation liner 2, and the silicon carbide power device 1 is installed on the On the isolation liner 2, and every two silicon carbide power devices 1 form a group, the wiring channels 17 of each group of two silicon carbide power devices 1 are arranged oppositely, and the casing 3 of the silicon carbide power device 1 is provided outside the isolation board , The housing 3 includes an upper housing 31 and a lower housing 32 respectively arranged on two sides of the isolation plate.

[0041] The silicon carbide power device 1 includes a chip casing 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com