Patents

Literature

33results about How to "Obvious effect of energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for underground coal gasification

InactiveCN102287177AEfficient developmentChange areaConstructionsFluid removalMultiple injectionChemical reaction

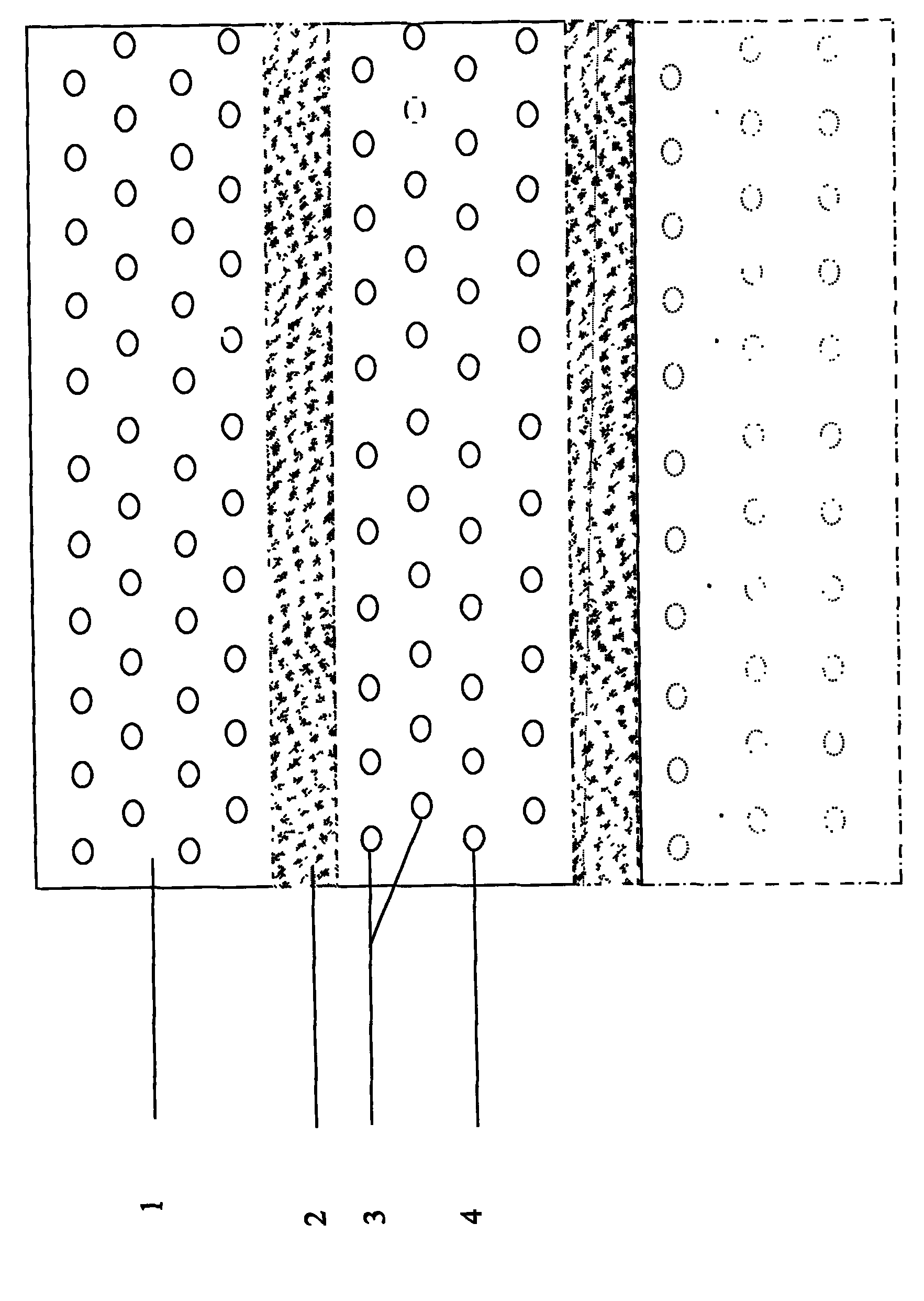

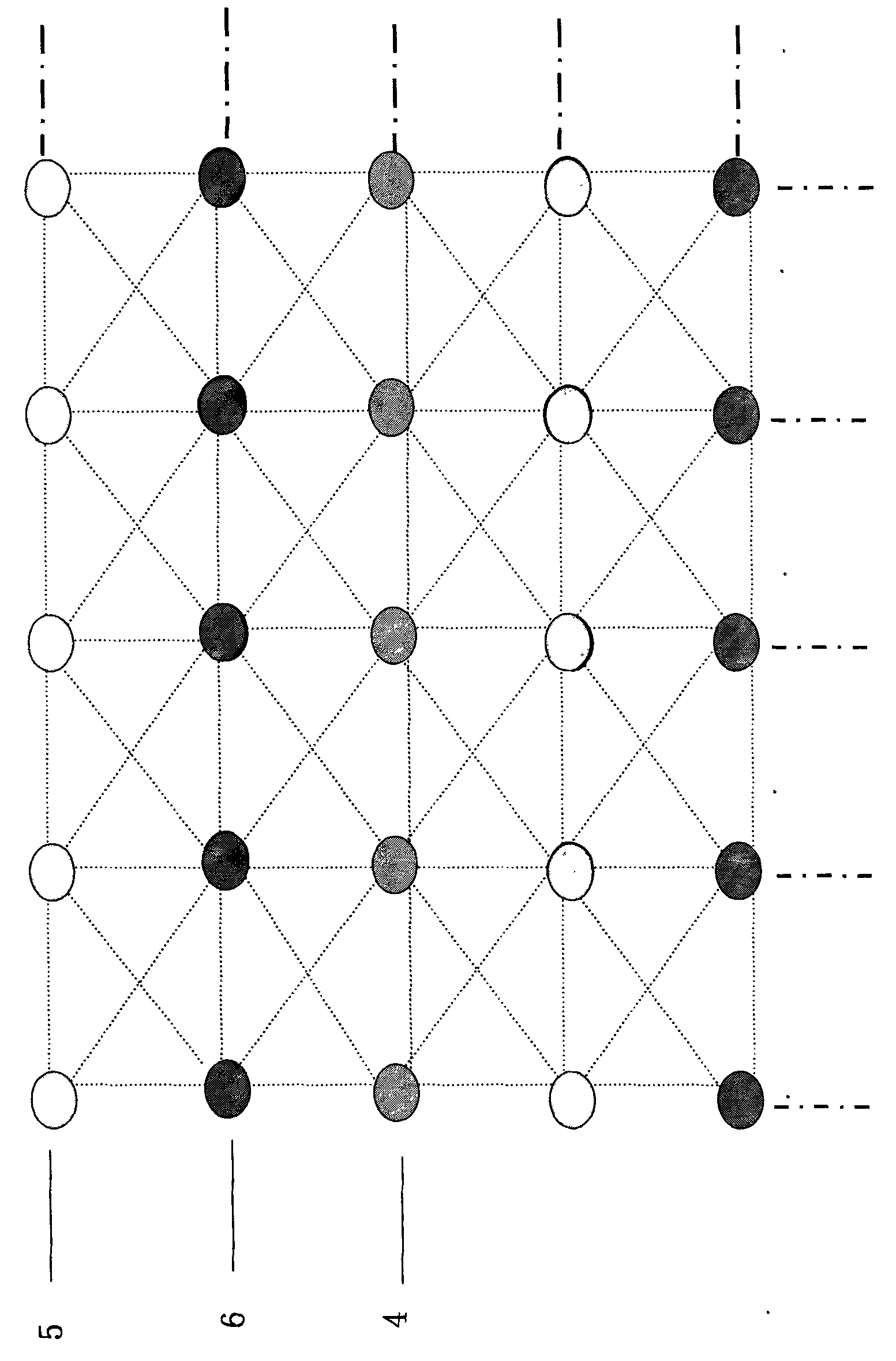

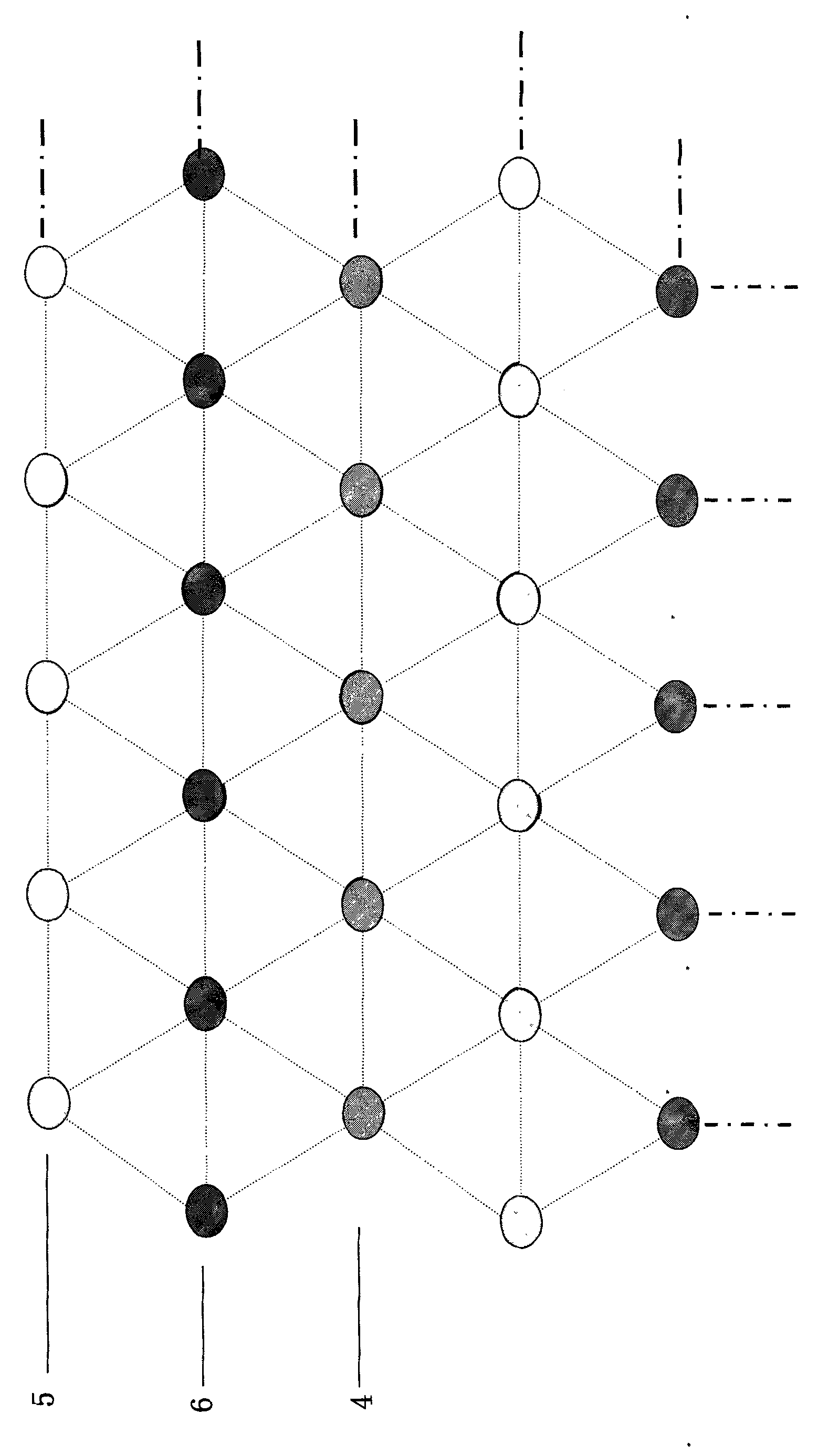

An underground coal gasification method. The method comprises disposing multiple injection wells (3) and gas collection wells (4) in a gasification operation zone; adding a catalyst and a propping agent into injection wells and gas collection wells by means of a fluid medium; fracturing and reforming the coal layer using a fracturing device to form large areas of fissures and cracks; forming gasification paths in the form of directional wells between the injection wells and gas collection wells; adding a gasification agent, a catalyst, and water through the injection wells to cause coal layer combustions and chemical reactions; collecting at the gas collection wells the gas produced by means of collection devices. The fissure paths between the wells formed by reforming large fractures, and the metal mineral particles used as a propping agent for the paths between wells effectively enable the maintenance of the effective communication in the injection well network for long durations; the metal mineral particles also function as a catalyst and an aggregating agent during gasification, thereby substantially enhancing the coal gasification volume.

Owner:秦勇 +2

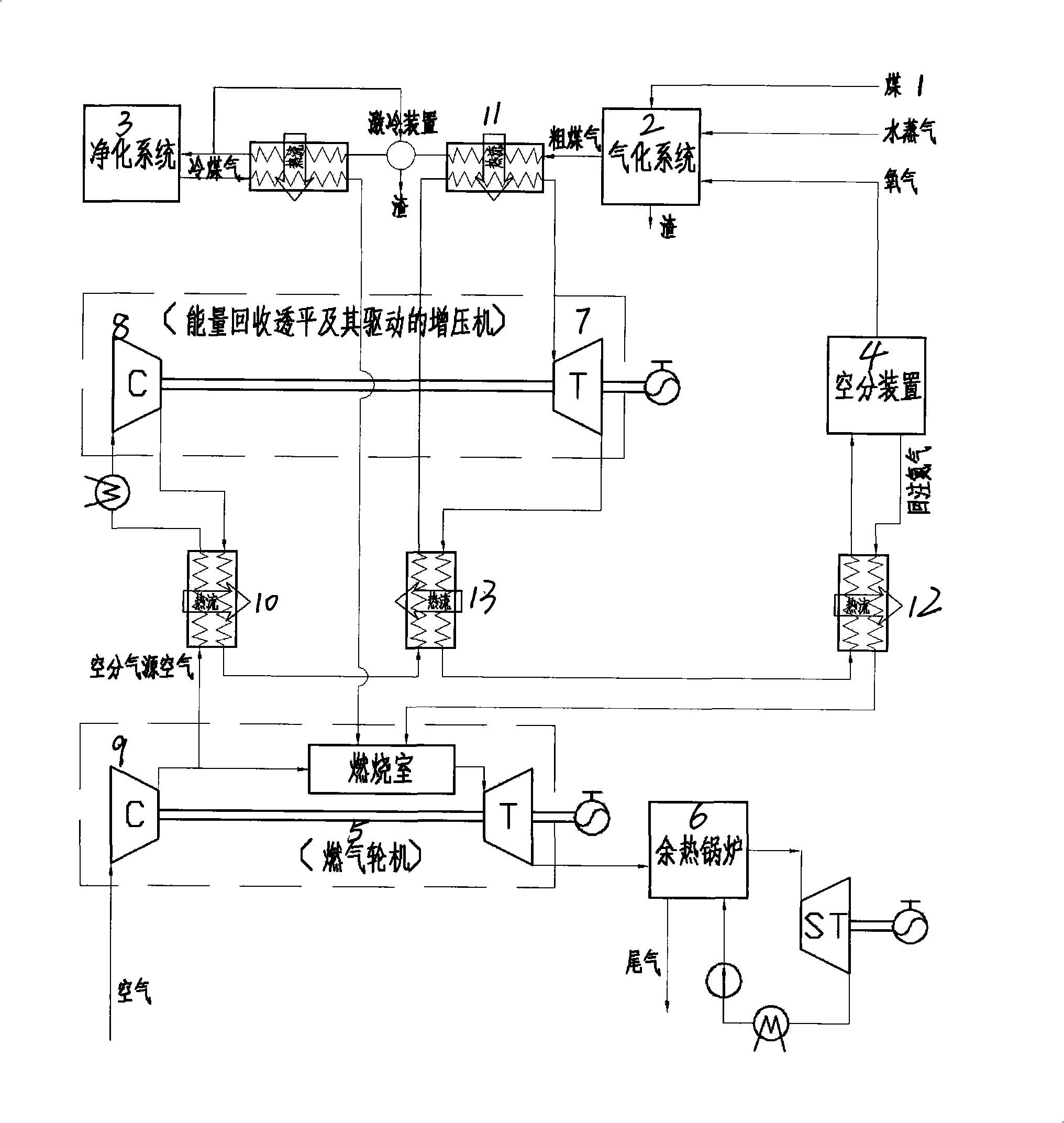

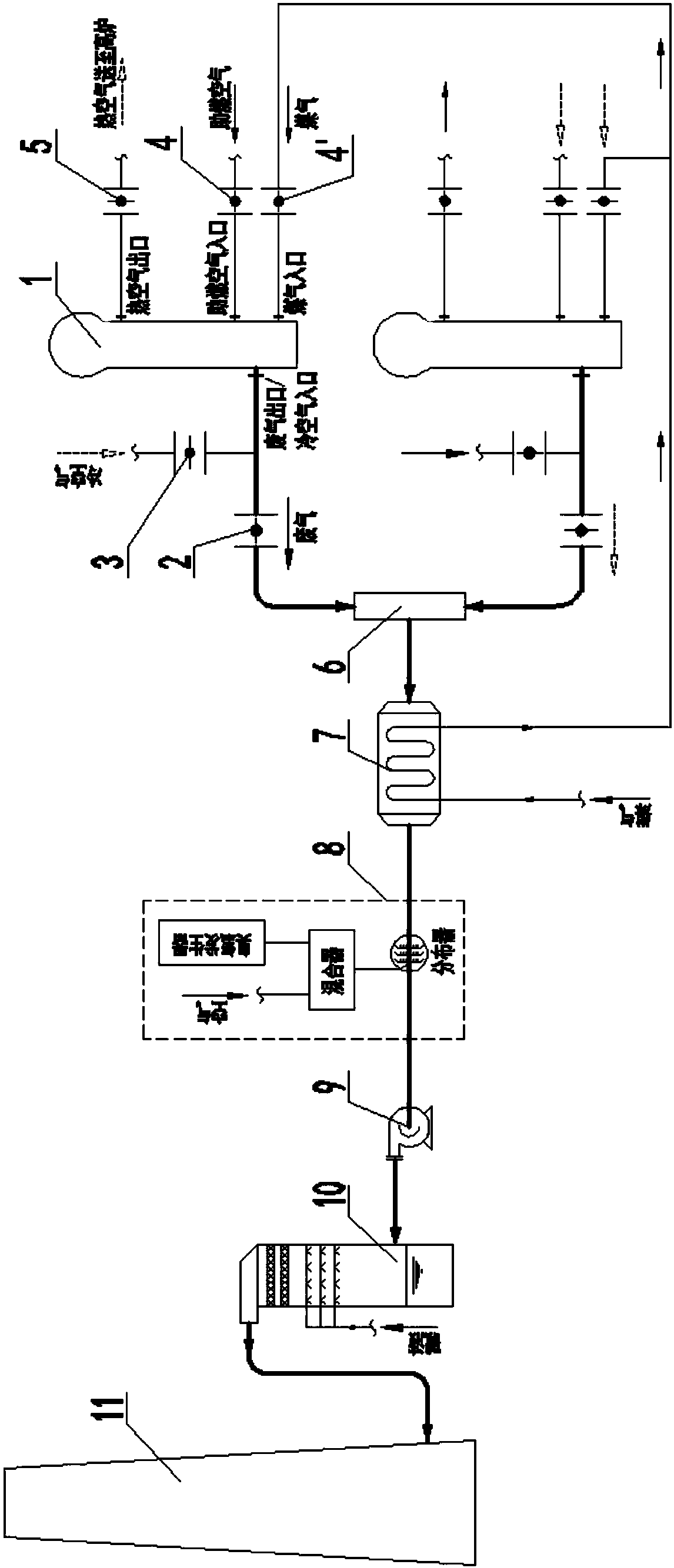

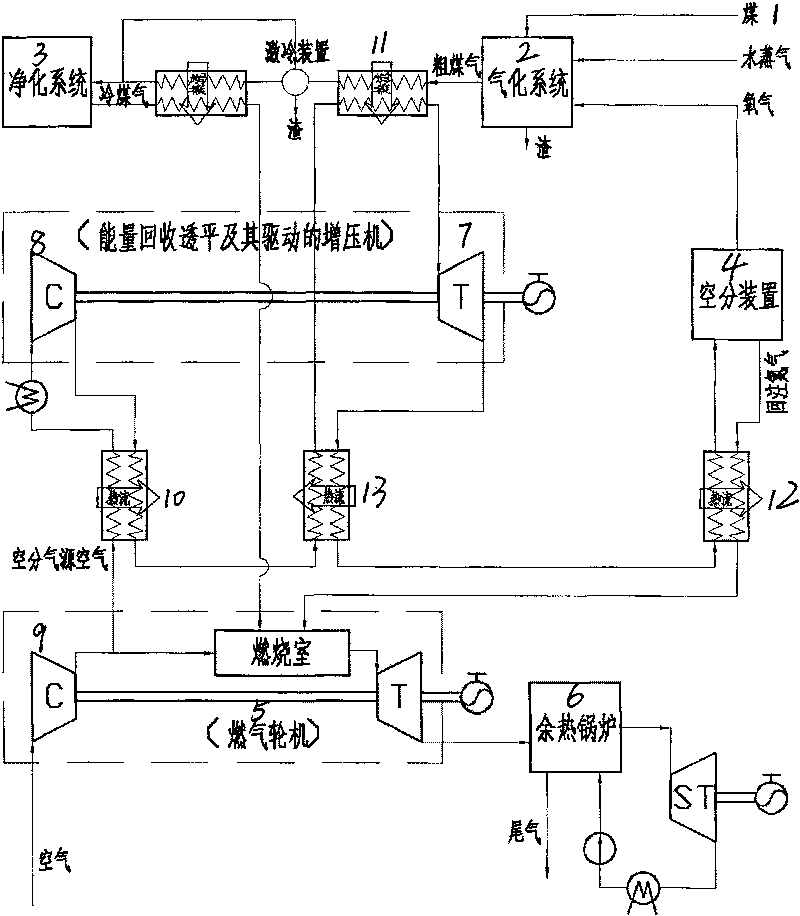

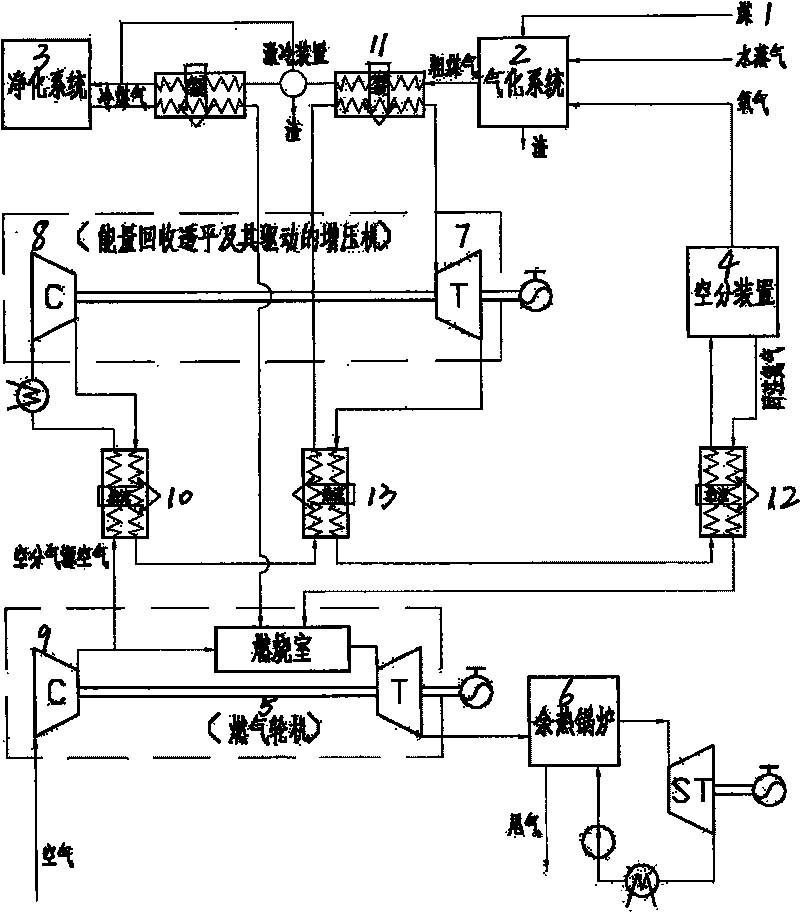

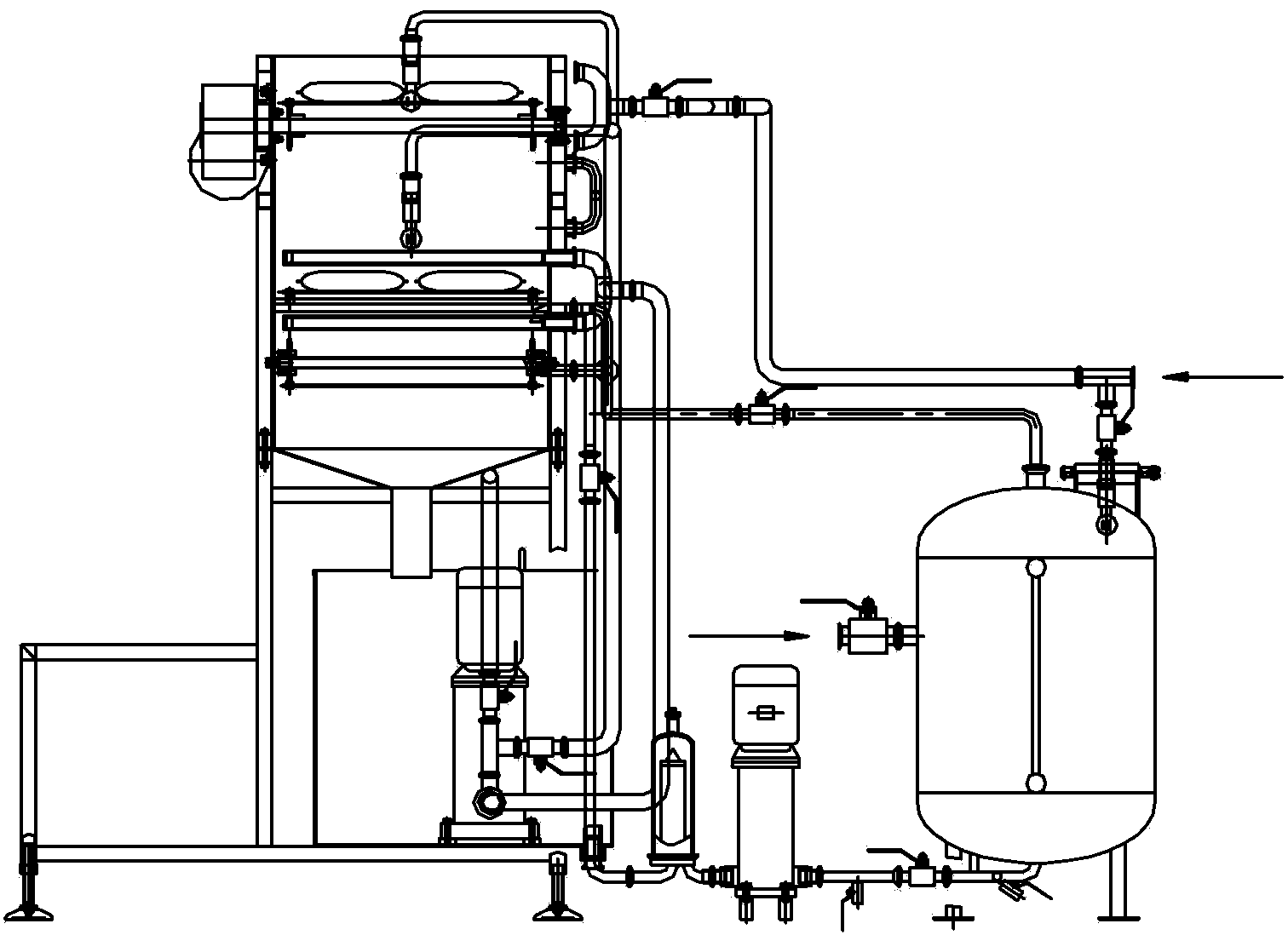

Energy conversion and recovering method of coal gasification supercharging association circulating power generation system

ActiveCN101270689AImprove work efficiencyAchieve recyclingSolidificationLiquefactionThermal energyPressure rise

The invention relates to a method of energy transformation and recovery of a combined cycle generating system of gasified pressure rise. The method comprises two parts, which are the process of gasifying and purifying coal and gas-vapor combined cycle generating process. Coal gas and high-pressure air are mixed and burnt in a combustion chamber and the produced gas with high temperature and pressure drive an expansion machine to do working, thus providing impetus to a gas booster and an electric generator. Sufficient raw material of air provided by gas turbine system is used as working fluid. The working fluid undergoes the processes of heat exchange and heat control, pressurization, repeated reheat and gradual heating up and the heat of high temperature coal gas is obtained from the outlet of a gasification device, thus making the temperature of the working fluid high enough. And a pressurization wheel is dragged and generates electricity by the turbine expansion action of energy recovery. Afterwards, the procedure of heat exchange and temperature control is practiced. At last, the air with proper pressure and temperature is transported to an air segregating unit that comprises a coal gasification device, a purifying device and a gas-vapor combined cycle generation device. In addition, an energy recovery turbine and a gas compressor and a plurality of heat exchangers driven by the energy recovery turbine are added. The method has the characteristics of easy and reliable practice and simple device structure. Moreover, the method can increase working efficiency of heat recovery turbine and output power, so the generating efficiency of IGCC system is raised by 3 percent, thus achieving the effects of saving energy and reducing consumption.

Owner:杭州杭氧透平机械有限公司

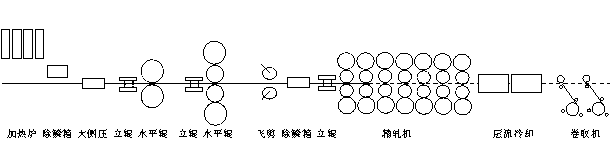

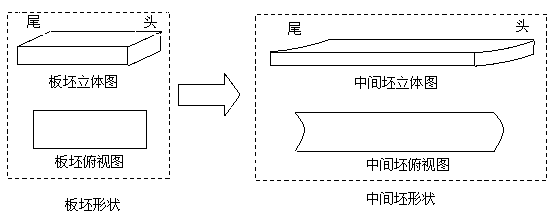

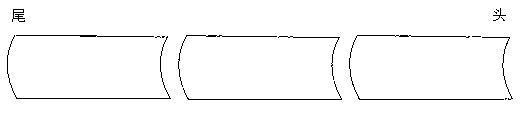

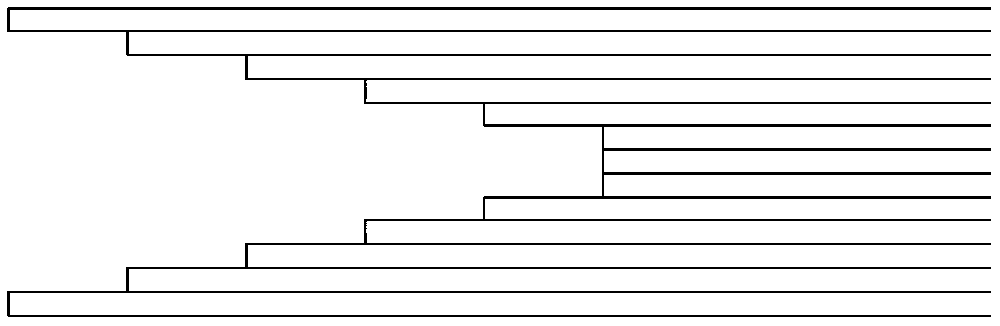

Continuous cast slab head and tail shape pre-controlling method capable of reducing hot-rolled intermediate slab head and tail cutting quantities

InactiveCN103252347AReduce cutting lossHigh yieldMetal rolling arrangementsArch heightMechanical engineering

A pre-control method of head and tail shapes of continuous casting slab for reducing the removed amount from the head and tail of hot-rolled intermediate slab. By a pre-control cutting process for the head and tail shapes of continuous casting slab, the slab is cut into a shape such that its head end surface dents inwards and its tail end surface extrudes towards outside of the slab. In the pre-control cutting process, the head and tail shapes of the slab is cut in accordance with the curve which is linearly symmetrical with respect to the width center of the slab, and the arch height (i.e., the maximum value of the denting portion of the head or the extruding portion of the tail) is controlled in the range of 0 mm to 50 mm. In such a manner, the length of the non-uniform deformation portions of the head and tail of the intermediate slab can be significantly reduced, and thus the reduction of the removed amount from the head and tail of hot-rolled intermediate slab is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

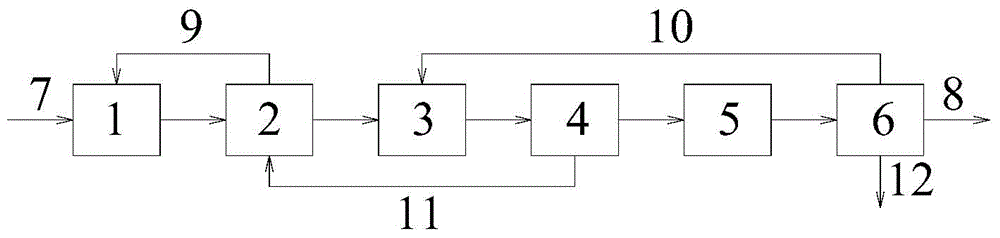

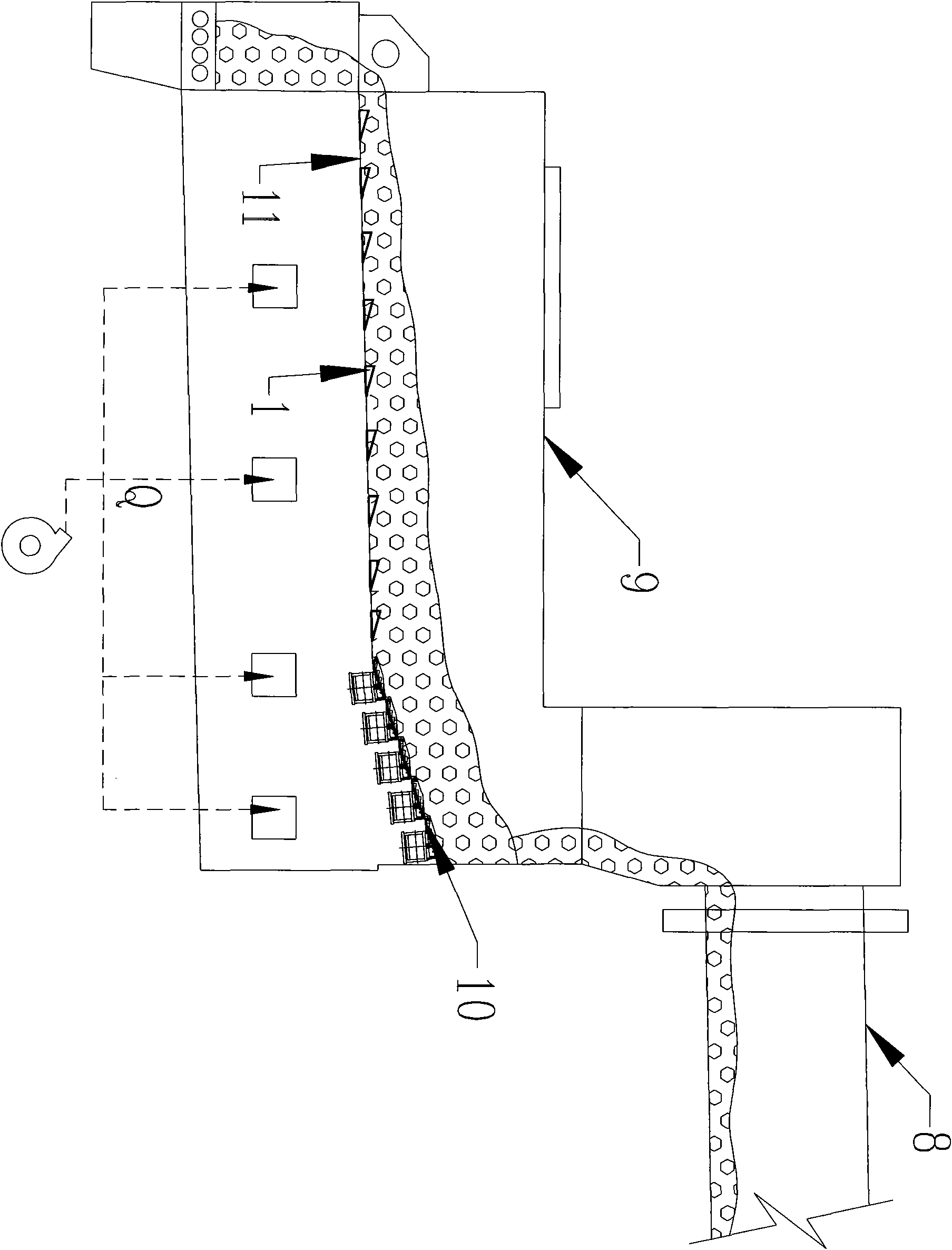

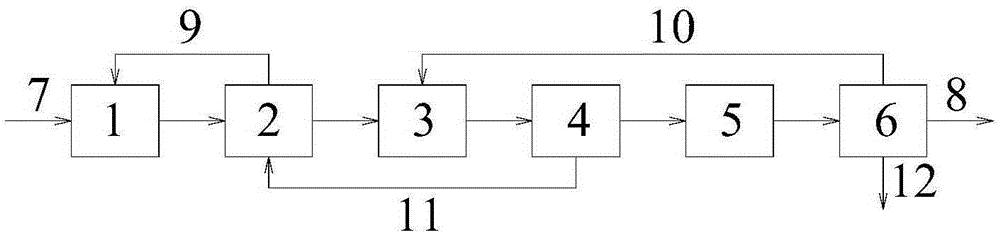

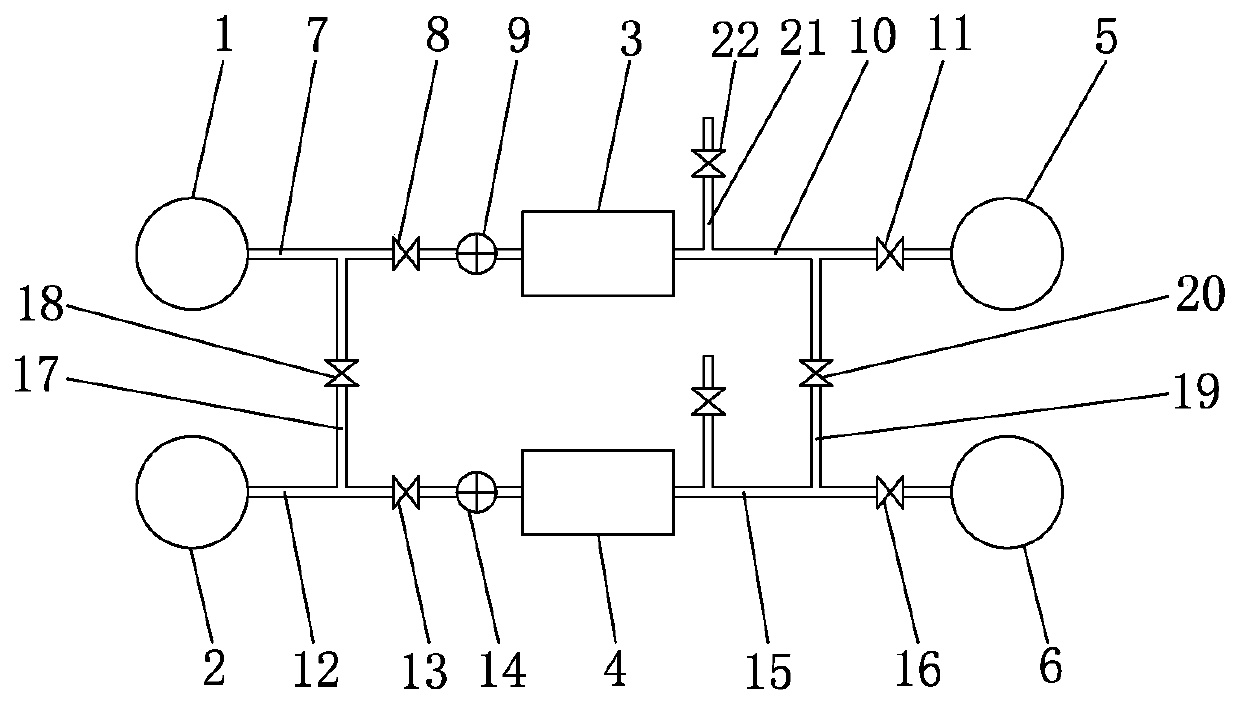

A2/O-MBR composite processing system and method based on efficient utilization of carbon source

ActiveCN104445840AObvious effect of energy saving and consumption reductionShort hydraulic retention timeTreatment using aerobic processesMultistage water/sewage treatmentNitrogen removalWater quality

The invention relates to an A2 / O-MBR composite processing system and method based on efficient utilization of carbon source, and belongs to the technical field of sewage treatment. The A2 / O-MBR composite processing system based on efficient utilization of carbon source mainly comprises an anaerobic tank, a first anoxic pond, an aerobic tank, an oxygen elimination tank, a second anoxic pond, and a membrane pool, wherein the anaerobic tank is connected with the first anoxic pond, the first anoxic pond is connected with the aerobic tank; the aerobic tank is connected with the oxygen elimination tank; the oxygen elimination tank is connected with the second anoxic pond; and the second anoxic pond is connected with the membrane pool. The A2 / O-MBR composite processing system and method based on efficient utilization of carbon source are aimed for requirements of enhanced nitrogen removal of high discharge standard municipal sewage treatment plant; the efficient utilization of carbon source and the enhanced nitrogen removal are achieved by adding the oxygen elimination tank and the anoxic ponds in the conventional A2 / O and MBR composite technology system, and using the oxygen elimination tank to remove the adverse effect of the dissolved oxygen to the technology denitrification in the backflow nitrified liquid, and completely using the inner source nitrification effect of the anoxic pond. The A2 / O-MBR composite processing system and method based on efficient utilization of carbon source have the advantages that the utilization ratio of carbon source is high, the effect of denitrification and dephosphorization is good, the water quality of the discharged water is good, the ability to resist impact load is strong the effect of saving energy and reducing consumption is obvious, and the like.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

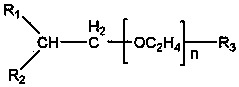

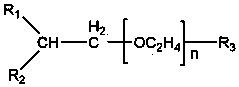

Aluminum hydroxide dehydrating agent and preparation method thereof

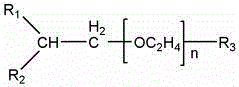

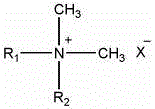

InactiveCN102974325AReduce moisture contentLow priceAluminium compoundsOther chemical processesAluminium hydroxideOxygen

The invention discloses an aluminum hydroxide dehydrating agent which consists of the following raw materials by weight percent: 10-20 percent of polyoxyethylene type anionic surfactant, 3-10 percent of polyoxyethylene type nonionic surfactant, 1-3 percent of quaternary ammonium salt cationic surfactant, 1-3 percent of cosolvent and the balance of water. The aluminum hydroxide dehydrating agent has the advantages of being convenient to use, low in cost and obviously reducing moisture content of aluminum hydroxide filter cake during aluminum hydroxide production.

Owner:CHINA RES INST OF DAILY CHEM IND

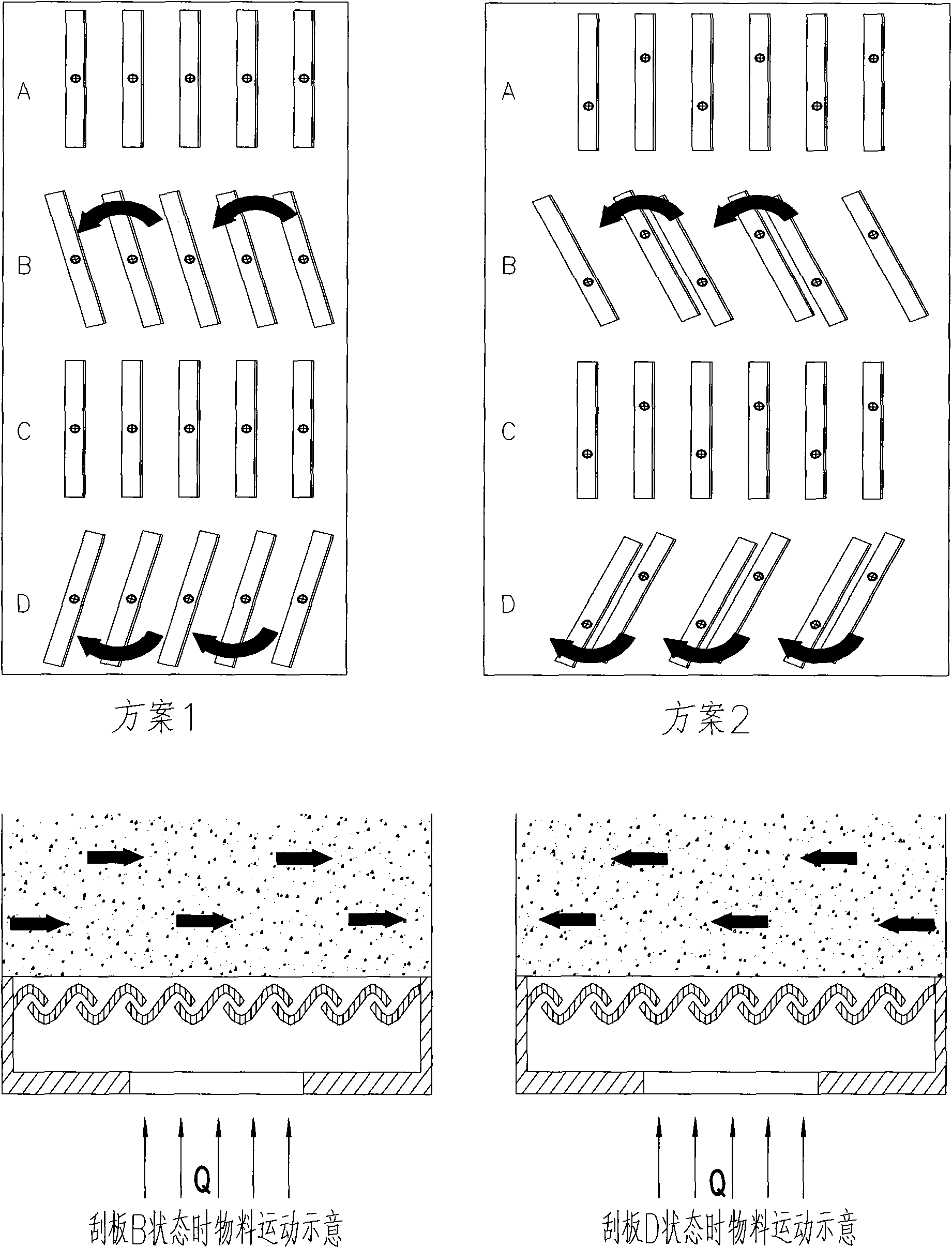

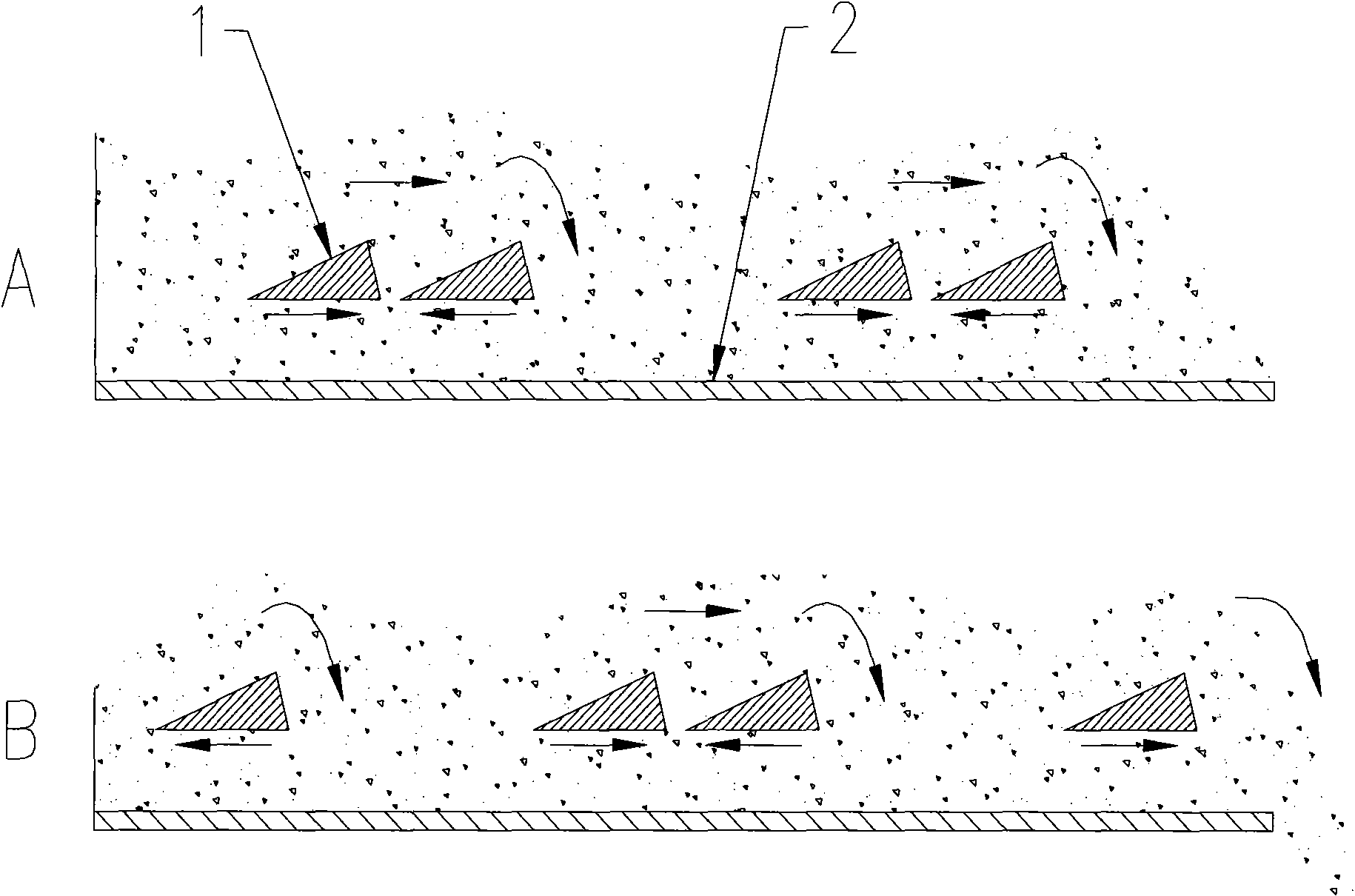

Method and cooler for cooling hot-state granular material during enhanced convection heat exchange

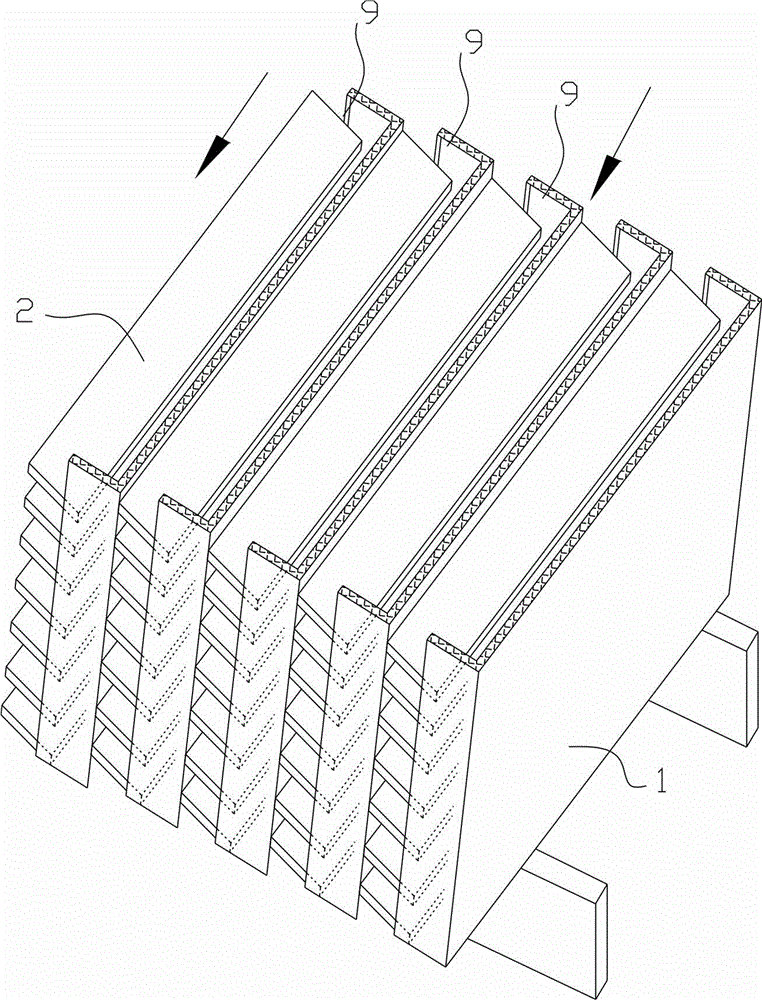

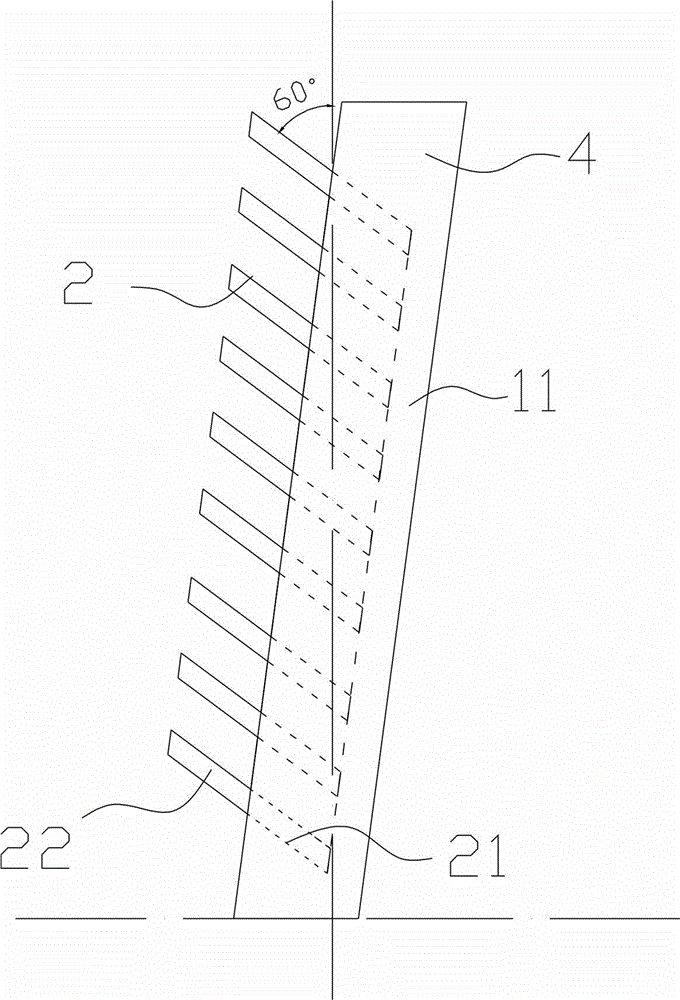

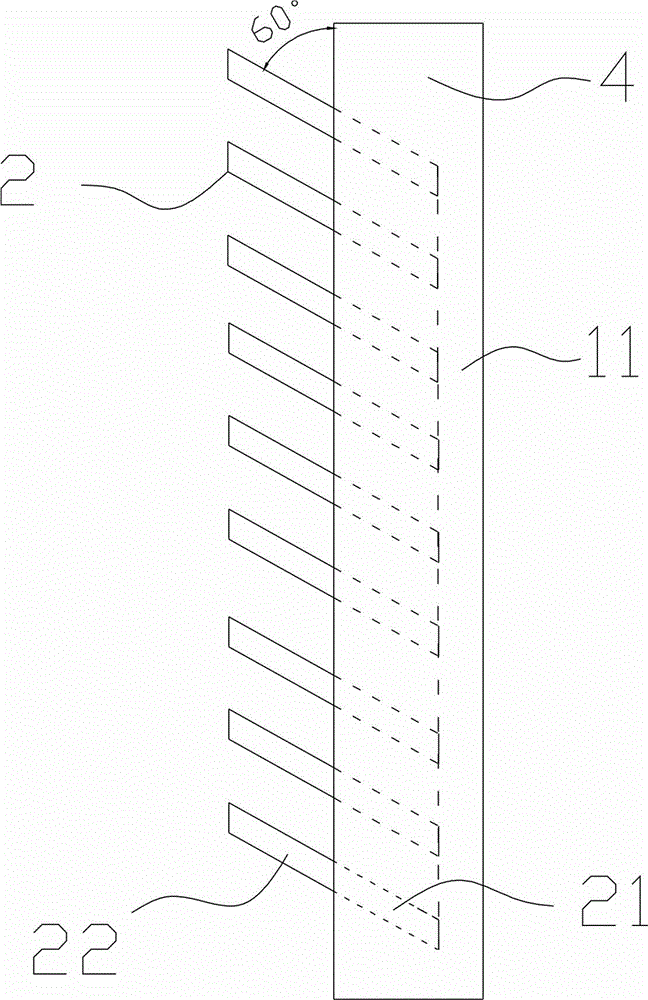

InactiveCN102374789AIncrease exposureIncrease the areaHandling discharged materialThree-dimensional spaceEngineering

The invention provides a method and a cooler for cooling a hot-state granular material during enhanced convection heat exchange. The method relates to a cooling process of clinker granular materials generated by industrial furnace equipment such as a rotary cement kiln and the like, and through the method, a high-temperature granular material from a rotary kiln is conveyed to a step grate at an inlet of the cooler and then enters a horizontal grate, and cooling air from the downside of the grate passes through the grate to exchange heat with a hot-state granular material layer to achieve an effect of cooling the hot-state granular material; after the material enters the horizontal grate, a reciprocating pendulum sweeping type material-pushing scraper can make the hot-state granular material generate superposition of two motions including forced stirring homogenization and rolling advancing in the process of heat exchange; granules form curve running tracks in a three-dimensional space; the temperature distribution of the material correspondingly trends to be balanced; and the uniform distribution of the granules actively balances the resistance of the whole material layer to ensure that the cooling air is distributed more uniformly, the dependence on an automatic air flow control valve under the grate is reduced, and the heat exchange efficiency and the heat exchange speed are obviously increased.

Owner:成都建筑材料工业设计研究院有限公司

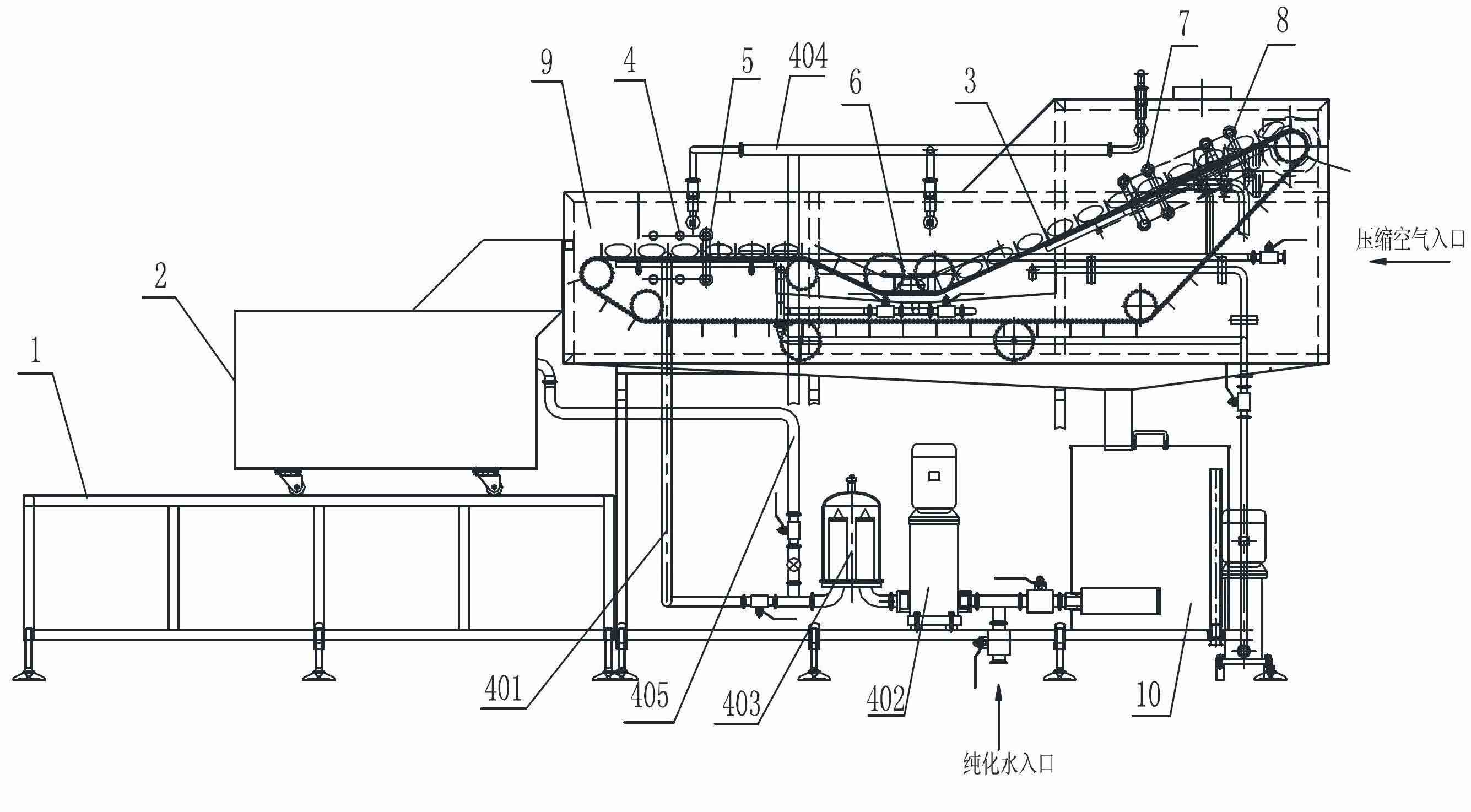

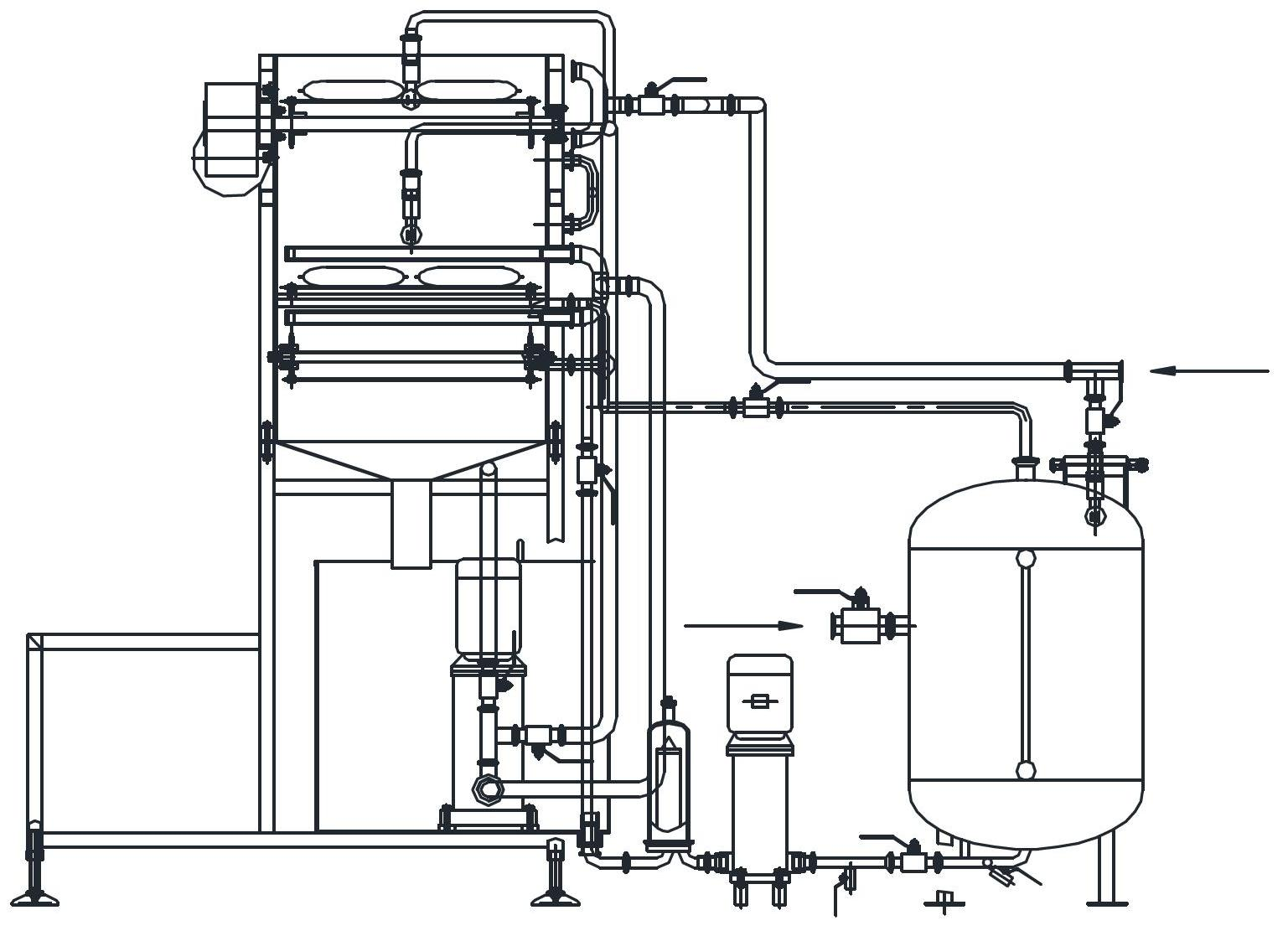

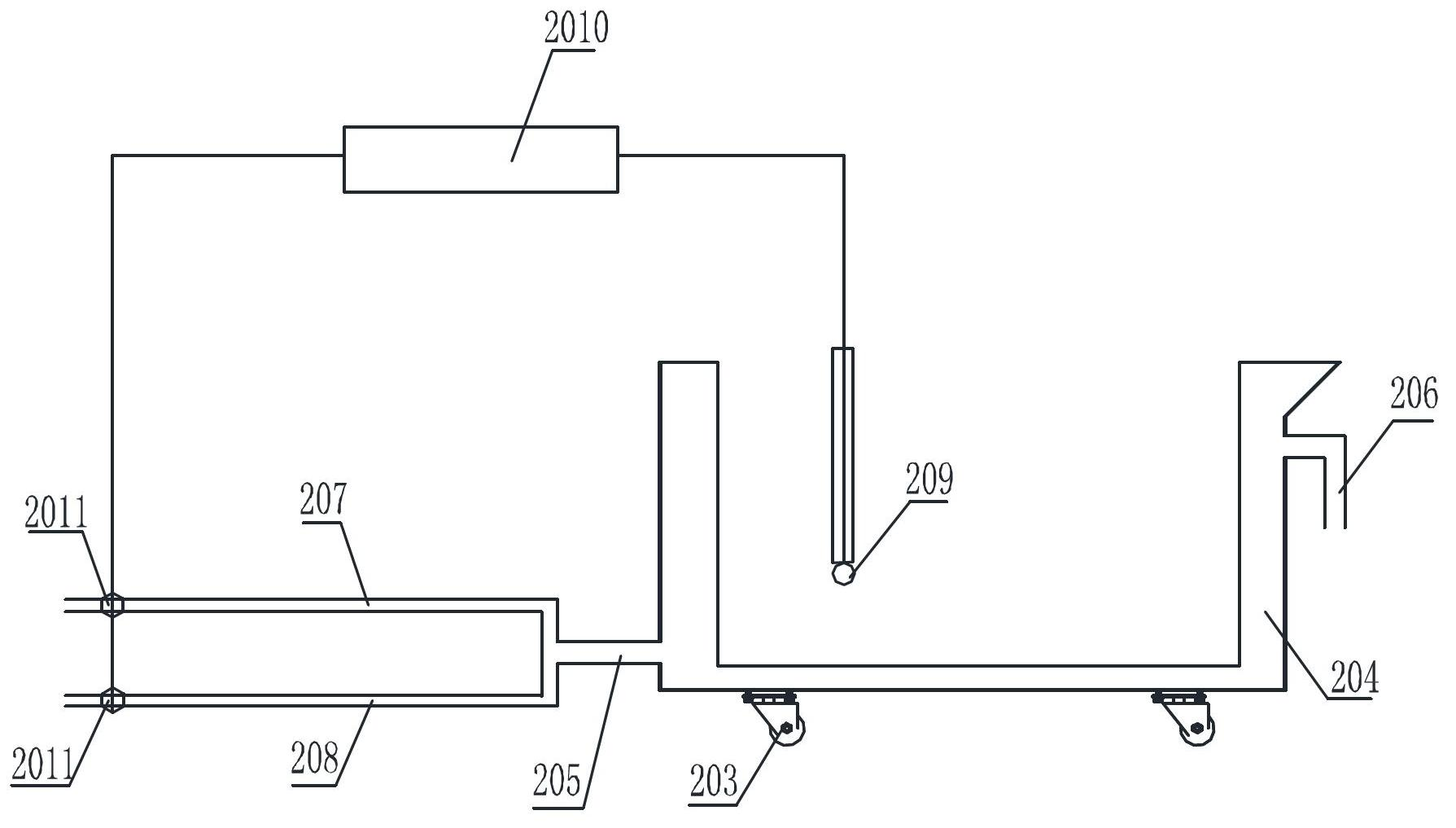

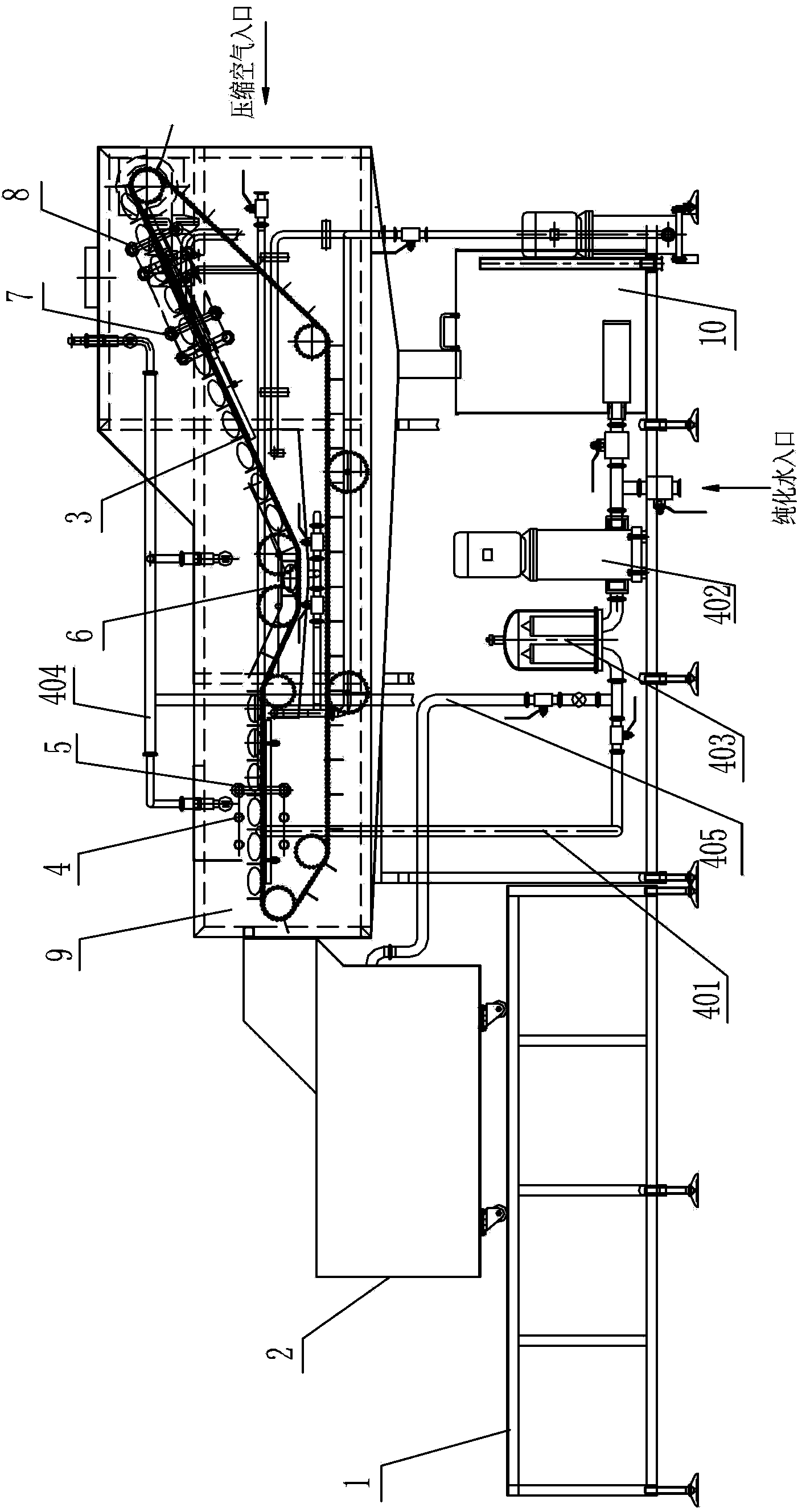

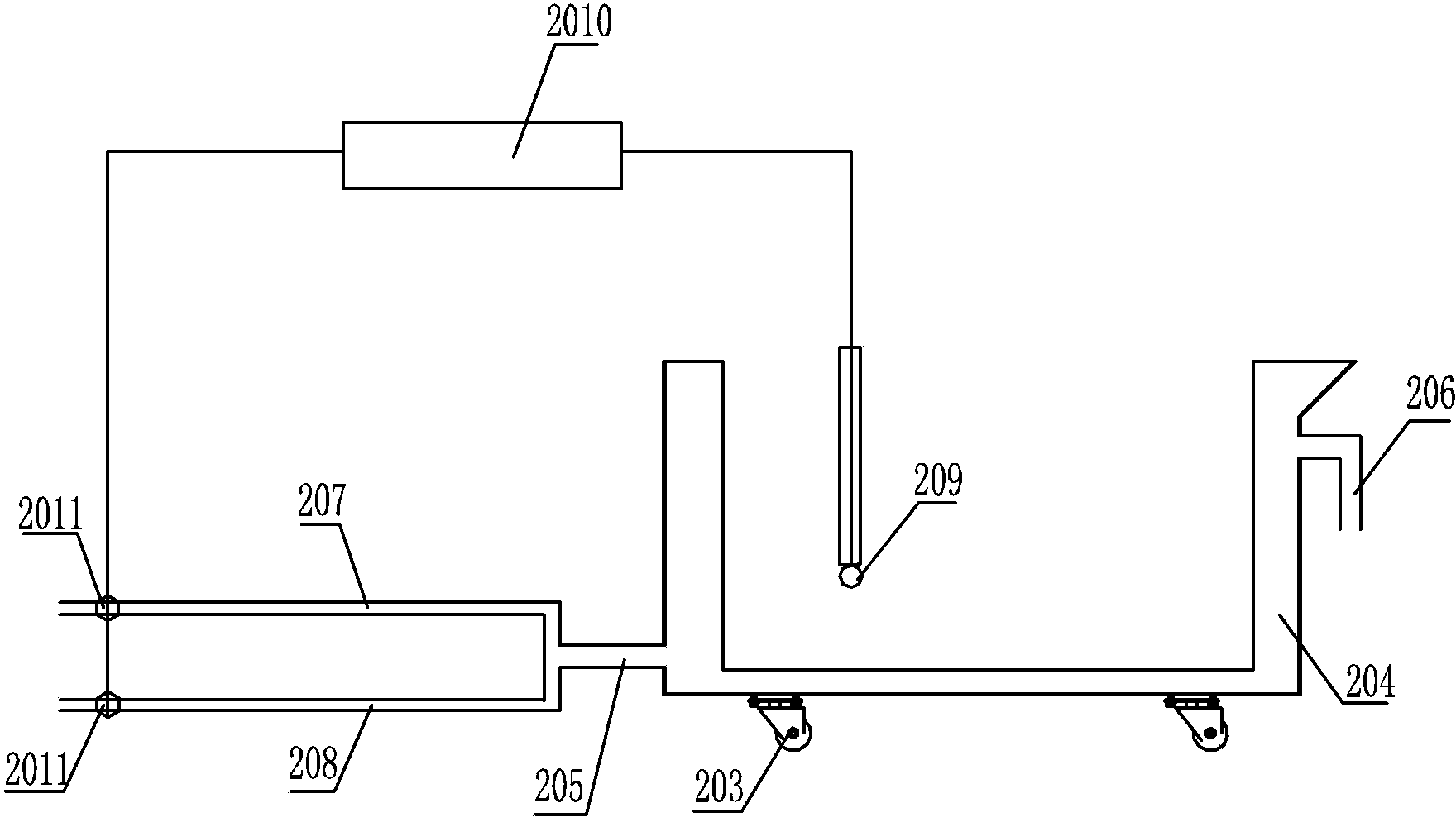

Online controller for controlling circulating, insulating, cleaning and plasma melting of raw blood plasma bags

ActiveCN102692910AReduce labor intensityAvoid human errorTemperatue controlProgramme total factory controlBlood plasmaDrug biological activity

The invention discloses an online controller for controlling circulating, insulating, cleaning and plasma melting of raw blood plasma bags. The online controller mainly comprises a working platform, a circulating, insulating and soaking tank, an equipment box body, a circulating water washing station, a first compressed air washing station, a conveyer belt, an alcohol tank, a conveyer belt, a fresh water washing station, a second compressed air washing station, a main transmission motor, a circulating water and alkali liquor circulating system, an alcohol circulating system and an electrical appliance control system. According to the invention, by virtue of the accurate online control on plasma melting temperatures, biological activities of various biological proteins in blood plasma are protected, and the loss of the plasma proteins in an upstream process is effectively reduced; a series of continuous cleaning operations of automatic cleaning, disinfection and leaky bag eliminating and the like on the blood plasma bags in a plasma melting process are implemented by virtue of online computer automation control, thus avoiding cross contamination caused by open-type operation in the plasma melting process; in addition, the water circulating and alcohol filtering devices are designed and mounted, thus greatly reducing the consumption of alcohol and water for injection and achieving remarkable benefits of energy conservation and consumption reduction.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD +1

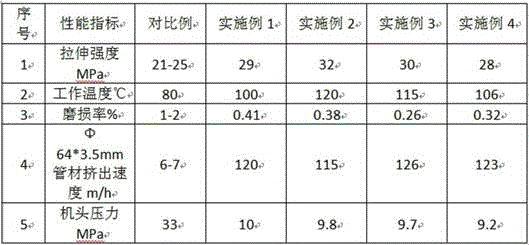

Ultra-high molecular weight polyethylene alloy tube and preparation method thereof

The invention provides an ultra-high molecular weight polyethylene alloy tube and a preparation method thereof. The tube comprises an alloy tube body and polyethylene composite layers composited on the inner wall and the outer wall of the alloy tube body; each polyethylene composite layer is prepared from, by weight, 40-95 parts of ultra-high molecular weight polyethylene, 3-50 parts of a macromolecule reinforced rheological agent, 2-10 parts of compatilizer, 0.1-2.5 parts of an antioxidant and 0.2-5 parts of additives. According to the ultra-high molecular weight polyethylene alloy tube and the preparation method thereof, the melting viscosity of processing can be reduced, the processing fluidity is improved, tube extrusion molding is prone to occurrence, the tube property is improved, the machine head resistance generated when processing is conducted is reduced, and the production efficiency is improved. More tubes are extruded every hour, the electric energy consumption is less, and the effects of saving energy and reducing consumption are achieved.

Owner:深州市工程塑料有限公司

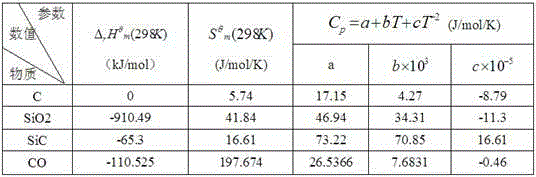

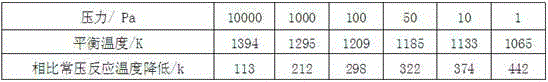

Synthesis method of beta-SiC micro-powder and whiskers

InactiveCN103387231AMild reaction conditionsLower requirementSilicon carbideSolid-phase synthesisRaw material

The invention relates to the technical field of solid phase synthesis of silicon carbide micro-powder and especially relates to a synthesis method of beta-SiC micro-powder and whiskers. The synthesis method of the beta-SiC micro-powder and whiskers utilizes crushed and uniformly mixed carbon and silicon raw materials as reaction raw materials and is characterized by comprising the following steps of filling the reaction raw materials into a vacuum resistance furnace, closing the vacuum resistance furnace, carrying out vacuum-pumping on the vacuum resistance furnace so that the pressure in the vacuum resistance furnace is below 100Pa, supplying power to the vacuum resistance furnace to heat it to a temperature of 1400-1500K, carrying out heat preservation, stopping the power supply when the pressure in the vacuum resistance furnace is below 10Pa for more than 60min, and carrying out natural cooling to obtain the product. The synthesis method realizes accurate control of beta-SiC micro-powder and whisker synthesis conditions, has a simple process and a low production cost, and can realize industrial synthesis of the beta-SiC micro-powder and whiskers. The beta-SiC micro-powder and whiskers obtained by the synthesis method has high integrity, high purity and good quality.

Owner:张兴材

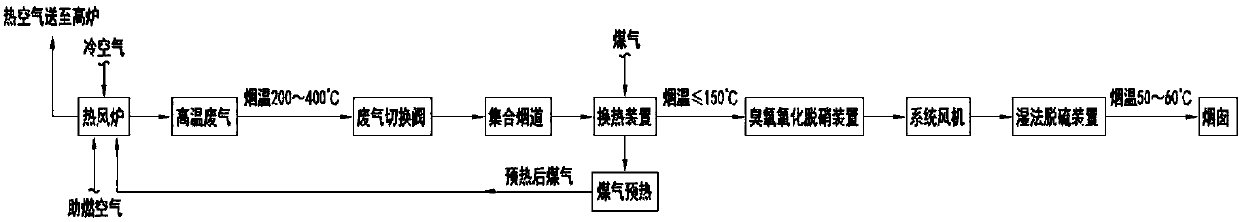

Desulphurization-denitration cooperative treatment method for flue gas of hot-blast stoves

InactiveCN107899414AObvious effect of energy saving and consumption reductionSmall resistanceDispersed particle separationAir quality improvementEngineeringHeat energy

The invention relates to a desulphurization-denitration cooperative treatment method for flue gas from hot-blast stoves. The method comprises the following steps: controlling all the heat-accumulatingtype hot-blast stoves to be in a working state of alternate combustion heat accumulation and hot air conveying, allowing high-temperature flue gas produced in a combustion stage to exchange heat withgas used as a fuel, and conveying the preheated gas to the hot-blast stoves for combustion; allowing the cooled flue gas to pass through an ozone oxidation denitration apparatus for denitration; subjecting the flue gas to desulphurization with a wet-process desulphurization apparatus; and after desulphurization, discharging purified gas. The cooperative treatment method provided by the inventioncarries out flue gas purification, hot-air conveying and waste-heat recovery synchronously, efficiently removes sulfur dioxide and nitrogen oxide in the flue gas, purifies the flue gas, meets emissionrequirements prescribed in new standards or ultra-low emission requirements, recycles the heat energy of the flue gas, lowers operation cost and saves energy and resources.

Owner:中钢集团天澄环保科技股份有限公司

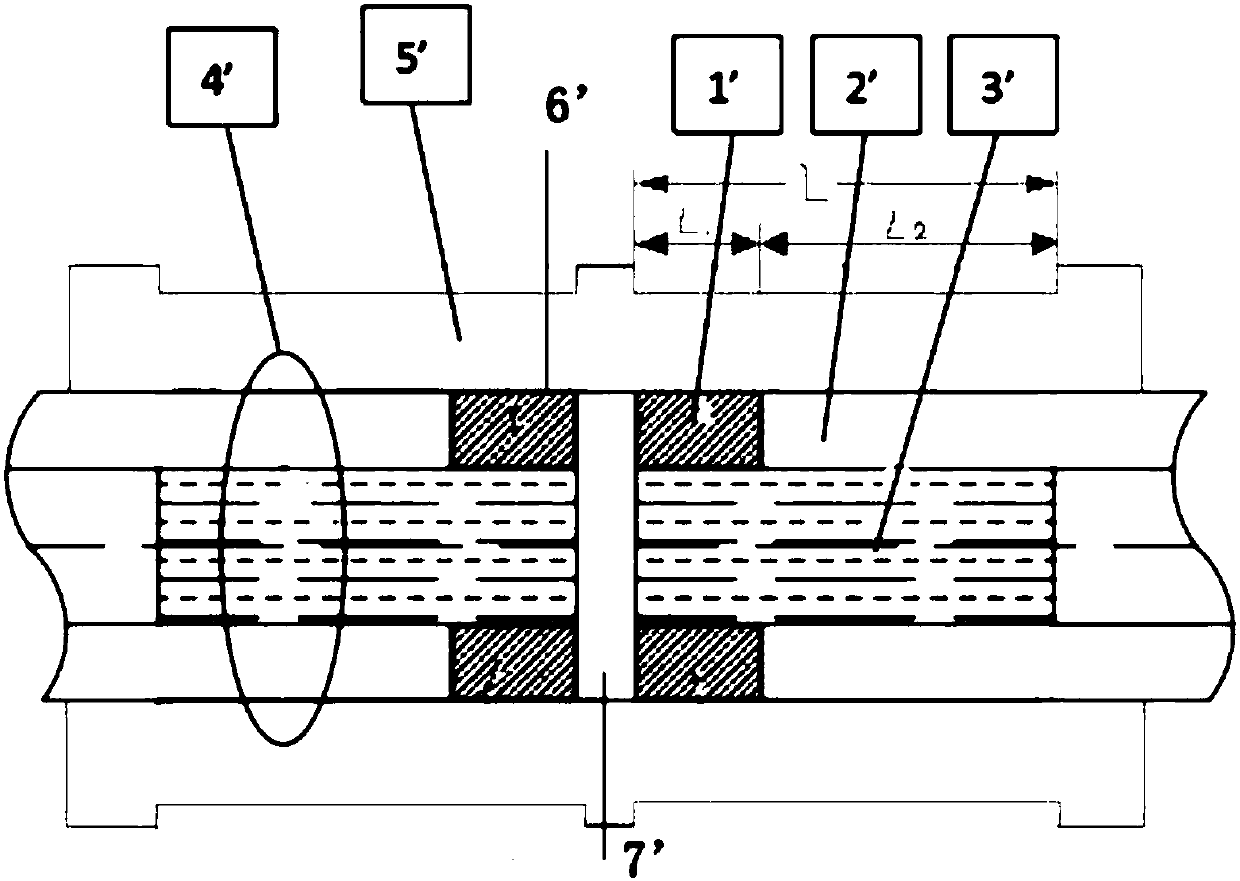

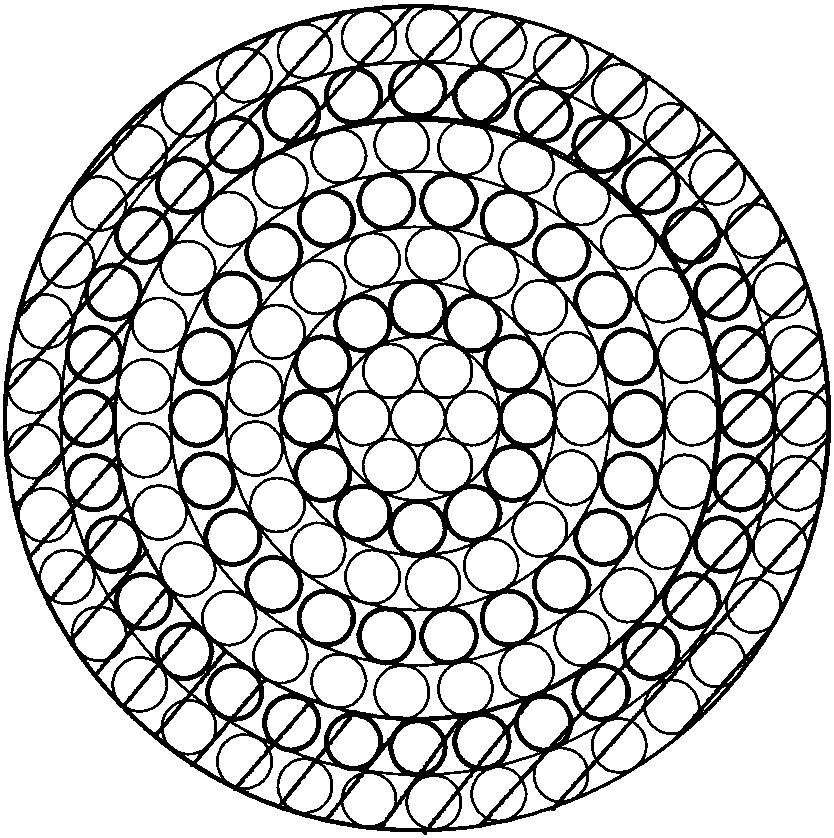

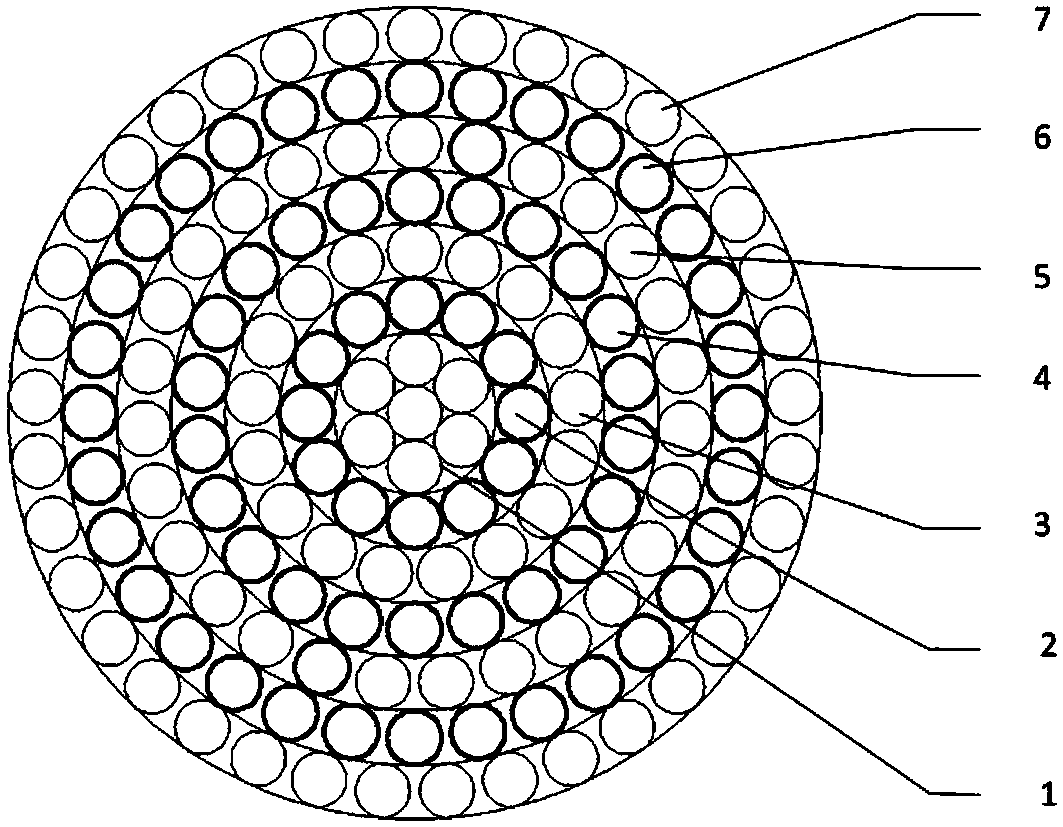

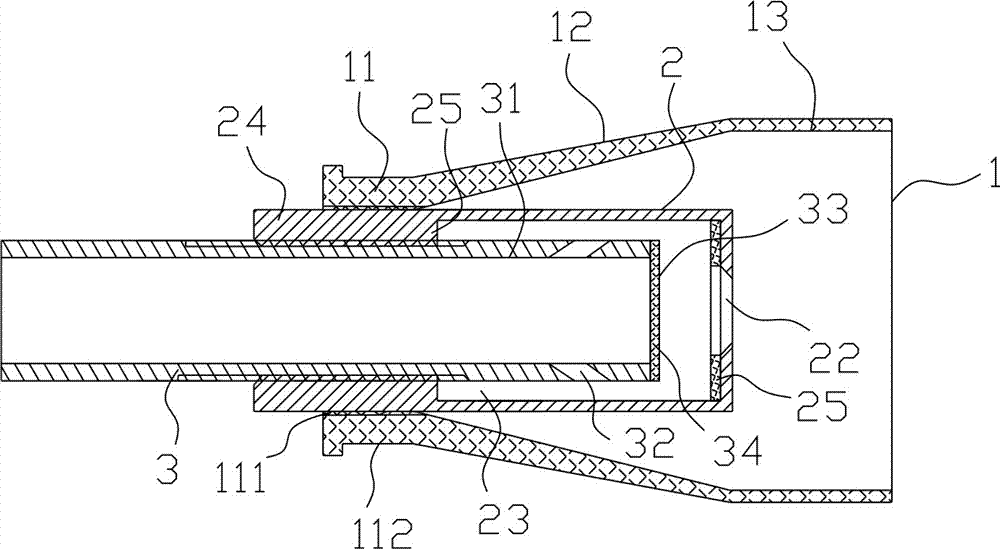

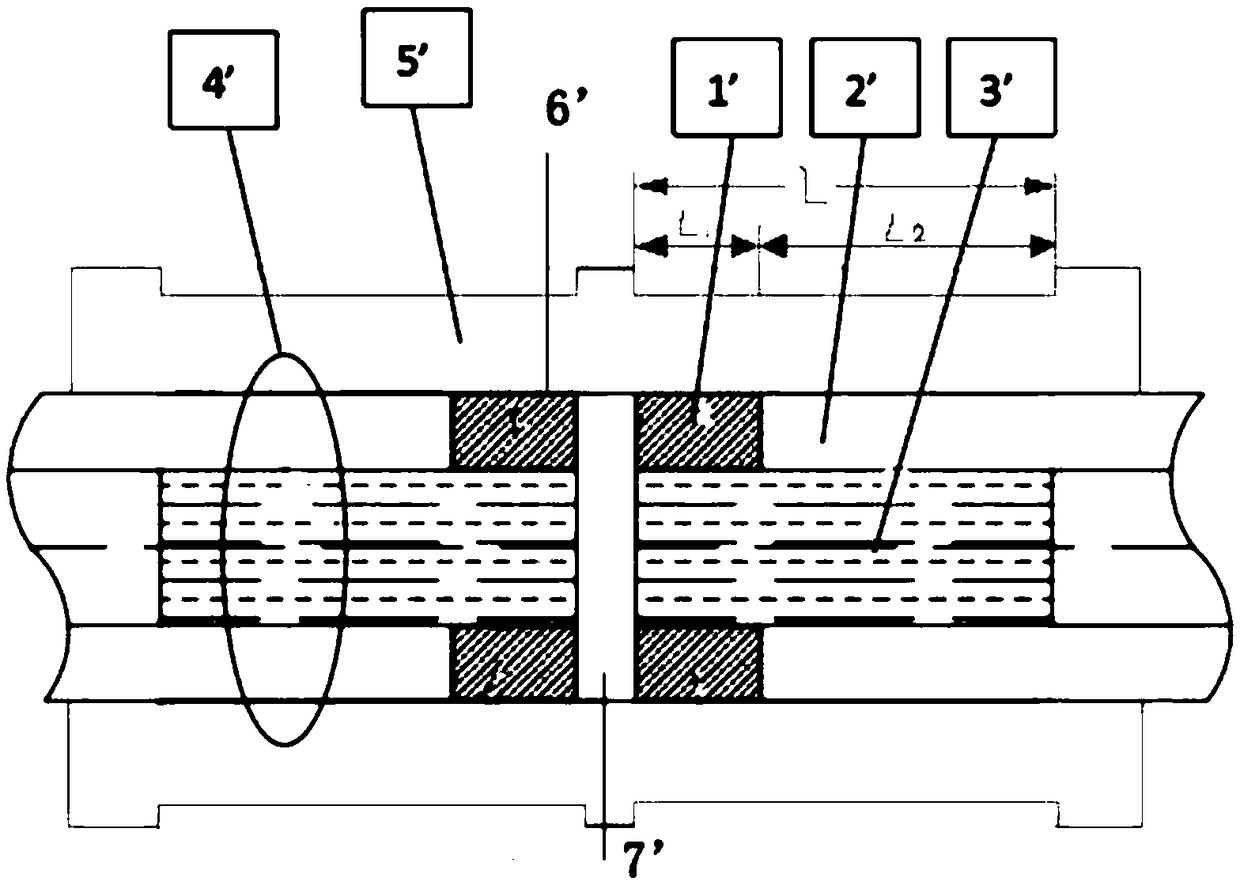

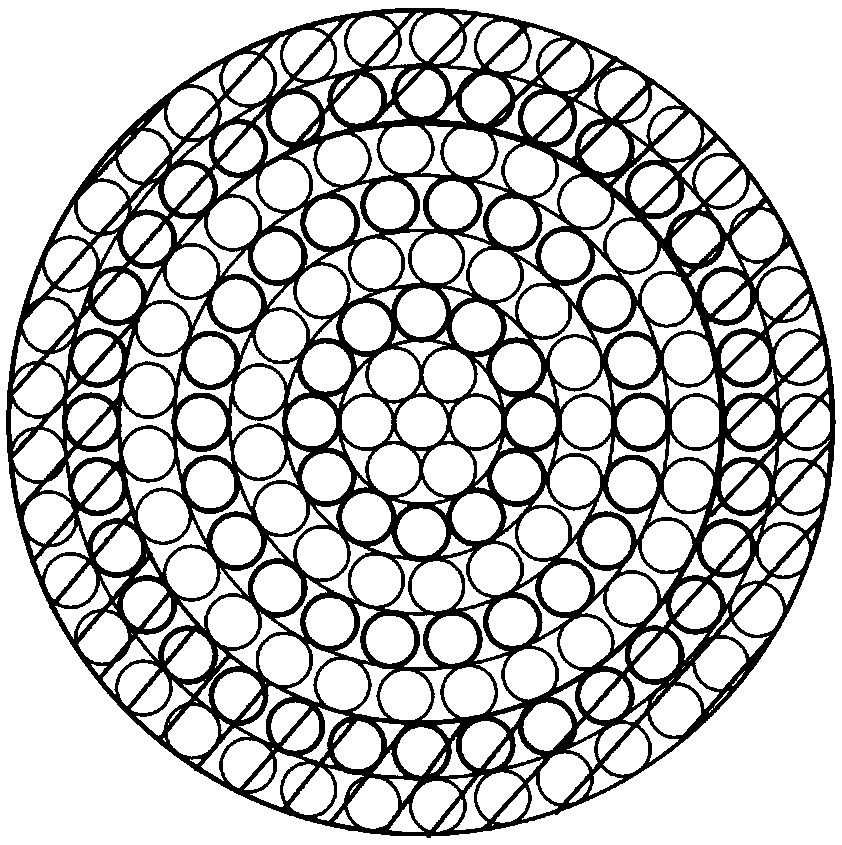

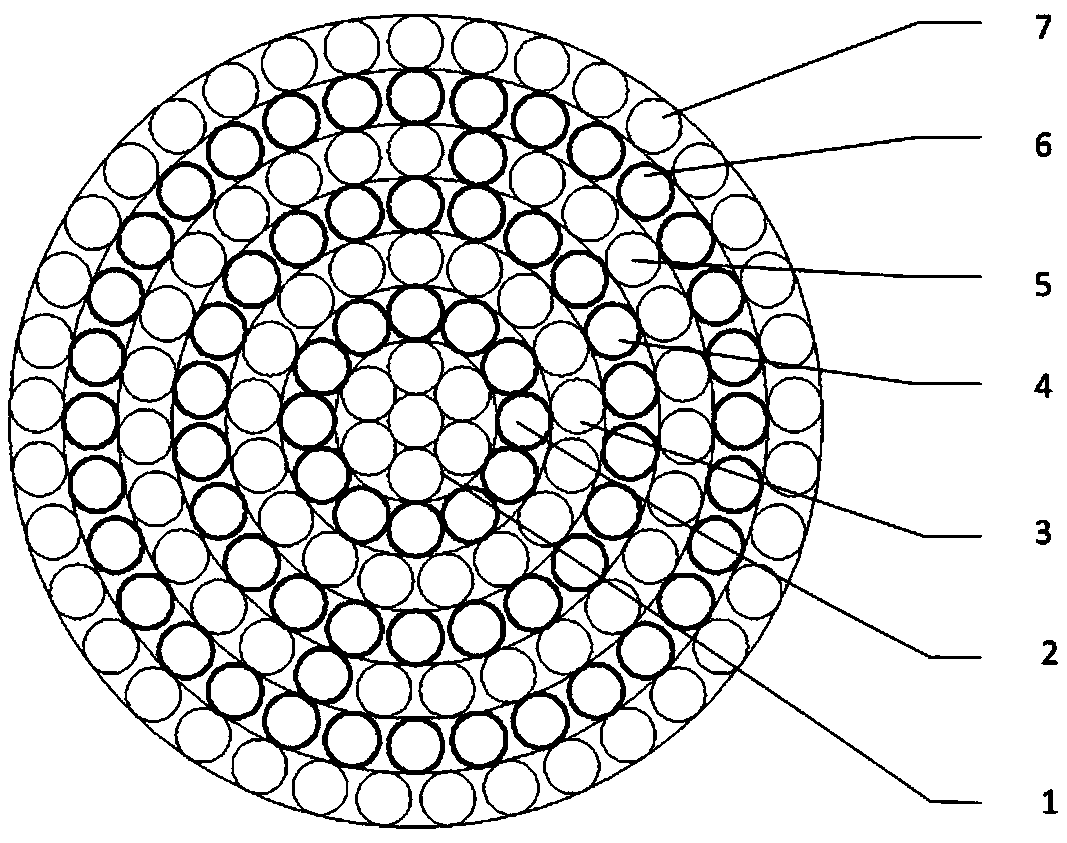

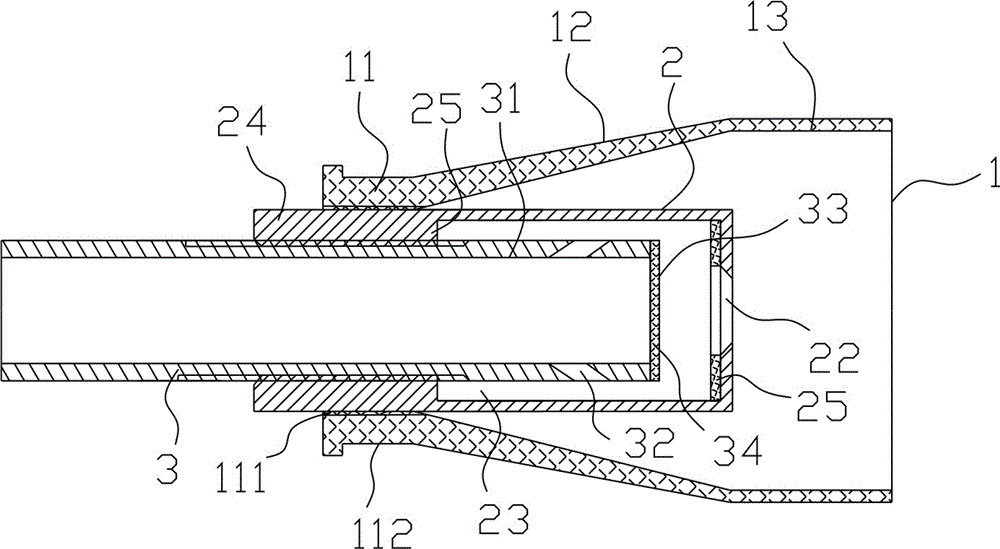

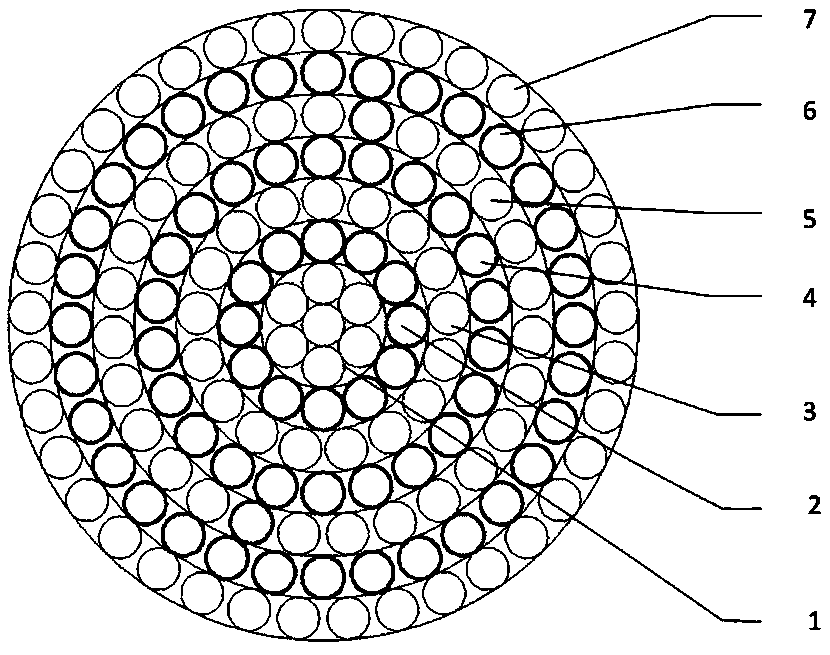

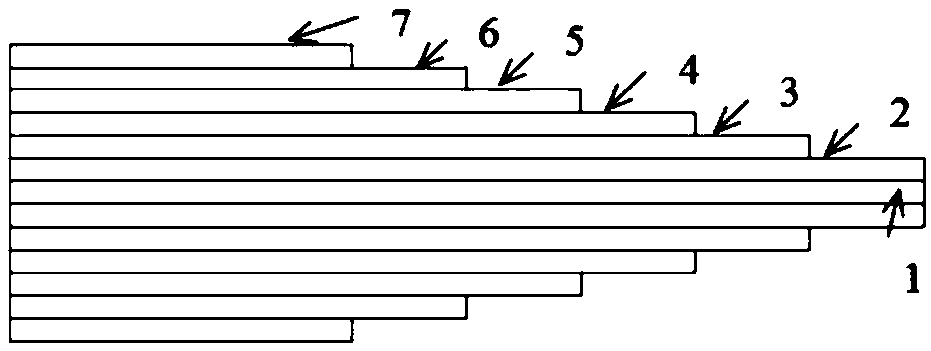

Crimping type cable conductor connector with current sharing effect and preparation method

ActiveCN107611627AReduce skin effectReduce AC resistanceLine/current collector detailsConnections effected by permanent deformationElectrical resistance and conductancePower cable

The invention belongs to the fields of a power transmission line and a power cable, and particularly relates to a crimping type cable conductor connector with a current sharing effect and a preparation method. Each layered insulating conductor consists of a first cylinder positioned in the centre of the conductor, and a second cylinder and a third cylinder with hollow-out central parts and arranged outside the first cylinder in a sleeving manner; the layered insulating conductor is inserted into a hollow conductor connecting pipe from the two ends of the conductor connecting pipe; in a crimping process, a crimping die surrounds the upper and lower sides of a crimping section of the conductor connecting pipe; and the cable conductor connector is extruded by die closing of the crimping die,and the conductor connecting pipe and the layered insulating conductor are subjected to micro deformation. By virtue of the crimping type cable conductor connector, the alternating current resistanceof the large-section cable conductor with the layered insulating structure in the conductor connector position can be lowered, so that the problem of temperature rise in the conductor and the connector positions when the large-section layered insulating conductor is applied can be overcome.

Owner:STATE GRID CORP OF CHINA +3

Vortex type solid-liquid separation purification device and settling tank with the purification device

ActiveCN103585798BLow investment costReduce dosageSedimentation settling tanksWater qualitySettling basin

Owner:ZHEJIANG LIANCHI WATER EQUIP

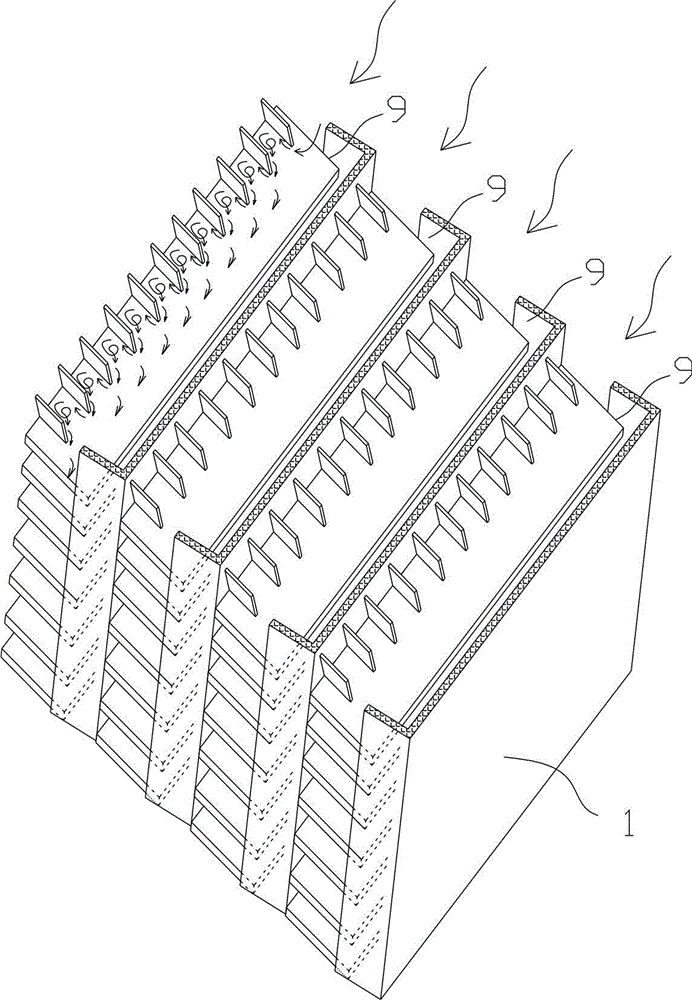

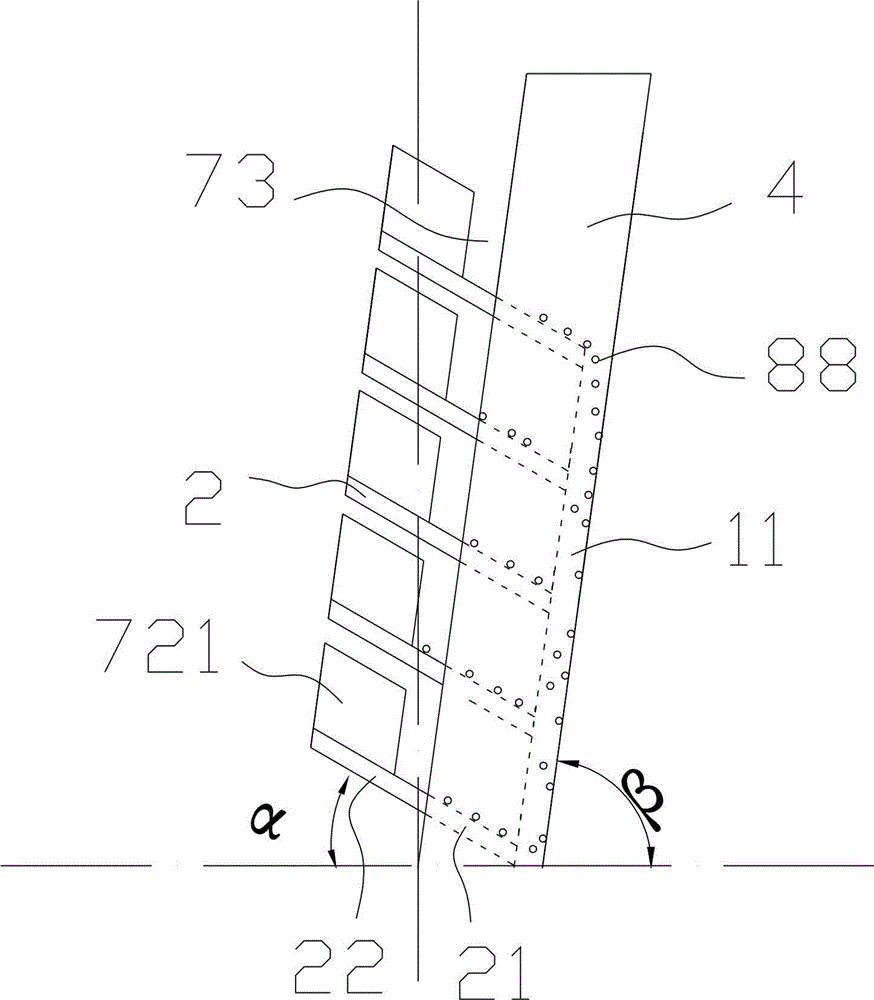

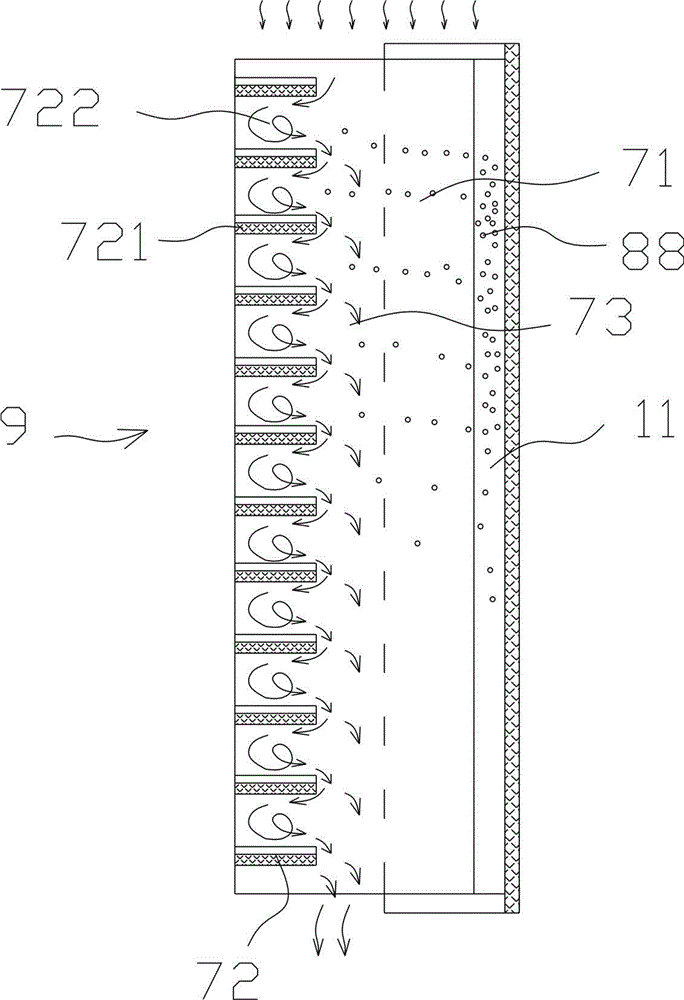

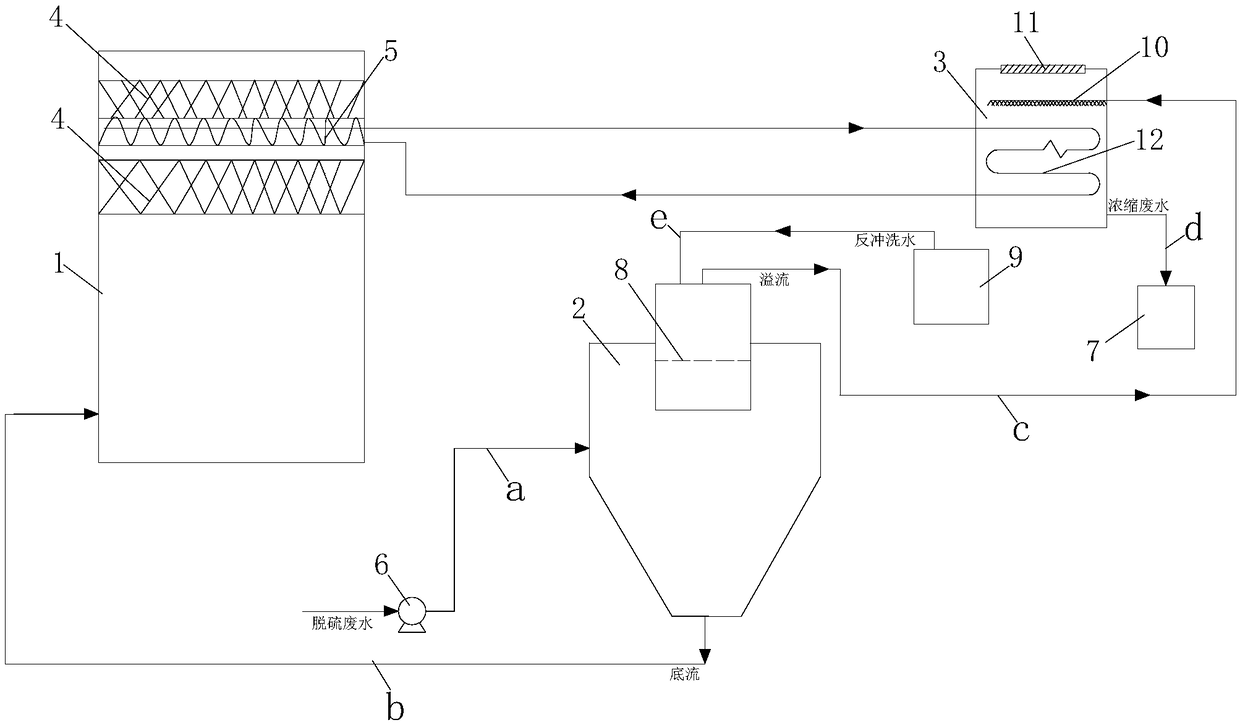

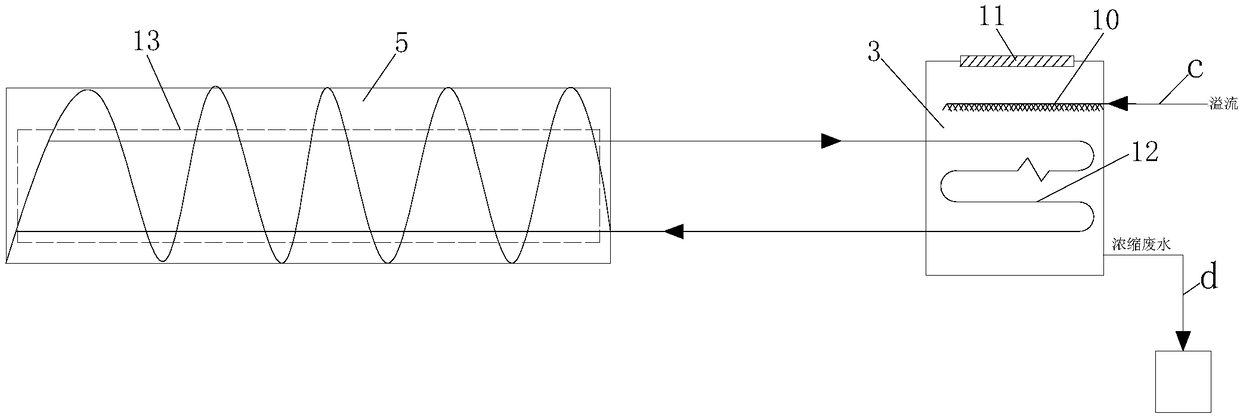

Synergistic desulfurization wastewater dedusting and defogging device and dedusting and defogging technology

The invention relates to a synergistic desulfurization wastewater dedusting and defogging device and a dedusting and defogging technology, and belongs to the technical field of wastewater pollution control. In the synergistic desulfurization wastewater dedusting and defogging device, a filter element is mounted inside a high-efficiency cyclone separator; high-efficiency defoggers and a condenser are mounted inside a wet desulfurization tower; a warming section is mounted inside the condenser; the warming section is communicated with a cooling section; the cooling section and a sprinkling device are mounted inside a circulating cooling water system; an exhaust fan is mounted at the top of the circulating cooling water system; a wastewater pump is communicated with the high-efficiency cyclone separator through a desulfurization wastewater pipeline; the wet desulfurization tower is communicated with the high-efficiency cyclone separator through an underflow pipeline; the high-efficiency cyclone separator is communicated with the sprinkling device through an overflowing pipeline; the circulating cooling water system is communicated with a flue evaporation system through a concentratedwastewater pipeline; a backwashing water tank is communicated with the high-efficiency cyclone separator through a backwashing pipeline. Through resource reutilization of desulfurization wastewater, awater resource is saved; through synergistic desulfurization wastewater dedusting and defogging, a new idea is provided for desulfurization wastewater treatment.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

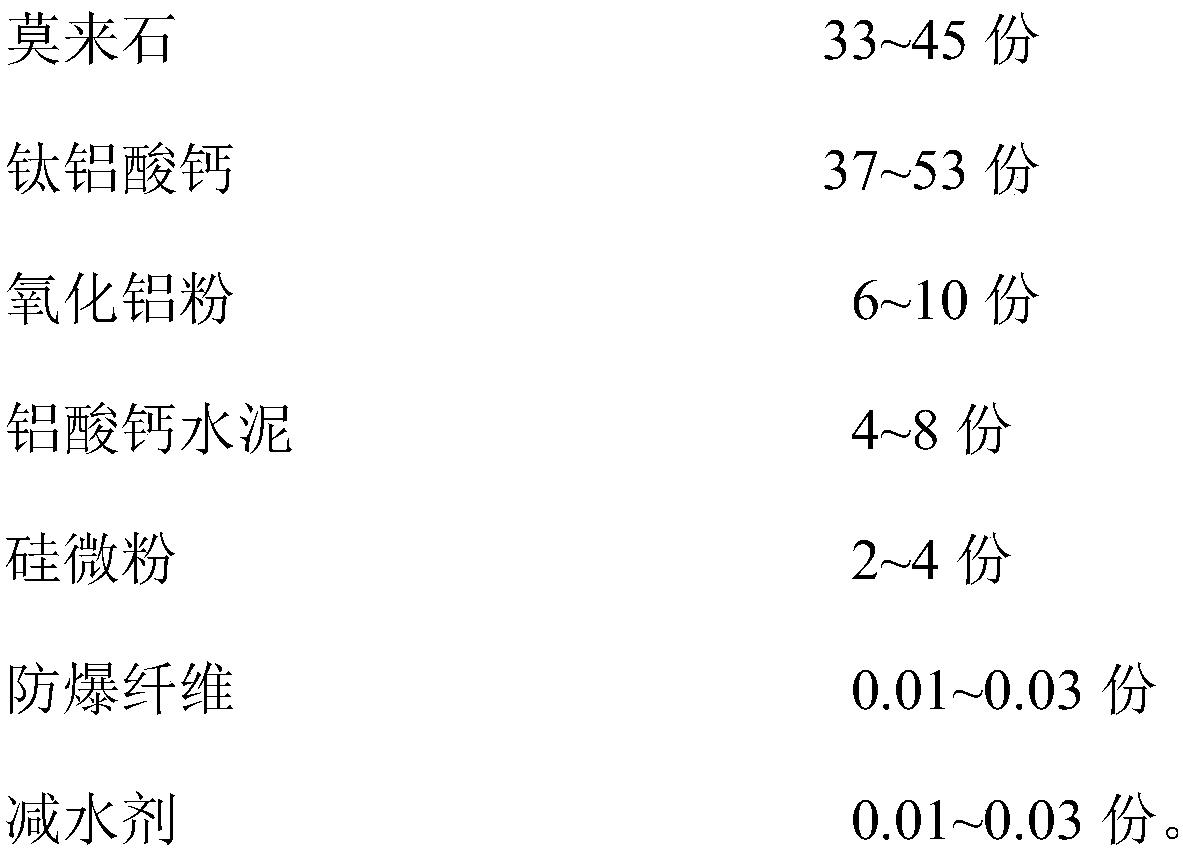

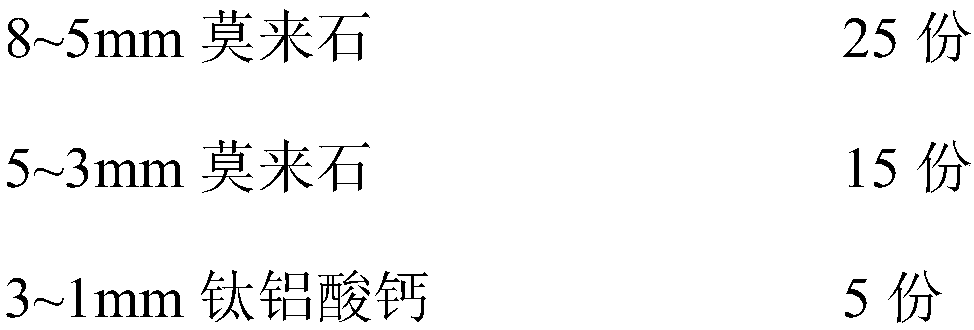

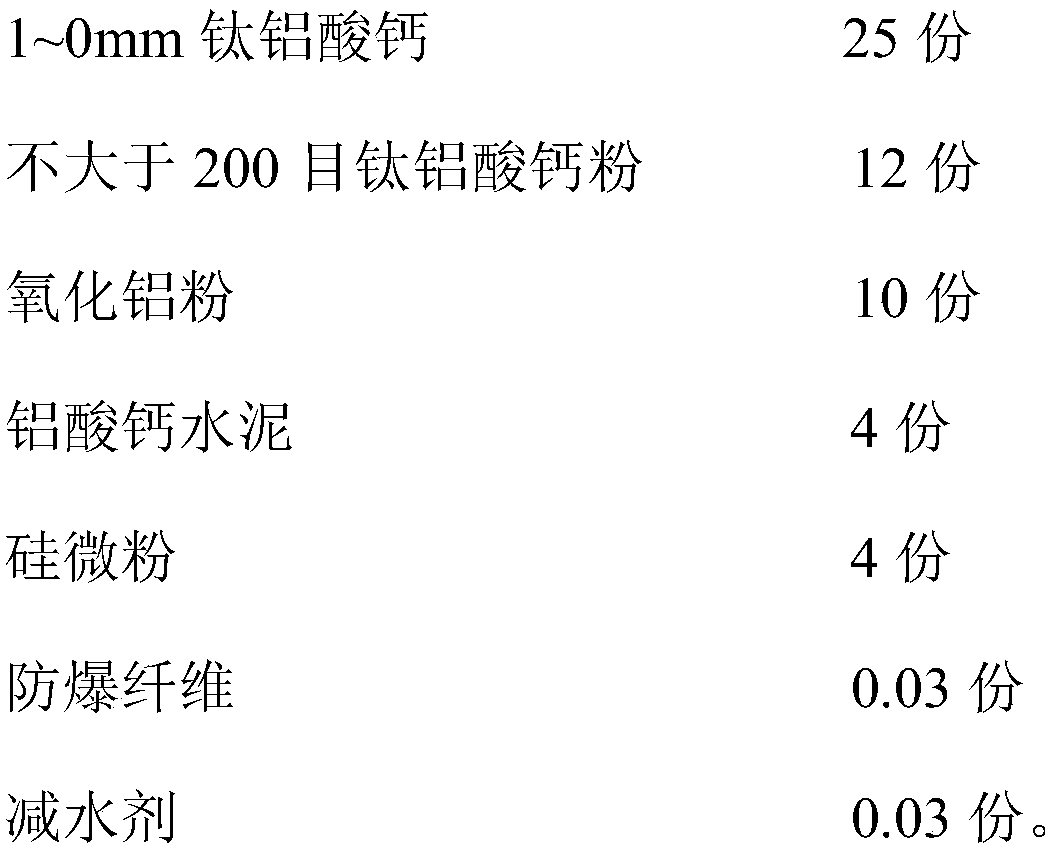

Casting material for rear kilneye of cement rotary kiln rear kiln opening

The invention relates to a casting material for a rear kilneye of a cement rotary kiln rear kiln opening. The casting material is prepared from the following ingredients in parts by weight: 18 to 25 parts of mullite being 8 to 5 mm, 15 to 20 parts of mullite being 5 to 3 mm, 5 to 10 parts of calcium alumino-titanatetitanium calcium aluminate being 3 to 1 mm, 20 to 25 parts of calcium alumino-titanatetitanium calcium aluminate being 1 to 0 mm, 12 to 18 parts of calcium alumino-titanatetitanium calcium aluminate powder not greater than 200 meshes, 6 to 10 parts of alumina powder, 4 to 8 parts ofcalcium aluminate cement, 2 to 4 parts of silica powdersilicon micro powder, 0.01 to 0.03 part of explosion-proof fiber and 0.01 to 0.03 part of water reducing agents. Mullite and calcium alumino-titanatealuminum titanium calcium are used as composite aggregates; mullite reaction in substrates and material phase change in calcium alumino-titanatetitanium calcium aluminate are used for generatingmicro expansion effects; the thermal shock resistanceheat shock resistant performance of the casting materials is improved; meanwhile, the oxidization phenomenon due to introduction of silicon carbidematerials is also avoided.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Horizontal split-flow inclined plate purification device and settling tank with the purification device

Owner:ZHEJIANG LIANCHI WATER EQUIP

Flow-adjustable duckbill valve

ActiveCN103486303AExtended service lifeImprove microbial activityCheck valvesValve members for absorbing fluid energyEngineeringWorking environment

The invention discloses a flow-adjustable duckbill valve. The flux-adjustable duckbill valve comprises a valve body and a flow regulator arranged in the valve body, wherein the valve body sequentially comprises an inlet section, an elastic flat-cone-shaped transition section and an elastic tabular outlet section; the flow regulator comprises an outer pipe and an inner pipe which are sleeved with each other, a gap for media to flow is formed between the inner wall of the outer pipe and the outer wall of the connecting section, at least one shunting hole communicated with the gap is formed in the side wall of the connecting section, an outlet hole for the media to flow out is formed in the lower end part of the outer pipe and is located in the transition section (12), and a blocking end for blocking the outlet hole is arranged at the lower end part of the connecting section. The flow-adjustable duckbill valve has the advantage of being suitable for different working environments through regulating the flow according to requirements; the circulation tracks of the media are changed through the flow regulator arranged in the valve body, so that the gap at a valve mouth cannot be deformed due to the large-area circulation of the media, and the service life is prolonged.

Owner:ZHEJIANG LIANCHI WATER EQUIP

Inhibitor for eliminating filament breakage in the process of producing alkali-free glass fibers

ActiveCN101891393ALower melting temperatureObvious effect of energy saving and consumption reductionFiberGlass fiber

The invention discloses an inhibitor for eliminating filament breakage in the process of producing alkali-free glass fibers. A raw material of coal-measures kaoline, hard kaolin or refractory clay is subjected to ore proportioning, crushing and grading to prepare superfine powder, namely the inhibitor, and the inhibitor comprises 44.0 to 50.0 percent of SiO2, 36 to 42 percent of Al2O3, 0.3 to 0.8 percent of Fe2O3, 0.5 to 2.0 percent of TiO2, 0.1 to 1.5 percent of K2O+NaO2, 0.1 to 1.5 percent of CaO+MgO and 12 to 16 percent of H2O. The inhibitor accelerates glass generation and reduces energy consumption by controlling product granular size and size distribution and other means, and prevents minerals from changing phase and further generating impurities so as to reduce the phenomenon of filament breakage. The product can completely replace alkali-free clay powder used in the conventional glass fiber industry.

Owner:宜昌慧龙科技开发有限公司

Method for preparing molybdenum powder for preparing molybdenum end cap of magnetron

The invention provides a method for preparing molybdenum powder for preparing a molybdenum end cap of a magnetron, comprising the following steps of: 1, preparing polyvinyl alcohol and water into adhesives; 2, mixing the adhesives and molybdenum powder serving as a raw material into slurry; 3, placing the slurry in a spray drying tower for granulation to obtain granules; and 4, sieving the granules to obtain molybdenum powder for preparing the molybdenum end cap of the magnetron. The method for preparing the molybdenum powder for preparing the molybdenum end cap of the magnetron has the advantages of high production efficiency and yield, and low energy consumption; the prepared molybdenum powder has even granule, and good fluidity and formability; and the molybdenum end cap of the magnetron prepared by the method has the advantages of even and consistent density, small size deviation and high working performance.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Aluminum hydroxide dehydrating agent and preparation method thereof

InactiveCN102974325BReduce moisture contentLow priceAluminium compoundsOther chemical processesAluminium hydroxideOxygen

The invention discloses an aluminum hydroxide dehydrating agent which consists of the following raw materials by weight percent: 10-20 percent of polyoxyethylene type anionic surfactant, 3-10 percent of polyoxyethylene type nonionic surfactant, 1-3 percent of quaternary ammonium salt cationic surfactant, 1-3 percent of cosolvent and the balance of water. The aluminum hydroxide dehydrating agent has the advantages of being convenient to use, low in cost and obviously reducing moisture content of aluminum hydroxide filter cake during aluminum hydroxide production.

Owner:CHINA RES INST OF DAILY CHEM IND

Synthesis method of beta-SiC micro-powder and whiskers

InactiveCN103387231BLower requirementLow reaction temperatureSilicon carbideSilenesSolid-phase synthesis

The invention relates to the technical field of solid phase synthesis of silicon carbide micro-powder and especially relates to a synthesis method of beta-SiC micro-powder and whiskers. The synthesis method of the beta-SiC micro-powder and whiskers utilizes crushed and uniformly mixed carbon and silicon raw materials as reaction raw materials and is characterized by comprising the following steps of filling the reaction raw materials into a vacuum resistance furnace, closing the vacuum resistance furnace, carrying out vacuum-pumping on the vacuum resistance furnace so that the pressure in the vacuum resistance furnace is below 100Pa, supplying power to the vacuum resistance furnace to heat it to a temperature of 1400-1500K, carrying out heat preservation, stopping the power supply when the pressure in the vacuum resistance furnace is below 10Pa for more than 60min, and carrying out natural cooling to obtain the product. The synthesis method realizes accurate control of beta-SiC micro-powder and whisker synthesis conditions, has a simple process and a low production cost, and can realize industrial synthesis of the beta-SiC micro-powder and whiskers. The beta-SiC micro-powder and whiskers obtained by the synthesis method has high integrity, high purity and good quality.

Owner:张兴材

Energy conversion and recovering method of coal gasification supercharging association circulating power generation system

ActiveCN101270689BImprove work efficiencyAchieve recyclingSolidificationLiquefactionCombustion chamberWorking fluid

The invention relates to a method of energy transformation and recovery of a combined cycle generating system of gasified pressure rise. The method comprises two parts, which are the process of gasifying and purifying coal and gas-vapor combined cycle generating process. Coal gas and high-pressure air are mixed and burnt in a combustion chamber and the produced gas with high temperature and pressure drive an expansion machine to do working, thus providing impetus to a gas booster and an electric generator. Sufficient raw material of air provided by gas turbine system is used as working fluid.The working fluid undergoes the processes of heat exchange and heat control, pressurization, repeated reheat and gradual heating up and the heat of high temperature coal gas is obtained from the outlet of a gasification device, thus making the temperature of the working fluid high enough. And a pressurization wheel is dragged and generates electricity by the turbine expansion action of energy recovery. Afterwards, the procedure of heat exchange and temperature control is practiced. At last, the air with proper pressure and temperature is transported to an air segregating unit that comprises acoal gasification device, a purifying device and a gas-vapor combined cycle generation device. In addition, an energy recovery turbine and a gas compressor and a plurality of heat exchangers driven bythe energy recovery turbine are added. The method has the characteristics of easy and reliable practice and simple device structure. Moreover, the method can increase working efficiency of heat recovery turbine and output power, so the generating efficiency of IGCC system is raised by 3 percent, thus achieving the effects of saving energy and reducing consumption.

Owner:杭州杭氧透平机械有限公司

A crimping type cable conductor joint with current equalizing function and preparation method thereof

ActiveCN107611627BReduce skin effectReduce AC resistanceLine/current collector detailsConnections effected by permanent deformationElectrical resistance and conductanceElectrical conductor

The invention belongs to the fields of a power transmission line and a power cable, and particularly relates to a crimping type cable conductor connector with a current sharing effect and a preparation method. Each layered insulating conductor consists of a first cylinder positioned in the centre of the conductor, and a second cylinder and a third cylinder with hollow-out central parts and arranged outside the first cylinder in a sleeving manner; the layered insulating conductor is inserted into a hollow conductor connecting pipe from the two ends of the conductor connecting pipe; in a crimping process, a crimping die surrounds the upper and lower sides of a crimping section of the conductor connecting pipe; and the cable conductor connector is extruded by die closing of the crimping die,and the conductor connecting pipe and the layered insulating conductor are subjected to micro deformation. By virtue of the crimping type cable conductor connector, the alternating current resistanceof the large-section cable conductor with the layered insulating structure in the conductor connector position can be lowered, so that the problem of temperature rise in the conductor and the connector positions when the large-section layered insulating conductor is applied can be overcome.

Owner:STATE GRID CORP OF CHINA +3

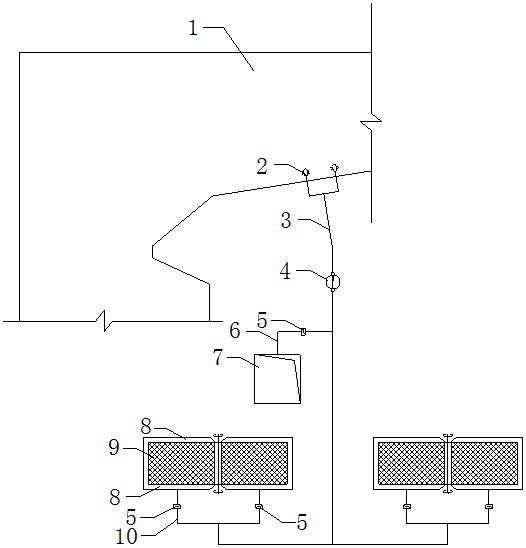

Soot blowing system for horizontal flue of boiler

PendingCN111810975AImprove reliabilityObvious effect of energy saving and consumption reductionSolid removalFlueAir volume

The invention discloses a soot blowing system for a horizontal flue of a boiler, wherein the soot blowing system performs coupling optimization of air leakage recovery of an existing rotary air preheater and soot blowing of the horizontal flue. The soot blowing system comprises a soot blowing nozzle and a soot blowing air duct connected to the inlet of the soot blowing nozzle, wherein the outlet of the soot blowing nozzle is arranged in the horizontal flue; the boiler is equipped with rotary air preheaters; the sealing gaps of the rotary air preheaters are provided with negative pressure air chambers which are connected to the inlets of booster fans through air leakage collecting air ducts; the outlets of the booster fans are connected to the soot blowing air duct; the air leakage collecting air ducts are provided with adjustment blocking plates which are used for adjusting the air volume of corresponding pipelines; and the soot blowing nozzle adopts a continuous blowing-swinging operation mode. The soot blowing system for the horizontal flue of the boiler has good economy. The reliability of the soot blowing nozzle is high. The effect of energy conservation and consumption reduction is significant.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

A2/o-mbr composite treatment system and method based on efficient utilization of carbon sources

ActiveCN104445840BObvious effect of energy saving and consumption reductionShort hydraulic retention timeTreatment using aerobic processesMultistage water/sewage treatmentNitrogen removalMunicipal sewage

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Flow adjustable duckbill valve

ActiveCN103486303BHigh activityExtended service lifeCheck valvesValve members for absorbing fluid energyWorking environmentEngineering

The invention discloses a flow-adjustable duckbill valve, which comprises a valve body and a flow regulator arranged in the valve body. The valve body successively includes an inlet section, an elastic flat-conical transition section and an elastic flat-shaped outlet section. The flow regulator includes an outer tube and an inner tube that are nested with each other; a gap for medium circulation is provided between the inner wall of the outer tube and the outer wall of the connecting section, and at least one diverter hole communicating with the gap is provided on the side wall of the connecting section; The lower end of the tube is provided with an outlet hole for the medium to flow out, and the outlet hole is placed in the transition section 12; the lower end of the connecting section has a plugging end for blocking the outlet hole. The flow rate can be adjusted according to the needs to adapt to different working environments; 2. Through the flow regulator installed in the valve body, the flow path of the medium is changed, so that the gap at the valve mouth will not be deformed by the large area of medium flow, Extended service life.

Owner:ZHEJIANG LIANCHI WATER EQUIP

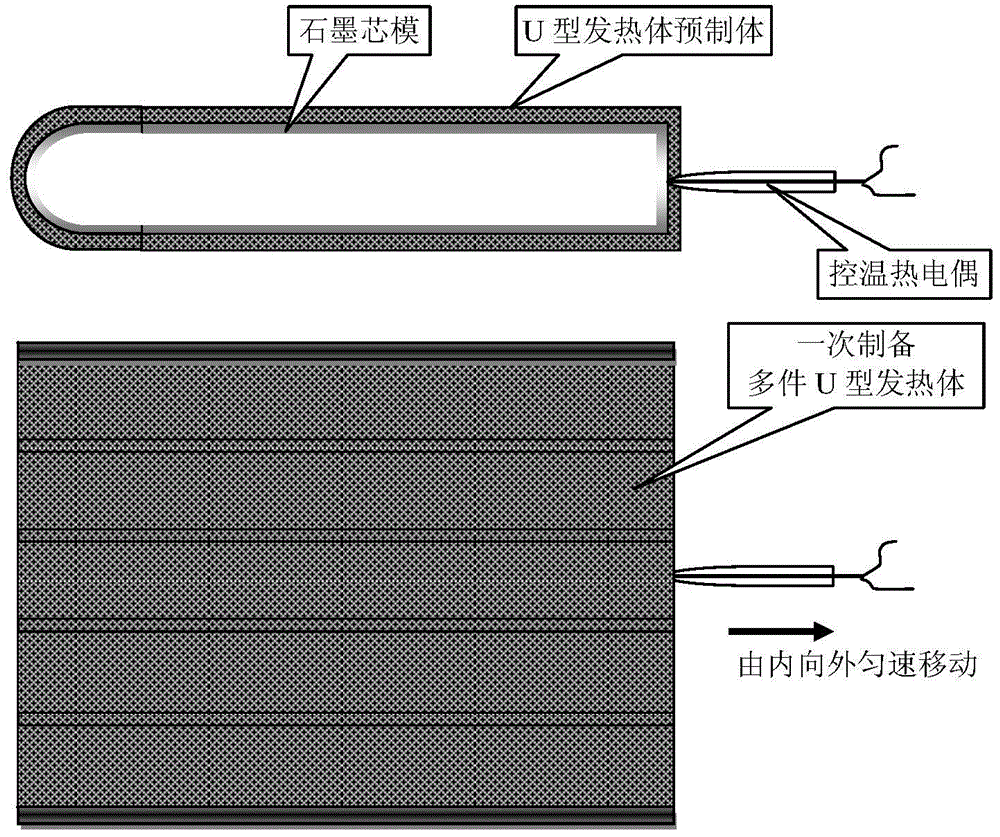

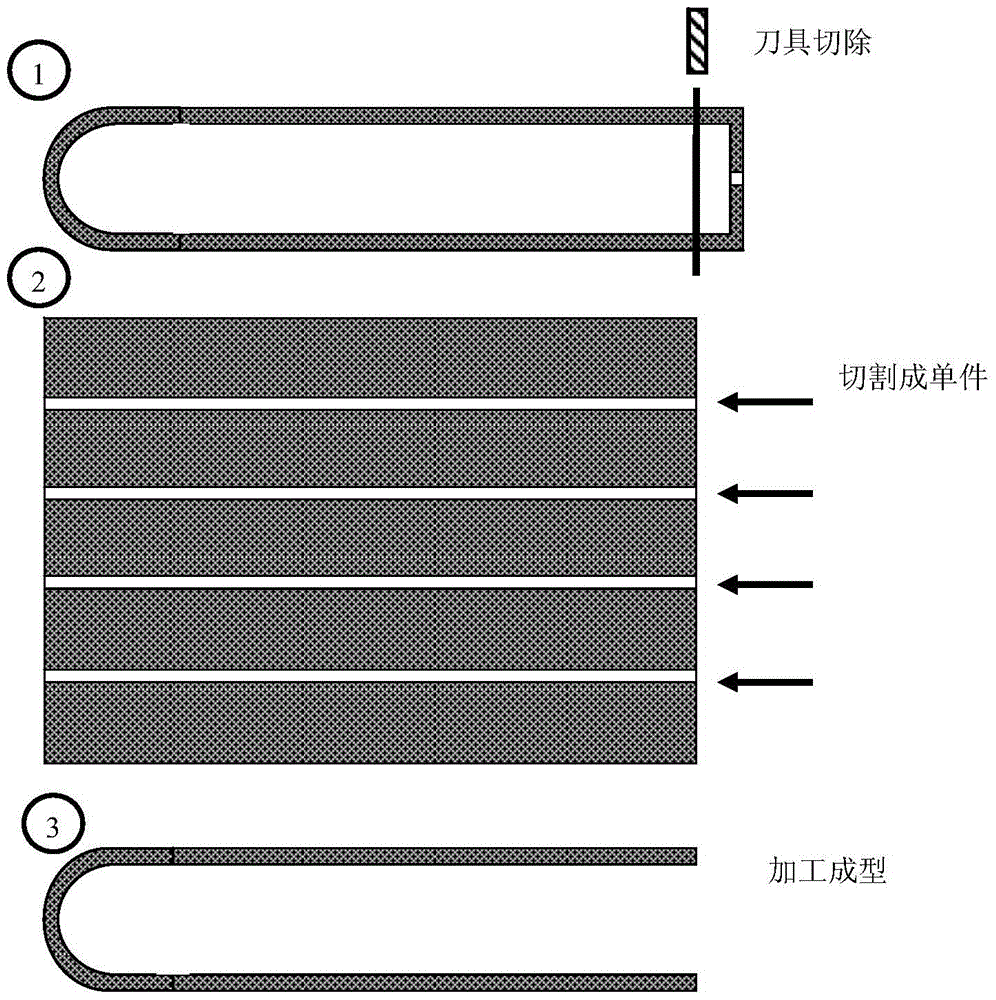

Gas-phase rapid preparation method of u-shaped carbon/carbon heating element

ActiveCN104710184BObvious effect of energy saving and consumption reductionAchieve mass productionDeposition temperatureFiber

The invention provides a preparation method of a U-type carbon / carbon heat-generating body. The preparation method comprises the following steps: (1) preparing a graphite core mould according to the size of a U-type heat-generating body, wherein the graphite core mould is used to support a carbon fiber preform and give off heat after being electrified; (2) wrapping a plurality of layers of carbon cloth on the core mould or laminating multiple layers of carbon cloth together and then stitching the carbon cloth together so as to obtain a carbon fiber preform; (3) installing an assembled unit of the carbon fiber preform and graphite core mould into a precipitation chamber, and fixedly connecting the assembled unit to the upper electrode and lower electrode; (4) directly electrifying the graphite core mould to achieve heating; (5) embedding a temperature thermocouple into the carbon fiber preform, controlling the temperature of the carbon fiber preform to reach a precipitation temperature, and moving the carbon fiber preform from inner to outer at a specific speed to achieve rapid gas-phase densification; (6) after the predetermined precipitation temperature is reached, continuously introducing reaction gas in a certain flow rate. The U-type carbon / carbon heat-generating body is prepared through a gas-phase densification treatment and a machining moulding treatment. The provided method can produce a plurality of heat-generating bodies at one time.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD +1

Hot-blast stove high-temperature waste gas recycling method

InactiveCN110617715AImprove operational stabilityTake advantage ofAir heatersWaste heat treatmentTemperature controlFlue gas

The invention discloses a hot-blast stove high-temperature waste gas recycling method. The method comprises the following steps that when a first hot-blast stove is in overhaul and medium repair periods, the first hot-blast stove is shut down, no high-temperature waste gas is discharged from a first high-temperature waste gas pipeline, at the moment, a first common regulating valve is opened, a first high-temperature induced draft fan is started, a first flue gas furnace inlet regulating valve is opened, so that a part of high-temperature waste gas generated by a second hot-blast stove passesthrough a first common pipeline and enters a mixing chamber of a first flue gas furnace under the air draft action of the first high-temperature induced draft fan. According to the method, by arranging the first common pipeline, the first common regulating valve, a second common pipeline and a second common regulating valve, high-temperature waste gas of the hot-blast stove and high-temperature drying gas of the flue gas furnace are further recycled, the waste gas utilization rate of the hot-blast stove is improved, the temperature control performance of a furnace hearth of the flue gas furnace is improved, the use amount of blast furnace gas is saved, the high-temperature waste gas and the drying gas which are diffused into air is reduced, and the harm of toxic and harmful substances in the diffused waste gas to the surrounding environment and personal safety is reduced.

Owner:YUNNAN DESHENG STEEL CO LTD

Inhibitor for eliminating filament breakage in the process of producing alkali-free glass fibers

The invention discloses an inhibitor for eliminating filament breakage in the process of producing alkali-free glass fibers. A raw material of coal-measures kaoline, hard kaolin or refractory clay is subjected to ore proportioning, crushing and grading to prepare superfine powder, namely the inhibitor, and the inhibitor comprises 44.0 to 50.0 percent of SiO2, 36 to 42 percent of Al2O3, 0.3 to 0.8percent of Fe2O3, 0.5 to 2.0 percent of TiO2, 0.1 to 1.5 percent of K2O+NaO2, 0.1 to 1.5 percent of CaO+MgO and 12 to 16 percent of H2O. The inhibitor accelerates glass generation and reduces energy consumption by controlling product granular size and size distribution and other means, and prevents minerals from changing phase and further generating impurities so as to reduce the phenomenon of filament breakage. The product can completely replace alkali-free clay powder used in the conventional glass fiber industry.

Owner:宜昌慧龙科技开发有限公司

Online controller for controlling circulating, insulating, cleaning and plasma melting of raw blood plasma bags

ActiveCN102692910BReduce labor intensityAvoid human errorTemperatue controlProgramme total factory controlBlood plasmaDrug biological activity

The invention discloses an online controller for controlling circulating, insulating, cleaning and plasma melting of raw blood plasma bags. The online controller mainly comprises a working platform, a circulating, insulating and soaking tank, an equipment box body, a circulating water washing station, a first compressed air washing station, a conveyer belt, an alcohol tank, a conveyer belt, a fresh water washing station, a second compressed air washing station, a main transmission motor, a circulating water and alkali liquor circulating system, an alcohol circulating system and an electrical appliance control system. According to the invention, by virtue of the accurate online control on plasma melting temperatures, biological activities of various biological proteins in blood plasma are protected, and the loss of the plasma proteins in an upstream process is effectively reduced; a series of continuous cleaning operations of automatic cleaning, disinfection and leaky bag eliminating and the like on the blood plasma bags in a plasma melting process are implemented by virtue of online computer automation control, thus avoiding cross contamination caused by open-type operation in the plasma melting process; in addition, the water circulating and alcohol filtering devices are designed and mounted, thus greatly reducing the consumption of alcohol and water for injection and achieving remarkable benefits of energy conservation and consumption reduction.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD +1

A welded cable conductor joint with current equalizing function and its welding method

ActiveCN107579356BReduce skin effectReduce AC resistanceLine/current collector detailsSoldered/welded conductive connectionsElectrical resistance and conductanceElectrical conductor

The invention belongs to the power transmission line power cable field and particularly relates to a welding type cable conductor connector having the current sharing effect and a welding method. Thetotal layer quantity of conductors is N, when M layers of internal conductors are welded, low resistivity welding rods A are utilized, when O layers of middle conductors are welded, low resistivity welding rods A are utilized, when (N-M-O) layers of external conductors are welded, high resistivity welding rods B are utilized. The method is advantaged in that a problem of temperature rising of theconductors and connector points during application of large-cross section layered insulation conductors can be solved. On the condition that the layered energy saving and consumption reduction conductor performs the effective AC resistance reduction effect, disadvantages of relatively large AC resistance and relatively high temperature existing in a traditional crimping type cable conductor connector under long-term rated work conditions are ameliorated, the process is simple, field maneuverability is strong, line operation loss of the large-cross section AC power cable can be reduced, power transmission efficiency is improved, and the excellent energy saving and consumption reduction effect is realized.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com