Gas-phase rapid preparation method of u-shaped carbon/carbon heating element

A heating element, U-shaped technology, applied in the field of rapid preparation of U-shaped heating elements of carbon/carbon composite materials, can solve the problems of uneven product performance, complicated operation of impregnated carbon technology, high cost, etc., and achieve a significant effect of energy saving and consumption reduction , Precise control of final performance, uniform and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

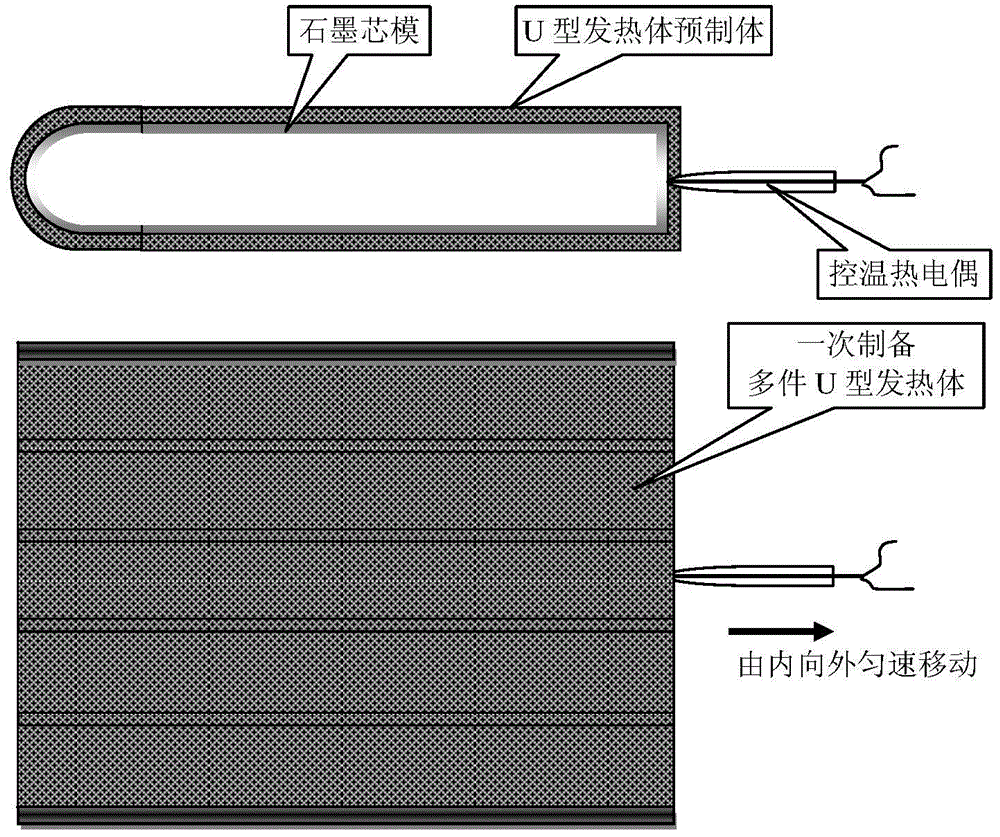

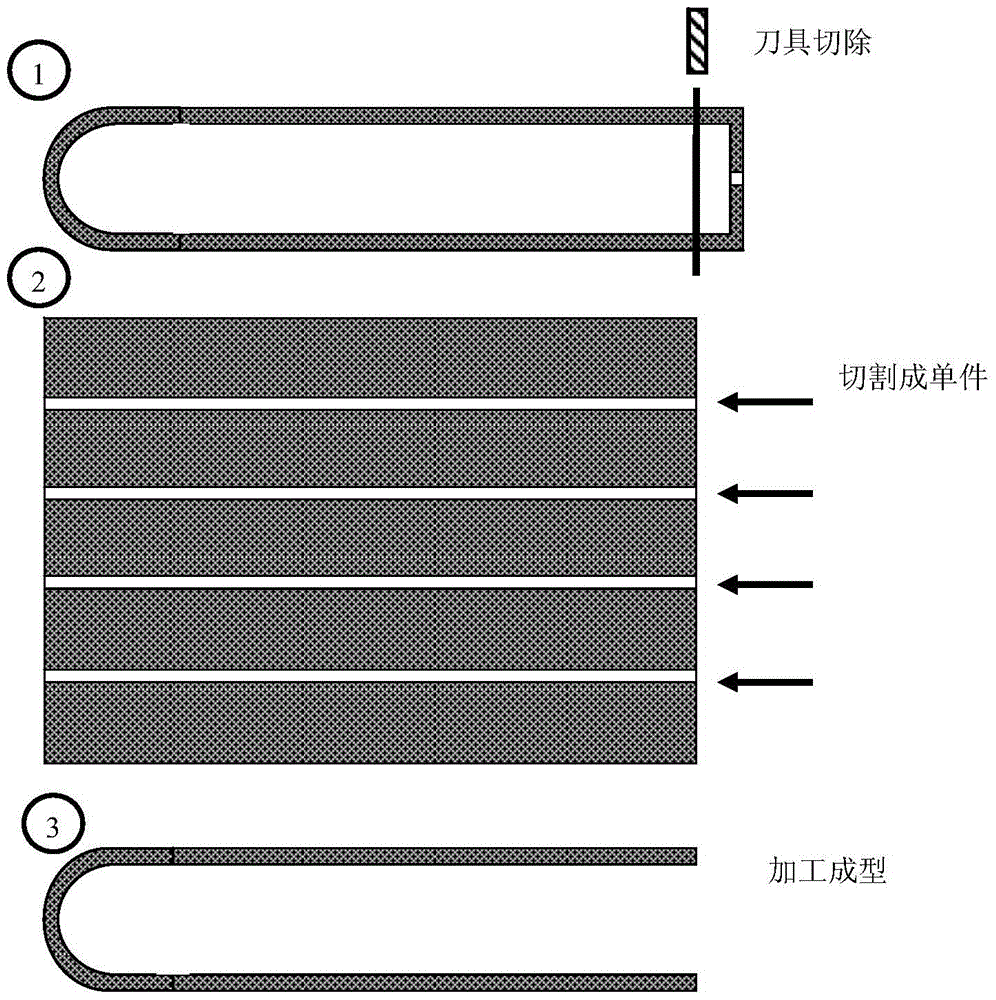

[0020] (1) According to the requirements, prepare a U-shaped heating element with an inner diameter of R75, a length of 1350mm, a width of 100mm, and a wall thickness of 8mm. Firstly, process a mandrel made of graphite material. , the length is 1370mm, the total height is 1550mm, the graphite mandrel is hollow, and the wall thickness is 10mm.

[0021] (2) Use PAN-based 12k carbon fiber, process it into plain carbon cloth, and lay layers on the graphite mandrel to prepare a carbon fiber prefabricated body. The thickness of the prefabricated body is controlled to be 15-16mm, and the calculated initial density is 0.35g / cm 3 .

[0022] (3) Place the assembly of carbon fiber prefabricated body and graphite core mold in the deposition chamber, install energized electrodes, and install temperature control thermocouples, such as figure 1 As shown, the thermocouple is located inside the bottom of the U-shaped preform and is in direct contact with the graphite mandrel.

[0023] (4) Va...

Embodiment 2

[0027] (1) According to the requirements, prepare a U-shaped heating element with an inner diameter of R80, a length of 1760mm, a width of 90mm, and a wall thickness of 12mm. First, process a mandrel made of graphite material. , length 1780mm, total height 1650mm, graphite mandrel is hollow, wall thickness is 15mm.

[0028] (2) Use PAN-based 6k carbon fiber, process it into plain carbon cloth, and lay layers on the graphite mandrel to prepare a carbon fiber prefabricated body. The thickness of the prefabricated body is controlled to be 18-20mm, and the calculated initial density is 0.52g / cm 3 .

[0029] (3) Place the assembly of carbon fiber prefabricated body and graphite core mold in the deposition chamber, install energized electrodes, and install temperature control thermocouples, such as figure 1 As shown, the thermocouple is located inside the bottom of the U-shaped preform and is in direct contact with the graphite mandrel.

[0030] (4) Vacuum the deposition chamber t...

Embodiment 3

[0034] (1) According to the requirements, prepare a U-shaped heating element with an inner diameter of R115, a length of 2050mm, a width of 120mm, and a wall thickness of 15mm. First, process a mandrel made of graphite material. , length 2075mm, total height 1850mm, graphite mandrel is hollow, wall thickness is 18mm.

[0035] (2) Use PAN-based 12k carbon fiber, process it into unidirectional carbon cloth, and lay it on the graphite mandrel to prepare a carbon fiber prefabricated body. The thickness of the prefabricated body is controlled to be 22-25mm, and its initial density is calculated to be 0.46g / cm 3 .

[0036] (3) Place the assembly of carbon fiber prefabricated body and graphite core mold in the deposition chamber, install energized electrodes, and install temperature control thermocouples, such as figure 1 As shown, the thermocouple is located inside the bottom of the U-shaped preform and is in direct contact with the graphite mandrel.

[0037] (4) Vacuum the depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com