Aluminum hydroxide dehydrating agent and preparation method thereof

A technology of aluminum hydroxide and dehydrating agent, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of unknown composition of dehydrating agent, high price of dehydrating agent, inconvenient use, etc., and achieve the effect of energy saving and consumption reduction , The effect of low raw material price and green environmental protection use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Raw material weight percentage is composed of:

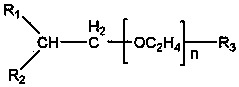

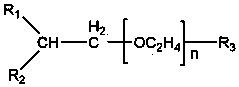

[0029] C12-14 fatty alcohol polyoxyethylene ether carboxylate (EO=5) 15%

[0030] C12-14 fatty alcohol polyoxyethylene ether (EO=9) 5%

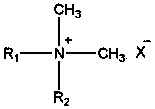

[0031] C12-14 Alkyl Trimethylammonium Bromide 3%

[0032] Ethanol 2%

[0033] water balance

[0034] Preparation:

[0035] Raw materials are composed according to their weight percentages. Heat 60% of the total required water to 40°C, add C12-14 fatty alcohol polyoxyethylene ether carboxylate (EO=5) and C12-14 fatty alcohol polyoxyethylene ether ( EO=9), stir until the material is completely dissolved and transparent, adjust the pH to 8 with sodium hydroxide, then add C12-14 alkyltrimethylammonium bromide and ethanol, continue stirring until the material is dissolved and transparent, add the rest of the water, and stir Uniformly obtain the described aluminum hydroxide dehydrating agent.

Embodiment 2

[0037] Raw material weight percentage is composed of:

[0038] C12-14 fatty alcohol polyoxyethylene ether sulfate (EO=3) 20%

[0039] C12-14 fatty alcohol polyoxyethylene ether (EO=15) 3%

[0040] Bis C16-18 alkyl dimethyl ammonium chloride 1%

[0041] n-octanol 1%

[0042] water balance

[0043] Preparation:

[0044] Raw materials are composed according to their weight percentages. Heat 70% of water to 70°C, add C12-14 fatty alcohol polyoxyethylene ether sulfate (EO=3) and C12-14 fatty alcohol polyoxyethylene ether (EO=15), Stir until the material is completely dissolved and transparent, adjust the pH to 6 with sodium hydroxide, then add bis-C16-18 alkyl dimethyl ammonium chloride and n-octanol, continue stirring until the material is dissolved and transparent, add the rest of the water, and stir evenly to obtain Described aluminum hydroxide dehydrating agent.

Embodiment 3

[0046] Raw material weight percentage is composed of:

[0047] C16-18 fatty alcohol polyoxyethylene ether sulfonate (EO=9) 10%

[0048] C12-14 fatty alcohol polyoxyethylene ether (EO=5) 10%

[0049] Bis C12-14 alkyl dimethyl ammonium chloride 2%

[0050] Isopropanol 3%

[0051] water balance

[0052] Preparation:

[0053] Raw materials are composed according to their weight percentages. Heat 70% of water to 60°C, add C16-18 fatty alcohol polyoxyethylene ether sulfonate (EO=9) and C12-14 fatty alcohol polyoxyethylene ether (EO=5) , stir until the material is completely dissolved and transparent, adjust the pH to 7 with sodium hydroxide, then add bis C12~14 alkyl dimethyl ammonium chloride and isopropanol, continue stirring until the material is dissolved and transparent, add the rest of the water, and stir evenly Promptly obtain described aluminum hydroxide dehydrating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com