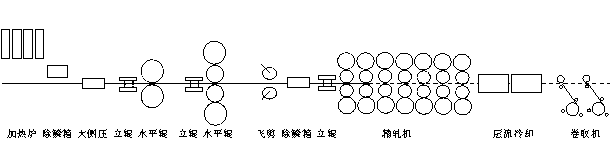

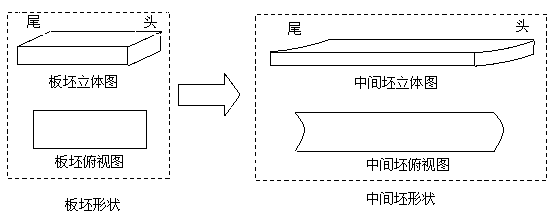

Continuous cast slab head and tail shape pre-controlling method capable of reducing hot-rolled intermediate slab head and tail cutting quantities

一种连铸坯、头部形状的技术,应用在金属轧制、金属轧制、制造工具等方向,能够解决中间坯头尾形状成材率损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

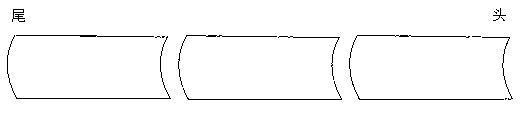

[0049] In order to verify the pre-control effect of the shape of the slab head and tail, the slab cutting and rolling tests were carried out in hot rolling. Taking the test as an example, the pre-control method of the shape of the slab head and tail, the head and tail cut amount of the intermediate slab after rolling and the effect on reducing the cut amount are introduced.

[0050] Slab condition: In order to verify the control effect of the slab head and tail shape pre-control under different bow heights, four groups of experiments were designed. Two slabs with the same thickness and width specifications were selected for each group of tests, one of which was pre-controlled for the shape of the head and tail (the arc bow height of the head is concave, and the arc bow height of the tail is convex), and the other is Conventional cuboid slabs are used for comparison. A total of eight slabs were selected. See Table 1-1 to Table 1-4 for slab-related data.

[0051] Table 1-1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com