A method for preparing high-performance ito granulated powder

A granulated powder, high-performance technology, applied in the field of preparing high-performance ITO granulated powder, can solve the problems of inability to meet the requirements of high-performance ITO targets, uneven structure of the green body, unfavorable densification of the target, etc., and achieve a microstructure. And the effect of uniform composition, small deformation and wide range of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

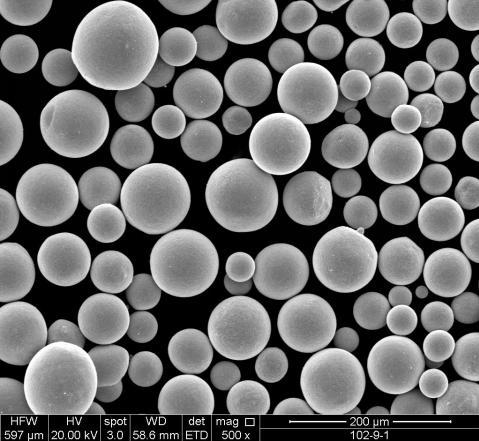

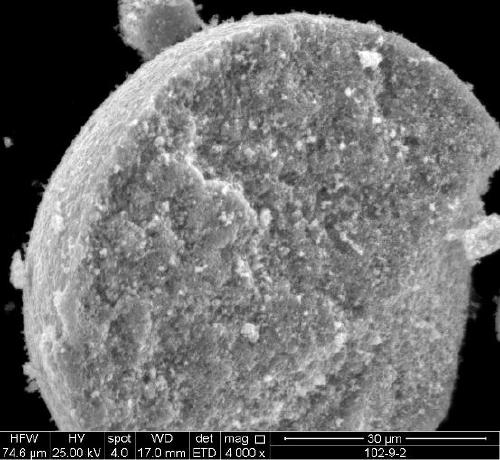

[0031] The method for preparing high-performance ITO granulated powder involved in the present invention is: Weigh indium oxide and tin oxide nano-powders with a mass ratio of 9:1 and a purity greater than 99.99%, add deionized water and a dispersant, and make a certain solid content After the slurry is ball-milled by a sand mill, it reaches a certain fineness. Add binder and defoamer, spray dry to obtain powder. A certain amount of dispersant and water are added to the powder to form a slurry with a certain solid content. After high-speed dispersion, the final granulated powder is obtained by spray drying.

[0032] A method for preparing high-performance ITO granulated powder, the specific steps are as follows: (1), according to In 2 o 3 : SnO 2 =9:1 mass ratio, weigh indium oxide and tin oxide nanopowder, the particle size of indium oxide D50=10~500nm, preferably D50=70~200nm; the particle size of tin oxide nanopowder D50=10~500nm, Preferably D50=70~200nm;

[0033] (2) ...

Embodiment 1

[0043] Weigh 9kg of nano-indium oxide powder and 1kg of nano-tin oxide powder, the particle size of nano-indium oxide powder is D50=10nm, the particle size of nano-tin oxide powder is D50=20nm, add 10kg of deionized water and 0.08kg of ammonium polyacrylate to prepare into a slurry; after that, transfer the slurry to a sand mill for ball milling for 2 hours, and the corresponding D90 is 0.3 microns; then add 0.25kg of polyvinyl alcohol to the slurry, and the polyvinyl alcohol is first dissolved in deionized water to form Add 10% of the solution; then ball mill for 0.5h to produce slurry, add ethanol to the slurry after ball milling for defoaming to obtain a mixture; add the mixture to a spray drying tower for spray drying, wherein: The temperature is 200°C, the outlet air temperature is 100°C, the atomizer frequency is adjusted to 30Hz, and the powder is obtained by granulation.

[0044] Afterwards, get the powder and the cyclone powder of the spray drying tower during the pri...

Embodiment 2

[0047] Weigh 9kg of nano-indium oxide powder and 1kg of nano-tin oxide powder, the particle size of nano-indium oxide powder is D50=300nm, the particle size of nano-tin oxide powder is D50=200nm, add 5kg of deionized water and 0.15kg of dispersant to make Slurry, wherein the dispersant is composed of polyacrylic acid and ammonia water with a mass ratio of 1:1; after that, the slurry is transferred to a sand mill for ball milling for 0.5h, and the corresponding D90 is 0.1 microns; and then added to the slurry 0.2kg of polyethylene glycol, polyethylene glycol dissolved in water to make a 10% solution and then added; then ball milled for 1.0h after the slurry, adding a few drops of n-butanol to the slurry after ball milling for defoaming, the preparation Obtain a mixture; put the mixture into a spray drying tower for spray drying, wherein: the inlet air temperature is 250°C, the outlet air temperature is 130°C, the frequency of the atomizer is adjusted to 50Hz, and the powder is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com