Elastic cutting system for modified root-tuber crops

A technology of root crops and cutting system, applied in the field of agricultural machinery, can solve the problems of high labor intensity, influence economic value, danger, etc., and achieve the effects of reducing cutting loss, improving economic benefits and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

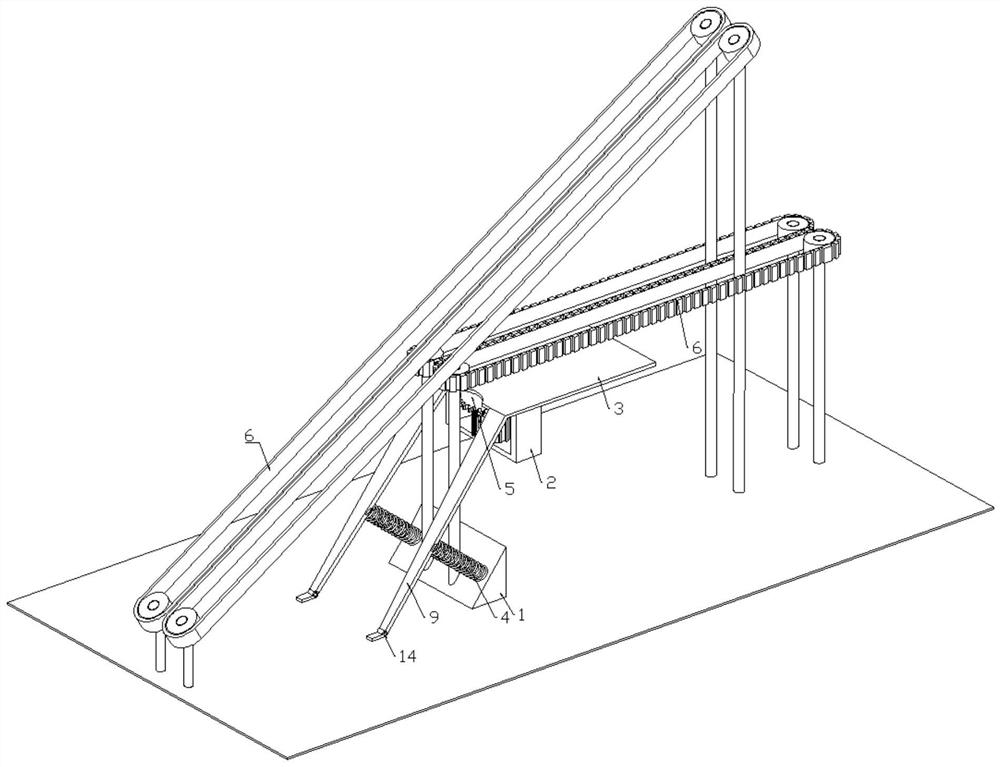

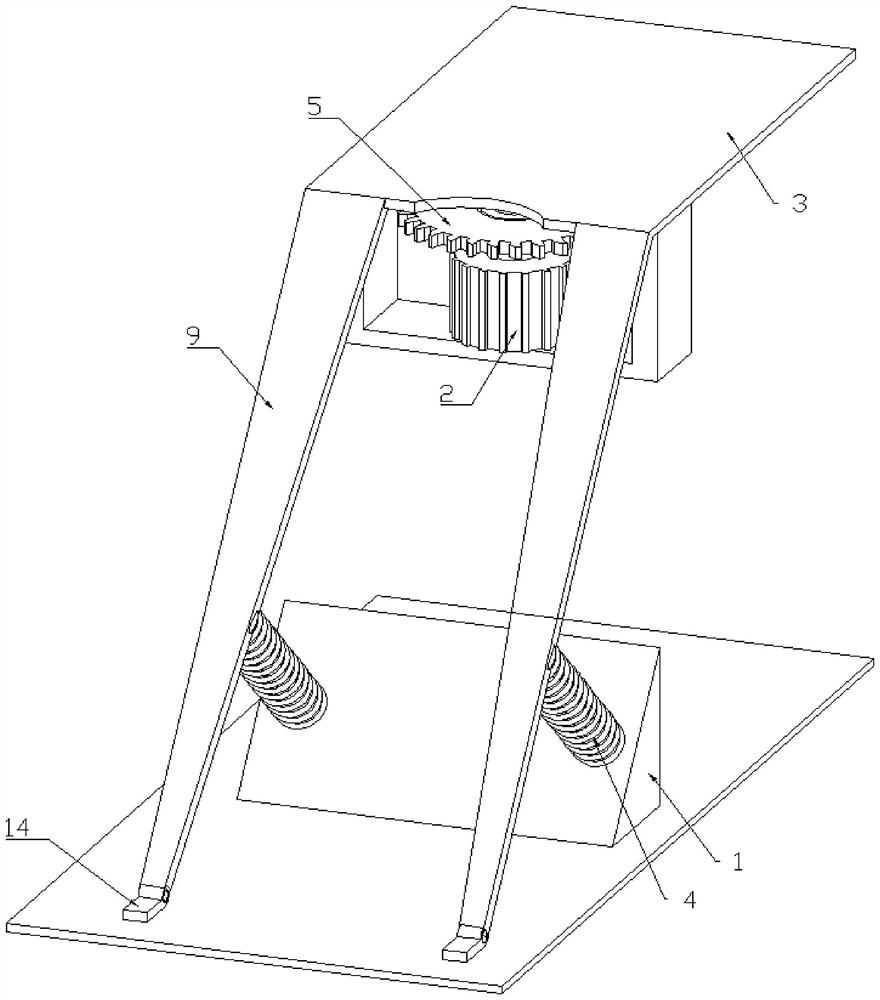

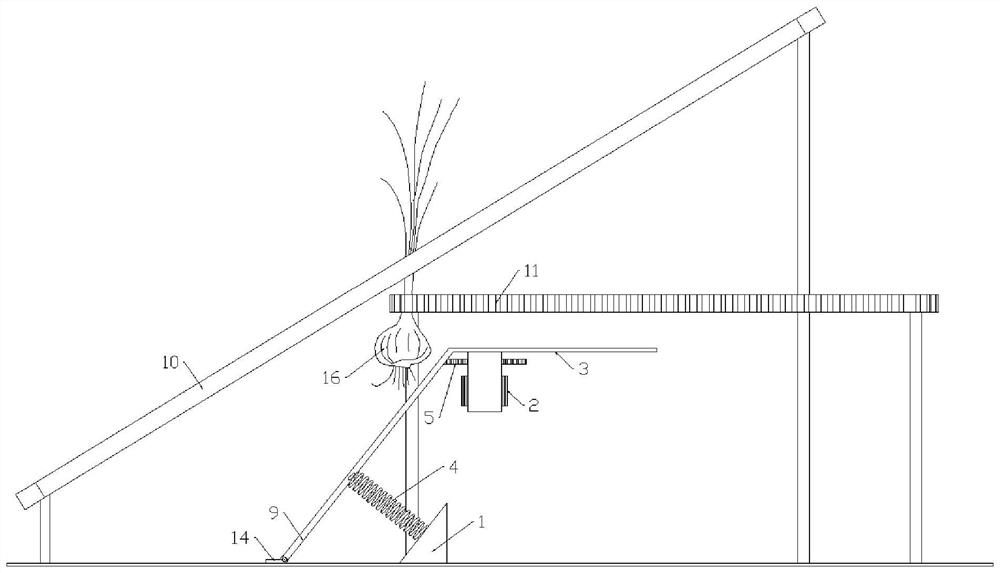

[0034] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides an elastic cutting system for abnormal root crops 16, including a base 1 and a driving device, a floating plate 3 is provided above the base 1, an elastic support mechanism is provided between the base 1 and the floating plate 3, and the floating plate 3 The bottom end of the bottom is provided with the first cutting knife 5, and the driving end of the driving device is connected with the first cutting knife 5, and the edge of the first cutting knife 5 protrudes outside the edge of the floating plate 3, and the top of the floating plate 3 is provided with a clamping conveyor belt 6. The clamping conveyor belt 6 clamps the metamorphic root crop 16 and moves toward the first cutting knife 5 .

[0035] Specifically, the top of the floating plate 3 is provided with a clamping conveyor belt 6, the bottom of the floating plate 3 is connected with the base 1 by an elastic support mechanism, a...

Embodiment 2

[0045] The difference between this embodiment 2 and embodiment 1 is that in this embodiment 2, the driving device does not float with the floating plate 3 , but is fixed, and other technical solutions are the same as those of embodiment 1, and will not be repeated here.

[0046] Such as Figure 4 with Figure 5 As shown, the driving device is a servo motor 7, the first cutting knife 5 is a toothed circular saw blade, the servo motor 7 is fixed below the floating plate 3, and the servo motor 7 and the first cutting knife 5 are connected by a universal flexible shaft 8 . It should be understood that in Embodiment 1, the micromotor 2 is fixed on the floating plate 3 to solve the driving problem of the first cutting knife 5, but it is possible that the driving force of the micromotor 2 is insufficient or the driving efficiency is too low, and it is necessary to use Servomotor 7 of larger model is fixedly driven, so adopt universal flexible shaft 8 in the present embodiment 2 (th...

Embodiment 3

[0048] The difference between the present embodiment 3 and the embodiment 1 and the embodiment 2 is that in the present embodiment 3, the second cutting knife 15 is also set between the righting conveyor belt 11 and the lifting conveyor belt 10, for dividing the stems and leaves of the abnormal root crops 16 parts and metamorphosed rhizome parts.

[0049] Such as Image 6 with Figure 7 As shown, a second cutting knife 15 is arranged between the centralizing conveyor belt 11 and the lifting conveyor belt 10 . Concretely, for the convenience of understanding, here still take garlic as an example to describe the specific working process of the present embodiment 3, after the root of garlic is excised by the first cutting knife 5, the lifting conveyor belt 10 still clamps the garlic leaf and moves obliquely upwards, Righting the clamping band to clamp the head of garlic to move in parallel, after a certain distance, the garlic leaves will be torn off, resulting in waste; After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com